Development of a High Performance Nickel-Free P/M Steel Bruce Lindsley

advertisement

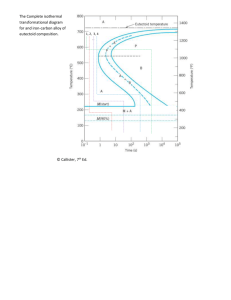

Development of a High Performance Nickel-Free P/M Steel Bruce Lindsley Senior Materials Engineer, Hoeganaes Corporation, Cinnaminson, NJ 08077, USA Abstract A developmental nickel-free P/M steel containing Cr, Mn, Si and Mo is being evaluated as a new high performance material. Bonded premixes with varying carbon contents were made with the AncorMax® D system and pressed to densities of 7.2 g/cm3. Sintering studies were performed at 1177°C and 1260°C. Higher strengths were achieved in the CrMnSiMo steel as compared to a Ni containing steel with a higher total alloy content. Ultimate tensile strengths over 1200 MPa and hardnesses of 70 HRA can be achieved in the sinter + temper condition. The effect of sintering temperature, cooling profile and carbon content on mechanical properties and microstructure will be discussed. Introduction The use of chromium and manganese in wrought steels is a result of the relatively low cost of these elements and their effectiveness as alloying elements. Cr and Mn improve both the mechanical properties and hardenability of low alloy steels. It would be desirable to incorporate these elements in P/M steels, especially with the adoption of sinter hardening practices. In addition, certain problems have arisen with currently used alloying elements in the P/M industry. The use of admixed Ni has become a concern, and copper additions have also become a problem with respect to scrap recycling. However, oxidation of Cr and Mn have limited the use of these elements. It has been shown that elevated oxygen contents in Cr containing P/M alloys adversely affect both static and dynamic mechanical properties (1,2). Mn P/M steel properties are also highly sensitive to oxygen (3). Cr-Mn (Ancorsteel® 41AB) and Si containing steels (Ancorloy MD series) have previously been introduced, but required high temperature (1260°C) sintering (4,5). A nickel free steel containing Cr, Mn, Si and Mo is being developed that utilizes the advantages of Cr and Mn (and Si) while limiting the amount of oxygen in a sintered part to acceptable levels. This steel no longer requires the high temperature sintering of the earlier Cr-Mn and Si containing steels. The properties of this new steel at two carbon contents are compared to a nickel molybdenum steel (FLN4-4405) over a range of sintering temperatures and cooling rates. Experimental Procedure Three high performance iron based P/M materials were chosen for study, Table I. FLN4-4405, which contains 0.8% prealloyed molybdenum, 0.6% added graphite, and 4% admixed nickel, was chosen as a reference material. The other materials are Cr, Mn, Si and Ancorloy, Ancorsteel and AncorMax D are registered trademarks of Hoeganaes Corporation. Mo containing nickel free alloys at two carbon levels. All mixes were binder treated and used either an EBS wax lubricant (FLN4-4405) or the AncorMax D lubrication system (CrMnSiMo) to achieve a green density of nominally 7.20 g/cm3. The compaction die was heated to 63°C (145°F) for the AncorMax D samples. Standard transverse rupture bars and dogbone tensiles (2.54 cm gauge length) were pressed to MPIF standards at 690 MPa and 620 MPa for the 0.6% and 0.35% graphite mixes, respectively. Table I. Alloy chemistry (in wt%). Alloy Graphite Mn FLN4-4405 0.6 0.1 CrMnSiMo 0.35 1 CrMnSiMo 0.6 1 Si 1 1 Ni 4 - Cr 0.9 0.9 Mo 0.8 0.8 0.8 Samples were sintered in a belt furnace with a 90 vol% nitrogen – 10 vol% hydrogen atmosphere and a nominal dew point of -40°C. Sintering temperatures of 1177°C (2150°F) and 1260°C (2300°F) were used. Time at temperature, defined as within 5°C of the set point, was 30 minutes. Three cooling conditions were used in the study. The different cooling profiles were achieved by varying the belt speed and the convective cooling system in the sintering furnace. After sintering, the samples were tempered at 200°C (400°F) for 1 hour in a nitrogen atmosphere. 