Master of Science in Civil Engineering

advertisement

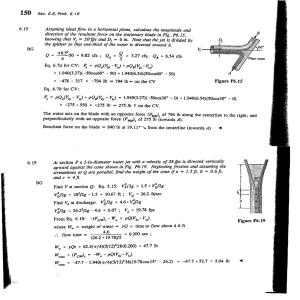

EXPERIMENTAL STUDY OF SUBMERGED SINGLE-PORT THERMAL DISCHARGES by GAROLD EUGENE KOESTER AB, University of Idaho (1968) SB, University of Utah (1972) Submitted in partial fulfillment of the Requirements for the Degree of Master of Science in Civil Engineering at the Massachusetts Institute of Technology May 1974 Signature of Author.., Dep drtment of Civil Engineering, May 10, 1974 Certified by Thesis Supervisor ................. Accepted by. Chairman, Departmen*(d'l Committee on Graduate Students of the Department of Civil Engineering ARCHIVES AUG 1 1974 4-IRARIF-9 ACKNOWLEDGEMENTS To E. Eric Adams, Graduate Research Assistant, whose guidance and constructive counsel were of inestimable help, gratefully give my most sincere thanks. Rosenson, undergraduate student, I owe and The assistance of Joseph is acknowledged. Supervision was provided by Prof. D. R. F. Harleman, Professor of Civil Engineering, and the manuscript was typed by S. Demeris. -2- ABSTRACT EXPERIMENTAL STUDY OF SUBMERGED SINGLE-PORT THERMAL DISCHARGES by GAROLD EUGENE KOESTER Submitted to the Department of Civil Engineering on May 10, 1974 in partial fulfillment of the requirements for the degree of Master of Science in Civil Engineering An experimental investigation of the temperature field induced by the heated effluent from a submerged single-port discharge is conducted. Primary emphasis is directed to the study of the interaction of a shallow water jet with the bottom and the free surface. The parametric Froude number Foranged between 4.9 and 15.7, the relative water depth H/D0 ranged between 1.9 and 6.3, the relative crossflow v/uo ranged between 0.020 and 0.074, and the relative discharge submergence z/H ranged between near surface (z/H = 0) and near bottom (z/H ~ 1). Graphic dimensionless relationships among the pertinent parameters are presented to illustrate the jet's behavior and for use in the preliminary design of shallow water thermal outfalls. Reasonable correlation has been found at large relative water depths with the analytical prediction of Stolzcnbach et al (1972). The non-dimensional relative jet penetration depth parameter hmax/H is introduced to define a discharge configuration as a hydrodynamically deep water or shallow water situation. Thesis Supervisor: Donald R. F. Title: Harleman Professor of Civil Engineering -3- TABLE OF CONTENTS 1'11TLE PAGE 1 ABSTRACT 2 ACKNOWLEDGEMENTS 3 TABLE OF CONTENTS 4 I INTRODUCTION 5 II THEORETICAL BACKGROUND 8 2.1 2.2 General Characteristics Mathematical Analysis 2.2.1 2.2.2 III EXPERIMENTAL EQUIPMENT AND PROCEDURES 3.1 3.2 3.3 3.4 IV Experimental Program Experimental Limitations Experimental Set-up Procedure and Data Acquisition 10 17 27 27 30 31 33 EXPERIMENTAL RESULTS 35 4.1 4.2 Introduction Single-port Discharge Without Crossflow 35 39 4.2.1 4.2.2 4.2.3 39 55 66 4.3 V Round Buoyant Jet Buoyant Near-Surface Discharge 8 10 Near-Surface Discharge Discharges with Variable Submergence Summary Single-port Discharge with Crossflow 73 4.3.1 4.3.2 73 83 Near-Surface Discharge Near-Bottom Discharge 88 SUMMARY AND CONCLUSIONS NOMENCLATURE 92 LIST OF FIGURES 96 100 REFERENCES -4- I iNTRODUCTION The large quantities of waste-heat discharged from steam electric power plants is a consequence of the low efficiency at which they operate. Present levels of efficiency are about 40% for fossil fuel plants and about 33% for nuclear-plants. Water, being the only economic cooling fluid for steam condensers, is the medium by which this heat is rejected to the environment. High concentrations of heat in natural bodies of water can be detrimental to the aquatic life and natural chemical