NOT FOR PUBLICATION UNTIL RELEASED BY THE HOUSE ARMED SERVICES COMMITTEE

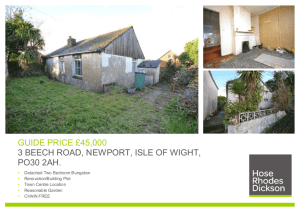

advertisement

NOT FOR PUBLICATION UNTIL RELEASED BY THE HOUSE ARMED SERVICES COMMITTEE SUBCOMMITTEE ON PROJECTION FORCES STATEMENT OF C. MICHAEL PETTERS CORPORATE VICE PRESIDENT AND PRESIDENT, NORTHROP GRUMMAN NEWPORT NEWS BEFORE THE SUBCOMMITTEE ON PROJECTION FORCES OF THE HOUSE ARMED SERVICES COMMITTEE ON THE US NAVY’S PROJECTED SUBMARINE FORCE STRUCTURE MARCH 28, 2006 NOT FOR PUBLICATION UNTIL RELEASED BY THE HOUSE ARMED SERVICES COMMITTEE SUBCOMMITTEE ON PROJECTION FORCES Chairman Bartlett, Ranking Member Taylor, distinguished members of the Projection Forces Subcommittee, thank you for this opportunity to appear before you to discuss the Navy’s projected submarine force structure and implications for submarine construction. Introduction I am privileged to be one of more than 18,000 shipbuilders at Northrop Grumman Newport News. Newport News has been delivering great ships since 1890 with its production of Hull Number 1, a 90-foot tugboat named Dorothy. Our relationship with the Navy dates back to 1893 with a contract for three gunboats. In our 116 year history, Newport News has built for the Navy 29 aircraft carriers, 55 submarines, 31 destroyers, 31 landing ships, 24 cruisers and 14 battleships, along with hundreds of other ships. Ours is a heritage of partnership with the Navy and service to the country. It is a history we are proud of and will work hard to sustain for as long as our Navy needs ships to defend the nation. Since 2001 Newport News has been an operating sector of Northrop Grumman Corporation. Northrop Grumman Newport News is the nation’s sole designer, builder and refueler of nuclear-powered aircraft carriers. Using the most modern design methods in the industry, Newport News is currently designing CVN 78, the first of the next generation of CVN 21 class aircraft carriers. The CVN 21 design team, which includes Electric Boat in a key role, is, in my view and the view of many, the best warship design team in the world today with the best people, the best tools and the best processes to be found anywhere. Advanced construction of some modules of this new carrier has begun with the bulk of construction to begin in 2008 with award of a construction contract. This design effort is taking place at the same time that the last of the Nimitz-class carriers is under construction. CVN 77, George H. W. Bush, will be christened this fall and is scheduled for delivery to the fleet late in 2008. We are also currently engaged in the forty-month mid-life refueling, overhaul, and modernization of our third Nimitz-class carrier, the CVN 70, USS Carl Vinson. -1- Newport News is one of only two companies capable of designing and building nuclearpowered submarines. General Dynamics Electric Boat is the other nuclear submarine design and construction company and, since 1997, we have teamed together for the construction of the Virginia-class submarine. I will focus on our teaming arrangement and the Virginia-class program shortly. In addition to submarine design and construction and aircraft carrier design, construction and mid-life refueling, Newport News has an active fleet maintenance program with work performed at Newport News and other locations on submarines, aircraft carriers, and a variety of other naval vessels. Newport News also does repair work on commercial vessels using one of several dry docks at our 550 acre facility in Hampton Roads. The men and women of Newport News who design, manufacture, and maintain nuclear powered submarines and aircraft carriers represent what is great about American industry. Our employees are skilled in the craft of shipbuilding and possess the tools and knowledge required for the many highly specialized requirements of nuclear ship construction and maintenance. Many of our shipbuilders come from families where for the past four or five generations at least one family member has worked at the shipyard. It is not uncommon today to find multiple generations of a family working side by side on a ship or in our shops. Each year we recognize shipbuilders who have reached their fortieth year of shipbuilding by designating them “Master Shipbuilders.” There are more than 400 Master Shipbuilders at work today at Newport News and many of them learned their craft through the shipyard’s Apprentice School – a nationally recognized center of excellence for training new shipbuilders. All of us at Newport News know and respect our heritage. We understand that the ships we deliver to the Navy today will carry the sons and daughters of America into harm’s way in defense of freedom tomorrow. This is a responsibility that we all take very seriously and it inspires us to produce the best ships in the world for the finest Navy in the world. -2- You have asked me to focus my remarks today on the nuclear submarine program. There are four key points I would like to make. First, the nuclear submarine production industry in America is alive today thanks to the wisdom of the Congress and the investment that the American people have made in this industry. Second, the team of Northrop Grumman Newport News and General Dynamics Electric Boat is strong and functioning well. Electric Boat delivered the USS Virginia, the first of the