EFFECT OF DENSITY ON THE MICROSTRUCTURE AND MECHANICAL BEHAVIOR

advertisement

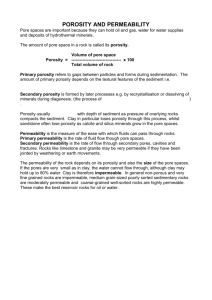

EFFECT OF DENSITY ON THE MICROSTRUCTURE AND MECHANICAL BEHAVIOR OF POWDER METALLURGY FE-MO-NI STEELS N. Chawla and X. Deng Mechanical Behavior of Materials Facility Arizona State University P.O. Box 876006 Tempe, AZ 85287-6006 M. Marucci and K.S. Narasimhan Hoeganaes Corporation Cinnaminson, NJ 08077 ABSTRACT The microstructure and mechanical properties of Fe-0.85Mo-Ni powder metallurgy (P/M) steels were investigated as a function of sintered density. A quantitative analysis of microstructure was correlated with tensile and fatigue behavior to understand the influence of pore size, shape, and distribution on mechanical behavior. Tensile strength, Young’s modulus, strain-to-failure, and fatigue strength all increased with a decrease in porosity. The decrease in Young’s modulus with increasing porosity was predicted by analytical modeling. Two-dimensional microstructurebased finite element modeling showed that the enhanced tensile and fatigue behavior of the denser steels could be attributed to smaller, more homogeneous, and more spherical porosity which resulted in more homogeneous deformation and decreased strain localization in the material. The implications of pore size, morphology, and distribution on the mechanical behavior and fracture of P/M steels is discussed. INTRODUCTION Ferrous powder metallurgy (P/M) components are typically characterized by residual porosity after sintering, which is quite detrimental to the mechanical properties of these materials [1-7]. The nature of the porosity is controlled by several processing variables such as green density, sintering temperature and time, alloying additions, and particle size of the initial powders [1]. In particular, the fraction, size, distribution, and morphology of the porosity have a profound impact on mechanical behavior [2-7].With an increase in porosity fraction (> 5%), the porosity tends to be interconnected in nature, as opposed to the situation where pores are isolated (< 5%) [1]. Under monotonic tensile loading, porosity reduces the effective load bearing cross-sectional area and acts as a stress concentration site for strain localization and damage, decreasing both strength and ductility [2]. Interconnected porosity causes an increase in the localization of strain in the relatively small sintered regions between particles, while isolated porosity results in more homogeneous deformation. Thus, for a given amount of porosity, interconnected porosity reduces macroscopic ductility [2]. The distribution of pores may also be inhomogeneous, because of the broad distribution of particle sizes in the sintered powder mixture, resulting in “pore clusters” where strain localization may also take place [8]. Porosity also significantly affects fatigue behavior, although the role of porosity in fatigue is somewhat different than that in tension. In many investigations [2-6, 9-11], crack initiation was reported at pores or pore clusters located at or near the specimen surface. Holmes and Queeney [9] proposed that the relatively high stress concentration at pores, particularly surface pores, is responsible for localized slip leading to crack initiation. Christian and German [10] showed that total porosity, pore size, pore shape, and pore spacing are important factors that control the fatigue behavior of P/M materials. In general, more irregular pores will have a higher stress concentration than perfectly round pores [1]. Pores have also been proposed to act as linkage sites for crack propagation through interpore ligaments [2, 6]. Polasik et al. [6] showed that small cracks nucleate from the pores during fatigue and coalesce to form a large crack that leads to fatigue fracture. Crack propagation was observed to be quite torturous in nature, due to the heterogeneous nature of P/M microstructures. Crack arrest and crack deflection mechanisms were attributed to microstructural barriers such as particle boundaries, fine pearlite, and/or nickel-rich regions. While the general effects of porosity on tensile and fatigue behavior of P/M steels have been reported, a comprehensive and quantitative