processes. For this reason, governmental agencies have imposed criteria regulating thermal discharges. A usual criterion of temperature regulations is that large induced temperature rises are restricted to a mixing (dilution) zone, defined as the area in the immediate vicinity of the point of discharge where the heated effluent is diluted with the receiving water. In this respect, the type of hydraulic structure used for the discharge of heated effluent has an important effect on the temperature distribution in the water environment; it determines the hydraulic characteristics of the discharge which govern the rate of dilution. In general, the rate of dilution is a function of the existing turbulence and velocity of the receiving water, the turbulence induced by the kinetic energy of the effluent, and the density difference between the effluent and receiving water. The areal extent of the temperature distribution is a function of the dilution rate plus the number and orientation of ports in the discharge structure. -5- __ ...... .......... Heated effluents are often discharged into water bodies which are shallow relative to the characteristic size of the discharge port. This occurs because the large quantities of heated effluent require discharge sources of large dimension. It is possible to construct hydraulic structures that induce surface spreading with minimal mixing. Consider a surface discharge characterized by surface spreading at low Froude numbers. The region of temperature increase tends to be localized because the rate of heat transfer to the atmosphere is great. total mixing, temperature By avoiding the volume of water which has a higher than normal is minimized. On the other hand, hydraulic structures can be constructed to achieve complete mixing with possible storage of waste heat below thermoclines. In shallow water, surface and submerged discharges at high Froude number exhibit similar temperature distributions. The general feature is that the mixing zone extends from the water surface to the bottom of the receiving body over long distances. With the extensive mixing, the tem- perature rise above the ambient is minimized, although the volume of water affected by a temperature rise is greatly increased. Heat dissipation to the atmosphere is reduced by the lower surface temperature. When mixing devices are used to keep temperature rise within allowable limits, there is likely to be a corresponding reduction in the heat flux from the water to the atmosphere by all processes: conduction. radiation, evaporation and The alternatives elected should depend on the -6- predicted ecological effects of the heated effluent. With this engineering decision in mind, this study is presented as part of the continuing research effort to understand and predict the behavior of thermal discharges at the Ralph M. Parsons Laboratory. Due to the complicated flow pattern which results from the interaction of a shallow water jet with the bottom and the free surface, a quantitative analysis of either surface or submerged bouyant jets in shallow water is beyond the scope of this study. The nature of this investigation is ex- perimental and addresses the problem of predicting temperature concentrations in a large body of water induced by the heat flow from a single port discharge structure. The objective is to present graphic dimensionless relationships of the pertinent parameters describing the heat flow with emphasis on the near surface configuration in a shallow body of water. Application of this study is anticipated to aid in the preliminary design of shallow water thermal outfalls. -7- 11 THEORETICAL BACKGROUND 2.1 General Characteristics A single-port discharge is in essence a round-buoyant