Fuente Filter For Beverage Applications Data Sheet

advertisement

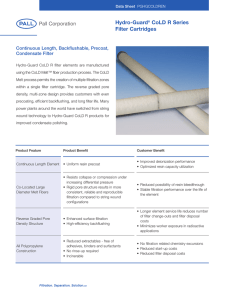

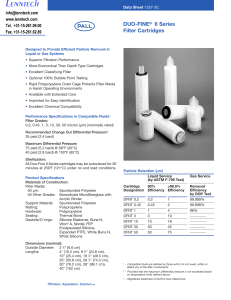

Data Sheet FBDSFFEN Fuente Filter For Beverage Applications Description The Fuente water filter is designed to meet the highest requirements of water bottlers for removal of particles, cysts, oocysts and bacteria in water filtration applications. It is a validated, 0.2 µm polyethersulfone membrane filter utilizing the unique Ultipleat® construction. Fuente filters last longer and provide high water quality at the lowest cost of ownership. Customer Benefits • Excellent Water Quality • Extended Filter Life • Validated Performance • Multiple Autoclave Cycles Toleration • Greater Differential Pressure Toleration • Small Footprint • No Liquid Waste Discharge • Lower Filtration Costs Filter Cartridges Features • Patented Ultipleat Construction – Greater Filter Area and Higher Production Per Unit Footprint • Filtration Media – Supor® Polyethersulfone • 0.2µm Membrane • Built in Asymmetric Prefilter Layer for Longer Life and Lower Filtration Costs • Differential Pressure Toleration – 1 bar (14.5 psi) During Steam in Place Quality Standards • Validated with Brevundimonas diminuta (ATCC 19146) at 107/cm2 • Manufactured Under a Quality Management System Certified to ISO 9001:2000 • Tested to Meet EEC Directive 2002/72/EC • Materials Per 21 CFR: 170-199 Housings Filter Specifications Materials of Construction Membranes Hydrophillic Polyethersulfone (PES) Support Drainage Polypropylene Core/Cage End Caps Polypropylene, TiO2 O-rings Silicone Elastomer (standard) Sealing Technology Thermal Bonding, No Adhesives Adaptor (Code 7) Polypropylene with Stainless Steel Reinforcing Ring Nominal Filter Dimensions Filtration Area 0.6 m2 (6.5 ft2) per 10" module Outer Diameter 2.75" (70 mm) Lengths Available 10" (254 mm); 20" (508 mm); 30" (762 mm); 40" (1016 mm) Operating Parameters* Clean Water Flow1 12.5 L/m (2.61 gpm) at 100 mbar (1.45 psi) differential pressure per 10" Maximum Differential Pressure (to 40˚C) 5.5 bar up to 104˚F (40˚C) (forward) Maximum Differential Pressure (to 80˚C) 4 bar up to 176˚F (80˚C) (forward) Maximum Steam Sterilization Temperature2 287˚F (142˚C) Maximum Hot Water Sanitization Temperature 185˚F (85˚C) Chemical Sanitization PAA (320 ppm total peroxides – 1000 hr) * Applies to fully compatible fluids which do not soften, swell or adversely effect the product or its materials of construction. 1 Typical performance with water at 68˚F (20˚C) (1cP) on a new filter in laboratory test. 2 On wetted filters with slow exhaust. Part Numbers/Ordering Information AB● FF ■ W ◆ Code ● 1 2 3 4 Cartridge Lengths (nominal) 10" (254 mm) 20" (508 mm) 30" (762 mm) 40" (1016 mm) Code ■ Cartridge Style 7 SOE Fin End, External 226 O-rings 3 SOE Flat End External 222 O-rings 8 SOE Fin End External 222 O-rings Code ◆ O-ring Material H4 Silicone elastomer J EPDM elastomer Pall Food and Beverage Visit us on the Web at www.pall.com/foodandbev New York – USA +1 516 484 3600 +1 866 905 7255 Pall Corporation has offices and plants throughout the world in locations including: Argentina, Australia, Austria, Belgium, Brazil, Canada, China, France, Germany,India, Indonesia, Ireland, Italy, Japan, Korea, Malaysia, Mexico, the Netherlands, New Zealand, Norway, Poland, Puerto Rico, Russia, Singapore, South Africa, Spain, Sweden, Switzerland, Taiwan, Thailand, United Kingdom, United States, and Venezuela. Distributors are located in all major industrial areas of the world. telephone toll free foodandbeverage@pall.com © Copyright 2012, Pall Corporation. Pall, , and Supor are trademarks of Pall Corporation. ® Indicates a Pall trademark registered in the USA. is a service mark of Pall Corporation. * Select-A-FAX is a registered trademark of CyberData, Inc. FBDSFFEN March 2012