Intelligent Paralleling and Circular Redundancy:

Two Technologies for Higher UPS Efficiency

Executive Summary

In order to optimize the energy used by an Uninterruptible Power Supply (UPS), Emerson Network Power has

developed proprietary technologies named Intelligent Paralleling for monolithic UPS and Circular Redundancy

for modular scalable UPS. Both technologies are capable of delivering higher operating system efficiency without

compromising reliability and availability.

This white paper will focus on these particular technologies to improve the UPS operating efficiency when the unit

is working at a reduced system capacity, which is the typical condition in a data center.

Through the Intelligent Paralleling and Circular Redundancy modes the UPS will automatically adapt and optimize

the energy consumption improving the system’s efficiency according to the actual load demand.

2

Intelligent Paralleling

The Intelligent Paralleling technology allows the

UPS to optimize the double conversion efficiency

when operating at partial load down to very low load

percentages, achieving superior cost savings and

reducing TCO.

Activating the Intelligent Paralleling mode allows

the system to automatically adapt capacity to meet

immediate load requirements by measuring the system

output current and the real power needed by the load

downstream, in order to switch excess units to standby

mode, while ensuring continuous system availability.

When units are running in an idle state, they are not

completely switched off but they still have the inverter

control active and synchronized, as well as the DC bus

charged in order to be ready to start up in case of load

increase. When idle units are activated, the remaining

active units will continue to supply the load without

AC

Mains

AC

Mains

AC

Mains

any interruption supporting a temporary overload

condition. Obviously, the specific load thresholds and

tolerances used by the Intelligent Paralleling algorithm

can be customized to meet specific customer

requirements in terms of available power, redundancy

and reliability levels.

Furthermore, the Intelligent Paralleling mode allows

each UPS unit to operate in standby for the same

amount of time, ensuring an equal life-span of module

components.

Here below in figure 1 and figure 2 is shown an example

of the Intelligent Paralleling mode enabled on the

Liebert® 80-eXL model considering 400 kVA units. We can

observe that through the Intelligent Paralleling mode,

the difference in terms of average system operating

efficiency brings a financial saving greater than 2,700 €*

over the first year (*with an energy cost of 0.1 €/kWh and

an air conditioning coefficient equal to 20%).

AC

Mains

33%

AC

Mains

AC

Mains

AC

Mains

AC

Mains

65%

System output

Figure 1. Liebert 80-eXL Intelligent Paralleling: distributed

parallel UPS configuration with four 400 kVA units at 33% load

each, achieving overall system efficiency around 96%.

System output

Figure 2. Liebert 80-eXL Intelligent Paralleling: two 400 kVA units

at 65% load each, system efficiency around 96.8%.

Z3

zoom (C1)

100 V/div

10.0 ms/div

313 V

330 V

∆y

17 V

Tbase

0.00 s

Roll

2.00 s/div

1.00MS

50 kS/s

Z3

zoom (C2)

100 V/div

10.0 ms/div

313 V

330 V

∆y

17 V

Trigger

Stop

Edge

Z3

zoom (C3)

100 V/div

10.0 ms/div

313 V

330 V

∆y

17 V

C1 DC

0V

Positivo

Figure 3. Waveform of a system made of three (3) Liebert 80-eXL 500 kW after two (2) idle units are activated.

3

Circular Redundancy

For modular, scalable UPS such as Emerson Network

Power’s Trinergy™ and the latest Trinergy™ Cube,

the Circular Redundancy mode works with the same

philosophy of the Intelligent Paralleling technology for

monolithic units.

Leveraging its modular architecture, the UPS unit

defines the necessary number of modules (CORES)

to supply the load and sets the remaining CORES in a

special idle state, maintaining also the requested level

of redundancy.

Similarly to the Intelligent Paralleling mode, also the

Circular Redundancy technology ensures that the

stand-by CORES have the inverter control active and

synchronized, as well as the DC bus charged in order

to be ready to start-up in case of load increase. Under

this condition when one sleeping module is activated,

while the unit is in Circular Redundancy mode, the

remaining CORES will continue to supply the load with

100% Load

All Cores are in operation

no interruption, while at the same time addressing

specific capacity, redundancy and reliability needs of

the critical infrastructure.

It is important to note that Circular Redundancy powers

only the minimum number of inverters required at

that load level, ensuring a periodic turnover of all the

available CORES. Therefore, through an auto-detection

feature which monitors the operating time of each

module embedded within the UPS algorithm, the idle

CORES are rotated in order to ensure the same ageing

for all module components part of the system.