jet. The physical processes that dominate its hydrodynamic behavior under unconfined conditions are generally grouped into three separate regions, see Figure 2-1. The NEAR FIELD processes are governed by the dynamic and buoyant characteristics of the discharge and of the ambient water in the immediate vicinity. Very near the outfall the fluid motion is dominated by inertia forces arising from the initial flux of momentum and is characterized by shear-generated free turbulence which induces entrainment flow of the ambient water into the jet. The increasing flow of the jet is diffused with a simultaneous reduction of velocities and temperature. Entrainment continues until the jet velocity is reduced to a velocity comparable with that of the ambient water. The buoyancy forces tend to deflect the axis of the jet toward the free surface or, as in the case of a near-surface jet, resist its vertical penetration. The second region is the TRANSITION between the near field and the far field. Further dilution of temperature due to en- trainment effectively ceases at this point. A stable region is achieved that is characterized by vertical stability of the surface layer of mixed water. currents, Buoyancy forces, generating density and the ambient currents convect the mixed water away from the near field. -8- Far Field Transition Near Field- Ix 4 z H D 0/ / / Figure 2-1: / /~ 77 /~/ / / / / / / / / Region of Physical Processes that Govern a Single-port Thermal Discharge / In the FAR FIELD the convection of the mixed water continues to be dominated by the ambient currents. Additional temperature decrease occurs through diffusion which is generated by ambient turbulence and through surface heat loss to the atmosphere which is the ultimate heat sink. This study pertains primarily to the near field phenomena. 2.2 Mathematical Analysis The mathematical analysis of a buoyant jet aims at a description of the jet flow field, temperature field and trajectory as a function of ambient flow parameters, initial jet parameters, and experimentally determined coefficients, see Figure 2-2. 2.2.1 Round Buoyant Jet For a round buoyant jet the governing equations of fluid motion and heat conservation are formulated under the following assumptions: a) The flow is steady: b) Fluctuating turbulent quantities are small compared a/Dt = 0. to the mean. c) Turbulent eddy velocities are the dominant transport mechanism. d) Viscous effects are neglected: e) The Baussinesq approximation is applied: Large Reynolds number. P -10- << 1 y x Ta 'a s AT 0r T op ,u 0 u Vb E) C D e Figure 2-2: Definition Diagram for Round Buoyant Jet -11- The time-average equations of motion are: Continuity (2-1) (rv) + Du = 0 as r Dr Axial Momentum: P a U~u + as pvu a ar _P + pg sine s a D (ru'v') r ar - p a v as (2-2) Radf.al Momentum: u3v Pa as +a -,2 a a r ara aP r vav ar au'v' as (2-3) Heat Conservation BT aT + v UT 1D __a-U'T' -r sT _ (rT'v') (2-4) in which s,r - cylindrical coordinates, D/a4 = V u,v - mean velocities in s,r directions u' ,v' - velocity fluctuations in s, r directions p - mean local density pa - constant ambient density T = mean temperature T' = temperature fluctuations 6 = angle between x axis and a axis The main properties of the jet flow field make simplification of the governing equations possible. -12- They are: a) The pressure around the jet is hydrostatic. b) The increase of mass flow rate is equal to the entrainment of ambient fluid per unit length of jet. c) The boundary layer approximation is utilized. Convection by transverse velocities are small compared to convection by axial velocities. Diffusion in the axial direction is small compared to diffusion in the transverse direction. d) A consequence of the first