Document 10552183

advertisement

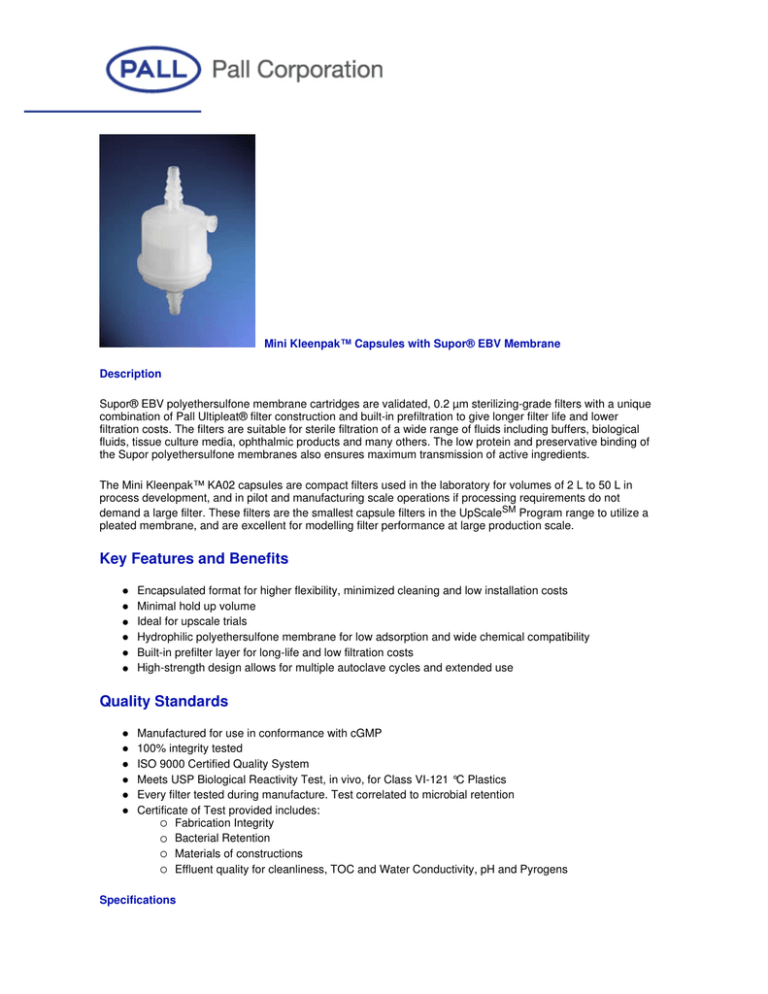

Mini Kleenpak™ Capsules with Supor® EBV Membrane Description Supor® EBV polyethersulfone membrane cartridges are validated, 0.2 µm sterilizing-grade filters with a unique combination of Pall Ultipleat® filter construction and built-in prefiltration to give longer filter life and lower filtration costs. The filters are suitable for sterile filtration of a wide range of fluids including buffers, biological fluids, tissue culture media, ophthalmic products and many others. The low protein and preservative binding of the Supor polyethersulfone membranes also ensures maximum transmission of active ingredients. The Mini Kleenpak™ KA02 capsules are compact filters used in the laboratory for volumes of 2 L to 50 L in process development, and in pilot and manufacturing scale operations if processing requirements do not demand a large filter. These filters are the smallest capsule filters in the UpScaleSM Program range to utilize a pleated membrane, and are excellent for modelling filter performance at large production scale. Key Features and Benefits Encapsulated format for higher flexibility, minimized cleaning and low installation costs Minimal hold up volume Ideal for upscale trials Hydrophilic polyethersulfone membrane for low adsorption and wide chemical compatibility Built-in prefilter layer for long-life and low filtration costs High-strength design allows for multiple autoclave cycles and extended use Quality Standards Manufactured for use in conformance with cGMP 100% integrity tested ISO 9000 Certified Quality System Meets USP Biological Reactivity Test, in vivo, for Class VI-121 °C Plastics Every filter tested during manufacture. Test correlated to microbial retention Certificate of Test provided includes: Fabrication Integrity Bacterial Retention Materials of constructions Effluent quality for cleanliness, TOC and Water Conductivity, pH and Pyrogens Specifications Materials of Construction Membrane Layers Serial layer polypropylene Support and Drainage Polypropylene Capsule Polypropylene Vent Polypropylene Sealing Technology Thermal bonding without adhesive Operating Parameters1 Maximum Operating Pressure 4.1 bar (60 psi) at 30oC Maximum Operating Temperature 60oC at 2.1 bar (30 psi) 1 In compatible fluids which do not soften, swell or adversely affect the filter or its materials of construction Sterilization Autoclaving at 125oC 3 cycles x 30 minutes Gamma irradiation Maximum 50 KGy* * For G option only Warning: Pre-sterilized products should not be resterilized. This product must not be sterilized in-situ by passing steam through under pressure Extractables < 1 mg in water at 20oC Nominal Dimensions Height 10.4 cm (4.1 in.) Diameter 5.1 cm (2.0 in) Typical Effective Filtration Area 200 cm2 (0.2 ft2) Typical Water Flow Ordering Information Pall Part Number Description KA02EBVP2G Suitable for autoclaving or Gamma irradiation with stepped hosebarb ½ in. to ¼ in. connections and filling bell*, 3 per box KA02EBVP2S Pre-sterilized hosebarb ½ in. to ¼ in. connections and filling bell*, 3 per box * Filling bell is removable for in line use Contact Information © Copyright Pall Corporation Visit us on the Web at www.pall.com