1.3 cm thick TRS bars were used to measure sintered oxygen and carbon. Oxygen was measured by infrared analysis of CO2 in a Leco oxygen/nitrogen detector. The chemistry measurements were made from the center of the bars to avoid surface effects such as de-carburization and de-oxidation. Results Oxygen An earlier study (6) on the CrMnSiMo alloy showed that oxygen contents below 0.02 wt% could be achieved at a sintering temperature of 1260°C. In the current study, the measured oxygen content for all alloys tested was higher than this value. The oxygen content of the Ni containing FLN4-4405 alloy was 0.04 wt%, and quite a bit higher than expected for an alloy with no oxygen sensitive elements. The 0.6% graphite CrMnSiMo alloy had a slightly higher oxygen content of 0.06 wt%. The ability to produce a sintered part containing roughly 1% each of Cr, Mn and Si that has a comparable oxygen content to a nickel molybdenum steel is exciting and the use of these oxygen sensitive elements may allow P/M part makers into markets currently reserved for wrought products. The 0.35 wt% graphite CrMnSiMo alloy had a higher oxygen content (0.08 wt%) than the 0.6% graphite alloy. Carbon content appears to play a role in the reduction of oxygen in this alloy. Given the effect of oxygen content on mechanical properties found by other researchers on alloyed steels (1-3), it is a significant finding that oxygen can be reduced to such low levels in these alloy systems. Table II. Sintered oxygen and carbon contents at 1260°C. Alloy O2 (wt%) FLN4-4405 0.04 CrMnSiMo (0.35) 0.08 CrMnSiMo (0.6) 0.06 C (wt%) 0.57 0.31 0.53 Cooling Rate Three cooling profiles were used in the sintering furnace, Figure 1. The first cooling profile did not use accelerated convective cooling, and has a traditional radiative cooling profile. The cooling rate was greatest at 650°C and slows as the temperature decreases. Table III lists average cooling rate from 650°C to 315°C and further breaks out the rate from 650°C to 370°C and from 370°C to 315°C. The cooling rate from 650°C to 370°C is similar to overall average rate, but the last 55°C, the rate decreases substantially. The second cooling profile had the same belt speed as the first condition, but also utilized convective cooling in the sintering furnace. The average cooling rate is more than twice the first condition and is more than 5 times as fast in the last 55°C. The last cooling condition (profile 3) used a belt speed roughly 3 times as fast as the first two conditions and utilized convective cooling. The cooling rate from 650°C to 370°C was three times as fast as the first condition. However, the samples then exited the convective cooling portion of the furnace and the cooling rate slowed to a low level. The three distinct cooling profiles lead to significant differences in microstructure and mechanical properties. Table III. Average cooling rates (in °C/sec) of the 3 profiles for the given temperature ranges. Temperature Range Profile 1 Profile 2 Profile 3 0.7 1.6 0.8 650°C to 315°C 0.8 1.4 2.4 650°C to 370°C 0.4 2.8 0.2 370°C to 315°C 700 600 600 500 500 Profile 1 400 300 200 Profile 2 100 A Ps o Temperature ( C) 700 o Temperature ( C) 3 CrMnSiMo Alloy - 0.49wt% Sintered Carbon at 7.1g/cm Continuous Sinter Cooling Transformation Diagram Profile 3 Bs A+P 400 A+B+P 300 Ms 200 A+B o 33 C/min M M+B M+B+P o 100 128 C/min o 186 C/min o 84 C/min 0 0 0 5 10 Time (min) 15 20 0 5 10 15 Time (min) 20 25 30 Figure 1. Cooling profiles used in the study. Figure 2. Cooling profiles overlaid on CSCT diagram (from ref. 6). Microstructure The different cooling profiles had a pronounced effect on the resulting microstructure. The 0.6% graphite CrMnSiMo steel consisted of 58% martensite, 31% bainite and 11% pearlite (excluding porosity) under the cooling conditions of profile 1. As the cooling rate was increased in profile 2, the amount of martensite increased to 96%, with 4% bainite. With profile 3, the amount of martensite was 57% (similar to profile 1) with the remainder bainite (43%). The reason for these various microstructures can be seen in Figure 2. The cooling profiles are plotted on a continuous sinter cooling transformation (CSCT) diagram for this alloy that was reported in reference 7. The CSCT diagram, similar to a CCT diagram, shows the cooling curves and measured transformation temperatures from dilatometry testing. The diagram has been modified so that the cooling profiles start at time 0 and 650°C. Profile 1 passes through the pearlite, bainite and martensite transformation curves, indicating that all three structures should form. This is indeed the case, as seen in Figure 3. Profile 2 passes to the left of the pearlite curve and proceeds quickly through the bainite region into martensite. The martensitic microstructure (with 4% bainite) found in the current samples correlates nicely with the CSCT prediction. Finally, profile 3 also passes to the left of the pearlite curve, but then remains in the bainite region during the slow cooling portion of the