assumption is that horizontal momentum of the jet is conserved. e) There is a similarity of flow. Velocities, temperature and density can be described very closely by Gaussian distributions, i.e., by equations of the form u(r,s) = uc(s)exp[-K(r/s) 2 AT(r,s) = (2-5) uc (s)exp[-KX(r/s) ] (2-6) Ap(r,s) -Apc (s)exp[-KA(r/s) 2] (2-7) where u(r,s) - the local velocity u C(s) - the velocity at the centerline AT(r,s) = the local temperatur e rise; ATc (s) = temperature rise at the centerline; AT =(T O-T a Ap(r,s) Ap c(s) the local density de ficit; Ap = AT = (T-Ta (pa - p) density deficit at the centerline; Apc =(pc-po) K and A = experimentally determined dimensionless coefficients describing the gross effects of the turbulent mixing process. -13- The density of the water is assumed to vary linearly f) with temperature p(T) pa - a(T-Ta)] where S is the coefficient of thermal expansion. (2-8) The concentration of the heat, ch, in the jet water is formulated in terms of density as P ch -p (2-9) hp a - p O Due to the entrainment of ambient water, the degree of dilution, D, is commonly defined as D C h p - p a 0 P -p (2-10) a where the local density p P = the density of the ambient fluid p - the density of the jet fluid Substituting Equation (2-8) into Equation (2-10) the temperature dilution is obtained T D -T T a T -T a (2-11) where T = the local temperature Ta = the ambient temperature T = the jet temperature at the jet exit The simplified governing equations become: -14- Continuity: r (rv) + au 0 as- (2-12) Momentum: uau+ vu o pg sine - 1a(r-uv-) r Dr ar s I ; -F2 (ra- 2 pg cosO rr (rv ) - (2-13) (2-14) Conservation of Heat: U sT + v ar-T - L(rT'v') r ar (2-15) With the boundary conditions: =0 v 0 u'vi as r AT =0 T'v' - W 0 The continuity equation, assuming small variation in density, can be expressed as d where 2u(s,r)rdr - Q'( (2-16) Q' is the rate of entrainment of the ambient water per unit length of the jet. The equation for the conservation of heat is d 2Tu(s,r)T(s,r)rdr ds TO si /~ = (2-17) 0 -15- fL The conservation of momentum equation in the horizontal direction is 21pu2 s,r)rdr cose -0 (2-18) o2 The conservation in the vertical direction is expressed by the equation 2Tpu 2 (s,r)rdr - g sinO f ds f 27T[p - p(s,r) rdr (2-19) where (2-8) p(T) - pa[1-(T-Ta)] Temperature, density and velocity along the trajectory of the jet are usually obtained as follows: 1) The assumed profiles, Equations (2-5) to (2-7), are substituted into the conservation equations. 2) Q1 in the conservation of mass equation is approximated by Q- -2nbv (2-20) -(Iu (2-21) where v - and hence (2-22) Q= 2nbauc where a is an experimentally determined entrainment coefficient and b is a local width of the jet, usually taken as b - (2-23) s -16- 3) The resulting ordinary differential equations are then solved Ap , and uC using the initial for ATc) conditions AT 2.2.2 discharge Apo, and u. , Buoyant Near Surface Discharge The engineering importance of the submerged jet as a means of dilution and disposal of heated water in large bodies of water has motivated numerous analytical and experimental studies. Of particular interest is a numerical model for determining jet properties at various distances from a buoyant near surface discharge in unconfined and unstratified water by Stolzenbach et al (1972). Their model considers a discharge Q water at temperature T of heated and density p0 from a rectangular open channel of depth h0 , width 2b0 , and initial horizontal angle 0 at the surface of a receiving body of water at temperature Ta, density pa and of large extent. A non-uniform current V may be present and it is assumed that the bottom of the receiving water does not interfere with the vertical development of the With the