Heeyong Park for the degree of Doctor of Philosophy in

advertisement

AN ABSTRACT OF THE THESIS OF

Heeyong Park for the degree of Doctor of Philosophy in

Mechanical Engineering presented on December 12. 1991.

Title: A Study of Laser Generated Rayleigh and Lamb Waves

in Graphite/Epoxy Composites.

Abstract Approved :

Redacted for Privacy

Clarence A. Calder

The application of laser generated ultrasonics was first

demonstrated in the mid-seventies and has shown good potential

when applied to isotropic materials.

However, its use with

composite materials is still in the early stages of development.

This study explores the potential for application of laser

generated Rayleigh and Lamb waves in graphite/epoxy composites.

Numerical results are obtained by the solution of the wave equations

using assumed solutions, and enforcing the boundary conditions.

Experimentally, Rayleigh and Lamb waves were generated by a Q-

switched ruby laser in the ablation regime and detected by piezo-

electric pinducers which permitted accurate phase velocity

measurements.

The Rayleigh wave velocity was measured at various directions

relative to the fiber direction and results were found to agree closely

with numerical predictions.

The increase of surface wave velocity

using thin plates could be useful for the application of delamination

detection in thick composites and an increase of Rayleigh wave

attenuation could indicate damages caused by impact.

waves can reflect from small surface cracks.

Also, surface

Therefore, laser

generated surface waves, particularly along the fiber direction, have

high potential for application in non-destructive testing.

Lamb wave experiments were conducted in aluminum plates

and gave distinctive signals, but there were some difficulties in

detecting the precise arrival of each Lamb wave mode for the

graphite/epoxy composite plates.

A Study of Laser Generated Rayleigh and Lamb Waves

in Graphite/Epoxy Composites.

by

Heeyong Park

A THESIS

submitted to

Oregon State University

in partial fulfillment of

the requirement for the

degree of

Doctor of Philosophy

Completed December 12, 1991

Commencement June 1992

APPROVED:

Redacted for Privacy

Associate Professor of Mechanical Engineering in charge of major

Redacted for Privacy

Head of Department of Mechanical Engineering

Redacted for Privacy

c

Dean of Graduate

6

hool

q

Date thesis is presented

December 12, 1991

Typed by researcher for

Heeyong Park

ACKNOWLEDGMENTS

I would like to express my deepest gratitude to Professor C. A.

Calder, for his academic guidance and financial support as my advisor

and his encouragement like my father in Korea.

I appreciate my

thesis committee members, T. C. Kennedy, M. N. L. Narasimhan, E.

Wolff, and Graduate Committe Representative, R. H. Cuenca, for their

support and Wyle Labs in Edwards Air Force Base for graphite/epoxy

specimens.

Patience, support, and love of my wife ( Young-mee Park ) and

my father ( Hae-chul Park ) are beyond description.

like to share my Ph.D with my mother in heaven.

Finally, I would

TABLE OF CONTENTS

1. INTRODUCTION

1.1. General

1.2. Literature Review

1.2.1. Rayleigh Wave

1.2.2. Lamb Wave

1.3. Purpose of Study

2. BACKGROUND

2.1. The Potential of Laser-generated Ultrasound

2.2. Generation of Ultrasonic Waves by Laser Deposition

2.2.1. Absorption of Laser Energy

2.2.2. Thermoelastic Effects of the Surface

2.2.3. Ablation of the Surface

2.3. Michelson Interferometer

3. NUMERICAL SOLUTIONS FOR RAYLEIGH AND LAMB

WAVES

3.1. Formulation of Equations for Rayleigh Waves

3.1.1. Wave Equation

3.1.2. Assumed Solutions for Rayleigh Waves

3.1.3. Secular Equation for Rayleigh Waves

3.1.4. Boundary-condition Determinant

3.2. Numerical Solutions of Rayleigh Waves

3.2.1. Numerical Procedure

3.2.2. Material Constants

3.2.3. Numerical Results

3.3. Formulation of Equations for Lamb Waves

3.3.1. Assumed Solutions for Lamb Waves

3.3.2. Secular Equation of Lamb Waves

3.3.3. Boundary-condition Determinant

3.4. Numerical Solutions of Lamb Waves

3.4.1. Numerical Procedure

3.4.2. Numerical Results

1

1

3

3

6

10

11

11

13

13

15

17

18

23

23

23

24

26

27

29

29

32

32

43

43

44

45

48

48

50

4. EXPERIMENTS

4.1. Experimental Arrangement

4.2. Preparation of Specimen

4.3. Experimental Procedure

4.4. Experimental Results and Discussion

4.4.1. Rayleigh Waves

4.4.2. Lamb Waves

5. CONCLUSIONS AND RECOMMENDATIONS

55

55

61

61

64

64

75

82

BIBLIOGRAPHY

84

APPENDIX A : PROGRAM FOR RAYLEIGH WAVES

93

APPENDIX B : PROGRAM FOR LAMB WAVES

101

111

APPENDIX C : COMPONENTS OF [Aii]

APPENDIX D : EXPERIMENTAL WAVEFORMS AND

FFT ANALYSIS OF RAYLEIGH WAVES

112

APPENDIX E : EXPERIMENTAL WAVEFORMS AND

FFT ANALYSIS OF LAMB WAVES

117

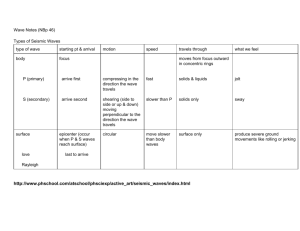

LIST OF FIGURES

Figure

Page

Thermoelastic effects of the surface

at low laser power density.

17

2.2.2.

Ablation of the surface at high laser power density.

18

2.3.1.

Basic Michelson interferometer.

19

2.3.2.

Sensitivity comparison of Michelson interferometer.

22

3.1.1.

Coordinate system for the Rayleigh wave propagation.

25

3.2.1.

Finding three roots of L3 from an eigen value plot.

30

3.2.2.

Flow chart for numerical search procedure of

2.2.1.

3.2.3.A

3.2.3.B

3.2.4.A

3.2.4.B

3.2.4.0

3.2.4.D

Rayleigh wave velocity.

31

Polar plot of Rayleigh and body wave phase velocities

in the unidirectional graphite/epoxy composite.

34

Rayleigh and body wave phase velocities in the

unidirectional graphite/epoxy composite as a function

of the wave propagation direction.

34

Normalized X,Y, and Z displacements vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite (0 = 0° ).

36

Normalized X,Y, and Z displacements vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite ( 0 = 10° ).

36

Normalized X,Y, and Z displacements vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite (0 = 30° ).

37

Normalized X,Y, and Z displacements vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite (0 = 90° ).

37

3.2.5.

3.2.6.

3.2.7.A

3.2.7.B

3.2.7.0

3.2.7.D

3.3.1.

3.4.1.

Angular deviation at the surface between Rayleigh

wave propagation directions and horizontal

displacement vectors given every 10°.

39

Change of horizontal displacement vector at every

0.02 wave length depth relative to the Rayleigh wave

propagation direction.

40

Normalized X,Y, and Z stresses vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite ( 0 = 0° ).

41

Normalized X,Y, and Z stresses vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite ( 0 = 30° ).

41

Normalized X,Y, and Z stresses vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite ( 0 = 60° ).

42

Normalized X,Y, and Z stresses vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite ( 0 = 90° ).

42

Coordinate system for the Lamb wave propagation

43

Combined eigen value plot of [Aid] according to the

L3 value.

49

Lamb waves propagation in the unidirectional

graphite/epoxy composite plates ( 0 = 0° ).

51

Lamb waves propagation in the unidirectional

graphite/epoxy composite plates ( 0 = 45° ).

51

Lamb waves propagation in the unidirectional

graphite/epoxy composite plates ( 0 = 90° ).

53

3.4.3.

Lamb waves propagation in the aluminum plate.

53

3.4.4.

The Ao mode velocities by the change of wave

propagation directions in the unidirectional

graphite/epoxy composite plates.

54

3.4.2.A

3.4.2.B

3.4.2.0

3.4.5.

4.1.1.

4.1.2.

4.1.3.

4.3.1.

4.4.1.