understanding of the effect of porosity on the mechanical behavior of P/M steels is still needed. In this study, we have systematically examined the effect of porosity on the tensile and fatigue behavior of a Fe-0.85Mo-Ni steel at three densities: 7.0 g/cm3, 7.4 g/cm3, and 7.5 g/cm3. Quantitative analysis of the microstructure was performed to determine pore size distribution and pore shape. The tensile behavior of the alloys was examined, showing an increasing Young’s modulus and tensile strength with increasing density. Analytical and microstructure-based numerical models were used to predict the Young’s modulus and overall monotonic stress-strain behavior as a function of density, respectively. The stress versus cycles (S-N) fatigue behavior of the alloys was also examined, which showed that decreasing porosity significantly increased the fatigue life of the alloys. Finally, fractographic analysis was carried out to correlate the observed tensile and fatigue behavior with the underlying fracture mechanisms. MATERIALS AND EXPERIMANTAL PROCEDURE Powder mixtures of Fe-0.85Mo pre-alloy powder, 2 wt.% Ni, and 0.6 wt.% graphite were blended and binder-treated using a proprietary process developed by Hoeganaes Corporation [12, 13]. Powders were compacted into rectangular blanks, and sintered at 1120ºC for 30 minutes in a 90% N2-10% H2 atmosphere. Conventional compaction and sintering were used to obtain sintered densities of 7.0 g/cm3 and 7.4 g/cm3, while a double-press, double sinter approach enabled achieving the highest density of 7.5 g/cm3. Following sintering, the sintered density of the alloys was measured using Archimedes and image analysis techniques. The fraction of porosity and pore shape were measured using conventional image analysis techniques. Pore shape was qualitatively characterized using a shape form factor, F: F= 4πA P2 [1] where A is the measured pore area and P is the measured pore perimeter. For the shape form factor, a value of “1” denotes a perfectly round pore, and values that approach zero correspond to increasingly irregular pores. Analysis of pores approximately larger than 75 µm2 was conducted from image analysis of optical micrographs, while pores approximately less than 75 µm2 were analyzed by scanning electron microscopy (SEM). Tensile and fatigue testing was conducted on uniform diameter cylindrical specimens machined from the sintered rectangular blanks. The specimens had a diameter of 5 mm and a gage length of 15 mm [6]. All testing was conducted on a servohydraulic frame. Tensile tests were conducted in strain control at a constant strain rate of 10-3/s. Fatigue specimens were hand polished to a 1 µm finish, prior to testing. Fatigue testing was conducted in load control, R-ratio (σmin/σmax) of – 1, and a frequency of 40 Hz (40 cycles per second). RESULTS AND DISCUSSION Microstructure Characterization The sintered density, measured by Archimedes technique, and porosity, calculated from sintered density and measured by image analysis, are shown in Table 1. The porosity measured by image analysis yielded values ranging from around 12% for 7.0 g/cm3 to 2.6% for 7.5 g/cm3. These values were similar to the porosity values computed from the sintered density of the alloys, although at the lower densities (7.0 g/cm3 and 7.4 g/cm3), the porosity measured from image analysis was slightly higher than that from Archimedes technique. This can be attributed to the fact that only open porosity is considered in the latter technique, so the contribution from closed porosity is not accounted for. Optical micrographs revealed significantly different microstructures for all three alloys, particularly in terms of pore size, morphology, and distribution, Fig. 1. The pores at the lowest density appeared to be much larger and more irregular than pores in the other two alloys. Pores at the lowest density also appeared to be more clustered and segregated along the interstices between particles. Table 1. Sintered density and porosity in Fe-Mo-Ni alloys Sintered Density (g/cm3) 6.98 7.43 7.53 Porosity from sintered density (%) 10.3 4.5 3.2 Porosity from image analysis (%) 12.1 ± 0.8 5.9 ± 0.6 2.6 ± 0.2 (b) (a) (c) Figure 1. Microstructure of P/M