new class of submarines, in 2004 and the Navy has reported that it is performing superbly. In fact, the success of the ship and crew in its Quick Reaction Assessment in 2005 enabled USS Virginia to conduct operations prior to completion of Developmental and Operational testing. Newport News is on the verge of delivering its first of this class, Texas, this spring after a ten-year hiatus from submarine construction. Third, I have spoken in other forums about the needs of the shipbuilding industry for stability if we are to successfully deliver ships to the Navy at a cost that the nation can afford. With the delivery by the Navy of a 30-year shipbuilding plan in February 2006, the industry can see that stability may be within reach. Continued commitment will be needed to ensure this plan is fully funded. Fourth, stability is critical to the shipbuilding industry, but volume is essential if costs are ever going to be reduced in a meaningful way. In the case of Virginia-class submarines, the sooner we reach production of two submarines per year, the sooner we will see meaningful reductions in the cost of these submarines. The Submarine Industry Today Before addressing the state of our industry, a bit of submarine history may be useful to provide context for where we are today. In the mid-1980’s the Navy requested and Congress funded work to begin on the Seawolf-class of nuclear attack submarines. The -3- Navy had intended that the class could be as large as 29 of these stealthy and technologically advanced submarines to replace the Los Angeles-class submarines as they reached the end of their service lives. Newport News was designated the lead design yard for Seawolf and both Newport News and Electric Boat prepared for work on this class by investing in facilities, training employees, and making preparations for efficient production. Newport News alone invested about $900 million in then year dollars from 1981 to 1990 modernizing and adding new facilities to handle the volume of work anticipated and the unique aspects of submarine construction. The initial contracts were awarded to Electric Boat and construction began in 1989. A short time later, the plan was changed to call for production of only two submarines. After President Clinton was elected in 1992, a third Seawolf was restored to the plan and this also was awarded to Electric Boat. Despite the investments Newport News had made for submarine production and the critical skills that everyone acknowledged existed in our yard, we were essentially told we were no longer needed to produce submarines. As the follow-on Virginia-class submarine was on the verge of being funded, Newport News and Electric Boat made the case to the Congress that it was vital to maintain skills and facilities at both Newport News and Electric Boat and that the best way to maintain the submarine industrial base at both yards was for Newport News and Electric Boat to share submarine construction for the Virginia-class through a teaming arrangement. After careful deliberation, the Congress agreed and in the FY 1998 National Defense Authorization Act, the first four Virginia-class submarines were authorized to be procured under a teaming arrangement which Electric Boat and Newport News had proposed in December 1996. The two companies jointly established the contractual and work procedures they would follow to build submarines together with Electric Boat as the prime contractor and Newport News the subcontractor. The teaming agreement was formally signed by both companies in February 1997. Subsequent Authorization Acts have continued the requirement to procure this class of submarines from the Electric Boat – Newport News team. -4- Fleet operators and strategists often speak of submarines as being asymmetric assets for the Navy. History has shown how one submarine operating or believed to be operating in an area can keep an entire fleet in port. The nation and the Congress have decided to invest in these asymmetric platforms and they have done so by ensuring that the United States has an unmatched industrial capability to produce technologically superior submarines. At Newport News we believe that the investment the country made carried with it a responsibility for us to be a good partner with Electric Boat and the Navy, to reconstitute our submarine workforce efficiently, to optimize our submarine construction facilities and processes for the most economical means of producing the Virginia-class and to actively work at delivering successive submarines at lower cost. We are fulfilling our responsibilities and we will continue to do so. Let me give just a few examples. Capital Investment In the past three years, Northrop Grumman shareholders have invested over $250 million of capital to modernize critical equipment and build new facilities to improve the efficiency of our operations and reduce costs on Navy programs. Some of our investments are in machinery and specialized shops which will benefit all Navy programs. Others are specific to the submarine program where the Virginia-class contract has provided additional incentives for us to do so. These incentives require an up-front use of shipyard capital with the possibility of earning an incentive, but only if the improvement actually delivers the savings that we estimated. We are