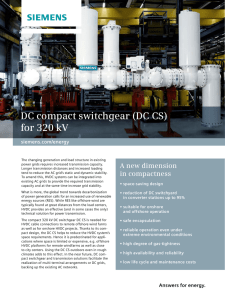

Win-TDC: Siemens HVDC Control & Protection System

advertisement