steels at three densities: 7.0 g/cm3, 7.4 g/cm3, and 7.5 g/cm3. Note the higher fraction of porosity, as well as larger, more irregular pores at the lowest density. Pore size distribution of large pores (> 75 µm2), shown in Figure 2(a), revealed that the alloy at 7.0 g/cm3 had the highest density of larger pores, while the highest density alloy, 7.5 g/cm3, Figure 2(b), had a much smaller average pore size and narrow size distribution. At smaller pore 100 7.0 g/cm3 80 7.4 g/cm3 4 3 7.0 g/cm 3.5 7.4 g/cm 3 Frequency (%) 40 Frequency (%) Frequency (%) 3 60 7.5 g/cm3 80 3 7.5 g/cm 2.5 2 1.5 1 60 40 0.5 0 20 300 375 450 525 600 675 750 825 900 975 2 Pore Size (µm ) 0 75 150 225 300 375 450 525 600 675 750 825 900 975 2 Pore Size (µm ) 20 0 1 15 30 45 2 Pore size (µm ) 60 75 (b) (a) 2 Figure 2. Pore size distribution for all alloys: (a) pores larger than 75 µm and (b) pores smaller than 75 µm2. As expected, a higher density of larger pores was observed at 7.0 g/cm3, while a higher density of smaller pores was observed at 7.5 g/cm3. size (< 75 µm2), as expected, a higher density of smaller pores was observed in the alloy with 7.5 g/cm3 density. Pore shape analysis of larger pores (> 75 µm2), indicated that all three alloys had approximately the same pore shape factor distribution, Fig. 3(a), although increasing density resulted in a somewhat narrower pore shape distribution. Interestingly, smaller pores (< 75 µm2) had a much more spherical shape and are likely a direct result of sintering, Fig 3(b). A direct comparison of pore shape versus pore size shows, indeed, that with increasing pore size the pores become increasingly irregular in shape, Fig. 3(c). 25 30 7.5 g/cm (a) 3 7.4 g/cm 20 3 7.5 g/cm 3 25 (b) 7.0 g/cm 3 20 15 7.0 g/cm 7.4 g/cm 3 3 15 10 10 5 0 5 0 0 0.2 0.4 0.6 0.8 1 0 0.2 2 Pore Shape Factor (F=4πA/P ) 0.4 0.6 0.8 Pore Shape Factor, F 7.0 g/cm 3 200 Figure 3. Pore shape factor of all three alloys: (a) pores smaller than 75 µm2, (b) pores larger than 75 µm2, (c) direct comparison of pore shape versus pore size. Increasing pores size results in an increase in irregularity of pore shape. 1 7.4 g/cm 3 150 100 50 (c) 0 0 0.2 0.4 0.6 Pore shape factor, F irregular 0.8 1 spherical Tensile Behavior The monotonic behavior of the alloys was clearly influenced by the fraction of porosity and the pore morphology. Increasing density resulted in increased Young’s modulus, proportional limit stress (taken as the onset of yielding in the material, as measured by a 2% deviation from the linear elastic portion of the stress-strain curve), tensile strength, and strain-to-failure, Table 2. Figure 4 shows a comparison of representative stress-strain curves for each alloy. Note that even a moderate amount of porosity (~10-12%) is sufficient in inducing a significant decrease in strength and strain-to-failure relative to the close to fully-dense material (7.5 g/cm3). Table 2. Tensile behavior of Fe-Mo-Ni steels. Density (g/cm3) 7.0 7.4 7.5 Young’s Modulus (GPa) 138.6 ± 1.2 171.6 ± 0.8 182.6 ± 1.9 It is well known that porosity decreases the Young’s modulus of a material [1]. Here we use the approach of Ramakrishnan and Arunachalam (R-A) [14], who model a single spherical pore surrounded by a spherical matrix shell. The R-A model also considers the intensification of pressure on the pore surface due to interaction of pores in the material. The Young’s modulus of a material, E, with a given fraction of porosity, p, is given by [14]: (1 − p )2 E = Eo 1 + κ E p Proportional Limit Stress (MPa) 160.0 ± 19.4 189.0 ± 8.1 196.4 ± 9.3 Ultimate Tensile Strength (MPa) 570.6 ± 8.1 745.2 ± 24.0 784.4 ± 16.3 Strain-toFailure (%) 2.1 ± 0.1 4.6 ± 0.4 6.5 ± 0.7 800 7.5 g/cm 7.4 g/cm 700 3 3 600 7.0 g/cm 3 500 400 300 200 100 Fe-Mo-Ni-C 0 0 0.01 0.02 0.03 0.04 0.05 0.06 Strain (mm/mm) Figure 4. Effect of density on tensile behavior of the P/M steels. A marked decrease in strength and ductility in the 7.0 g/cm3 alloy is observed, relative to the close to fullydense material, 7.5 g/cm3. where E0 is the Young’s modulus of the fully-dense steel (taken by extrapolating the experimental data to zero porosity, which yielded a value of approximately 201 GPa), and κE is a constant in terms of the