Welcome to GKN in Bruneck 1

advertisement

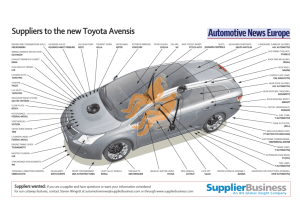

Welcome to GKN in Bruneck 1 1 1 Agenda: 8:30 Welcome and Introduction 8:45 General Presentation of GKN in Bruneck (Driveline, Land Systems, Sinter Metals) 9:30 Plant Tour Driveline and Land Systems 10:30 Plant Tour Sinter Metals 11:30 Questions & Answers 12:00 Departure for Lunch 2 3 Location Bruneck 4 Location Bruneck 5 Location Bruneck 6 7 the GKN WAY A common, global approach: • Focus on Technology • Continuous Improvement – Lean Enterprise • Raising the capability of the Group – Development of all our people • Common measurements to improve the health of the Group – The Business Excellence Model • Living the values to the full – The GKN Code 8 Bruneck 47 years of commitment, development and success 9 Milestones 1963 1967 Foundation of Birfield Trasmissioni Brunico Business Foundation of Formation Bound Brook Italia 1968 Start of driveshaft production for agricultural use 1970/1971 Incorporation of both sites into the GKN Group 1974 Realisation of the new production facility for Bound Brook Italia 10 Milestones 1979 Introduction of the first NC turning machine for CV-Joints 1986 Installation of the first full automated production line FAF 1988 Implementation of the Quality Management Systems Q1, ISO 9001, ISO TS 16949 1993 Worldwide crisis in Automotive 1997 GKN Bound Brook incorporated in GKN Sinter Metals 2003 GKN Birfield renamed to GKN Driveline Bruneck Consolidation 11 Milestones 2004 Reorganisation of the Sinter Metals Group 2004 P-Pump pilot project & between SM & DL for Ferrari und AMG Innovation Development 2006 SM-Product transfers to Bruneck during the restructuring 2006 Development of CV–Steering Joints 2007 Environmental Award – Premio Ambiente 2008 Global economic crisis, launch of e-Drive’s and project Eisberg, increased new business wins in all Divisions 2010 Record year in Bruneck in terms of turnover, revenues and development of new products 12 CVJ – Products & Applications 13 TORQUE – Products & Applications 14 DUJ – Products & Applications 15 Automotive – Products & Applications / 76% of turnover Shock absorbers Engine Bearings Brakes Seats Shock absorbers Mirror attachment Steering columns Seats Mirror attachment Door & roof fittings Steering Exhaust system Door & roof fittings Interior application Engine Cam lobes Exhaust system Interior application Pumps Cam lobes Bearings 16 Industrial – Products & Applications / 24% of turnover Bicycles Compressor Compressor White goods White goods Bicycles Power tools Fittings Lawn & garden Industrial clutches Cain buches Lawn & garden Fittings Cain buches Cosmetic Power tools Industrial clutches Cosmetics 17 Bruneck supplies to more than 700 customers 18 Awards (from Customers and GKN) GKN Land Systems Awards 2010 Best Sinter Supplier 2010 GETRAG Preferred Supplier 2011 GKN Sinter Metals – President Awards 2010: Customer Service Technology Innovation Performance Improvement For Production & Business Process Excellence Product Quality Performance Improvement through People Excellence Customer Service Quality Award Jaguar Land Rover 2011 19 Turnover by Region 60 % 7% 15 % 3% Total Turnover Italy Export 2011 240 m€ 36m € 15% 204 m€2085% GKN’s Importance to the local community Social / People Company performance in comparison 21 GKN Bruneck: More than just Production Global Account Team FIAT Centre of Excellence for Sinter Bearings IT/IS Competence Centre Development Centre for DO- and CV-Steering Joints Central SM - Tool Shop for Europe Test and Development Centre for Torque, CVJ and DUJ Core Competences for Torque- and DUJ-Manufacturing Processes and Development 22 People – the competitive advantage of Bruneck Low employee turnover 3 languages (German, Italian, English) 3 universities in the range of 100 km Skilled, flexible and reliable people People willing to learn new technologies and to apply them Keen to learn, deliver and succeed Used to deal with all global customers in different technologies and market segments Working for GKN in Bruneck means: Place for stable business environment Employees treated fairly Employees see Bruneck as the door to the GKN world Opportunities for development and growth 23 Our employees are our most important Resource They stand up to international comparison because of their - Creativity - Diligence - Reliability - Individual initiative - Multilingualism - German efficiency with Mediterranean spirit 24 International Leadership Automotive Peter Oberparleiter * Helmuth Rohregger * Sinter Metals (Driveline Finance Director) (MD North Europe) Peter Mölgg ** (President SM Europe & Asia Pacific) Gabriel Klement (Director IS/IT GKN SM and GKN DL) Karl Berger (SS Engineering Director) Roland Pahl Hannes Hellweger (Manuf. Eng. Director APJ) Gottfried Rier (VP Operations EU & China) Anton Holzer (VP Engineering EU & AP) Michael Ploner Kurt Gatterer (HR Director SEO) (Ops Director BRU, FIR, SLO, ESK) Hannes Prenn Andreas Mair Florian Klapfer Christian Carlando (Program Management SEO) (Engineering Italy, GPC) (Commercial Director FIAT) (Engineering FIAT) Elmar Auer (VP Sales & Marketing EU & AP) (Manufacturing Engineering EU) Land Systems (Off Highway) Walter Rohregger *** (Exec. VP Commercial & Eng.) Josef Hofer Andreas Rogger (Director IS IT) (HR Director PMD) * Members of the GKN Driveline Executive; ** Member of the SM Management Team *** Member of the Land Systems Management Team + Member of the GKN plc Executive Committee 25 GKN Bruneck Top Employer in the Region In the past 47 years GKN employed more than (Major Employers in South Tyrol by employee costs) 6000 employees. 