The So mode velocities by the change of wave

propagation directions in the unidirectional

graphite/epoxy composite plates.

54

Schematic diagram of experimental setup

for the single pinducer technique.

56

Schematic diagram of experimental setup

for dual pinducer technique.

57

Measurements of Rayleigh wave propagation time

by the single and the dual pinducer techniques.

60

Layout of laser deposition tests for Rayleigh and

Lamb waves generation.

62

Rayleigh waves in the unidirectional graphite/

epoxy composite as a pinducer moves from

a line source (0 = 0° ).

4.4.2.

4.4.3.

4.4.4.

66

Rayleigh waves in the unidirectional graphite/

epoxy composite as a pinducer moves from

a line source ( 0 = 90° ).

66

Relation between the laser energy and

the pinducer output.

67

Attenuation of Rayleigh wave amplitudes

in the graphite/epoxy composite

4.4.5.

4.4.6.

4.4.7.A

when 0 = 0° & 90° ( laser energy = 205 mJ ).

70

Calculations and experiments of Rayleigh wave

phase velocities in the unidirectional graphite/

epoxy composite and comparison with Rose's

results [see reference 57].

72

Comparison between the single and the dual

pinducer techniques in Rayleigh wave velocity

measurements.

74

Laser generated ultrasonic waves in an aluminum

plate of 0.8 mm thickness.

76

4.4.7.B

Frequency analysis of Fig. 4.4.7.A.

76

4.4.8.A

Laser generated ultrasonic waves in the unidirectional

graphite/epoxy composite plate of 0.87 mm thickness

perpendicular to the fiber direction.

78

4.4.8.B

Frequency analysis of Fig. 4.4.8.A.

4.4.9.

Digital filtering analysis for Lamb wave signal of

78

Fig. 4.4.8.A

i) Low pass filtering with a cut-off frequency

of 0.7 MHz,

ii) Band pass filtering between 0.7 and 1.7 MHz,

iii) High pass filtering with a cut-off frequency

of 1.7 MHz.

4.4.10.

79

Polar plot of surface wave phase velocities

on the graphite/epoxy composite plates of

thickness 0.87 & 16.25 mm.

80

LIST OF TABLES

Table

3.2.1.

Page

Material constants of graphite/epoxy specimen

with 60 % fiber volume fraction ( T300/5208 ).

32

4.2.1.

Dimensions of graphite/epoxy plates ( T300/5208 ).

61

4.4.1.

Attenuation calculation of a graphite/epoxy composite.

69

LIST OF APPENDIX FIGURES

Figure

D.1.A

Page

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 16.25 mm thickness ( 0 = 0° ).

112

D.1.B

Frequency analysis of Fig. D.1.A.

112

D.2.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 16.25 mm thickness ( 0 = 20° ).

113

D.2.B

Frequency analysis of Fig. D.2.A.

113

D.3.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 16.25 mm thickness ( 0 = 50° ).

114

D.3.B

Frequency analysis of Fig. D.3.A.

114

D.4.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 16.25 mm thickness ( 0 = 70° ).

115

D.4.B

Frequency analysis of Fig. D.4.A.

115

D.5.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 16.25 mm thickness ( 0 = 90° ).

116

D.5.B

Frequency analysis of Fig. D.S.A.

116

E.1.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 0.87 mm thickness ( 0 = 0° ).

117

E.1.13

Frequency analysis of Fig. E.1.A.

117

E.2.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 0.87 mm thickness ( 0 = 20° ).

118

E.2.B

Frequency analysis of Fig. E.2.A.

E.3.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

118

plate of 0.87 mm thickness ( 0 = 40° ).

119

E.3.B

Frequency analysis of Fig. E.3.A.

119

E.4.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 0.87 mm thickness ( 0 = 50° ).

120

E.4.B

Frequency analysis of Fig. E.4.A.

120

E.5.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 0.87 mm thickness ( 0 = 60° ).

121

E.5.B

Frequency analysis of Fig. E.S.A.

121

E.6.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

plate of 0.87 mm thickness ( 0 = 80° ).

122

E.6.B

Frequency analysis of Fig. E.6.A.

122

E.7.A

Laser generated ultrasonic waves

in the unidirectional graphite/epoxy composite

E.7.B

plate of 0.87 mm thickness ( 0 = 90° ).

123

Frequency analysis of Fig. E.7.A.

123

A STUDY OF LASER GENERATED RAYLEIGH AND LAMB WAVES

IN GRAPHITE/EPDXY COMPOSITES

CHAPTER 1

INTRODUCTION

1.1.

General

When the equations of motion for an infinite isotropic solid

are solved, it is found that there are two types of elastic body waves

that can propagate independently: 1) the longitudinal wave in which

the particle motion is parallel to the direction of propagation and

2) the transverse wave in which the motion is perpendicular to the

direction of propagation.

If the medium occupies a half-space and

has one free surface, then the solutions must satisfy the boundary

condition that the surface stresses are zero.

This condition can be

used to find the reflection coefficients for body waves, but a solution

exists that describes a wave confined to the near-surface. Waves of

this type are referred to as Rayleigh waves.

They propagate along

the free surface and decay exponentially in the direction normal to

the surface.

In a plate, there are two surfaces at which traction-free

boundary conditions must be satisfied.

When the boundary

conditions are imposed, the Rayleigh-Lamb equations relating the

wave number, K ( = 27c/X, ), and the angular frequency co are obtained.

2

It is found that, for a given value of K, there is an infinite number of

frequencies which satisfy the Rayleigh-Lamb equations.

These

correspond to different modes of Lamb waves.

Ultrasonic waves including Rayleigh and Lamb waves have been

one of the most powerful tools of NDE ( Non-Destructive Evaluation )

for isotropic materials.

However, the attention of the NDE

community has shifted toward composites because their very large

strength-to-weight and stiffness-to-weight ratios are attractive for a

wide range of applications, especially in the aerospace industry.

Many of the NDE tools available for testing of isotropic materials have

been applied to composites.

Quite naturally, ultrasonic testing

has been used for the NDE of composites with varying degrees of

success.

The major difficulty in case of composites arises from the

fact that the theoretical analysis of wave propagation is considerably

more difficult.

For example, in an isotropic material, the wave

propagation and energy propagation directions are the same: In an

anisotropic material, however, they are quite different in general.

The most popular tool of ultrasonic NDE has been the

conventional piezoelectric transducer and the various, associated

techniques have been developed.

There are, however, limitations

of piezoelectric transducers such as required physical contact,

temperature limits, flat surface for coupling, etc.

Therefore,

NDE of composites by laser generated stress waves with detection

using various interferometry techniques along with fiber optics is

currently under active development.

3

1.2.

Literature Review

1.2.1. Rayleigh Wave

Lord Rayleigh established the basic properties of acoustic

surface wave propagation along the surface of an elastic isotropic

solid.

He showed that the wave is non-dispersive, propagates at a

velocity slightly less than the shear wave velocity, and that most of

its energy is contained within a wave length of the surface [54].

It was realized during the 1950's that Rayleigh waves could be useful

for nondestructive testing.

Much of the early work in this field

was carried out in Russia and Germany.

Major contributions on

the application of Rayleigh waves to NDT ( non-destructive testing

were made by Victorov [73].

)

He pointed out that Rayleigh waves

in the ultrasonic range could be used to detect the presence of flaws

such as cracks and holes, near the surface of a sample.

Also, he

pointed out that the change in attenuation and velocity of Rayleigh

waves could be used as an indication of the material state near the

surface of a solid.

An important problem of great interest in structural mechanics

Surface cracks weaken

is the determination of the size of a crack.

a material and lead to its eventual fracture.

If it is assumed that

the Rayleigh wavelength is large compared to the size of the crack,

then it is possible to develop quasi-static theories for Rayleigh wave

scattering from a crack based on fracture mechanics theories.

The basic

Typically, surface cracks have a half-penny shape.

quantitative theory to determine these effects for Rayleigh waves was

4

developed by Kino [40].

An NDT technique for larger cracks, which

has been highly successful, was carried out by Silk [63].

He made

use of the fact that a surface wave incident on a crack propagates

along the surface of substrate, then along the surface of the crack,

and radiates as a body wave from the tip of the crack.

Detection of

this body wave can be obtained on the top or bottom surfaces of the

substrate, away from the crack.

