STANDARD SPECIFICATIONS FOR CONSTRUCTION OF TRAILS AND TRAIL

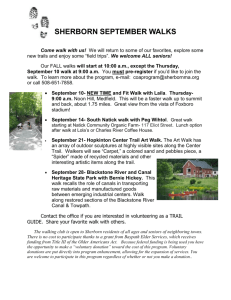

advertisement