Poisson’s ratio of the fully-dense material, νo: κ E = 2 − 3ν o For a fully-dense steel the Poisson’s ratio is approximately 0.3. A comparison of the experimental data and the R-A prediction is shown in Figure 5. The R-A predicts the experimental data very well, for the range of porosity examined here. The relatively good agreement between experiment and theory, based on a simple spherical pore geometry, indicates that the elastic properties of these materials do not appear to be significantly influenced by the shape and morphology of the porosity microstructure. This is supported by the analysis of Ramakrishnan and Arunachalam [14], who compared the bulk modulus of porous materials with spherical versus angular pore geometry by FEM. For the range of porosities studied here (< 10%), they observed that the decrease in modulus for angular pores versus spherical pores is less than 5%. The increase in proportional limit stress and ultimate tensile strength with an increase in density can be explained by modeling the damage evolution in the microstructure of each of the three alloys. The microstructures in Figure 1 were used as a basis for FEM analysis of uniaxial loading. The analysis was twodimensional (2D) under plane strain condition. It should be noted that the 2D analysis effectively treats the pores as holes in the microstructure. This model is quite different from the pores in actuality, which are three-dimensional (3D) and surrounded by matrix material. Nevertheless, the 2D analysis presented here shows a qualitative perspective of the effects of pore microstructure on localized plastic strain initiation and evolution around the pores. 3D microstructure-based visualization and FEM analysis, through the use of serial sectioning techniques, are currently underway to obtain a more quantitative description of the plastic strain evolution in porous materials [15]. 250 Experiment R-A Model 200 150 100 50 Fe-Mo-Ni-C 0 0 0.02 0.04 0.06 0.08 0.1 0.12 Fraction of Porosity Figure 5. Young’s modulus of P/M steels versus porosity. The R-A model predicts the experimental data very well. 1 Steel Matrix 0.8 3% Porosity 4% Porosity 0.6 10% Porosity 0.4 0.2 The macroscopic stress-strain 0 0 0.002 0.004 0.006 0.008 0.01 behavior predicted by the model is Strain shown in Figure 6. The stressFigure 6. Modeled stress-strain behavior by 2D FEM strain input for the fully dense analysis. A sharp decrease in strength is observed at 10% steel (extrapolated from the porosity, commensurate with the experimental data. experimental stress-strain behavior at the three different densities), is also shown. Note that even a slight decrease in porosity (4-10%) results in a significant decrease in strength of the steel, as was observed experimentally. The reason for this can be gleaned from the equivalent plastic strain evolution in each of the three microstructures, shown in Figure 7. A large amount of strain localization takes place in the sintered regions between pores. In particular, networks of pores are quite effective in localizing the strains in the steel ligaments between the pores. Thus, a very small section of the microstructure is actually being plastically deformed, so that a large portion of the materials is largely undeformed. The modeling results are confirmed by experimental observations that porosity causes deformation to be localized and inhomogeneous [16-18]. The strain intensification in the sintered ligaments between pores, likely serve as areas for crack initiation. Once the onset of crack initiation takes place, the large pores will be linked, and the effect load-bearing area of the materials locally will decrease very quickly, resulting in fracture of the material. An increase in porosity decreases the overall sintered ligament fraction and spacing between pores, thus accelerating the intensification of strain in the matrix material. Our modeling also shows that plastic strain intensification begins at the tips of the irregular pores in the microstructure. Vedula and Heckel [16] compared the damage mechanisms between round and angular pores in materials with identical pore fraction and observed that highly localized slip bands formed at the sharp tips of angular