Piezo Film Sensors Technical Manual Measurement Specialties, Inc.

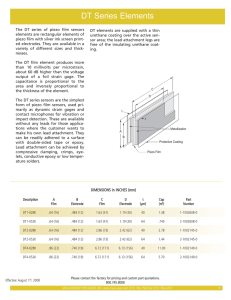

advertisement