focused on establishing multi-use, multi-purpose facilities that increase our flexibility to do work where it is best for our employees and where the work can be done most efficiently. Thus, for example, we have invested in covered modular assembly and modular outfitting facilities because we know that weather affects productivity and productivity drives labor costs. In the next five years we will continue our capital investments in our future and future Navy ships with another $320 million. I believe this is a clear indication of our commitment to the Navy to reduce costs on their programs in every way that we can. -5- Investments in People Equally as important, though far less visible than facility modernization, are the investments that we are making in our people at Newport News. We have realized for a number of years that we are challenged by shifts in demographics that are having a profound impact on our ability to perform. Given the changes that we have experienced in shipbuilding plans and programs in past years, our work force is now made up of a large group of new employees, with five years or less work experience, and a significant group of more experienced employees, with 25 or more years in the shipyard, who are now approaching retirement eligibility. This confronts us with two challenges – to accelerate the development of those with under five years experience, what we call our “green labor” issue, and to ensure that more experienced employees transfer their knowledge and lessons learned to newer ones who will ultimately have to replace them. We are addressing these challenges by investing in our people. First, we are maximizing the value of our flagship Apprentice School where we are training and developing new generations of shipyard leaders. We review and upgrade the curriculum to keep pace with continuously evolving and increasingly complex production processes. Because of our strong relationships with local community colleges, we project that in the near future almost half of our graduates will also receive an associate’s degree upon graduation from The Apprentice School. As the science of shipbuilding becomes even more complex and the industry and marketplace in which we operate changes, we anticipate that future graduates may require a bachelor’s degree. Second, we have developed specialized training courses aimed at new employees to improve their skills and to remedy deficiencies of their non-shipyard educational experiences. Our goal is to reduce the time required for an employee to become “proficient” from five years to three. To date we have revised or developed over 50 courses aimed at this critical segment of our work force with an equal number still in process. Third, we have strengthened and formalized on-the-job training. While this adds new requirements to front line supervisors, we recognize the need to provide a more structured degree of training under real world conditions. Fourth, we are working with partners in the community to provide -6- educational opportunities beyond the shipyard gates. We have strong relationships with high schools and community colleges in Hampton Roads and work closely on the development and delivery of specialized technical training that will benefit our workforce. Beyond technical and skills training, we have made a commitment to ensure that leadership is one of our core competencies. In recent years we developed a case-study based leadership course for first line supervisors – foremen, shop supervisors, engineering supervisors – to strengthen their leadership skills. We also are engaged in an intensive effort at the deck plate level, with the submarine program as our pilot, to coach front line leaders in ways to better manage schedules, workloads and costs. This program is helping us address the impact of green labor in construction and we are encouraged by what we have seen to date. The combination of strong leadership and technical proficiency has helped our front line leaders better manage and train new employees and oversee the transfer of knowledge from more seasoned employees. At Newport News, developing our people is not just a slogan – it is what we do every day. It is my strong belief that when well trained and motivated people have efficient processes with which to do their work, the results are strong performance. Investments in Process Improvements Without efficient processes, good people become frustrated and may perform in ways that are contrary to the good performance we expect on all of our programs. Realizing this, my first act as sector president in November 2004 was to appoint a vice president of Process Excellence and charge her with guiding the shipbuilding programs as they reviewed their processes, identifying those that are not as efficient as they need to be, and taking steps to improve them. To date we have performed critical value stream mapping of many of our cross-program functions such as steel delivery, pipe flows and planning. From these maps, we identified areas of potential improvement and have chartered teams -7- of experts under the leadership of sector vice presidents to identify the steps needed to improve the efficiency of these processes. In the submarine program we are also focusing on deck plate producibility improvements. We know that the best