Reducing Wind Effects on Overpressure Readings

advertisement

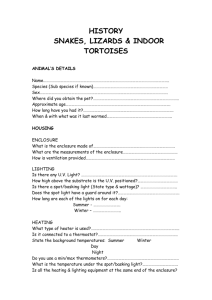

Reducing Wind Effects on Overpressure Readings Mahasen Sooriyabandara Monash University, Clayton Abstract A cubic enclosure made of sailcloth was suggested by [1] as suitable windscreen that would preserve the low frequencies that characterize blast waves. This was tested with an open and closed top in conjunction with the existing spherical foam windscreen. It was found that wind noise is dominated by frequencies in the 20-40 Hz range, with vanishingly small contributions up to 150Hz. Results show significant attenuation of frequencies in the 10-100 Hz range, which is more pronounced with a closed enclosure than an open one. Measured data for attenuation of frequency components in the 1-5 Hz regime is unreliable: unfortunately, airblasts are dominated by 1-2 Hz frequencies. Peak volume was reduced by 1-2 dB for open enclosures (roughly a 15-30% drop in measured overpressure) and 6+ dB for closed enclosures (at least a 50% drop in measured overpressure). 1. Introduction Environmental regulations require noise produced by mining blasts to be below a 120 dB threshold. However, wind noise alone can produce erroneously high readings that exceed these limits. For pressure-transducer diaphragm microphones, rapid changes in local pressure produced by turbulent flow are responsible. The standard way to reduce wind noise is to reduce the speed of the wind as soon as possible, before it reaches the microphone. In practice, this is achieved through open-cell foams, porous screens etc. We have chosen to use a sort of open-cavity windscreen that aims to slow the flow of air without attenuating low frequencies (as cavity absorbers are prone to do). 2. Wind Noise In figure (1), 70 mph (≈ 110 kmh−1 ) windspeeds correspond to a sound level of 110 dB for a microphone (with windscreen) perpendicular to the wind (same as the Dynamate setup). This is close the the recommended maximum sound pressure for airblast of 115 dB as prescribed by ANZEC [3] (see page 3), and as the recommended maximum sound pressure for human comfort in sensitive sites prescribed by the Australian Standard for use of explosives [4] (see page 115, or table J5.4(A)). In both standards, there is a hard limit of 120 dB for airblasts. The sound pressure level is defined as: 2 prms prms = 20 log10 , (1) L = 10 log10 pref pref Figure 1: Graph of wind noise from as a function of wind speed for various orientations of a diaphragm microphone, reproduced from [2] . where prms is the root mean square of air pressure and pref is a reference air pressure, 20µPa, the approximate lower threshold of human hearing at 1kHz. From [5], we find that for n incoherent sources, the combined sound pressure level (in decibels) is given by ! 2 n n X X Li pi L = 10 log10 = 10 log10 10 10 , (2) p ref i=1 i=1 where pref = 20 µPa and Li denotes the sound pressure level due to source i alone. This allows us to obtain a practical hard limit (i.e. such that combined sound pressure level is < 120dB) for airblasts in the presence of high winds. Substituting into equation (2) gives 2 2 ! pwind pairblast 120 = 10 log10 . + pref pref Rearranging, Lairblast = 10 log10 1012 − 10Lwind . (3) Now, the error tolerances of the Dynamate is quoted as being the lesser of 10% of pressure 2 in Pascals and 1 dB, though the first of these bounds is always smaller than the second, as can be seen by substitution into (1): 1.1 × prms = 20 log10 pref prms = 20 log10 + 20 log10 (1.1) pref ≈ L + 0.8279 Lupper 0.9 × prms = 20 log10 pref prms = 20 log10 + 20 log10 (0.9) pref ≈ L − 0.9151 Llower As an example, in 110kmh−1 winds (110dB for mic with windscreen, perpendicular to wind) and with a license limit of 120 dB, the maximum permitted sound pressure level of an airblast is ≈ 119.96 dB. A 0.04 dB difference is a smaller quantity than the Dynamate can accurately detect, so, practically, the maximum permitted sound pressure level of an airblast is still 120 dB, and we can ignore the wind. It seems the problem with wind isn’t so much that the combined effect of wind and airblast will exceed licence limits, but rather that wind alone will. For instance, a naked microphone, a naked microphone perpendicular to 100 kmh−1 wind can exceed a 120dB limit due to wind alone. It is worth noting that the formula for combined levels might only be valid for timeaveraged values, therefore unsuitable for impulses like airblasts: however, measurements are made at large distances from the blast source when the impulse has broadened sufficiently for (3) to be a reasonable approximation. 