In either case, a good estimation

of the crack depth can be made by measuring the extra time delays

due to propagation of the wave along the length of the crack.

In 1963 White demonstrated laser generation of acoustic waves

in a solid [75].

The first models describing the phenomenon were

one-dimensional [76,55,12,74], and assumed that the laser impact

occupied the entire surface of the material.

Since the laser

generated ultrasound was received by means of narrow passband

piezoelectric transducers, harmonic directivity patterns were

initially used for describing the ultrasonic waves generated by

a point laser impact [35,36].

Subsequently the use of broadband

receivers such as capacitive sensors [21,62], thick piezoelectric

discs [22], or laser interferometers [69,38,8] have made wideband

modelling of laser generated acoustic displacements necessary.

Laser generated ultrasound is now widely accepted as a versatile

NDT technique in the laboratory, and is starting to find industrial

applications [61,56,6,39,59,60,2].

Cooper, Dewhurst, and Palmer

studied interaction of laser generated Rayleigh pulses with surface

breaking slots in metal using a capacitance probe [20].

Surface

5

echoes reflected from the defect had two major components.

The

first arose from direct reflection of a Rayleigh pulse from the top of

the defect, whereas the second arose from a shear pulse originating

at the bottom of the defect which mode-converted to a Rayleigh

pulse on reaching the metal's surface at the critical angle [23].

On the other hand, fiber optic sensor systems for ultrasonic

NDT have been developed by many authors [24,25,9,17].

Fiber

optic sensors have some advantages over conventional transducers

and laser interferometers.

For example, a flexible fiber can

reach rather inaccessible surfaces and can be readily incorporated

into a scanning system.

Duffer, Burger, and Piper machined a

slot on a steel specimen and used a dual channel fiber tip interfero-

meter to detect the Rayleigh wave as it passed underneath each

sensor [26].

Comparison of the frequency spectrum of the

incident Rayleigh wave with that of the transmitted Rayleigh waves

contained information about the depth of surface cracks.

Recently, Huang and Achenbach employed a dual-probe

interferometer to obtain accurate measurements of the surface wave

forms on an aluminum plate with increasing degrees of surface

roughness [33].

McKie et al designed and developed a dual-beam

interferometer for the accurate measurement of surface wave

velocity on an aluminum block [49] .

A system of polarizing optical

components was used in order to efficiently derive two beams from

a single input laser beam.

By accurate Rayleigh wave measurement,

the degree of anisotropy of the test specimen could be obtained.

6

Development of laser-based ultrasonics for composites is now

in the early stages.

Addison, Jr., Ryden, and McKie made

measurements of the angular diffraction pattern for longitudinal

elastic waves from a laser generated thermoelastic source in both

aluminum and a graphite/epoxy composite [1].

Tittman, Linebarger,

and Addison, Jr. demonstrated a laser based transmission C-scan of

a simulated ( 10 mm by 10 mm ) delamination in a graphite/epoxy

composite [70].

1.2.2. Lamb Wave

The governing equations for Lamb waves were first derived

by Professor Horace Lamb in 1917 in his famous work [44].

He

formulated the problem using potentials and arrived at the wellknown Rayleigh-Lamb equation for wave propagation in isotropic

plates.

These equations were quite complicated and a solution

could be obtained only in the short and long wavelength limits.

The first comprehensive solution of Lamb waves was obtained by

Mindlin [50] in 1950.

Later, Viktorov dealt with the solution of

Lamb waves in great detail [73].

He provided the dispersion

curves for aluminum with a Poisson's ratio of 0.34.

Solie and Auld

investigated waves in anisotropic plates theoretically and compared

the results to the uncoupled shear vertical and longitudinal modes

[64].

Habeger, Mann, and Baum conducted a theoretical and

experimental study of ultrasonic Lamb waves in machine-made

7

papers [30].

The papers were modeled as homogeneous

orthotropic plates.

The dispersion equation for Lamb wave

propagation in the principal directions was developed analytically

and verified experimentally.

Moon used a variational method

to obtain an approximate solution for Lamb wave propagation in

laminated composite plates [51].

Sun and Tan derived an

approximate solution based on Mind lin's plate theory [68].

Stiffler and Henneke obtained a low-frequency Lamb wave solution

using elementary plate theory [67].

Mal developed a general

theory, based on a matrix formulation, to solve the wave propagation

problem in multi-layered composite laminates [46], and the results

have been corroborated with experimental data by Mal and BarCohen [47,5].

There are many methods to generate and detect Lamb waves in

composite materials.

wave method.

The most popular method is the leaky Lamb

In this particular method, two transducers and a

composite plate are immersed in a water tank.

By varying the

sending and receiving angles of the transducers, relative maxima

corresponding to Lamb modes are detected when the Lamb wave

energy leaks from the surfaces of the plate.

By knowing the angles

and the excitation frequencies, dispersion curves can be obtained

experimentally.

Worlton was the first one to confirm the theory of

Lamb waves and determined the dispersion curves for aluminum and

zirconium experimentally using this method [77].

Chimenti and

Nayfeh verified their approximate solution for unidirectional

8

composite plates in the fiber direction by the detection of null zones

that indicated the presence of leaky Lamb waves [19].

Bar-Cohen

and Chimenti studied the application of leaky Lamb waves for NDT of

composite laminates [4].

They observed a correlation between

the character of the excited Lamb wave modes and the presence of

certain defects such as porosity and delaminations.

Martin and

Chimenti refined this method by signal processing [48].

The results

of the leaky Lamb wave method look promising, but the technique

may not be particularly well suited for field inspection of composite

laminates because the method requires the plates to be immersed in

water.

A simple method similar to the acousto-ultrasonic technique

[72,32] has been studied by Stiff ler and Henneke to generate and

detect Lamb waves in composite laminates [67,27,66].

The experi-

mental data obtained by this simple method generally belong to the

lowest symmetric and anti-symmetric Lamb modes.

In this method,

two piezoelectric transducers acoustically coupled to the plate by

water-soluble couplant are directly in contact with the composite

plate to create and receive Lamb waves.

The Lamb wave speed can

be determined by measuring the change in arrival time of a phase

point on the receiving signal while moving the receiver a certain

distance.

Chapman used the same idea in the detection of

debonding in fiberglass-reinforced plastic lap joints [18].

In a

similar approach, Rose, Rokhlin, and Adler measured Lamb wave

speeds with energy flux deviation in composite laminates [58].

9

Liu generated Lamb modes and SH modes in a unidirectional

graphite/aluminum composite plate by a shear wave transducer and

used an electro-magnetic acoustic transducer ( EMAT ), which was

not sensitive enough to detect the signals [45].

Wormley and

Thompson, who used two EMATs as receivers, determined the wave

speed by cross-correlation between the two receiving signals and

thus evaluated the texture of rolled-metal plates [78].

Recently, laser-generated Lamb waves were studied by

Hutchins and Lundgren [37].

The Lamb wave was propagated

within thin materials ( aluminum and metallic glass samples ) and

detected by Michelson interferometer.

The thickness of the

samples and their elastic constants were estimated with good

accuracy.

Burger et al generated Lamb waves in a thin aluminum

plate by Nd:YAG laser and detected signals by a fiber optic system

[10].

They demonstrated good agreement between experiment

and finite element models.

Aussel and Monchalin measured the dispersion of Rayleigh

waves on thick and thin metallic substrates using laser-ultrasonics.

In order to enhance the precision of the measurements, the signalto-noise ratio was increased by focusing the Rayleigh wave with an

annular generating source [3].

Hutchins et al presented the

ultrasonic inspection of composite panels, fabricated by attaching a

thin layer of aluminum to a rigid foam substrate using an epoxy

resin, and of aluminum composites consisting of aluminum sheets

bonded together with an epoxy adhesive layer [34].

A ruby laser

10

beam was focused to a line source and the receiver was an EMAT for

the detection of vertical displacements.

They demonstrated that

the presence of high frequencies serves as a test for disbond.

1.3. Purpose of Study

To date, laser ultrasonics have been developed mainly for

isotropic materials as given in the literature review.

Recently,

it has been used for applications in composite materials, which are

highly anisotropic.