solutions to problems come from people who know the issues the best – our deck plate leaders and employees. This grass roots effort has identified a large number of improvements that could be made to reduce cost and improve efficiency. As these ideas surface, they are quickly evaluated and authorized for implementation. To date at both Electric Boat and Newport News, we have implemented initiatives that will save over $55 million in labor and over $30 million in material across the class of ships. This program will continue with ideas being freely and rapidly shared between the two teaming partners. Other process improvements are being made by identifying new manufacturing techniques and products that can reduce the costs of producing submarines. These techniques often come from our aircraft carrier construction or refueling programs or from work we are doing in fleet maintenance. Examples include new techniques of fusion splicing for fiber optics, automatic alignment of complex equipment, and vendorsupplied pre-mixed and pre-measured glue and paint. Our work in this area is far from complete, but we are investing a considerable amount of time and energy at every level of the sector – from the senior staff to deck plate employees – to root out waste and inefficiency and to maintain efficient, effective processes that deliver value at minimal cost. Delivering Results The initiatives we have undertaken in these areas are critical to the long-term success of Newport News. We have seen indications that our efforts have taken hold and our investments are beginning to pay dividends. In 2005, for example, Newport News redelivered four ships to the Navy. Each of these was redelivered under budget. -8- Favorable performance of our work on the Docking Planned Incremental Availability (DPIA) on CVN 73, USS George Washington, will translate into a return of about $30 million to the Navy. This is money the fleet can use to fund other critical needs. The CVN 69, USS Dwight D. Eisenhower, Refueling Complex Overhaul (RCOH), was cited by the former Assistant Secretary of the Navy John Young as a “win-win” for incentivebased Navy contracts. In the CVN 65, USS Enterprise, Extended Selected Restricted Availability (ESRA), we accomplished enormous amounts of emergent work on this 40year old carrier and completed our work under budget. Finally, the SSN 709, USS Hyman G. Rickover, Interim Dry Docking (IDD) was a firm fixed price contract where planning costs were reduced some twenty percent from other IDDs and we completed our work under budget. In each of these four redeliveries, the Navy was pleased with Newport News’ work performance, performance to budget and establishment of strong partnerships with the crew and overseeing Navy agencies. I will speak to the results being achieved in the submarine program shortly, but will say that with the successful delivery of Texas, the wisdom of the Congress in returning Newport News to submarine production will be confirmed. The Electric Boat-Newport News Team After nearly ten years of teaming with Electric Boat, I am proud to tell you that our team is strong. We share a common vision of what we need to do to make this program a success for the Navy, the nation and our corporations. Between us we have the finest nuclear shipbuilders in the world who are working well together. The teaming agreement established Electric Boat and Newport News as equal members of the team. This principle of equality is carried forward in how the submarines are constructed. To achieve equality in the work split and to play to the strengths of the two shipbuilders, the teaming agreement assigns certain of the modules that make up a submarine to a particular team member to build for all ships. To retain critical nuclear -9- construction skills, the construction of the reactor compartment and all of the work leading up to final ship acceptance – final assembly, testing, and outfitting – are alternated between the team members with Electric Boat performing these functions for even numbered ships and Newport News for odd numbered ships. By working on the same modules from ship to ship, employees in each yard develop specialized expertise on those modules, transfer lessons learned from one module to the next, and, ultimately, are able to manufacture and outfit those modules for fewer man-hours. Similar learning will occur in the assembly, test, outfitting and all other activities leading up to final acceptance as each yard performs these functions more than once. Just as the work sharing arrangement in the teaming agreement fosters efficiency in construction, the teaming agreement establishes a fee sharing formula that has a similar effect. Rather than each team member having a separate profit formula based solely upon its performance, the team shares only one profit which is paid to the team based upon the team’s performance under the prime construction contracts. In each of the two subcontracts awarded to date for Blocks 1 and 2, the team has shared this profit pool essentially equally. This aspect of the teaming agreement has proven to be the most farreaching of all and clearly shows the foresight of the agreement’s crafters in the shipyards and Congress’s wisdom in sanctioning the team agreement in the various statutes that have funded the ships. By sharing