NITROGEN ALLOYING OF PM STEELS: PROCESSING AND PROPERTIES

advertisement

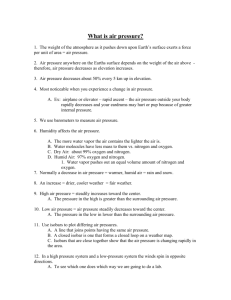

NITROGEN ALLOYING OF PM STEELS: PROCESSING AND PROPERTIES Chris Schade & Tom Murphy Hoeganaes Corporation Cinnaminson, NJ 08077 Alan Lawley & Roger Doherty Drexel University Philadelphia, PA 19104 ABSTRACT A process has been developed to introduce nitrogen as a bulk alloying element in low alloy PM steels. The use of nitrogen to replace carbon as an alloying element to develop Fe-N martensite instead of Fe-C martensite is of interest since it has been demonstrated that, in ingot steels, at a given strength level, Fe-N martensite exhibits enhanced ductility, compared with FeC martensite; nitrogen promotes the formation of tough lath at the expense of brittle plate martensite. Sintering and post sinter processing are detailed in relation to attendant microstructures and mechanical properties of PM Fe-N and equivalent Fe-C alloys, in particular strength and ductility. The hardenability of Fe-N, Fe-C and Fe-N-C alloys was also determined utilizing the jominy end quench test. In 4100 alloys the hardenability of Fe-C was superior to that of Fe-N and Fe-C-N. INTRODUCTION There is evidence that iron-nitrogen alloys can exhibit superior combinations of strength and toughness, when compared with the equivalent iron-carbon system. This has been attributed to the transition from tough lath martensite to brittle plate martensite at higher atomic interstitial content in iron-nitrogen compared with iron-carbon alloys. The higher nitrogen content leads to improved interstitial solid solution strengthening, and since the transition to plate martensite occurs at higher nitrogen contents, the strength and ductility combination is increased. Melting and atomization cannot be used to make iron-nitrogen alloys, since nitrogen can only be kept in solution at low temperatures. At high temperatures, particularly above the melting point, excessively high pressures are required for even a small concentration of nitrogen in solution [1]. The bulk nitrogen concentration in iron at 0.1 MPa (14.7 psi) is < 0.05 w/o. Nitrogen solubility in both liquid and solid iron can be increased by melting under nitrogen pressure, for example, 1.5 w/o nitrogen at 200 MPa nitrogen pressure [2-3]. Since the solubility of nitrogen gas also increases with temperature, it is difficult to produce material without excessive porosity and the cost of production precludes using this method. It is this limitation that has prevented the production of bulk iron-nitrogen alloys. Currently iron-nitrogen alloys are limited to surface-nitrided layers by interaction with gases at various nitrogen equivalent pressures- usually ammonia/hydrogen mixtures (NH3/H2). Mittemeijer et al. reported nitriding iron to a depth of 400 µm in 12 h at 810 oC, with longer times at that temperature leading to the precipitation of free nitrogen as voids [4]. Commercial methods commonly used are gas-phase-nitriding and plasmaion-nitriding [5] While the introduction of nitrogen at the surface of iron-alloys has benefits such as increased hardness and wear resistance the kinetics of nitrogen diffusion and the cost of these process make them unsuitable in the bulk alloying of nitrogen. The purpose of the present work was to develop a PM process for bulk nitrogen alloying. The mechanical properties of Fe-C PM alloys are compared with those of equivalent Fe-N alloys and Fe-C-N alloys in relation to microstructures, mechanical properties and hardenability. ALLOY PROCESSING AND TESTING To produce bulk samples with nitrogen alloyed throughout the entire thickness of the specimen, a new approach using conventional PM processing was developed. One of the benefits of PM is that various additives can be mixed with the base powder and during sintering these elements diffuse into the matrix alloying the bulk of the specimen (or part). Given sufficient time at temperature this approach can produce a homogenous alloy. This “Inside/Out” approach was used in the present study to produce homogenous nitrogen containing alloys. It is common in PM applications to use ground ferroalloys mixed with base iron powders to produce alloy powders [6]. Materials include ferrochromium, ferromanganese and silicon containing ferroalloys. The dissolution of the particles and diffusion of the alloying elements normally depends on time at temperature but practical experience has suggested that particles with