The characteristics of laser generated stress

waves including Rayleigh waves, Lamb waves, and body waves need to

be fully explored and understood so that NDE of composite materials

by laser systems will soon be possible.

In this study the characteristics of laser generated Rayleigh

waves and Lamb waves was studied for unidirectional graphite/epoxy

composite plates.

Graphite fibers with an epoxy matrix

constitute one of the most popular composites.

The velocity

changes of Rayleigh and Lamb waves according to wave propagation

direction was studied numerically and verified experimentally as far

as possible.

Also, the attenuation of Rayleigh waves and their

dependence on wave propagation direction and on the distance

between laser source and detection point was studied for future

NDE applications using graphite/epoxy and similar composites.

11

CHAPTER 2

BACKGROUND

2.1. The Potential of Laser-generated Ultrasound

By far the most commonly used method of generating and

detecting ultrasound has been by piezoelectric transducer.

Historically, piezoelectric crystals such as quartz were

predominantly used as transducer materials.

Many of the problems with piezoelectric generation and

reception lie not in the transducer, but in the coupling which is

necessary between transducer and specimen.

The choice of

couplant ( often an oil or grease ) and its method of application often

tend to be an art rather than a science.

Variability of couplant

thickness and partial transmission and partial reflection of the

ultrasonic energy in the couplant layer result in loss of sensitivity,

change of waveform, unwanted resonances and time-of-flight

measurement errors.

The entire test structures are often

immersed in a tank of water or coupling fluid.

Although the

couplant allows acoustical energy to propagate into the test material,

it causes several problems in addition to potential harm to the

material, particularly porous ceramics or polymer-based materials.

There are additional problems and limitations of using piezoelectric

transducers [60,61].

The laser generation of ultrasound can

eliminate the need for any coupling between source and sample and

overcomes all of these problems.

12

Calder and Wilcox showed the potential of laser-generated

ultrasound through the following developments:

1) demonstration

of the detection of an artificial flaw, a 1.5 mm diameter hole located

midway across a 25 mm aluminum plate [13];

2) the measurement of

dilatational and mode-converted pulse arrivals in rods along with

calculation of the elastic constants of many isotropic materials [14,15];

3) the use of laser energy deposition and wave detection by Michelson

interferometer to provide a unique method for the measurement of

acoustic velocity in liquid metals [16].

They pointed out some distinct advantages of laser ultrasonics

over the conventional transducers:

1) The laser loading produces a large stress pulse amplitude of

short duration so that tests of highly attenuating or very thin

materials are possible.

2) The short measurement time of a few microseconds or less

can be made at a precise instant in time.

3) The noncontact feature is especially useful for testing in severe

environments and with toxic materials.

4) There are few restrictions on specimen size and configuration.

( Laser beams can be focused to a point or a line by optical

methods. )

5) The specimen can be far removed from the instrumentation

hardware.

13

The following sections will give the background of how

ultrasonic waves are generated by laser deposition and detected by

Michelson interferometer.

2.2. Generation of Ultrasonic Waves by Laser Deposition

2.2.1. Absorption of Laser Energy

A pulsed laser emits bursts of coherent electro-magnetic

radiation. When low intensity radiation ( 106 W/cm2) is incident on

a metal surface, the combination of electric and magnetic fields

generates currents in the conduction band near the surface of the

material.

Some of the incident energy is absorbed by resistive

losses and converted into heat, while the remainder is re-radiated

as a reflected pulse. Most of the absorption and reflection takes

place very close to the surface, within what is called "skin depth" 8.

At longer wavelengths in the infrared, the following classical

expression for 5 can be used [7]

S2

1

Eafligo

(2.2.1)

where a = conductivity of material

g = relative permeability of material

f = frequency of the incident radiation

P.O = 4n x 10-7 H/m = permeability of free space.

14

For a Nd:YAG laser of wavelength 1.0611m in the near infrared, the

skin depth is - 5 nm in aluminium.

Again,using classical electromagnetic theory [7) the reflectivity

of the material R can be calculated as the ratio of the reflected

energy Er to the incident energy Ei i.e.,

R=

Er

2-2t+t2

=

(2.2.2)

2+2t+t2

where t = 1.10005

c = velocity of light.

For a metal, t »1 for all frequencies up to visible light, so that

reflectivity can be approximated as

4

R=1-T

(2.2.3)

.

Therefore, the absorbed energy Ea is given by

Ea =

(1 R)

=

(2.2.4)

For example, theoretical absorption ratio is 6% for aluminium.

Thus in a low power regime where other effects can be

neglected, the pulsed laser acts as a transient heat energy source at

the surface.

If the absorption of energy is assumed to occur so

rapidly that thermal conductivity into the bulk of the material can be

neglected, the deposition of energy Ea in a surface layer of area A

and depth 8 causes a temperature rise sr given by

AT =

Ea

spAS

(2.2.5)

15

where s = specific thermal capacity of material

P = density of material.

Substituting Ea from eq (2.2.4) gives

4

AT =

ilocpase

(AJ

(2.2.6)

Therefore the temperature rise is proportional to the mean incident

energy density.

Over the timescales of typical laser pulses ( 10 ns to 100 ns ),

there is, in fact, appreciable thermal conductivity into the bulk of

most materials [55,76].

The main effects as regards the generation

of ultrasound are that the volume of heated material increases as a

function of time.

2.2.2. Thermoelastic Effects of the Surface

The sudden rise in temperature of the surface layer by the

absorption of thermal energy should be accompanied by thermal

expansion.

If the volume expands from v.M to V + AV, then

AV = 3aVAT

(2.2.7)

where a = coefficient of linear expansion.

Substituting for AT from eq (2.2.5) and for Ea from eq (2.2.4) gives

AV =

3a

sp

E =

a

3a

sp

(1-R) Ei

(2.2.8)

16

Therefore, the absorption of laser energy causes thermoelastic

strains equivalent to the sudden insertion of a volume AV of material

immediately below the surface that is proportional to the incident

energy Ei.

Note that the magnitude of the increased volume is

independent of both the beam area A and the thickness 8 at

constant reflectivity R.

If the source is situated deep in the

material, it will appear to be a pure expansion and will generate only

compressional waves in all direction. However, the close proximity

of the actual source to the surface introduces some conversion of

the compressional waves to shear waves [11].

As shown in Fig.

2.2.1.A, compressive dipolar stresses parallel to the surface are

unchanged, and the boundary conditions require zero net stresses

normal to the surface.

However, since the heating occurs to the

skin depth, the source is actually just below the surface so that a

small normal stress can be produced.

This thermoelastic source

of ultrasound is different from a piezo-electric compressional

transducer which principally generates a stress normal to the

surface.

For many applications it is adequate to treat the thermo-

elastic source of ultrasound as a point or line source, provided

sufficient beam focusing is employed.

When the surface is

constrained by oil layer, glass, plastic cover, etc. as shown in Fig.

2.2.1.B, the stress normal to the surface becomes dominant and

is the cause of dramatic increase in the generation efficiency of

longitudinal waves.

17

Incident

Incident

Laser Pulse

Laser Pulse

Skin

Depth

Constraining

5

- - el.

Layer

40- --

-P.

ik.

Dipolar Surface Stress

(A) Free Surface

Normal stress due to

Thermal Expansion

(B) Constrained Surface

Fig. 2.2.1 Thermoelastic effects of the surface

at low laser power density.

2.2.3. Ablation of the Surface

From eq (2.2.6.), the surface temperature increases linearly

with incident energy or power density.

As the optical power

density is increased, whether by increasing the energy per pulse

or by focusing a constant energy onto a small surface area using a

converging lens, the temperature must rise until the melting point of

the surface material is reached and ablation takes place from the

surface.

Once ablation occurs, some of the incident energy is

dissipated as kinetic energy of the material vapor.

During transient

heat pulses of short duration, thermal equilibrium is not reached, so

that the surface can become superheated for a short time above the

18

boiling point of the material.

The detailed interactions among the

laser pulse, plasma, and surface are beyond the scope of the present

discussion [431.

When the laser intensity is sufficient to cause ablation, the

impulse force given to the surface by the vaporization of coating

material or ablation of the surface itself produces a strong impulsive

recoil force, by the transfer of momentum, as with a constrained

surface in the thermoelastic region ( refer to Fig. 2.2.2 ).

