EXPERIMENTAL INVESTIGATION OF TEARING FRACTURE ... SHEETS UNDER QUASI-STATIC LOADING

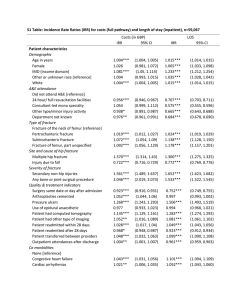

advertisement