Safety Information for Staff and Students

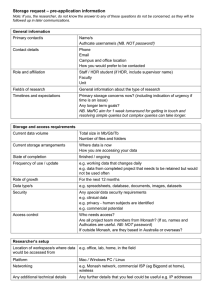

advertisement