only a single profit pool, the necessary incentives are in place for employees at both yards to work together effectively to reduce costs, to collaboratively and quickly resolve issues which arise, and to share ideas on ways to accomplish work more efficiently. Sharing a single profit pool equally makes the success of each yard dependent on the success of the entire team. Problems that develop at one yard, if not resolved quickly, will degrade the performance of both team members. The result of all this is that there has been an active exchange of people, best practices, lessons learned and other information between the two yards – all to the benefit of the program. Before the start of construction, the team developed more detailed plans concerning the general module assignments set forth in the teaming agreement. As the team has gained - 10 - construction experience, we have recognized that within the broad outline of the module assignments established in the teaming agreement we could streamline the construction process by being able to shift some work between the two yards when it would fit better in a different phase of construction. For example, one yard might be scheduled to install a component in a module before it becomes a larger module at the other shipyard. Deck plate employees, however, might see that it would be more efficient and cheaper to install the component after the larger module had been formed. The teaming agreement provides both yards flexibility to make these deck plate initiated changes rapidly and efficiently. As a result, to date over a million man-hours of work have shifted between Newport News and Electric Boat with the benefits going to the program. Our team has now seen the delivery of the first of this class, USS Virginia, by Electric Boat, and shortly will see the first Newport News-delivered submarine, Texas. These are noteworthy achievements for both yards and for the team as a whole. No one should underestimate the difficulty of successfully delivering the first of a class of any ship. There are challenges that arise that no one could have anticipated and the timeline to delivery is unforgiving. But we are meeting those challenges and soon the fleet will have the two finest submarines in the world. Just how successful this team has been can be seen by comparing our performance today on the delivery of lead ships with other classes of submarines. Electric Boat delivered USS Virginia within four months of a schedule established twelve years earlier in 1993. This was its first lead ship delivery in eight years. Texas will be delivered by Newport News within eleven months of the original schedule. This will be our first lead ship delivery since USS Los Angeles in 1976, our first submarine delivery in ten years, and comes only after reconstituting our submarine workforce. In contrast, the lead Seawolfclass submarine completed 25 months beyond original schedule; the lead Los Angelesclass 26 months beyond original schedule; and the lead Ohio-class thirty months beyond schedule. - 11 - The team currently has contracts to build the first ten submarines of the Virginia-class in two blocks as shown in Figure 1. 100% 100% 95% Total Percent Complete (EB and NN) EB Delivery NN Delivery 80% 80% 69% 60% 52% 39% 40% 20% 16% 10% 5% 5% 0% SSN 774 Virginia SSN 775 Texas SSN 776 Hawaii SSN 777 North Carolina SSN 778 New Hampshire SSN 779 New Mexico SSN 780 TBD SSN 781 TBD SSN 782 TBD SSN 783 TBD EB Delivery Oct-04 NN Delivery May-06 EB Delivery Mar-07 NN Delivery Jun-08 EB Delivery Feb-09 NN Delivery Apr-10 EB Delivery Apr-11 NN Delivery Apr-12 EB Delivery Apr-13 NN Delivery Apr-14 Block 1 Block 2 Block 1 Block 1 Block 1 PSA underway at EB Final testing underway Pressure hull complete Pressure hull All NN modules complete Jul-06 to EB by Jan-07 Block 2 Block 2 Block 2 Block 2 Block 2 Working modules Working modules Working modules Material procurement Material procurement Figure 1: Virginia-Class Submarines Blocks 1 and 2 As can be seen, there is considerable activity throughout the program and good progress is being made. Three vessels have their pressure hulls complete with the fourth due to complete this summer. Both shipyards are working on modules for four of the six ships in Block 2 and Newport News will complete and ship its final modules to Electric Boat on ship 5, New Hampshire, early next year. Closing pressure hulls and bending steel are important, but so too is making progress on reducing costs and this team is achieving precisely that. It has become apparent to me as the program has progressed that performance in each block of ships is reflective of the phase of reconstitution taking place in the submarine construction industry. Block 1 ships, ships one through four, started their construction as - 12 - the shipyards were reconstituting their submarine work forces. In the case of Newport News, this meant hiring some new employees and moving others from our carrier programs and certifying or recertifying them in SUBSAFE and other submarine-specific procedures. Specialized facilities were coming on line and equipment modernization unique to submarine production was being accomplished. This period marked the return of Newport News to the submarine construction business and, as a result, some inefficiencies existed. In spite of