For example, in figure 4, the Circular Redundancy

technology applied on a 1.6 MVA Trinergy Cube UPS

is shown. Compared to a configuration with all CORES

in operation, it allows a difference in terms of average

system operating efficiency leading to a financial saving

greater than 3,200 €* over the first year (*with an

energy cost 0.1 €/kWh and an air conditioning coefficient

equal to 20%).

Figure 4. Example of Trinergy Cube Circular Redundancy for a 1.6 MVA UPS system.

4

50% Load

Two Cores in idle state, two Cores in operation

Conclusion

Emerson Network Power’s Intelligent Paralleling and

Circular Redundancy technologies further improve

UPS operating system efficiency at typical load

conditions, without compromising system reliability

and availability.

Other methods used to maximize system efficiency,

as for example running UPS via ECO mode operation,

have a very limited scope of application with modern

mission critical load types and are not providing any

power conditioning to the load downstream. On the

contrary, energy saving technologies such as Intelligent

Paralleling and Circular Redundancy offer the maximum

level of load protection and power conditioning being

a real alternative solution to the standard double

conversion mode (VFI) or line interactive mode (VI),

keeping financial and environmental costs associated

to the energy consumption to a minimum optimal

value, always in line with the actual load demand.

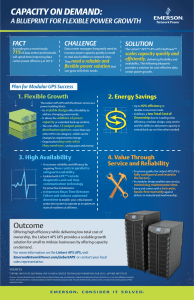

Within the medium and large UPS product portfolio,

Emerson Network Power offers different UPS

platforms meeting specific customer and installation

requirements, including both monolithic T-free and

T-based models and modular scalable T-free UPS up to

3 MW (see figure 5 here below for product details).

All of these products are equipped with energy

saving features as Intelligent Paralleling or Circular

Redundancy to maximize efficiency at partial load

operation to reduce the overall total cost of ownership

(TCO).

Liebert® 80-eXL

Liebert® NXL

Trinergy™ Cube

Product Architecture

Monolithic T-free

Monolithic T-based

Modular Scalable T-free

Power Range

160-500 kW

400-800 kVA

150-3000 kW

Modular Energy saving

System

Intelligent Paralleling

Intelligent Paralleling

Circular Redundancy

VFI Efficiency

Up to 96.8%

Up to 94%

Avg. 98.5%(1)

1 Year Saving(2) using the

Modular Energy Saving

System

>2,700 €

>2,000 €

> 3,200 €

Energy Saving Mode

Advantages

•Higher system operating efficiency at partial load

•System capacity automatically adapted to the real load requirement

•Lower Opex and reduced TCO

(1) Average operating efficiency as a result of the Trinergy Cube three functioning modes (VFI, VFD, VI)

(2) Four units/modules in parallel with two in idle state, energy cost 0.1 €/kWh, air conditioning coefficient equal to 20%.

Figure 5. Emerson Network Power’s product offering with Intelligent Paralleling and Circular Redundancy energy saving technologies

available as standard.

5

Ensuring The High Availability

Of Mission-Critical Data And Applications.

About Emerson Network Power

Emerson Network Power, a business of Emerson (NYSE:EMR), is

the world’s leading provider of critical infrastructure technologies

and life cycle services for information and communications

technology systems. With an expansive portfolio of intelligent,

rapidly deployable hardware and software solutions for power,

thermal and infrastructure management, Emerson Network Power

enables efficient, highly-available networks.

Learn more at www.EmersonNetworkPower.eu

Locations

Emerson Network Power

Global Headquarters

1050 Dearborn Drive

P.O. Box 29186

Columbus, OH 43229, USA

T +1 614 8880246

Emerson Network Power

Europe Middle East And Africa

Via Fornace, 30

40023 Castel Guelfo (BO) Italy

Tel: +39 0542 632 111

Fax: +39 0542 632 120

ACpower.Networkpower.Emea@Emerson.com

Emerson Network Power

United Kingdom

George Curl Way

Southampton

SO18 2RY, UK

T +44 (0)23 8061 0311

F +44(0)23 8061 0852

While every precaution has been taken to ensure accuracy and completeness herein,

Emerson assumes no responsibility, and disclaims all liability, for damages resulting

from use of this information or for any errors or omissions.

Specifications subject to change without notice.

EmersonNetworkPower.eu

Globe Park

Fourth Avenue

Marlow Bucks

SL7 1YG

Tel: +44 1628 403200

Fax: +44 1628 403203

UK.Enquiries@Emerson.com

Follow us on Social Media:

Emerson. Consider it Solved, TrinergyTM, Liebert®, Emerson Network Power and the Emerson Network Power logo are trademarks and service marks of Emerson Electric Co. or one of its affiliated companies.

©2015 Emerson Electric Co. All rights reserved.