M

Laser Pulse

Momentum due to

Surface Vaporization

iii

-> Dipolar Surface Stress

due to Thermal Expansion

Normal Stress due to

Momentum Transfer

Fig. 2.2.2 Ablation of the surface at high laser power density.

2.3. Michelson Interferometer

As described in sec. 2.1, laser-generated ultrasound has great

potential in NDE.

Many types of interferometric techniques [28,651

19

can be useful for noncontact, remote sensing, optical detection.

The Michelson interferometer shown in Fig. 2.3.1 is the basic one

which has been widely used.

The basic principle of fiber optic

detection is also the same as that of the Michelson interferometer.

Therefore, the following discussion on the principles of Michelson

interferometry will also be useful for understanding other laser

based interferometric methods.

Fig. 2.3.1 shows a schematic for this interferometer.

from a laser is divided by a beam splitter into two parts.

Light

One part

goes through the beam splitter and strikes a movable reflecting

surface at a distance Xi from the beam splitter.

The other part of

beam is reflected by the beam splitter to a fixed reference mirror

located at a distance X2 from the beam splitter and is reflected back.

Reference Mirror

Specimen

Beam

Splitter

Out of plane motion

Detector

(Photomultiplier Tube)

Fig. 2.3.1 Basic Michelson interferometer.

20

The two beams are recombined at the beam splitter and travel

Because these beams originate from the

together to the detector.

same coherent source, sharp interference fringes are produced at

the detector which represent a measure of the difference in the

Note that the optical path

optical paths of the two beams [531.

length changes twice as much as the out of plane motion of the

For large displacements, it is necessary to count

fringes since each fringe indicates an optical path difference of only

specimen.

X/2.

For changes less than X/2 , a measure of the variation in the

fringe intensity gives the change in position, since the fringe

intensity varies sinusoidally as a function of optical path difference.

For very small displacements, the interferometer can be stabilized

on the most sensitive position of the sine wave resulting in an

output that is nearly linear with displacement.

The light intensity Lt measured at the detector of an

interferometer is

Lt = [ IC, Re exp { i (KX coot + 2KX1(t ) + 01(t ))}

± 4172 Re exp { i (KX

coot + 2KX2(t ) + 02(t )) }]2 (2.3.1)

where co. = 27cf. (fo = optical frquency )

= intensity of the object beam (i=1) or reference beam (i=2)

K = 2rc / X = wave number

cOi(t ) = noise fluctuations in object beam (i=1) or ref. beam (i=2).

Since all the contributions to the signal from extraneous thermal or

mechanical fluctuations are contained in 41(t) and (02(t ), X2 can be

21

considered constant and the variation of X1(t) from its equilibrium

value ( X1(0)) is the variable of interest, e.g. AX, (t ) = X1(t) X1(0).

Then, eq (2.3.1) can be written

2 1.

1 = L1 +L2 F O r T 2 cos ( 2KAX,(t ) + A4)(t ) +43 )

where octo = K [ Xi (0)

(2.3.2)

X2(0) l,

04) .-. 4)1(t ) _ 4)2(t )

= noise displacement.

Obviously, 4) is a system parameter and can be adjusted to any

convenient value, i.e. it / 2.

Therefore, after removing electronically

the constant term from eq (2.3.2), the signal is given by

Ls =

II7I72 sin ( 2KAXs(t )+ A4)(t ))

(2.3.3)

Fig. 2.3.2 shows the sensitivity change of interferometer.

The sine

function is most sensitive to changes in As when the argument is

small ( or - nn ,where n = integer ).

is directly proportional to AXs.

Then, the measured intensity

However, if 2ICAX2(t )+ A4)(t ) - it / 2

( or (n + 1) 7E / 2 ), the interferometer is operating at its least sensitive

position and relatively large changes in AXs cause little change in

the observed intensity.

Because, typically, 2KAXs(t ) « 1 and

dA4)(t ) / dt « dAXs(t)/dt, the noise A4)(t) causes the signal to drift in

and out of the most sensitive region.

This noise results in low

frequency shift of the output signal, which changes signal sensitivity

and makes the system unstable.

It is important to compensate for

this noise to maintain the interferometer at its most sensitive

position [6].

22

Most Sensitive

Case

Least Sensitive

Case

2 kAXs

2 IcAXs

Optical Phase

Fig. 2.3.2. Sensitivity comparison of Michelson interferometer.

23

CHAPTER 3

NUMERICAL SOLUTIONS FOR RAYLEIGH AND LAMB WAVES

3.1. Formulation of Equations for Rayleigh Waves

3.1.1. Wave Equation

In a perfectly elastic, homogeneous, anisotropic medium without

body forces and piezoelectric effects, the wave equation can be written

by using the usual summation convention,

a2 Ui

P Tat

a2 Uk

corm

axiax,

(3.1.1)

where Ui = displacement component along the Cartesian axes Xi

to which the stiffness tensor Ciikm is referred

P = density of the medium

j, k, m = 1, 2, 3.

Here, the epoxy matrix of the graphite/epoxy composite is assumed

to be elastically isotropic and the fibers are assumed to be transversely isotropic.

If fibers are distributed randomly in the matrix,

then the graphite/epoxy can have hexagonal symmetry.

Of course,

this is not homogeneous in a microscopic point of view.

However,

if the wave length of the Rayleigh wave is large with respect to the

diameter of fibers ( the diameter of the graphite fibers is about 5 lim),

then the scattering by the individual fibers can be ignored and the

graphite/epoxy composite can be treated as homogeneous and

transversely isotropic.

24

If the medium is infinite in all directions, the simplest

solutions of eq (3.1.1) are given by the real part of

U = A exp[iK(LiXi

with A = ii (xi

vt)]

(3.1.2)

= 1, 2, 3), where ii is a unit vector along the Xi axis and K

is a wave number. The phase velocity v of the wave is measured along

the propagation vector K, whose direction cosines are given by the Li

(K=

ii).

These homogeneous plane waves are called bulk waves.

In general, there will be three distinct velocities of body wave

propagation [421.

The values of these velocities will depend on the 21

elastic constants of the material, and on the direction of propagation.

3.1.2. Assumed Solutions for Rayleigh Waves

The coordinate system for the Rayleigh wave problem will use

X3 as the outward normal to the traction-free surface of the medium

as shown in Fig. 3.1.1.

The axis X1 is chosen in the convenient

direction, e.g. along the fiber direction.

Solutions for Rayleigh waves are assumed to decay with depth

below the surface and to be homogeneous plane waves whose

displacements are independent of the distance perpendicular to the

wave propagation direction. Therefore, the solutions are assumed to

be linear combinations of terms in the form

Ui = ai exp[iK(LiXi - vt )]

= ai exp[iKL3X3] exp[iK(Li XI + L2X2

(3.1.3)

vt )]

25

which satisfy the wave equation (3.1.1) and the traction-free surface

condition.

Conceptually, the term oci exp[iICL3X3] is regarded as the

"amplitude" of the solution which varies in the X3 direction over the

planes of constant phase.

The planes of constant phase are taken to

be perpendicular to the surface and to the propagation vector.

The

next term is taken as the wavelike properties. Thus, the propagation

vector is always assumed to be parallel to the surface so that L1 and L2

are assumed to be real and can be initially defined.

(outward normal

to the surface)

X3 (Z)

Surface

of material

Fiber direction

A

..........

L1= COS°

L2 = sine

Plane of Constant Phase

K Propagation Ve ctor

Fig. 3.1.1. Coordinate system for the Rayleigh wave propagation.

26

The quantity 1,3 should be such that the amplitude of all the

displacement components vanish as X3 ---> -00.

In other words,

L3 with a negative imaginary part can only satisfy the boundary

condition of zero displacement at infinite depth.

3.1.3. Secular Equation for Rayleigh Waves

The assumed solutions of the Rayleigh waves should satisfy the

wave equation (3.1.1).

Substituting eq (3.1.3) into eq (3.1.1), the

following homogeneous set of equations are obtained:

Ajk

8jk PV2

aj = 0

where Ajk = LiLinCijkm (i, j, k, m = 1, 2, 3).

(3.1.4)

Details are given in

appendix C.

In order to have nontrivial solutions, it is necessary that the

determinant of the coefficients be zero,

Ajk

8jk PV2

=0.