pores, producing uneven distribution of strain around angular pores. This resulted in highly localized and inhomogeneous plastic deformation compared to the deformation around round pores which was much more homogeneous. (a) Figure 7. Effective plastic strain contours in modeled microstructures: (a) 7.0 g/cm3, (b) 7.4 g/cm3, and (c) 7.5 g/cm3. Larger and interconnected pores cause strain intensification, while smaller, more homogeneously distributed pores contribute to more homogeneous deformation. (b) (c) The distribution of the pores is also important, since it has been shown that plasticity may initiate at pore clusters because of the higher localized stress intensity associated with these defects [2, 6, 19]. The plastic strain distribution in the modeled microstructure for the densest steel, 7.5 g/cm3, shows that when the pores are much smaller and more homogeneously distributed, the plastic strain distribution is more uniform and the deformation is more uniformly distributed throughout the material. We are now able to explain why only a slight increase in density from 7.43 g/cm3 to 7.53 g/cm3 resulted in a significant increase in strain-to-failure, although the strength of the material increased only slightly. This may be attributed to a narrower and more homogeneous distribution of pores in the 7.5 g/cm3 alloy versus 7.4 g/cm3, although the total amount of porosity in the latter alloy was not significantly higher. Thus, while the strength of the material is controlled by the fraction of pores, macroscopic ductility is also influenced by the size distribution and degree of clustering of the pores, since the sintered ligaments of the steel control fracture of the material. An equally important result of the model is that, even in the highest density material, a large amount of strain intensification takes place at as ingle pore cluster in the microstructure, Fig. 7. Thus, even when the overall amount of porosity is relatively low (4-5%), strain intensification may take place around pore clusters. It follows that the homogeneity and distribution of the porosity is as important as the fraction of porosity in controlling the evolution of plastic strain, and thus, the onset of crack initiation. Fractography of tensile fracture surfaces provided further insight into the role of porosity in fracture of these materials. At the lowest density, fracture took place primarily by localized void nucleation and growth in sintered necks of the material, Fig. 8(a). At higher densities, however, the fracture morphology was more characteristic of that of fully-dense materials, with a combination of ductile rupture as well as brittle fracture from fully dense pearlitic grains, Fig. 8(b). 10 µm (a) (b) Figure 8. Tensile fracture in (a) 7.0 g/cm3 alloy and (b) 7.5 g/cm3 alloy. Localized void growth is observed at the lower density, while a combination of void growth and brittle cleavage fracture is observed at higher density. Fatigue Behavior Perhaps the most significant influence of porosity was in fatigue behavior, Fig. 9. Stress versus cycle curves revealed that the 7.0 g/cm3 alloy had significantly lower fatigue endurance limit than the other two alloys. It is well known that single large pores or clusters of pores act as stress concentration sites for fatigue crack initiation [2-6, 8-10]. As in the case of tensile loading, pores with a more irregular shape will have a higher stress concentration and are more probably sites for crack initiation. Thus, the higher observed fatigue strength with increasing density can be 400 attributed to a higher density of isolated porosity, more rounded pores, and a lower degree of pore clustering. Fe-Mo-Ni-C 350 300 7.5 g/cm 3 250 3 7.4 g/cm Fatigue fractography provided additional insight into the 200 influence of microstructure on 3 7.0 g/cm fatigue damage. Figure 10 shows 150 the fatigue fracture surface of the 3 7.0 g/cm alloy. The fracture surface characteristics are 100 103 104 105 106 107 108 somewhat similar to that observed Cycles to Failure, Nf under tensile loading, showing localized dimple rupture, and Figure 9. Stress versus cycles (S-N) fatigue behavior of P/M evidence of void nucleation and steels as a function of