a mean particle size (d50) of 8 to 10 µm can be processed at reasonable sintering temperatures (1120 oC to 1260 oC). This same concept can be used with nitrogen containing ferroalloys. Table I shows the composition of the three additives used in the present study. All three are available commercially in the required particle size distribution for PM applications. In the “Inside/Out” approach, the additive particles are blended with a base powder, compacted, and during sintering the nitrogen (and other alloy elements) diffuse into the matrix. Since, the additives are distributed throughout the specimen, the nitrogen is present homogenously throughout the thickness of the specimen after sintering. Table I: Composition of additive particles containing nitrogen. (w/o). In order to examine the influence of nitrogen on mechanical properties, two sets of alloys were prepared with compositions close to AISI 4140 (Table II). The first PM alloy, 4140C, was made by admixing appropriate levels of ferrosilicon, high carbon ferrochromium and ferromanganese with a prealloyed powder containing 0.30 w/o Mo (Ancorsteel 30HP). Additional graphite was added to achieve a sintered carbon content of 0.40 w/o. This alloy was used as the baseline for the study. The second alloy, 4140N, was prepared in a similar fashion: however, silicon nitride, chromium nitride and manganese nitride were added to the 0.30 w/o Mo powder. After sintering, this alloy contained 0.46 w/o nitrogen and only trace amounts of carbon (< .03 w/o). Table II: Composition of Experimental Alloys (w/o). TR specimens were compacted at 690 MPa from the two compositions and sintered in a continuous belt furnace at 1120 oC in an atmosphere containing 90 v/o nitrogen and 10 v/o hydrogen. Accelerated cooling was utilized in order to aid the transformation to martensite. In order to assess the hardenability of Fe-C versus Fe-N in the 4100 alloy system, Jominy end quench samples were prepared and hardness profiles determined on samples austenitized at 900 oC and water quenched using standard procedures. Microstructures were characterized by optical microscopy utilizing specimens prepared by standard metallographic techniques. The microstructures were examined in the unetched and etched (2 v/o Nital - 4 w/o Picral) conditions. RESULTS AND DISCUSSION Mechanical Properties TR test results are shown in Table III. The 4140 alloys exhibited the expected apparent hardness and TR strength, based on the alloy content utilized. In contrast, 4140N, which contained an equivalent amount of alloy content, did not exhibit the strength or apparent hardness expected. Table III: Transverse Rupture Properties of Experimental 4140 Alloys. In order to determine the reason for the low mechanical properties, the microstructures of the two alloys were compared (Figure 1). The microstructure of the 4140C consisted of lath martensite, consistent with its mechanical properties. The microstructure of the 4140N exhibited a mixture of pearlite and ferrite, notwithstanding the fact that the ferroalloy particles appeared to have diffused into the matrix. The nitrogen level of the alloy was confirmed by Leco combustion analysis (0.46 w/o). It would appear that the cooling rate resulting from the accelerated cooling in the sintering furnace was sufficient to transform the carbon-bearing 4140 to martensite, but not the nitrogen-bearing alloy. (a) (b) Figure 1. Representative microstructures: (a) 4140C -lath martensite (b) 4140N- pearliteferrite Tensile properties of the Fe-N and Fe-C alloys are shown in Table IV. Examination of the microstructure of oil quenched 4140N revealed a microstructure of lath martensite similar to the 4140C. Despite the similar microstructures, the 4140C exhibited a higher apparent hardness, indicating that the hardenability of Fe-C is higher than that of Fe-N. The 4140N exhibits a surprisingly high level of ductility in relation to yield strength. Table IV: Tensile Properties of Experimental 4140 Alloys. Hardenability Figure 2 shows the hardness profiles from three Jominy end quench specimens with low levels of interstitials (< 0.45 w/o); (i) carbon only (0.42 w/o), (ii) nitrogen only (0.25 w/o) and (iii) carbon and nitrogen ( C+N = 0.38 w/o). Figure 3 shows similar data fort interstitial contents > 0.60 w/o. (a) (b) Figure 2. Hardenability of 4100 PM Alloys with interstitial elements: (a) < 0.45 w/o and (b) > 0.60 w/o. The hardness profile of the Fe-C alloys was superior