3. Windshield 3.1. Foam Windshield From [6] and [7], suggest the use of a foam windscreen to mitigate wind noise. In particular, Hessler investigated wind noise suppression while preserving low frequencies, finding superior results with a 175mm spherical open cell foam windscreen (model ACO Pacific WS-7-80T, probably similar to Ecotech’s proprietary foam windscreen) over 7 other commonly used windscreens (all of which produced better results than no windscreen, except one which produced resonances at a certain frequency). In addition, the 175mm windscreen exhibited negligible attenuation of low frequency signals - no weighting was necessary to compensate for its use. Interestingly, the treated (for outdoor use) foam windshield performed better at low frequencies than the untreated shield. It was found that in wind speeds above 10m/s, wind-induced noise becomes an issue even with a windscreen. Hessler suggests that even larger spherical foam windscreens be used if low frequency measurements are needed in high winds where a 175mm windshield is insufficient. 3.2. Shade Cloth Enclosure Bies and Hansen [1] (page 110) suggests a 1m × 1m × 1m shade cloth enclosure with an open top as a means of mitigating wind noise for low frequency measurements. In theory, it would slow some wind down without behaving as a cavity absorber. Ideally, the shade cloth 3 should behave as a porous linear sheet [5], which will strongly attenuate high frequencies while transmitting low frequencies. Since blast locations are not recorded, we need to ensure that measurements are isotropic. In practice, the enclosure should have been spherical, or at least cylindrical. However, for constructional expediency, the enclosure was a cuboid. Pine rods with 18mm square cross-section was used for the frame. Coolaroo 70% was used for the shade cloth. The choice was arbitrary: ideally, the shade cloth should have been accompanied by an openness factor/porosity , noise reduction coefficient or sound absorption average, however, none of these were available. Accurate quantification of these properties for a variety of materials would allow for a more informed choice based on the theory of locally reacting absorbers and acoustic properties of porous materials [5] [1]. Dimensions were chosen to be 43.6cm × 43.6cm × 36.4cm. Since the microphone has a linear response between 5-276 Hz, we do not need to worry about resonances due to high frequencies. The maximum value of any dimension of the box is limited by half the smallest wavelength detected by the microphone (corresponding to the resonance in the fundamental mode between opposing faces of the enclosure). Suppose this is 276Hz, then cs = νmax (2λmin ) 1 =⇒ λmin = cs /νmax 2 ≈ 0.62m is an upper limit to any dimension of the enclosure, where cs is the speed of sound in air (340.29 ms−1 in dry air at 20◦ C), νmax is the maximum frequency admitted by the microphone, and λmin is the minimum wavelength for resonance. 62cm is greater than the chosen dimensions, so resonance between opposing faces should not be an issue. 3.3. Existing Audio Equipment ACO Pacific 1/2 inch 7052S capsule diaphragm microphone ACO Pacific 4052 Pre-amp Proprietary 175mm spherical open-cell foam windshield, treated for outdoor use -3dB points of microphone are 5-250dB (According to documentation, 5-276dB in practice). 4. Results Each test (labelled by its event code in Dynamaster) compares the behaviour of two microphone setups. The setup labelled Standard approximates the existing in-field microphone setup for the Dynamate: the ACO capsule microphone and amplifier suspended inside 4 Ecotech’s spherical open-cell foam windscreen. The Open Enclosure setup consists of the standard setup inside a 43.6cm × 43.6cm × 36.4cm box with all sides covered by shadecloth, except the top, which is left open. The Closed Enclosure setup consists of the standard setup inside a 43.6cm × 43.6cm × 36.4cm box with all sides covered by shadecloth, including the top. The two microphone setups were then affixed to tripods, side-by-side, on the roof walkway of the Ecotech building. The enclosure was attached to the same stand that held the microphone inside it. Measurements were made on a day with roughly 70 kmh− 1 gusts for two reasons: (1) so that there would be sufficiently measurable wind noise event with the