Fremont Tribune, NE 06-20-07 ‘cheese’ during National Dairy Month Say

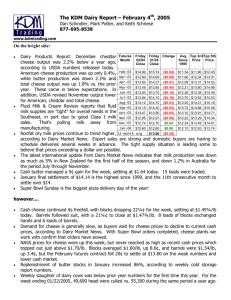

advertisement

Fremont Tribune, NE 06-20-07 Say ‘cheese’ during National Dairy Month By Ellen Lund/Daily Bread June is National Dairy Month and a great time to think about cheese. For me, it’s a great time to think about my absolutely favorite cheese - Maytag Blue Cheese. This widely celebrated Midwestern product has its roots in our neighboring state of Iowa. Maytag Blue Cheese is the result of a long-ago collaboration between the Iowa State University Dairy Science Department and the Maytag Dairy Farm of Newton, Iowa. The Maytag Dairy Farm was established in the early 1900s by E.H. Maytag. Maytag, who was the son of the founder of the Maytag appliance business, wanted to provide a safe supply of milk for his family and his community. He began a herd of Holsteins that he passed on to his sons, Fred and Robert. His heirs decided that they wanted to enhance the bottling operation of the dairy and consulted with an Iowa State University Dairy Science Department team that was working on a way to make Roquefort cheese from cow’s milk instead of the traditional sheep’s milk. According to a Web article by Myrna Ver Ploeg, president of Maytag Dairy Farms, “Fred offered to build the cheese plant and to pay royalties to ISU in return for the opportunity to create an American Blue Cheese.” Production started in 1941 and the rest is history. Ver Ploeg states that the business grew without advertising or a sales force. “Folks came to tour the dairy, taste the cheese, and carry it home with them around the country and around the world,” she wrote. To keep up with modern times and marketing strategies, the company does maintain a Web site - www.maytag.com - that features a wonderful online catalogue so shoppers can order directly from the company. I was fascinated by Ver Ploeg’s article that describes in detail the process by which this wonderful cheese is manufactured. According to Ver Ploeg, “the cheese starts out as whole, raw milk. Twice a day a small milk truck brings in milk from local dairy herds, which probably still have cows with the bloodline from the original herd of E.H. Maytag. Once the milk is delivered to the cheese plant, the cheese maker separates the milk from the cream and then adds both of them back into warm vats. As the cheese takes shape in the vats, wire harps are used to cut the cheese into cubes, forming the curds in the whey. The whey is poured off and the curds are hand scooped into stainless steel hoops. Fresh wheels of cheese are placed onto drying tables to expel any further liquid, and each wheel is hand turned to obtain the correct moisture level. Workers pull off the hoops the following day and place the 4-pound wheels in caves dug into the hillsides of the Newton farm. There, the cheese is exposed to high humidity and cool temperatures. Each lot is individually checked to make sure that the cheese hasn’t aged too quickly or too slowly.” To make sure that the quality of every batch is an unqualified success, Ver Ploeg personally tastes a wheel from every vat of cheese that is produced. Now that would be my ultimate job perk!