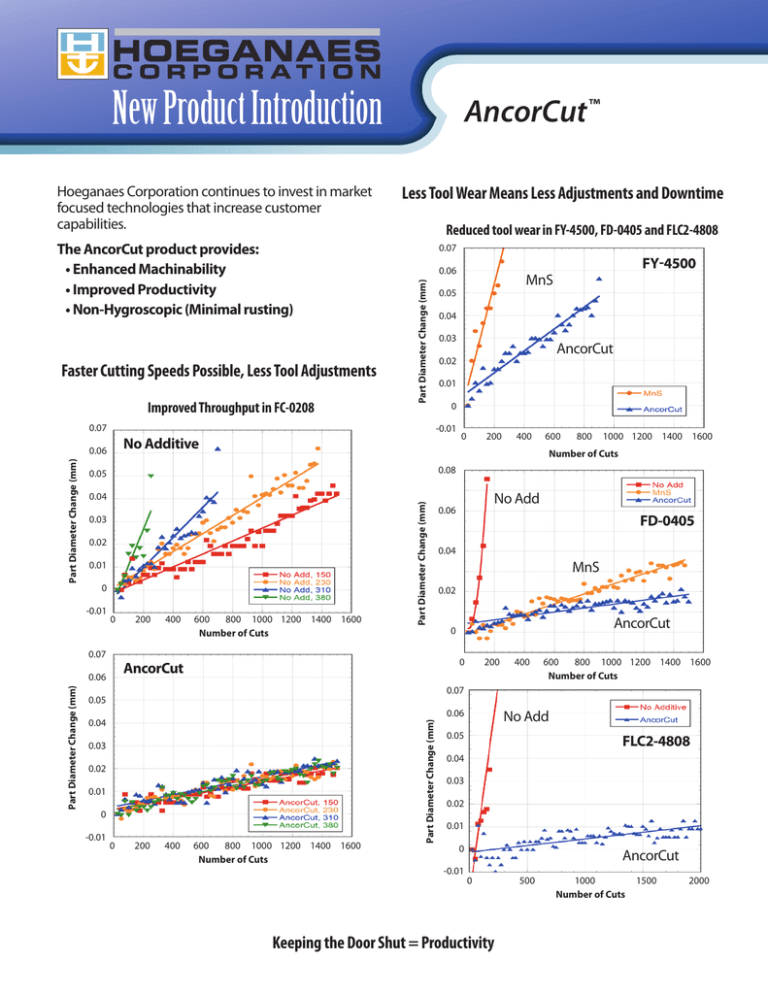

New Product Introduction

The AncorCut product provides:

• Enhanced Machinability

• Improved Productivity

• Non-Hygroscopic (Minimal rusting)

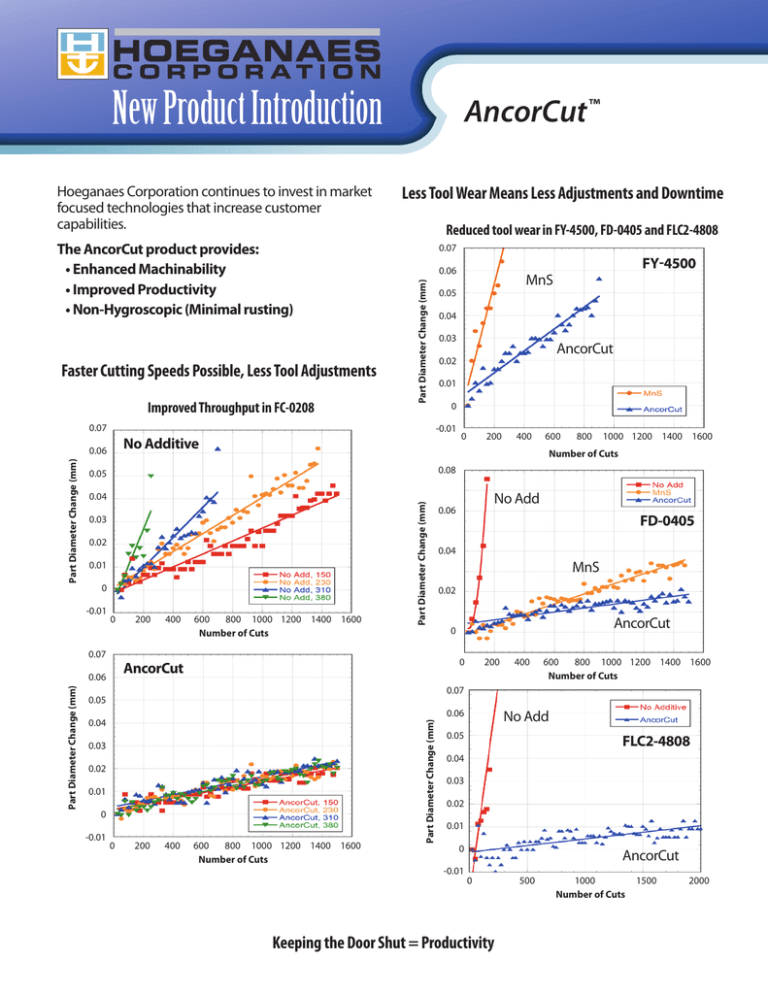

Faster Cutting Speeds Possible, Less Tool Adjustments

Improved Throughput in FC-0208

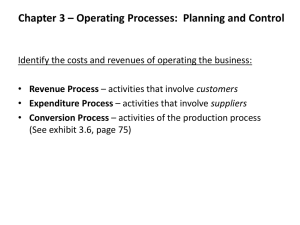

Less Tool Wear Means Less Adjustments and Downtime

Reduced tool wear in FY-4500, FD-0405 and FLC2-4808

0.07

0.06

Part Diameter Change (mm)

Hoeganaes Corporation continues to invest in market

focused technologies that increase customer

capabilities.

AncorCut™

0.07

0.03

0.02

0.01

0

0

0.07

400

600

800 1000 1200 1400 1600

Number of Cuts

0.01

0

0

200

400

600

800

1000 1200 1400 1600

No Add

0.06

FD-0405

0.04

MnS

0.02

AncorCut

0

0

AncorCut

0.06

Part Diameter Change (mm)

200

Part Diameter Change (mm)

0.04

200

400

600

800 1000 1200 1400 1600

Number of Cuts

0.07

0.05

0.06

0.04

0.03

0.02

0.01

0

-0.01

AncorCut

0.02

Number of Cuts

0.05

-0.01

0.03

0.08

0

200

400

600

800 1000 1200 1400 1600

Number of Cuts

Part Diameter Change (mm)

Part Diameter Change (mm)

0.06

0.04

-0.01

No Additive

MnS

0.05

No Add

0.05

FLC2-4808

0.04

0.03

0.02

0.01

0

-0.01

AncorCut

0

Keeping the Door Shut = Productivity

500

1000

Number of Cuts

1500

2000

New Product Introduction

AncorCut™

Non-Hygroscopic = Minimal Rusting

No Additive

AncorCut

MnS

FC-0208 – 10 Days Humidity Exposure

All of this work was completed in Hoeganaes’s Advanced Machining Lab, part of the new Innovation Center.

Key equipment includes our CNC lathe and mill.

CNC Lathe Haas ST-10

CNC Mill Haas VF-1

Please contact your local account manager or application engineer concerning samples and more detailed

information.

© Hoeganaes Corporation All Rights Reserved. 100 12.14