26 Safety Environment 2 5000 1,5 4000 KWh/ tonne Serious Injury Rate Development of significant KPI‘s 1 0,5 0 3000 2000 1000 0 2004 2009 2010 B 2011 2016 2004 2009 2010 B 2011 2016 Serious Injury / 1000 people Productivity 250 2004 2008 2010 B 2011 2016 Thousands € % to Sales Non Quality Cost 3,5 3 2,5 2 1,5 1 0,5 0 200 150 100 50 0 2004 2007 2010 B 2011 2016 Turnover/Employee 27 43 Innovation Awards for Bruneck 28 Environmental Project 2009 Water cooling system Fresh water supply at a temperature of 10 °C Machine cooling (all year round) Water cooling system (compressor cooling unit/ air cooling unit) from 17°C 10°C Completed Closed water supply network with compressor cooling and an air cooling unit. Discharge to sewerage system at a temperature of approx. 17 °C Maintain water temperature at 10°C - otherwise the heat exchanger system of 110 machines would have to be replaced. Reduction of annual water consumption from 444.000 35.000 m³/a Reduction of annual water costs 290.000 25.000 €/a Payback in Bruneck 2,9 years - in Munich < 1 29 year! Environmental Project 2007 „Heat Recovery“ Project description: • In close cooperation with the local energy supplier Stadtwerke Bruneck, equipment was developed and installed to recover waste heat from the sinter furnaces, which is now used to heat the entire building. • The existing plant heating system was replaced, allowing surplus energy to be sold back to the local network supplier for redistribution. Savings per year: 160,000 kg of CO2 emissions The same as driving around the world (40,075km)in a mini (158 g/kg) 25 times (= 2 years and 4 months of non stop driving at 50 kph) Earnings per year: 43,293 € from sale of heat, which is enough to buy 3 new minis 47,250 litres of fuel oil per year That’s three tanker loads costing 41,107€ 30 1963-2013 50 Years of GKN in Bruneck Strong support from local government for investments in innovation and sustainable development Structured and flexible education and training facilities open to receive our need and inputs Positive GKN image in the community – GKN in Bruneck is an employer of choice Positive company climate – in good and in bad times Strong and reliable partnership with works council and external unions 31 Another 50 Years – What's next? Innovation, Operational Excellence and Sustainability 32 Automotive Market & Technology Trends Electrification: torque systems & auxiliary units Further development of engines and transmissions New Automotive Innovation & Growth Team (NAIGT) Stakeholder Validation Event, London, 5 February 2009 33 Market Analysis and Trends for PM applications Starter Components Variable Cam Lobes 3 34 Low Carbon Agenda Reduction of the climate impact Optimisation of the energy efficiency Utilisation of renewable energy Lightweight - Construction Intelligent Generators Automotive Technology Drivers High efficient torque systems Fuel efficiency Weight reduction Vehicle electrification Vehicle Mgmt. systems Energy recovery systems Alternative drive systems Electrical Pumps Start Stop Automatic 35 Automotive Technology Drivers Powder Metallurgy Technology Drivers High efficient torque systems Fuel efficiency Weight reduction Vehicle electrification Vehicle Mgmt. systems Energy recovery systems Alternative drive systems Light metals Soft magnetics Fine powder technology Porous materials Filters und Substrate HP gear boxes Design for PM, Net shape 36 Who drives Innovation? Innovation is mainly driven by our Employees and Customers - less driven by independent R&D Centres Open Innovation supported by the end user Early identification of future trends and needs – online communities 37 Strategic Developments and Key Projects CV-Joint for special vehicles and applications Hybrid and e-Drives for passenger and commercial cars 38 Strategic Developments and Key Projects PTO Power Take off Generator DUJ – driveshafts for special vehicles and applications 39 Strategic Developments and Key Projects Energy efficiency for home appliance and automation gewichtsreduzierte Pleuel für Kühlgeräte P-Pump for the fuel injection Schließmechanismen (z.B. für Schubladen) Start-Stop System New camshaft application to substitute forged products 40 GKN Bruneck Strategic Allignment GKN Bruneck will focus on Innovation to ensure to our Customers, Shareholders and Employees a continuous growth and value increase through the development of new business opportunities Growth Focus on the development of new products and applications Customer account Mgt. and Industrial Plans Development of Automotive und Non Automotive Markets Operational Excellence as opportunity and challenge Product conversion from alternative technologies Sustainability Focus retention on technology and innovation Achievement of preferred supplier status and development partner for our customers Sustainable focus on continuous HSE improvements Further implementation of LEAN Principles Remain the employer of choice Achieve Excellence 41 Thank you for your attention 4 42