(3.1.5)

This secular equation can be regarded as a cubic equation in v2

with L3 as a parameter and the phase velocity v can be calculated from

the eigenvalue of tensor A.

Or the equation can be considered as a

sextic equation in L3 with v as a parameter.

For any specified value

of v, any root L3 of eq (3.1.5) gives a solution of eq (3.1.3).

In a

general anisotropic material, there are three pairs of complex

27

conjugate roots in this equation for each value of v. If the wave is

propagating on the plane of material symmetry, eq (3.1.5) becomes

bicubic due to material symmetry. However, the roots L3 with

negative imaginary part are taken to satisfy the boundary condition as

discussed in the previous section 3.1.2.

In case of isotropic

materials, all roots lie on the imaginary axis of the complex plane.

Therefore, three roots of

I.z3

should be combined together for

the assumed solution to eq (3.1.3) because they satisfy eq (3.1.5) and

each term has the same phase velocity v.

The assumed solution is

3

= ± Wn ap) exp[ iK(Li XI + L2X2 +L(3n)X3

vt)]

(3.1.6)

n=1

a.(n)= thee components of the eigenvector of eq (3.1.4)

according to the root Ij3n)

Wn = weighting factor.

These three weighting factors Wn should be determined by the

satisfaction of traction-free surface boundary conditions.

3.1.4. Boundary-condition Determinant

The boundary conditions at the surface are given as follows.

T3j = C3jkm

auk

axm =

at X3 = 0

(j=1,2,3)

(3.1.7)

28

Substituting eq (3.1.6) into the boundary conditions eq (3.1.7) and

setting X = 0 and t = 0 in order to omit the constant term,

3

T3i

C3 jkm Wn a(kn) i K 1(n11)

(3.1.8)

n =1

3

Ir

,c3Jkm 4,1) Om° Wni K =0

n=1

where L(in) = L1 and L2) = L2 for notation convenience.

Therefore, three linear homogeneous equations from the surface

traction-free boundary condition are given as follows.

B. W. = 0

1.1

(i, j = 1, 2, 3)

(3.1.9)

where Bij = C3ikm ak

In order to get a nontrivial solution, the determinant of the

coefficient should be zero.

IBij

I =0

(3.1.10)

It should be noted that the eigenvectors a(k) can be complex here.

The latter determinant " Boundary-condition Determinant " is

complex in general [291.

29

3.2. Numerical Solutions of Rayleigh Waves

3.2.1. Numerical Procedure

As discussed in section 3.1.3., there are three pairs of complexconjugate roots to eq (3.1.5) for each assumed value of phase velocity

in a general anisotropic material.

These roots L3 should satisfy eq

(3.1.4).

In other words, one of the eigenvalues of [

,

v

(i, j = 1, 2, 3)

should be equal to pv2 for any assumed value of v and propagation

direction. But the correct eigenvalue can be found only when wave

propagation direction is parallel or perpendicular to the fiber

direction.

Otherwise, the coupling of equations leads to calculation

errors during L3 root finding resulting in incorrect eigenvalues.

In order to get the correct eigenvalues and eigenvectors, a root

search method other than direct root finding will be used.

In

Fig.3.2.1, only half of eigenvalue plot is given and [ Ai) has three

eigenvalues for each negative imaginary value of L3.

In the case of

an isotropic material, two of three eigenvalues are equal, i.e.,

degenerated.

Here, "limit eigenvalue" EL can be defined as the

smallest eigenvalue at L3 = 0 and "limit velocity" VL can be given by

EL.

This means that the Rayleigh wave velocity VR is limited by

0 < V R < VL

VL,

(3.2.1)

where VL = 4/TTP .

Also, the limit velocity of an isotropic material is the shear velocity.

For an assumed phase velocity v, there are three intersections

between three eigenvalue plots and the "assumed eigenvalue" pv2

30

which is less than EL . Therefore, the root L3 can be found by a

suitable search algorithm for each eigenvalue.

Root Root

Root

Fig. 3.2.1. Finding three roots of L3 from an eigenvalue plot.

The Rayleigh wave velocity can be found when the boundary

condition determinant (BCD) is equal to zero as follows ( refer to Fig.

3.2.2.):

1) The search interval of the phase velocity should be carefully

selected from a rough plot of BCD.

Wide interval selection can

result in an wrong value of phase velocity because of the abrupt

change in the BCD value.

2) The interval is reduced until the specified tolerance is met.

The tolerance should be small enough to make both the real

and imaginary part value of the BCD close enough to zero.

If

the tolerance is not met, return to step 1 and select the other

interval.

31

start

)

.LIM111

Plot rough BCD value

Reduce search interval

by root finding algorithm

BCD value

is close enough to

zero ?

Yes

Plot displacements

Decay of

displacements

with depth?

Yes

Try

Another?

End

Fig. 3.2.2. Flow chart for numerical search procedure

of Rayleigh wave velocity.

32

3) After the velocity calculation, the displacement plot should be

checked to make sure that displacements decay with depth.

Otherwise, an incorrect velocity can be obtained.

3.2.2. Material constants

Typical material constants of graphite/epoxy are given in Table

3.2.1 [52,41].

Only 5 material constants are needed for a transversely

isotropic material and Tsai's index convention is used [71].

Table 3.2.1. Material constants for graphite/epoxy specimen with

60 % fiber volume fraction ( T300/5208 ).

Density

p

1.52 g / cm3

Poisson's ratio

v 21

0.31

v23

0.54

E1

138.5 GPa

E2

11.0 GPa

G12

6.3

Young's modulus

Shear modulus

GPa

3.2.3. Numerical results

For given material constants, the phase velocity of the

Rayleigh wave can be calculated by the numerical procedure given in

33

section 3.2.1.

Also, there are three body waves in anisotropic

materials as discussed in section 3.1.1: one quasi-longitudinal wave

( QL ) and two quasi-transverse waves ( QT ), which can be calculated

from eq (3.1.4).

Note that these body waves generally do not have

particle displacements which are purely parallel or perpendicular to

the wave propagation direction.

Therefore, the body waves of

anisotropic materials are generally neither longitudinal nor

transverse as those of isotropic materials [31].

If three velocities

are different, eq (3.1.4) implies that the vibration directions

corresponding to the three velocities are mutually perpendicular.

In Fig. 3.2.3.A and B, the QL wave always shows the highest wave

velocity.

The QL wave is about four times faster than the QT wave

when wave propagation is parallel to the fiber direction.

This

results from the high Young's modulus along the fiber direction.

For wave propagation perpendicular to the fiber, the QL wave

velocity approaches the value of the two QT wave velocities.

As expected, Rayleigh wave velocity is below the limit velocity

corresponding to the slowest body wave.

Rayleigh wave velocity

has its maximum 2.02 ( km/sec ) at 0 = 0°, and is continuously

decreased to its minimum 1.44 ( km/sec ) at 0

= 90°.

Displacements are given by the real part of the complex

solution of eq (3.1.6).

Note that the X axis is parallel to the fiber

direction and the Z axis is outward normal to the surface in Fig. 3.1.1.

The X and Y displacement solutions have only real parts and the Z

displacement solution has only an imaginary part.

This means that

34

10

Body wave QL, QT

Rayleigh wave

VELOCITY (KM/SEC), PARALLEL TO FIBER

Fig. 3.2.3.A Polar plot of Rayleigh and body wave phase velocities

in the unidirectional graphite/epoxy composite.

10

__

Body wave

Rayleigh wave

------- ------------------------------------- _

.............r-a-na,-..,

----------------------------------------------

10

20

30

40

50

60

70

80

90

ANGLE RELATIVE TO THE FIBER DIRCTION (DEGREE)

Fig. 3.2.3.B Rayleigh and body wave phase velocities in the

unidirectional graphite/epoxy composite as a function

of the wave propagation direction.

35

the Z displacement is ic/2 phase shifted relative to the X and

displacements.

Y

Therefore, for comparison with the X and Y

displacements, the Z displacement is plotted with an imaginary part.

From Fig. 3.2.4.A to 3.2.4.D, the right end of abscissa is the surface of

material and the left end is the inside of the material.