the many challenges presented by reconstitution at Newport News, a June 2005 assessment conducted by the Independent Review Team of the Assistant Secretary of the Navy (Research, Development and Acquisition) concluded that, barring unexpected technical problems, the labor hours and dollar cost of Newport News’ lead ship, Texas, at final acceptance should be approximately the same as that expected for Electric Boat’s lead ship, Virginia, at final acceptance. This is a tribute not just to the men and women of Newport News, but to the entire Electric Boat – Newport News team. Performance on Block 2, ships five through ten, has been influenced by a healthy infusion of the benefits of the teaming arrangement and the wisdom of the structure created in 1997. As we study the data we are seeing on these ships and look at the trends they represent, we have every reason to expect that with our ongoing initiatives Newport News can complete its work on these ships on budget. We are currently on budget for ship 5, the lead boat of Block 2, and are driving efficiencies to achieve similar results on the remaining ships. This is the industry commitment that is essential to make the CNO’s 30-year Shipbuilding Plan a reality. Can I quantify all of the actions today that will guarantee such an outcome? No. These ships deliver between 2009 and 2014, construction hasn’t even begun on some, and all require continued ship-over-ship learning, but the goal of “on budget” performance is the reason we believe it essential to continue working with our teaming partner, with the submarine industrial base, and with the Navy to identify opportunities that we each control to lower cost. Newport News is committed to doing this and we will continue to work collaboratively toward that goal. - 13 - Block 3, the next block of ships to be put under contract, will derive the full benefit of the teaming structure, learning that has taken place, process and facility improvements that have occurred, and volume production. If the current positive trends continue for shipbuilding costs, the government successfully executes its plans to reduce the cost of government furnished equipment, and we increase the rate of submarine production to two ships per year under a multi-year procurement with economic order quantity (EOQ) purchases, I am confident that block 3 submarines can be delivered to the Navy in accordance with the plan of “2 boats for $4 billion” in 2005 dollars. I am also confident that the teaming agreement and its unique equal sharing of work and profit is the best way for the shipbuilders to achieve this cost goal. Stability is Key Shipbuilding has suffered for too long from the lack of a coherent, agreed-upon, Navy shipbuilding plan. At the end of the Cold War, the Berlin Wall fell and took with it the national consensus on how big a fleet America needed to ensure its national security. As the nation has struggled to re-define its global responsibilities in a new era, the Navy’s long-range shipbuilding plans have become more notional than real. The shipbuilding industry is highly specialized. Because it is capital intensive, shipbuilders must be able to plan ahead if they are going to find investors willing to fund the facility modernization and maintenance requirements they have. Shipyard labor forces are also very specialized. One does not become a qualified shipbuilder overnight. Throughout the shipbuilding industry, it is generally recognized that five years of training and experience are necessary before a new employee is truly proficient. Nuclear skills require additional training and a variety of certifications which must be earned and re-validated periodically. Developing these skills requires investments by shipyards in formal training and certification programs, on-the-job training programs, mentorship programs and additional supervision for newer employees. - 14 - Beyond specific skills, there is a culture within a nuclear shipyard that must become second nature to all nuclear-qualified employees. Nuclear work is driven by carefully documented procedures that must be followed to the letter for the safety of employees and to ensure the product which is ultimately delivered will perform as it is supposed to without issue. Nuclear-qualified employees must also learn to adapt a questioning attitude. If an employee does not think that his work is proceeding as it is supposed to, the employee has learned to stop immediately and call the issue to the attention of a supervisor, much as some assembly lines can be stopped by an employee who detects a quality or process issue. The consequences of nuclear-qualified employees not asking questions all the time can be significant either in the construction process or later when the ship is at sea. These cultural factors require time to absorb, close supervision and greater investment by the shipyards. When shipbuilding plans are not stable, shipyards risk hiring too many employees and investing in their training only to find the anticipated need for these employees evaporate. At that point, these employees must be moved to other work, if there is any, or let go. When the shipbuilding plan changes again and employees are needed again, shipyards have to try to re-hire employees they previously trained or hire new employees and start all over