assumptions presented in Section 2.2.1 surface jet. the basic equations of mass, momentum and heat conservation may be simplified in rectangular coordinates: Continuity: S+ ax Dy + az = 0 (2-24) x-Momentum: 2 + ax + ay u 9z g ax -17- dz - au'v' y Du'w' az (2-25) y-Momentum: + + - g dz + u2 3z yax x Cs (2-26) Heat Conservation: r)uT + kvT + wT _ 3x y az - Dw'T' 5z 5y (2-27) The technique used to develop the solution of these equations is to assume a structure for the velocity and temperature within the aiocharge and boundary conditions at the outer edges. The structure of the discharge is shown in Figures 2-3 and 2-4. The longitudinal velocity and temperature distributions are taken to be as follows, where Tris the water surface elevation: u = u + VcosO AT - AT u = Q<jyj<s c u fc ) + Vcose O<jyj<s AT = AT t(C ) u =u f(c ) + Vcos6 c y s<IyI<s+b AT = ATc y ) u = uc f(y ) z) + VcosO s< y j<s+b AT = AT t(c )t( Z) where y f bb . and -z-r z = h -18- -(r+h)<z<-r (2-28) Cross Flow = V = V(x) kIlt H E) ATO o I- 2 0V ~1 e y N Top View **,*N b+s x y 0 z ATO u Jet Centerline .x IV 0 f Jet Boundary 'I Figure 2-3: Coordinate Definitions z h S r 0 AT c x _ - - h Side View I_~' ___ Region Veloci ty Distribution vC Temperature Distribution v 4go I.' 0 b boisLJci x K --- _ - Top View Figure 2-4: Discharge Structure jRegion 1 Rego Cross Section The lengths r and s pertain to the initial core region and h and b to the turbulent region of the jet (see Figure 2-4). The particular forms of the similarity functions are assumed to be as follows: (2-29) i? -1 t(Q) The lateral velocity is geometrically related to the longitudinal velocity by: - u (2-30) tan $ where $ is the lateral jet stream line angle from the centerline in excess of the non-buoyant value. v db + (f - E)u C 1/2 Then s<|yi<s+b (2-31) v 0 elsewhere where the following conditions are satisfied: 0 at y = 0 1) tan$ 2) tan $ = ( dx ) at y = b+s, where e is the lateral spreading rate of a non-buoyant jet under the same conditions. Since the gravitational spread is induced by the lateral temperature gradient, the y dependence of is used to distribute tan $ between y = 0 and -21- y = b+s. The boundary conditions are then given to be v = u'v' = v'T' = 0 y = 0 (2-32) -r (2-33) jyl=s (2-34) uw' = 0 w = wr r <yl<s z W - Wh W s+b< y I W0 0 =+ vs v s< Iyt<s+b y) u'V't v v- = -r<z<l -(r+h)<z<-r + v Sb (Z) V~ 0 z<-(r+h) u + vT ax W Dy z = fl (2-35) z = (2-36) u'w' - 0 w'T' k(T - T ) 11 The outer boundaries of the jet occur at the entrainment surface where no heat is transferred. The boundary conditions are: u'w' = w'T' = 0 w = e dh - Vcos --dx W = w f( e y - 0<Iyl<s z = -(r+h) dh Vcosq d dx s<IyI<s+b -22- (2-37) u'v' = v'T' = 0 v =+ v + Vcos -+e -r<z<Tl -d dx y v - + v f (C ) + Vcose --where w e z e - and v e = s+b (2-38) -(r+h)<z<-r dx are the entrainment velocities. The entrainment velocities are assumed to be given by V uC we gAT Ch mz a h exp[-C U z2 C c (2-39) 1C uc where the exponent is in the form of a Richardson number. The entrainment coefficients, a y and (x , are determined such that z the solution for the non-buoyant case (T0 = T ) agrees with the experimental observations that the growth of a non-buoyant turbulent region is symmetrical: db dh dx dy (2-40) ds _dr dx dx For non-buoyant jets discharging into a quiescent receiving water the spread rate, e , is constant. In these cases = 0.22 for the similarity functions, f and k, used here. 6 boundary conditions at x = The 0 are related to the discharge channel geometry, the flow rate Q , and the initial discharge temperature T. 0 -23- r =h s -b h -b -0 U M U - 0 0 h 2h b + Vcos 00 AT - AT C 0 x-0 (2-41) 0 0 x =0 -y Using their numerical model, Stolzenbach et al found the following trends in the stable