to that of the Fe-N alloys at low and high carbon levels. However, when carbon and nitrogen are combined, after an initial drop in hardness the hardness profile levels off to a stable value relatively quickly. This is most likely related to the microstructure and is currently under evaluation. INTERPRETATION From the observations and results, it is concluded that the use of nitrogen to replace all the carbon in an alloy is not justified, due to the extra processing steps required to achieve hardenability. However the higher ductility at equivalent strengths does suggest some advantages to the use of nitrogen as an alloying element. The literature on carbonitriding suggests that nitrogen facilitates the dissolution of carbon in iron and will contribute to a significant increase in the kinetics of the diffusion process; thus nitrogen in the diffused layers will enhance the activity of carbon in austenite [7]. Both these factors will move the isothermal cooling curve to the right and may results in a synergistic effect of carbon and nitrogen on the martensite transformation. It has also been found that the transition from lath to plate martensite occurs at higher levels of nitrogen, leading to a superior combination of strength and toughness. This suggests that a combination of carbon and nitrogen may lead to superior properties. To examine this possibility, an alloy of 4140C+N was produced in which the nitrogen level was held constant at 0.20 w/o and various levels of carbon were added in the form of graphite. The nitrogen was added by the method outlined previously. (a) (b) Figure 3. Comparison of tensile properties: (a) yield strength, and (b) elongation for 4140C (carbon only) and for 4140C +N (carbon + nitrogen). For carbon + nitrogen alloys - interstitial content = 0.2 w/o N + X w/o C. Figure 3 shows the yield strength and elongation of a 4140 alloy with a combination of carbon plus nitrogen, in excess of the levels in 4140 using only carbon. Both sets of alloys were pressed at 690 MPa and sintered at 1120 oC in 90 v/o nitrogen/10 v/o hydrogen. The sintered density of the two alloys was equivalent. Both groups of specimens were austenitized at 900 oC and oil quenched. The 4140C yield strength and ductility drop off dramatically at ~0.5 w/o C. In comparison, the 4140C+N has a much more gradual drop off in properties. The reason for the improved properties is clear from Figure 4 which shows that the transition from lath to plate martensite occurs at higher levels of interstitial content (carbon and nitrogen) in the 4140C+N alloy. Since the transition from lath to plate occurs at a higher interstitial content, solid solution strengthening is increased. Note that this increase in strength does not result in a decrease in ductility of 4140C+N. 4140C+N Lath C+ N = 0.76 % Increasing carbon or nitrogen 4140C Plate C = 0.60 % Figure 4. Microstructure of 4140C+N versus 4140C showing the levels of lath and plate martensite. CONCLUSIONS • Nitrogen can be used as a replacement for carbon in PM alloys but requires special processing to be effective. • Fe-N exhibits a superior strength to ductility ratio compared with Fe-C. • The hardenability of PM Fe-N is lower than that of PM Fe-C. • There is a synergistic effect of nitrogen in the presence of carbon in iron in relation to diffusion and the martensite transformation. • The hardenability of Fe-C is superior to that of Fe-C-N and Fe-N. REFERENCES 1. J.W. Christian and D.V. Edmonds, “Phase Transformations in Ferrous Alloys,” Scripta Metall., 1988, vol. 22, no. 4, pp.567-580. 2. J.Rawers, G. Slavens and H. Du, “High-Pressure Processing and Characterization of Fe-High-C/N Alloys,” Journal of Materials Synthesis and Processing, 1998 vol. 6, no. 2, 1998, pp.147-154. 3. J. Rawers, “Melting Fe-C Alloys Under Varying Nitrogen Pressures,” Materials Science and Engineering, 1994, vol. A187, pp. 167-176. 4. E.J. Mittemeijer, M. van Rooijen, I. Wierszyllowski, H.C.F. Rozendaal and P.F. Colijn “Tempering of Iron-Nitrogen Martensite,” Z.Metallkde, 1983, vol. 74, pp. 473-483. 5. J. Salik, “Nitriding Steels with Ion Beams,” Metal Progress, 1985, vol. 127, No. 4, pp.55-56. 6. D. Schaeffler, “High Strength Low Carbon Powder Metallurgy Steels: Alloy Development with Transition Metal Additions,” 1991 PhD Thesis, Drexel University, Philadelphia, PA. 7. G.E. Totten, K. Funatani and L.Xie. Du, Handbook of Metallurgical Process Design, 2004 Marcel Dekker Inc., New York, NY, pp.534-538.