density. Increasing density significantly coalescence in the sintered necks increases fatigue life. bonding the particles. A large number of spherical submicron MnS particles were also observed, although the influence of MnS inclusions on fatigue crack nucleation and/or propagation is unclear. It would be appear that the effect of the inclusions would be negligible when the pore size is much larger than the inclusion size, since the pores acts as the weakest links for crack initiation in the material. Localized fatigue striations were also apparent, although the propensity of these increased with an increase in density. Figure 11 shows a region of localized fatigue striation in an alloy with density of 7.4 g/cm3. Localized striations have also been observed by Polasik et al. [6] and have been hypothesized to form in areas of the microstructure that are favorably orientation to the loading axis. 10 µm 1 µm Figure 10. Fatigue fracture surface of 7.0 g/cm3 alloy: (a) low magnification and (b) high magnification inset of (a), showing localized void growth at MnS particles. (a) (b) Figure 11. Fatigue fracture surface of 7.5 g/cm3 alloy: (a) low magnification and (b) high magnification inset of (a) showing localized fatigue striations. In general, the fatigue strength of P/M materials is correlated to the ultimate tensile strength, by computing the fatigue ratio (σfat/σuts), in order to obtain some estimate of the fatigue strength relative to the monotonic strength. In P/M materials the fatigue ratio is typically between 0.30.4, which is much lower than that reported for conventional wrought steels, 0.4-0.5 [1]. The lower fatigue in P/M materials can be attributed to the presence of porosity. Nevertheless, correlating fatigue strength to the ultimate tensile strength may not be the best approach, since the ultimate tensile strength is really a measure of large-scale macroscopic damage that takes place at relatively large applied stress or plastic strain. Fatigue damage, on the other hand, is more complex, and typically takes place at much lower applied stress by localized plasticity at defects in the material. Thus, a more appropriate measure of fatigue strength may be the proportional limit stress or the Young’s modulus of the porous material. The proportional limit stress is a measure of the onset of plasticity during monotonic loading. Thus, while the onset of plasticity under monotonic conditions is certainly not equivalent to cyclic plasticity, it may be a better measure of the fatigue strength, since the onset of plasticity is related to the onset of damage in the material. Young’s modulus may also be a good measure of the fatigue strength in heterogeneous materials, such as porous materials, since for a given stress, an increase in Young’s modulus will result in a lower applied strain to the material. A lower macroscopic applied strain will result in a lower degree of strain localization, which should decrease fatigue damage and increase fatigue life. In particle reinforced metal matrix composites, for example, an increase in the volume fraction of high stiffness reinforcement particles results in an increase in fatigue strength [20]. Lewandowski et al. [21] showed that the higher fatigue resistance could be attributed to the increase in Young’s modulus brought about by the increase in reinforcement volume fraction. Similarly, in porous materials, an increase in Young’s modulus can be correlated to an increase in load bearing area and a decrease in the localization of strain. Figure 12 shows a plot of proportional limit stress and Young’s modulus versus fatigue strength. While there is no exact correlation between σpl and E with σfat, there is certainly a good correlation between these parameters. It should be noted that the lower proportional limit stress 5. CONCLUSIONS Proportional limit stress (MPa) 210 210 200 200 190 190 Proportional limit stress 180 180 Young's modulus 170 170 160 160 150 150 140 140 130 140 160 180 200 220 240 260 130 280 Fatigue strength (MPa) In this study the effect of Figure 12. Correlation between fatigue strength and: (a) porosity on the mechanical proportional limit stress and (b)Young’s modulus. behavior of sintered steels was