region of the surface jet, for F > 3: 0 AT -A AT D - IF ' o -1.4 5 (2-42) AT 0-) (AT ac a F (2-43) and h max 0.42 F ' (2-44) XiT 00 where AT o (AT) 8- T 0 - T a average fractional stable excess surface temperature rise in the jet (AT s = stable surface centerline temperature rise -24- F densimetric Froude number - u //g' 0 - 0 A 0 aspect ratio - h /b m o1/4 IF u //g'(hb) 0 u 0 0 0 to F A 0 discharge velocity m - Q /2h b 0 00 - maximum vertical penetration of the jet. h max The circular discharge (Single-port) structure can be schematized so as to be used in their predictive model. The geometric form of the discharge is described by an aspect ratio h A (2-45) 0 where a) h h is the actual maximum discharge channel depth; b) 0 b =D 0 is such that the correct discharge channel area is preserved: b o channel area 2h (2-46) 0 -h Hence 2h 2 A0 channel area The aspect ratio of a circle is A -25- 2.55. See Figure 2-5. , , , ATApQ 0 , , 0 0 ,~ / / h / max / / I~ / / my / , Figure 2-5: f f / / / / / / Schematic of the Single-port Heated Discharge / / / / III EXPERIMENTAL EQUIPMENT AND PROCEDURES 3.1 Experimental Program The experimental program considers a discharge water at temperature T diameter D Q of heated and density p0 from a circular pipe of at the edge of a receiving body of water of large extent, whose temperature Ta, density pa and depth H are uniform. A uniform current v may be present in the receiving water and is parallel to the shoreline. See Figure 3-1. For the results of the experiments to be relevant to field conditions, the correct scaling laws were observed. Dimensional analysis and a study of the equations governing turbulent jet behavior provide the dimensionless parameters which must be modeled. In this study the scaling length is the diameter of the outfall, D . Stolzenbach has shown that the basic scaling length should be proportional to the square root of the discharge flow area 2h b . In his study this length is taken as the square root of one half of the discharge flow area, h bT. 0 0 From Equations (2-45) to (2-47) VU Ab 0 0 0.63 D (3-1) 0 Since entrainment increases with increasing jet momentum and decreases with increasing jet buoyancy, the densimetric Froude number F is used as a parameter for jet induced mixing. The densimetric Froude number is defined by -27- z h H D0 7 Side View 77 Ambient Crossflow V -- L]c DT 0 Plain View Figure 3-1: Schematic of Heated Discharge -28- I u = IF S (3-2) 0 /g'D0 where g' = (p0 - Pa /Pa)g is the reduced acceleration of gravity at the discharge port. A more general Froude number is the Aspect Densimetric Froude number which has been defined as F' o - I 0 A1/4 = u /g (3-3) AT0b0 It incorporates the geometric as well as the dynamic characteristics of the discharge into one parameter and is useful when applying the results of this study to other discharge configurations. The dimensionless water depth parameter is H/D0, the relative discharge submergence is z/H and the crossflow parameter is v/u . The remaining dimensionless parameter characterizing the discharge is the Reynolds number, IRe, defined as: u D R e (3-4) V in which V is the kinematic viscosity of water. In many free shear flows the gross characteristics of the flow fields are independent of Reynolds number provided that the Reynolds number is great enough for the flow to be turbulent throughout. -29- 3.2 Experimental Limitations The steady-state temperature concentrations induced by a single-port thermal discharge in a shallow body of water of large extent is desired. This relatively unconfined prototype situation, out of laboratory necessity, is confined in a basin model of finite extent. As a consequence, correct steady state results can never be achieved for long