again. This is, at best, uneconomical and can lead to shipyards not having enough employees with the right skills and certifications when they are needed. The enunciation of a coherent 30-year shipbuilding plan by the Chief of Naval Operations in recent months has come as a welcome relief to a long stretch of instability and uncertainty for our industry. While there are areas of the plan where some of us might prefer alteration, Admiral Mullen’s clear declarations that he intends to stick with his plan and that he will make every effort to fund it appropriately are important steps in the right direction. I applaud the CNO’s effort to work to a plan that is based on sound military judgments about future threats to our security. As a shipbuilder and a citizen, I hope that the Congress will also support the CNO’s plan with the funding needed to build these ships. This must be a long-term commitment - 15 - which is supported by the American people and will, perhaps, require special funding mechanisms to mitigate the spikes which come in years when large capital ships are procured. Volume is Essential for Cost Reduction While stability is critical to maintaining a vibrant shipbuilding industry, we cannot lose sight of the fact that the costs of producing a series of ships will come down in a meaningful way only when there is sufficient volume flowing through the shipyards. Even in the absence of volume, the Electric Boat – Newport News team has worked hard at reducing costs and the success of these efforts is beginning to be seen, particularly with Block 2 ships. But performance and innovation alone are not enough. Nor is volume alone enough. It takes the combination of volume with good performance, innovation, process improvements and investment to successfully reduce costs. The reality of the situation, in my view, is that reaching and sustaining a cost of Virginiaclass submarines at $2 billion in 2005 dollars requires an increase in production rates and the increase needs to come as soon as possible. As a shipbuilder focused on nuclear submarines and aircraft carriers, I know that I may be a bit parochial as I look at my ship programs in isolation. I have no doubt other shipbuilders do the same with their programs. Balancing national priorities is a responsibility best left to those who serve the nation in the civilian and military leadership of the Navy and the Department of Defense and the Congress. Disrupting a plan sometimes brings with it unintended consequences that we must all be wary of. We have experienced this at Newport News as two one-year delays in the start of production of the CVN 21 have added over $1 billion to that program. More specifically to the submarine program, the Electric Boat – Newport News team was originally supposed to begin producing two submarines per year in 2002; that date is now 2012. There is no question that this change has added significant cost to the submarine program. - 16 - I pledge to continue to work with the Navy and the Congress to provide all the information they need to make these difficult decisions on how to balance competing priorities. At the same time, I know that we will achieve the CNO’s goal of reducing the costs of the Virginia-class submarine most quickly by going to a production rate of two submarines per year as soon as possible. Shipbuilders and Navy officials know that the cost of Navy ships has three components: shipbuilder labor, shipbuilder material and government costs which include government material and support agency costs. Currently on the Virginia-class shipbuilder labor accounts for about forty percent of the total cost; shipbuilder material accounts for twenty-five percent; and government material and support accounts for about the remaining third. As shipbuilders we have been taking steps to reduce our labor and material costs, but attention must be given to all three components. The Navy must continue to take steps to stabilize requirements, minimize unnecessary design changes after production begins, and reduce the cost of government furnished equipment and the support provided by Navy laboratories and other Navy agencies. There is ample evidence from previous classes of submarines and other serial ship production that when production goes into series, labor costs are reduced. Our history with the production of Los Angeles-class submarines in the 1990’s demonstrated a steady decline in man-hours required to build the ships when shipbuilders had the opportunity to find more efficient ways to accomplish similar tasks from ship to ship and were able to sustain steady movement down a learning curve. We are seeing a similar pattern in the Virginia-class program. Both shipyards are currently seeing labor man-hour reductions as both yards move beyond their initial submarines and, especially, perform work on Block 2. When volume is increased, there will be an even greater positive impact on shipyard labor costs. We also know from our experience with the Los Angeles-class that there are risks inherent with design changes and major insertions of new technologies, other than those - 17 - intended to simplify production and reduce costs. Recognizing that these changes will affect costs, careful consideration needs to be given to balancing the cost of technology insertion with the benefits