Note that the

absolute value of the calculation has no importance, and X, Y, and Z

displacements are normalized relative to the surface Z displacement.

There is no Y displacement when 0 = 0° and no X displacement when

0 = 90°, because of material property symmetry.

High stiffness of

the fiber makes X displacement relatively small and almost zero at a

depth lower than 0.1 wave length.

The Y displacement direction

changes between the surface and a depth of about 0.2 wave length.

The Z displacement shows a maximum value essentially at the surface

and disappears at a depth of about 5 wave lengths.

From 0 = 30° to

overall displacement patterns are similar and show only minor

changes of amplitude. When 0 = 90°, the displacement pattern of a

90°

,

unidirectional graphite/epoxy is exactly the same as that of isotropic

materials because the plane of wave propagation is transversely

isotropic.

Isotropic materials have no horizontal transverse displacement

component of the Rayleigh wave.

However, the unidirectional

graphite/epoxy has a horizontal transverse displacement component

and there is an angular deviation between the wave propagation

direction and the horizontal displacement vector.

When 0 = 30°,

angular deviation at the surface is about 25.7° as shown in Fig. 3.2.5.

36

1.2

X disp.

00000

Y disp.

Z disp.

0.8

0.6

0.4

0.2

0.2

5

4.5

4

3

3.5

2.5

2

1.5

1

0.5

0

DEPTH (Z) / WAVE LENGTH

A) 0 = 0°

1.2

X disp.

00000

1

Y disp.

Z disp.

0.8

0.6

0.4

0.2

0.2

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

DEPTH (Z) / WAVE LENGTH

B ) 0 = 10°

Fig. 3.2.4. Normalized X,Y, and Z displacements vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite

37

1.2

X disp.

00000

1

Y disp.

Z disp.

0.8

0.8

0.4

0.2

0

0.2

5

4.5

4

3.5

3

2.5

1.5

2

1

0.5

0

DEPTH (Z) / WAVE LENGTH

C ) 0 = 30°

1.2

1

0.8

0.6

0.4

0.2

0

0.2

5

4.5

4

3.5

3

2.5

2

1.5

1

0.5

0

DEPTH (Z) / WAVE LENGTH

D)

= 90°

Fig. 3.2.4. Normalized X,Y, and Z displacements vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite

38

At increasing value of depth Z, this deviation becomes larger toward

the Y axis and the X displacement approaches zero as shown in Fig.

The high Young's modulus along the X axis minimizes the X

3.2.6.

displacement inside the material resulting in the X displacement

rapidly reducing to near zero at about 0.1 wave length depth.

Stresses can be easily calculated using generalized Hooke's law

given as

T1 = Cijk,

aDUk

(i, j = 1, 2, 3)

(3.2.2)

The three normal stresses disappear at a depth of about three wave

lengths.

T11 ( ax ) is dominant when 0 = 0°, but T22 (6y ) is dominant

when 0 = 90°.

The stress plots shown in Fig. 3.2.7.A to 3.2.7.D were

normalized relative to the surface T22 for comparison and T11 can be

regarded as the average value assuming homogeneity of the graphite/

epoxy composite because the axial normal stress T11 of the fiber is

much higher than that of the matrix at the same elongation.

39

2

Wave Propagation direction

Displacement Unit Vector

1.8

1.6

E-

1.4

1.2

1

w

a.

0.8

4.1

0.6

0.4

rn

0.2

0

0

0.5

1

1.5

2

0 DEGREE (FIBER DIRECTION)

Fig. 3.2.5. Angular deviation at the surface between Rayleigh

wave propagation directions and horizontal

displacement vectors given every 10°.

40

L6

c:4

1.4

Displacement Unit Vector

Wave Length

1.2

E1

0.8

a.,

1:1-

0.6

44

0.4

A

rn

0.2

0

0

0.5

1

15

0 DEGREE (FIBER DIRECTION)

Fig. 3.2.6. Change of horizontal displacement vector at every

0.02 wave length depth relative to the Rayleigh wave

propagation direction.

41

60

50

0 0 0 0

40

6Z

30

20

10

.;

0

-10

-5

-4.5

-4

-3.5

-3

31,,

-2

-2.5

-1.5

711,111

-1

-0.5

0

DEPTH (Z) / WAVE LENGTH

A ) 0 = 0°

16

14

12

0000

10

8

6

4

2

0

2

-5

-4.5

-4

-3.5

-3

-2.5

-2

-1.5

-0.5

0

DEPTH (Z) / WAVE LENGTH

B ) 0 = 30°

Fig. 3.2.7. Normalized X,Y, and Z stresses vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite

42

ax

3.5

a

0 0 0 0

aZ

2.5

1.5

0.5

----------

-0.5

-5

-4

-4.5

-3.5

-3

-2

-2.5

-1.5

-1

-0.5

DEPTH (Z) / WAVE LENGTH

C) 0 = 60°

1

ax

0.8

0 0 0 0

a

aZ

0.6

0.4

0.2

0

-0.2

-5

-4.5

-4

-3.5

-3

-2.5

-2

-1.5

-1

-0.5

0

DEPTH (Z) / WAVE LENGTH

D) 0 = 90°

Fig. 3.2.7.

Normalized X,Y, and Z stresses vs. depth plot

for Rayleigh wave propagation in the unidirectional

graphite/epoxy composite

43

3.3. Formulation of Equations for Lamb Waves

3.3.1. Assumed Solutions for Lamb Waves

Lamb waves occur in relatively thin plates.

The coordinate

system for the Lamb wave problem here will be similar to that of the

Rayleigh wave problem with X3 (Z) as the outward normal to the

traction-free surface of the medium as shown in Fig. 3.3.1.

X3 (Z)

(outward normal

to the surface)

Fiber direction

Ll = COS°

L2 = sine

N----11°'

Plane of Constant Phase

K Propagation Vector

X

Fig. 3.3.1 Coordinate system for the Lamb wave propagation.

44

The axis X1 (X) is chosen along the fiber direction and

X2 (Y)

perpendicular to the fiber direction.

As before, the propagation

vector H lies at 0 degrees from the X1 (X) axis.

As with the Rayleigh wave solution, the solution for the Lamb

wave is assumed to be linear combinations of the terms of the form

U = A exp[iK(LiXi

vt )]

(3.3.1)

which satisfy the wave equation (3.1.1) and the traction-free surface

boundary conditions.

The propagation vector is always assumed to be parallel to the

surface ( L1 and L2 are assumed to be real and can be initially

defined ).

Displacements do not necessarily vanish at the bottom

surface similar to Rayleigh waves in the semi-infinite domain and

can have any amplitude as long as eq (3.1.1), eq (3.3.1), and the

traction-free surface boundary conditions are satisfied.

Therefore,

the quantity L3 can have either a positive or negative imaginary part.

3.3.2. Secular Equation for Lamb Waves

The assumed solutions of the Lamb wave should satisfy the

wave equation (3.1.1).

Substituting eq (3.3.1) into eq (3.1.1), the

following equation is obtained as found previously ( eq.3.1.4 ),

( Ajk

8jk pv2 ) aj = 0

(3.3.2)

45

where Ajk =LiLmCiikm (i, j, k, m = 1, 2, 3).

In order to have a nontrivial

solution, it is necessary that the determinant of the coefficients be

zero,

I Aik

8jk pv2 I = 0

(3.3.3)

.

This secular equation is also the same as that of the Rayleigh wave.

Therefore, six roots of L3 should be combined together for the

assumed solution eq (3.3.1) because they satisfy eq (3.3.3) and each

term has the same phase velocity v. The assumed solution is

I

6

tii =

wn 41) exp[ iK(Li Xi + 11X2 +II3n)X3

vt)]

(3.3.4)

n =1

where a.( `)= the components of the eigen vector of eq (3.3.2)

according to the root L(3n)

Wi, = weighting factor.

These three weighting factors Wn should be determined by the

satisfaction of traction-free surface boundary conditions.

3.3.3. Boundary-condition Determinant

With the enforcement of boundary conditions, the solution

procedure is similar to that for the Rayleigh wave.

The boundary

conditions at the top and bottom surfaces are given as follows.