periods of time. The size of the model within the basin determines the duration that the model is allowed to run before significant boundary distortion comes into play. The scale size should be chosen small enough so that the near field mixing occurs in a small portion of the model and boundaries have small effect on the induced flow pattern and yet the scale size must be large enough to provide resolution in measurement and avoid scale effects. A comparative study of the performance of different discharge configurations on a relative basis is easily achieved. But the results of the laboratory experiments as applied to prototype design problems are subject to a variety of interpretations. -30- 3.3 Experimental Set-Up Figure 3-2 shows the model set-up. The basin is 60' x 40' x 1 1/2' and is located on the first floor of the R. M. Parsons Laboratory. Being situated in an enclosed area, the model is free from undesirable disturbances due to weather. The shoreline is in effect a vertical breakwater constructed of 8" cinderblocks and the floor is covered with a 30 gauge vinyl liner. A recirculating crossflow is achieved using five (5) hp pumps drawing from five equal length manifolds on the suction side and supplying water to a mixing manifold which feeds five equal length manifolds on the pressure side. The purpose of the mixing manifold is to provide water of uniform temperature across the basin. A uniform flow distribution is maintained by using vertical slot weirs and a 4" thick section of rubberized horsehair matting on both upstream and downstream sections of the basin. Discharge flow is warmed by passage through a steam heat exchanger and is mixed in a constant heat tank above the basin. The discharge structure is a section of PVC 80 pipe. The depth of the discharge can be adjusted from near surface to near bottom. Dye may be injected into the discharge to visualize the flow development and a small pump at the end of the basin removes water at the same rate as the discharge flow. Temperatures are measured using an array of 100 Yellow Springs Instrument thermistors (Series 700, time constant = 9 -31- Mixing nifold From Crossflow Pumps Crossf low Manifolds Probe SupportFrames ubberized Horsehair Vertical Slot Crossflow Weir Li Heated Water __ Discharge Box Breakwater - /0/// Model Wall To Crossflow Pumps "60' Figure 3-2: Experimental Setup //0/0/ To Intake Pump seconds). 98 probes are mounted on two wooden probe platforms using aluminum Dexion and two additional probes monitor hot water In the heaid tank and in the discharge box. Probe elevation may be adjusted during run operation by turning light handoperated screw jacks located in the corners of the platforms. A computer data acquisition system consisting of a digital thermometer and an electronic scanner manufactured by Digitec and a Hewlett Packard 2114B computer are used to record temperatures on a digitized tape. The tape is then converted to cards and data is run through a Fortran program which reduces it to dimensionless temperature rises. The results are printed in a format corresponding to the probe arrangement in the basin. 3.4 Procedure and Data Acquisition A typical run takes about 60 minutes and starts when the basin is quiet and well-mixed. Initial scans on the surface and the bottom are taken to determine if any initial stratification exists and to reference subsequent temperature differences. Discharge and intake waters are turned on, a small quantity of dye is injected into the discharge and the plume is allowed to develop. After about 10 minutes scans are begun starting with the near surface and continuing to the near bottom, followed by a final scan on the.surface. 