of the new capabilities. When such insertions are determined to be necessary or beneficial, the Virginia-class can be the vehicle to maintain critical submarine design skills on a real platform that will get the product to sea. This is key to ensuring the robustness of the design change and is a good measure of whether critical design skills are being maintained. Nonetheless, too many large design changes will add cost to the program. Increasing volume will also have an important impact on material purchases. When shipbuilders are able to buy required construction material and components from subcontractors in volume, savings are achieved. This is one of the great benefits of being authorized and funded to procure material in advance of construction. Just as shipbuilders can achieve learning curve savings with volume production, suppliers are better able to manage their workforces, maintain continuity in production, maintain critical skills, and achieve un-interrupted learning curve efficiencies. As production rates increase, the shipyards use economic order quantity purchases to aggressively negotiate with vendors and to achieve the lowest price on these materials. Delivering Results We have seen the benefits of the current multi-year contract with economic order quantities in Block 2. To date the Electric Boat – Newport News team has achieved a target set by the Navy to save $240 million on material purchases for ships six through ten. The Navy intends to achieve savings of $160 million on government furnished equipment for a total of $400 million in savings. In addition, the shipyards have found $23 million in savings on 35 key material items above and beyond the target of $240 million. We can reasonably expect that similar results will be achieved as the program hits its stride with greater volume. - 18 - Before concluding I want to return to the labor picture for a few final comments. In the Los Angeles-class submarine program in the 1990’s, once the program reached optimal production levels with stable build plans and technology insertion issues behind it, labor costs were decreased with each successive ship. In the Virginia-class program, Virginia and Texas have borne the brunt of early design changes. As changes were made on Virginia, they were passed to Texas which was following closely behind. These design changes had a significant impact on the labor costs. We believe that the design is now locked down and the team can capitalize on standardization to achieve cost savings. Both shipyards are seeing a twenty percent reduction in labor man-hours on recurring costs from their first delivered ship to their second. From Virginia to Hawaii, Electric Boat is on track for a twenty percent reduction in labor. From Texas to North Carolina, Newport News is also on track for a twenty percent reduction in labor. The ability to achieve such reductions is even more astonishing given the significant impact of very low production rates of Seawolf at Electric Boat and the fact that there was no submarine construction at Newport News for the previous ten years. Both yards are seeing evidence that the trends are moving in the right direction – downward. Continued adherence to the tenets of the teaming agreement coupled with an increase in production rates will help this program be as successful as the Los Angeles-class program. Conclusion The Virginia-Class Submarine is going to be an invaluable asset to the Navy throughout the century. By the end of this year, the Electric Boat-Newport News team will have delivered the first two submarines to the fleet. Good progress is being made by the team on the remaining ships of Blocks 1 and 2 and the ground work is being laid for an even more successful and cost-effective Block 3 in the near future. We have been able to get to this point in the program because of the investment made by the American people in the specialized facilities and skilled employees at both Electric Boat and Newport News. - 19 - I am optimistic about the future because we have, at long last, a shipbuilding plan from the Navy and one that the Navy leadership has pledged to support and fund. Stability is a necessary condition for successful shipbuilding, but stability alone will not drive down the cost of producing these technological marvels. Volume is also essential if we are to further drive down the cost of producing these submarines. History is clear in the shipbuilding industry as well as other manufacturing industries that the cost of production falls when there is serial production. We must get there – soon. In the absence of volume, our team will continue to take out cost everywhere we can. We are not sitting idly by waiting for serial production to begin before we try to reduce costs. We have been attacking them from day one of the program and we will continue to attack them until the final ships sail from our shipyards to their new homes at Naval bases. The shipbuilding team is actively engaged in this battle just as the Navy’s program office is working to reduce the government component of the total cost. With the continued support of the Congress, in the not too distant future we will all look back on this teaming arrangement and acknowledge that together we have made an important difference in safeguarding our national security. - 20 -