spherical foam windscreen; (2) other noise sources such as traffic, ventilation fans etc. would not contribute significantly to measurements. The Standard setup was used in every test and is represented by a black line. It used PID134. The other two setups used PID-75. Microphone serial numbers were not recorded. Microphones were not switched between tests. Data relating to the maximum measured volume (denoted AB, for airburst) for each test is shown in tables 1 and 2. Three figures are shown for each test: the raw response from the two microphone setups; the spectrum of each signal represented as magnitudes of frequency components (1-200Hz) obtained by discrete Fourier transform;, and the ratio of the magnitude frequency components of each signal, which, by an abuse of notation, is denoted fenclose /fstandard . This is intended to give a measure of the frequency profile of the enclosure (i.e. how strongly it attenuates at a given frequency, n.b. I’m not sure if this is the precise terminology, but I will continue to use it). The discrete Fourier transform is smoothed with a 7-point moving average filter to obtain an estimate of a continuous transform. These averages are not accurate in the 1-5 Hz range, as will be discussed in the following section 4.1. Overview Table 1: Table of standard setup vs. open enclosure tests. Event Max AB (Pa) ASH08J ASH08J ASH08L ASH08L ASH08N ASH08N 11.02 6.97 6.93 6.14 3.2 2.58 Max AB (dBL) Unit Type 114.8 PID 134 Standard 110.9 PID 75 Open Encl. 110.8 PID 134 Standard 109.7 PID 75 Open Encl. 104.1 PID 134 Standard 102.2 PID 75 Open Encl. 5 Table 2: Table of standard setup vs. closed enclosure tests. Event Max AB (Pa) ASH08I ASH08I ASH08K ASH08K ASH08M ASH08M 9.93 4.25 9.99 5.28 7.62 2.81 Max AB (dBL) Unit Type 113.9 PID 134 Standard 106.5 PID 75 Closed Encl. 114 PID 134 Standard 108.4 PID 75 Closed Encl. 111.6 PID 134 Standard 102.8 PID 75 Closed Encl. 4.2. Open enclosure Figure 2: Results for the first test, open enclosure (event code ASH08J). 6 Figure 3: Results for the second test, open enclosure, (event code ASH08L). Figure 4: Results for the third test, open enclosure, (event code ASH08N). 7 4.3. Closed enclosure Figure 5: Results for the fourth test, closed enclosure (event code ASH08I). Figure 6: Results for the fifth test, closed enclosure (event code ASH08K). 8 Figure 7: Results for the sixth test, closed enclosure (event code ASH08M). 5. Discussion 5.1. Overview Table 1 shows the maximum measured sound pressure level in pascals and decibels for each unit for tests with an open enclosure. Sound pressure level is reduced by 1-4 dBL, which corresponds to a reduction of roughly 0.5-4 Pa, which represents a significant proportion of the total overpressure. Table 1 shows the same data for closed enclosures. For these tests, sound pressure level is reduced by 5-9 dBl, or 4-5 Pa. This data alone is insufficient to judge whether either enclosure has performed well. We need to see how well they attenuate frequencies in the high end of the linear frequency response range, how well they preserve low frequencies, and how well they reduce noise attributable to wind. 5.2. Problems with frequency spectra In the Fourier transform of every measurement made with PID-75 appeared to have an unnaturally large 1Hz component. This is what is responsible for the ‘kick’ seen at the start of every red line in the frequency spectrum of figures in 4.2 and 4.3 (the moving average filter ‘smears’ the large initial discrepancy across neighbouring values). The seemingly asymptotic behaviour of the frequency component ratio (as f approaches zero) is a combined consequence of the too large 1 Hz component and the moving average filter. 9 Interestingly, there was a little more to the problem. Table 3 compares the normalized absolute values of the first ten components of the Fourier transforms from figure 4.2 (before applying the filter). The values for 6-10 Hz components seem comparable, however, the value for 1 Hz is roughly 7 times larger for PID-75 than PID-134. Components corresponding to 2-5 Hz are 2-7 times smaller for PID-75 than PID-134. This behaviour is shared by all measurements. It is unlikely that the enclosure would be able to impart a strong 1 Hz frequency and simultaneously attenuate 4-5 Hz frequencies by almost an order of magnitude. This suggests instrumental error: either an issue with calibration or the equipment itself. This could have been mitigated or corrected for if units and/or