profile, resulting in 43% bainite, until passing into the martensite region. No pearlite was observed in these samples. Profiles 1 and 3 cross into the martensite region at similar times and have similar martensite contents (58% and 57%, respectively). Again, the quantitative metallographic results correspond to the predicted microstructure for the cooling profile and the CSCT diagram. It should be noted that the average carbon content of the CSCT samples was slightly lower than the samples in the current study. In the Ni-Mo alloy, cooling profile 1 produced a mixed microstructure of approximately 50% pearlite and 50% martensite, with an occasional region of bainite (Figure 4). As the cooling rate was increased in profile 2, the amount of pearlite decreased significantly so that the martensite content was roughly 80% of the microstructure. Profile 3 resulted in a similar response to the 0.6% graphite CrMnSiMo alloy, in that the rapid cooling to 370°C avoided the pearlite transformation, and the resulting microstructure is martensite and bainite. Those regions of the microstructure that were pearlite in the earlier profiles transformed to bainite with profile 3, resulting in a martensite-30% bainite microstructure. The 0.35% graphite CrMnSiMo alloy was predominately ferrite and pearlite (75%) when cooled to Profile 1. Profile 2 resulted in 20% pearlite, 25% martensite and balance bainite. Profile 3 resulted in 35% pearlite and 20% martensite, balance bainite. The hardenability of the lower carbon alloy was not sufficient to avoid the ferrite / pearlite transformation with any of the cooling conditions used in the sintering furnace. Figure 3. 0.6% graphite CrMnSiMo alloy microstructure sintered at 1260°C and cooled with Profiles 1, 2 and 3, respectively. P = pearlite, B = bainite, M = martensite. Figure 4. FLN4-4405 microstructure, sintered at 1260°C and Profiles 1, 2 and 3, respectively. Physical Properties The change in strength associated with the changes in microstructure outlined above is shown in Table IV. Cooling profile 2 generally led to the highest strengths in each alloy. Exceptionally high yield and tensile strengths were obtained in the 0.6% graphite CrMnSiMo alloy. Even at the lowest cooling rate (Profile 1), the ultimate tensile strength of the alloy was greater than 1200 MPa (175,000 psi) at both sintering temperatures. When cooled at a fast rate (Profile 2), the yield strength exceeded 1200 MPa and the tensile strength was greater the 1400 MPa (200,000 psi). High strength and good ductility was achieved with profile 3 due to the martensite / bainite microstructure. This combination of high tensile strength and ductility led to higher transverse rupture strengths than was found with profile 2. The 0.35% graphite alloy follows a similar trend as the 0.6% alloy, except that strengths and hardness are considerably lower and ductility higher. With a slightly higher base carbon, this alloy is a likely candidate for carburizing. The Ni-Mo alloy also has excellent mechanical properties, especially at the higher cooling rates. While the yield strength is lower than the CrMnSiMo alloy, the ultimate tensile strength is similar and the elongation superior. It should be noted that the Ni-Mo sintered density is roughly 0.15 g/cm3 higher than the CrMnSiMo when sintered at 1260°C. Table IV. Physical properties of the alloys tested. (GD is green density, SD is sintered density, D.C. is dimensional change, TRS is transverse rupture strength, YS is 0.2% offset yield strength and UTS is ultimate tensile strength.) Dimensional Change Dimensional change from die size of a sintered sample is dependent upon the green expansion, amount of sintering, alloying and cooling rate. Cooling rate will affect the phase transformation from austenite to several possible microstructures (martensite, bainite, pearlite). Each of these microstructures contribute a different amount of growth to the sample relative to the austenite phase. Martensite is the least dense phase and causes the greatest amount of growth in a sintered part. A typical length change from 100% austenite to 100% martensite is 1.4% (8). Therefore, fast cooling rates that result in martensite formation should increase the amount of dimensional change in a positive direction. This effect can be seen in Table IV. The samples cooled with profile 2, which produced the greatest amount of martensite, had the largest dimensional change at each condition. (In the case of the Ni-Mo alloy, the values of dimensional change were less