46

auk

°

(j = 1, 2, 3 )

(3.3.5)

T3i = C3jkm axm = °

(j= 1,2,3)

(3.3.6)

T3j = C3jkm axm

at X3 =0

auk

at X3 = -h

Substituting eq (3.3.4) into the boundary conditions eq (3.3.5) and

setting X = 0 and t = 0 in order to omit the constant term,

6

E C3ikmwvvn ak

T3i

1K

(n)

(3.3.7)

n=1

6

E [C3jkm

=

Lm61) Wni K = 0

at X=0 &t=0

n =1

where Li = L1 and L2(n) = L2 for notation convenience

.

Again, substituting eq (3.3.4) into the boundary conditions eq (3.3.6)

and setting X1 = 0 = X2 & t = 0 in order to omit the constant term,

6

E

T3i =

(n)

(n)

C3jkm %lc ak

i KLm

exp(-iKL3() h)

(3.3.8)

n =1

6

E [C3jkm okn)

=

exp(-iKLV h)] Wni K = 0

n=1

at X = (0,0,-h) & t=

Therefore, six linear homogeneous equations from eq (3.3.7) and eq

(3.3.8) result from the surface traction-free boundary conditions and

are given as

47

Dij Wi = 0

(

j = 1, ..., 6)

where Dm" = C3mki C1") 11")

(3.3.9)

for m = 1, 2, 3

Dnin = C3 6,1_3 )ki a(11,1) L(in) exp(-iK041) h)

for m = 4, 5, 6

k, j = 1, 2, 3.

In order to get a nontrivial solution, the determinant of the

coefficients should be zero.

I

Dmn

l

=0

(3.3.10)

The latter determinant is the "Boundary-condition Determinant" for

Lamb wave propagation.

48

3.4.

Numerical Solutions of Lamb Waves

3.4.1. Numerical procedure

The search method for Lamb wave solutions is similar to that

of the Rayleigh wave except for minor differences.

Rayleigh wave

velocity has an upper limit, i.e., limit velocity VL, and L3 can have

negative imaginary values only.

The Lamb wave velocity is not

restricted by VI, and L3 can have a real or pure imaginary value

depending on the assumed velocity.

Therefore, a modified search

method is used for evaluation of Lamb wave velocities.

L3 is real

for solid lines and is pure imaginary for dotted lines in Fig. 3.4.1.

There are three intersections E1, E2, E3 of solid and dotted lines at

L3 = 0.

Four different search regions of L3 are divided as follows.

Region I

: 0 < pv2 < Ei

Region II

: El < pv2 < E2

,

4 imaginary roots & 2 real roots

Region III

: E2 < pv2 < E3

,

2 imaginary roots & 4 real roots

Region IV

: E3 < pv2

6 imaginary roots

6 real roots

The numerical search procedure given in Fig. 3.2.2 can also be used

for the Lamb wave velocity calculation, but the boundary value

determinant of the Lamb wave is different from that of the Rayleigh

wave and a modified search method of L3 should be used. Instead

of checking decay of displacement with depth, the displacement

pattern should be a symmetric or anti-symmetric mode as given in

the next section.

49

X10-5

E3

E2

El

Eigenvalues with imaginary L3

Eigenvalues with real L3

-1.5

1

0.5

0

0.5

1

15

L3 or L3/i

Fig. 3.4.1. Combined eigen value plot of [Aid] according to the

L3 value.

50

3.4.2. Numerical Results

The Lamb wave has a different phase velocity depending on

the propagation direction as with the Rayleigh wave but is dispersive

unlike the Rayleigh wave. The phase velocity v of the Lamb wave is

related to wave number K, wave length X, period T, and frequency co

as follows:

v=

co

K

= 27r

- X- =

X,

T 27c

(3.4.1)

T

For a dispersive wave, the relationship between phase velocity and

wave length X is nonlinear. There are an infinite number of

solutions satisfying eq

and eq (3.3.10) for the given values of

plate thickness h and wave length X. They can be divided into two

(3.3.3)

groups as for Lamb waves in isotropic materials.

When the vertical

Z displacement is symmetric about the central plane of the plate, it

is called the " symmetric mode".

If the Z displacement is antisymmetrical about the central plane of the plate, it is called the

"anti-symmetric mode" corresponding to flexural vibrations of the

plate.

First two symmetric modes So, S1 and anti-symmetric modes

Ao, Al are given for the cases of 0

= 0°, 45°,

90°.

When 0 = 0°, the Ao

mode velocity is continuously increasing and approaches the

Rayleigh wave velocity as ha increases as shown in Fig. 3.4.2.A.

The So mode velocity approaches the QL wave velocity when the

plate is very thin (11/A 0) and approaches the Rayleigh wave velocity

as the plate becomes thicker.

When 0 = 45° in Fig.

3.4.2.B,

the So

51

10

-

9

SYMMETRIC MODE

ANTISYM. MODE

8

7

6

2

5

4

O

3

2

1

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

1.8

2

PLATE THICKNESS ( h ) / WAVE LENGTH

A) 0 = 0°

7

SYMMETRIC MODE

6

ANTISYM. MODE

5

4

3

2

1

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

PLATE THICKNESS ( h ) / WAVE LENGTH

B) 0 = 45°

Fig.3.4.2. Lamb waves propagation in the unidirectional

graphite/epoxy composite plates

52

mode velocity has reduced significantly compared with Fig. 3.4.2.A

The Al mode velocity of a very thin ( hA - 0) plate approaches the

QL wave instead of the So mode velocity.

.

When 9 = 90°, Ao and So

modes in Fig. 3.4.2.0 show the same dispersion pattern as those for

an isotropic material as given in Fig. 3.4.3.

This reflects that the

wave propagation plane is transversely isotropic as expected.

As the thickness of the plate increases, the velocities of Ao

and So modes of every plot converge to the Rayleigh wave velocity.

As hA increases, Al and S1 mode velocities approach the QT wave

velocity.

When the plate is thick enough, the Rayleigh wave on

one surface can be regarded as a linear combination of Ao and So

modes, and vise versa in isotropic plates [73].

The same

interpretation can be applied to the composite plate.

The Ao

mode velocities are continuously increasing and reach 90% of the

Rayleigh wave velocity at h/2t, 0.5 regardless of the wave

propagation direction as shown in Fig. 3.4.4.

The So mode

velocities for a very thin plate ( hA < 0.4 ) are close, but show a large

rise very close to the fiber direction ( 0° 5 9 < 10 °) in Fig. 3.4.5.

53

3

SYMMETRIC MODE

-------

ANTISYM. MODE

2.5

SI

2

So

1.5

1

0.5

0

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

PLATE THICKNESS ( h ) / WAVE LENGTH

C) 0 = 900

Fig.3.4.2. Lamb waves propagation in the unidirectional

graphite/epoxy composite plates

PLATE THICKNESS ( h ) / WAVE LENGTH

Fig. 3.4.3. Lamb waves propagation in the aluminum plate.

54

PLATE THICKNESS ( h ) / WAVE LENGTH

Fig. 3.4.4. The Ao mode velocities by the change of wave

propagation directions in the unidirectional

graphite/epoxy composite plates.

10

0=0°

0000

8 =45°

8 =90°

3

2

---------- ------------ ------------------------------------------

1

oo

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

2

PLATE THICKNESS (h)/ WAVE LENGTH

Fig. 3.4.5. The S0 mode velocities by the change of wave

propagation directions in the unidirectional

graphite/epoxy composite plates.

55

CHAPTER 4

EXPERIMENTS

4.1.

Experimental Arrangement

Schematic diagrams of the experimental setup for single and

dual sensors are shown in Fig. 4.1.1 and Fig. 4.1.2, respectively.

Velocity measurements using these two methods will be compared

in section 4.4.

The experiments were conducted using a laser

ultrasonic wave generation system, wave detection sensors ( piezoelectric pin transducers ), and a high-speed digital data acquisition

system.

The ultrasonic wave generation system consists of a ruby laser

with its remote control unit.

The ruby laser produces a light pulse

with a wave length of 0.694 gm, a pulse duration of about 30 nsec, a

maximum energy of 1.2 J, and a beam diameter of about 11 mm.

It is

operated in a Q-switched mode in order to generate a strong single

impulse onto the specimen.

The remote control unit, which can

provide a trigger signal to the digital oscilloscope, is used to set the

laser power level and control the pockel cell operation.

The