systematically studied. The following conclusions can be made based on the results of this study: • Increasing sintered density resulted in lower pore fraction, smaller average pore size, and more spherical pore shape. Increase pore size was directly correlated with an increase in the irregularity of pore shape. • Tensile strength increased with an increase in sintered density. Microstructure-based FEM modeling showed that larger, irregular, and highly clustered pores contribute to significant strain localization which results in premature failure at lower densities. At higher densities, the pores were more spherical and more homogeneously distributed, resulting in a more homogeneous distribution of plastic strain over a larger fraction of material. • Fatigue strength also increased with an increase in sintered density. Here, the increase in fatigue strength may be attributed to smaller overall pore size and a lower degree of pore clustering, which acts a stress concentration for fatigue crack initiation. • Direct correlations exist between fatigue strength and the following two quantities: Proportional limit stress and Young’s modulus. These correlations may be more effective than fatigue strength to tensile strength, since the latter quantity is a measure of large-scale plasticity and damage that takes place at much higher stresses than high cycle fatigue stresses. ACKNOWLEDGMENTS The authors acknowledge Hoeganaes Corp. for financial support to conduct this research and D. Babic for experimental assistance with this work. Young’s modulus (GPa) relative to fatigue strength may be attributed to our definition of fatigue strength as fatigue runout at 107 cycles. Recent work has shown that fatigue failures can take place at longer fatigue lives than 107 cycles [22]. Thus, at very long fatigue lives it is possible that the fatigue strength may approach the proportional limit stress. REFERENCES 1. A. Salak: Ferrous Powder Metall., Cambridge, Cambridge International Science Publishing. 2. A. Hadrboletz and B. Weiss, Int. Mater. Rev., (1997) 42 1-44. 3. N. Chawla, S. Polasik, K.S. Narasimhan, M. Koopman, and K.K. Chawla, Int. J. of Powder Metal., (2001) 37 49-57. 4. N. Chawla, T.F. Murphy, K.S. Narasimhan, M. Koopman, and K.K. Chawla, Mater. Sci. Eng. A, (2001) A308 180-188. 5. N. Chawla, D. Babic, J.J. Williams, S.J. Polasik, M. Marucci, and K.S. Narasimhan, Adv. Powder Metall. Part. Mater., (2002), vol. 5, Metal Powder Industries Federation, p. 104. 6. S.J. Polasik, J.J. Williams, and N. Chawla, Metall. Mater. Trans. A, (2002) 33A 73-81. 7. N. Chawla, B. Jester, and D.T. Vonk, Mater. Sci. Eng. A, (2003) A346 266-272. 8. H. Danninger, G. Tang, B. Weiss, and R. Stickler, Powder Metall. Int., (1993) 25 170. 9. J. Holmes and R.A. Queeney, Powder Metall., (1985) 28 231-235. 10. K.D. Christian and R.M. German, Int. J. Powder Metall., (1995) 31 51-61. 11. U. Lindstedt, B., Karlsson, and R. Masini, Int. J. Powder Metall., (1997) 33 49-61. 12. F.J. Semel, Adv. Powder Metall. Part. Mater., Metal Powder Industries Federation, Princeton, NJ, 1989, p. 9. 13. S.H. Luk, and J.A. Hamill Jr., Adv. Powder Metall. Part. Mater., Metal Powder Industries Federation, Princeton, NJ, 1993, p. 153. 14. N. Ramakrishnan and V.S. Arunachalam, J. Am. Ceram. Soc., (1993) 76 2745-2752. 15. X. Deng and N. Chawla, unpublished work, (2003). 16. K.M. Vedula, and R.W. Heckel, Modern Developments in Powder Metall., Metal Powder Industries Federation, Princeton, NJ, 1981, p. 759. 17. W.A. Spitzig, R. E. Smelser, and O. Richmond, Acta Metall., (1988) 36 1201-1211. 18. G. Straffelini and A. Molinari, Mater. Sci. Eng., (2002) A334 96-103. 19. R.J. Bourcier, D.A. Koss, R.E. Smelser, and O. Richmond, Acta Metall., (1986) 34 24432453. 20. N. Chawla, C. Andres, J.W. Jones, and J.E. Allison, Metall. Mater. Trans. A., (1998) 29A 2843. 21. J.J. Lewandwoski, in Comprehensive Composite Materials, (A. Kelly and C. Zweben, eds.), vol. 3 , (2000), Elsevier Press, pp. 151-187. 22. D. Spoljaric, H. Danninger, B. Weiss, D.L. Chen, and R. Ratzi, Proc. Int. Conf. Deformation and Fracture in Structural PM Materials (L. Parilak, H. Danninger, J. Dusza, and B. Weiss, eds.), IMR-SAS Kosice, (1996), vol. 1, pp. 147-158.