negative). The effect of alloy is also apparent on dimensional change. The presence of admixed nickel in FLN4-4405 results in a large amount of shrinkage (>0.5%) and overwhelms any effects of cooling rate and tempering. In the CrMnSiMo alloy, the increase in carbon content from 0.35% to 0.6% increases dimensional change by roughly 0.1%. The effect of sintering temperature on dimensional change was largest in the Ni-Mo alloy. Sintering Temperature Effects The effect of sintering temperature (1180°C, 1260°C) is subtle with respect to microstructure and mechanical properties. Sintering at 1260°C resulted in an increased density of 0.02 g/cm3 in the CrMnSiMo alloys and 0.05 g/cm3 in the nickel alloy as compared to 1180°C, along with a corresponding decrease in dimensional change. The microstructural components show little effect with sintering temperature. A small increase in martensite was observed in the FLN4-4405 alloy with the higher temperature as more nickel diffusion occurs. Increased pore rounding was also observed at the higher temperature. The average change in mechanical properties for each alloy due to sintering temperature was minor. Hardness and transverse rupture strength showed little effect with temperature, while the yield and ultimate tensile strength increased an average of 97 MPa (14,000 psi) in the two 0.6% graphite alloys and 28 MPa (4,000 psi) in the 0.35% graphite alloy. Elongation was also found to increase an average of 0.3% for the three alloys with the higher sintering temperature. A combination of lower oxygen contents, increased alloying and pore modification can explain these increases in properties. The higher sintering temperature would most likely have a larger effect on impact and fatigue properties, neither of which was analyzed in this paper. Conclusions An experimental nickel-free P/M steel containing Cr, Mn, Si and Mo is being developed for high performance applications. Higher strengths and hardnesses were achieved in the CrMnSiMo steel as compared to a steel containing 4% Ni with a higher sintered density. Yield strengths of 1000 MPa, ultimate tensile strengths upwards of 1400 MPa and hardnesses above 70 HRA were obtained after sintering and tempering. The effect of sintering temperature, heat treatment and carbon content on mechanical properties and microstructure are summarized below: 1. The 0.6% carbon CrMnSiMo alloy has excellent hardenability. High levels of martensite were found at relatively slow cooling rates, resulting in high strength and hardness. The CrMnSiMo alloy has higher strength than FLN4-4405 at comparable carbon contents and at low cooling rates. 2. The oxygen content in the CrMnSiMo alloy can be controlled to levels similar to a NiMo steel (0.06% and 0.04%, respectively). Low sintered oxygen levels (<0.1%) were obtained at 1260°C for all alloys tested. 3. Large differences in mechanical properties were found within the range of cooling rates that could be achieved in a high temperature belt furnace. 4. Sintering temperatures below 1260°C can be used with the CrMnSiMo system. 5. The CSCT diagram can be effectively used along with actual cooling profiles to predict microstructural constituents. References 1. Motooka, N., Kuroishi, N., et al., "Strength and ductility of Mn-Cr sintered steel", MPR, November 1983 p.629-631. 2. Sigl, L. S., Delarbre, P., “Impact of oxygen on the microstructure and fracture morphology of Fe(Cr,Mo)-PM steels”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, part 7 2003 p. 54. 3. Youseffi, M., Mitchell, S.C., Wronski, A.S., and Cias, A., “Sintering, microstructure, and mechanical properties of PM manganese-molybdenum steels”, Powder Metallurgy, Vol. 43, No.4 2000 p.353. 4. James, W.B., and Causton, R.J., “Surface Hardenable Heat Treated P/M Steels”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, Vol. 5. 1992 p. 65. 5. James, W.B., Causton, R.J., Baran, M.C., and Narasimhan, K.S., “New High Performance P/M Alloy Substitutes for Malleable and Ductile Cast Irons,” Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, part 13 2000 p.123. 6. Lindsley, B., “Development of a High Performance Nickel-Free P/M Steel”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, 2004. 7. Lindsley, B., “Effects of Cooling Rate on the Hardenability of Chromium Containing P/M Steels”, Advances in Powder Metallurgy & Particulate Materials, Metal Powder Industries Federation, Princeton, NJ, 2004. 8. Reed-Hill, R. E., Physical Metallurgy Principles, 2nd Edition, PWS-Kent Publishing, 1973, p. 730.