microphones had been swapped between setups after each test. In light of this, it not quite clear to what extent we can trust the rest of the measurements. Since the overall character of the observations fits our expectations (i.e. the open enclosure attenuates less than the closed enclosure, that they each have frequency profiles etc.), we can hope that these errors are limited to the 1-5 Hz region. Unfortunately, this is precisely the region we are most interested in, since most of the energy of a blast wave is in the 1-2 Hz range. Given that the 6-10 Hz values of the DFT in both the standard and Open Enclosure in table 3 are so similar, we will suppose that higher frequencies are accurate enough to warrant further discussion. Table 3: Normalized discrete Fourier transform components for Open Enclosure test 1 4.2. Note proportionately large differences in first five values. Frequency (Hz) Standard (PID-134) 1 0.0070 2 0.0126 3 0.0248 4 0.0499 5 0.0451 6 0.0345 7 0.0578 8 0.0231 9 0.0656 10 0.0655 Open Encl. (PID-75) 0.0690 0.0096 0.0032 0.0069 0.0103 0.0348 0.0212 0.0228 0.0331 0.0103 5.3. Frequency profiles of open and closed enclosures By superficial inspection of the frequency spectra, wind noise appears to be concentrated in the 20-40 Hz region. Both open and closed shade cloth enclosures attenuated strongly in this region, the closed enclosure more so. In early tests, it was thought that we could simulate a blast wave using a 30 Hz sine wave from a function generator fed to a subwoofer. The effectiveness of a windshield would then be based on how well it attenuated wind noise and how little it affected the 30 Hz sine wave. However, from the fact that 30 Hz is in the middle of the frequency range that wind noise is concentrated in, this would have been a poor metric for effectiveness. 10 The frequency profiles of the closed enclosures showed consistently higher attenuation across all frequencies, averaging less than 50% of each frequency component. The open enclosure fared better with an average of around 70%. These proportions are comparable to the reductions in overpressure discussed in section 5.1: that is, it may be that the reductions of measured airblast may be due to the enclosures reducing all noise by a constant factor. However, neither enclosure had a truly flat frequency response: the open enclosure seems to absorbs strongly at around 25 Hz and resonate at around 130 Hz. The closed enclosure, on the other hand, does not seem to have any pronounced characteristics, though it does seem to resonate at around 100 Hz. This might be due to structural resonance, and could have been avoided if the enclosure was mechanically isolated from the microphone it contained by using shock mounts or dampeners. 6. Conclusion The open enclosure seems more promising than the closed enclosure. Both attenuate strongly in the region where wind noise is most pronounced, however the open enclosure doesn’t affect low frequencies nearly as much. It difficult to make statements about very low (1-5 Hz) frequencies due to the questionable accuracy of data measured by PID-75 in this region. Wind noise appears to be concentrated in the the 20-40 Hz range, with lesser contributions up to roughly 150 Hz. Both setups attenuate strongly in this region. If implemented, the enclosure would need to be or spherical to ensure isotropy of measurements. An alternative would be to follow Hessler’s advice and use a larger spherical treated open-cell foam windscreen. 11 [1] D. A. Bies, C. H. Hansen, Engineering Noise Control, 4th Edition, Spon Press, 2009. [2] V. J. Stachura, D. E. Siskind, A. J. Engler, Airblast instrumentation and measurement techniques for surface mine blasting. [3] Australia and New Zealand Environmental Council (ANZEC), Technical basis for guidelines to minimise annoyance due to blasting overpressure and ground vibration (1990). [4] Standards Australia, Explosives — storage and use, Part 2: Use of explosives (2006). [5] F. Fahy, Foundations of Engineering Acoustics, Academic Press, 2001, purple cover. [6] J. Edward R. Maniet, Wind tunnel measurements of windscreen performance, The Journal of the Acoustical Society of America 111 (5) (2002) 2373–2374. [7] G. F. Hessler, D. M. Hessler, P. Brandstatt, K. Bay, Experimental study to determine wind-induced noise and windscreen attenuation effects on microphone response for environmental wind turbine and other applications, Noise Control Engineering Journal 56 (4) (2008) 300–309. 12