3 1/2 minutes: Each scan requires approximately 2 minutes for scanning and 1 1/2 minutes for recording on digitized tape, during which time the platform is -33- cranked into position for the next scan. From 7 to 9 scans (including the initial two scans) were performed for each of the runs, depending on the water depth. Each run thus consists of 700 to 900 temperatures which are read into the computer. is in the form of a dimensionless temperature rise for each probe at each scan. -34- Output IV EXPERIMENTAL RESULTS 4.1 Introductio The parametric study consisted of 49 laboratory experiments. The relevant physical variables and non-dimensional parameters are tabulated in Table 4.1. The densimetric Froude number ranged between 4.9 and 15.7, the relative water depth H/D IF 0 between 1.9 and 6.3, the relative crossflow v/u ranged ranged between 0.020 and 0.074, and the relative discharge submergence z/H ranged between near surface (z/H % 0) and near bottom (z/11 % 1). The jet Reynolds number IRa varied between 7.900 and 12.000 indicative of turbulent flow. The test results were analyzed with respect to induced surface temperature rise. rise AT s/AT AT AT s The non-dimensional temperature at the surface is defined as T ace- ufae - a( T a T- o T o The particular case of the non-dimensional surface centerAT line temperature at the surf ace sc is defined as AT T ATsc AT 0 T AT face centerline T 0 -T a -35- 0 Ta 4-2 TABLE 4-1 EXPERIMENTAL DATA OF PARAMETRIC STUDY ON' I' U v Run H No. (ft) (fps) U0 (fps) Experimental Results Non-Dimensional Parameters Physical Parameters D (ft) (f t) AT H h 00 ( * F) F IFT z/H v/u 0.0 a / AT H/Do H/ 6.3 10 0.46 -- 6.3 10 0.37 12017 -- 6.3 10 0.26 0.0 12017 -- 6.3 10 0.18 0.0 12017 1.00 12017 0.75 1 0.67 0.0 1.13 0.07 .106 16.7 17.9 14.2 0 2 0.67 0.0 1.13 0.07 .106 16.8 17.5 13.9 .33 0.0 12017 3 0.67 0.0 1.13 0.07 .106 18.4 16.7 13.2 .67 0.0 4 0.67 0.0 1.13 0.07 .106 17.0 17.8 14.1 1.0 5 0.48 0.0 1.13 0.07 .106 17.6 17.3 13.7 0 6 0.48 0.0 1.13 0.07 .106 15.6 19.8 15.7 .33 0.0 12017 7 0.48 0.0 1.13 0.07 .106 16.5 17.5 13.8 .67 0.0 8 0.48 0.0 1.13 0.07 .106 16.9 17.0 13.5 1.0 9 0.40 0.0 1.13 0.07 .106 16.6 19.1 15.1 0 10 0.40 0.0 1.13 0.07 .106 11 0.40 0.0 1.13 0.07 .106 12 0.40 0.0 1.13 0.07 13 0.20 0.0 1.13 14 0.20 0.0 15 0.20 16 0.79 5.0 7.2 0.50 -- 5.0 7.2 0.37 12017 -- 5.0 7.2 0.26 0,0 12017 -- 5.0 7.2 0.19 0.0 12017 1.34 3.8 6 0.37 -- -- .33:0.0 12017 -- 3.8 6 -- 17.9 18.4 14.5 .67 0.0 12017 - 3.8 6 0.33 .106 16.7 19.0 15.0 1.0 0.0 12017 -- 3.8 6 0.20 0.07 .106 16.4 18.2 14.4 0.0 12017 2.55 1.9 3 0.41 1.13 0.07 .106 17.3 17.2 13.6 0.5 0.0 12017 -- 1.9 3 0.44 0.0 1.13 0.07 .106 16.4 18.3 14.5 1.0 0.0 12017 -- 1.9 3 0.35 0.0 0.82 0.08 .125 16.1 11.5 0.0 10191 0.42 6.3 10 0.37 - 9.1 0 0 TABLE 4-1 (CONTINUED) EXPERIMENTAL DATA OF PARAMETRIC STUDY Physical Parameters V. .. Run H v u o o Do No. (ft) (fps) (fps) Po (ft) (ft) AT (OF) 0 (ft)AT0 I LO kxperimental Results Non-Dimensional Parameters h F t F 0 0 (f1 z/H / v/u 'e e H 11/% H/E AT AT o o AT9 17 0.79 0.0 0.82 0.08 .125 16.1 11.7 9.3 .33 0.0 10191 6.31 10 0.50 18 0.79 0.0 0.82 0.08 .125 16.3 ~11.1 8.8 .67 0.0 10191 6.3 10 0.20 19 0.79 0.0 0.82 0.08 .125 15.7 11.4 9.0 0.0 10191 6.3 10 0.16 20 :0.47 0.0 0.82 0.08 .125 17.4 11.0 8.7 0 0.0 10191 0.78 3.81 6 0.46 21 0.47 0.0 0.82 0.08 .125 17.7 10.9 8.7 .33 0.0 10191 3.81 6 0.43 22 0.47 0.0 0.82 0.08 .125 16.3 11.5 9.1i .67 0.0 10191 3.8 6 0.25 23 0.47 0.0 0.82 0.08 .125 17.1 11.0 8.7 0.0 10191 3.8 6 0.25 24 0.24 0.0 0.82 0.08 .125 16.6 11.0 8.7 0.0 10191 1.54 1.9 3 0.44 25 0.24 0.0 0.82 0.08 .125 16.6 11.0 8.7 0.5 0.0 10191 1.9 3 0.41 26 0.24' 0.0 0.82 0.08 .125 16.4 11.1 8.8 1.0 0.0 10191 1.91 3 0.31 27 0.82, 0.0 0.49 0.10 .161 16.1 6.2 4.9 0 10.0 7912 0.33 4.51 8 0.53 28 0.82 0.0 0.49 0.10 .161 16.5 5.9 4.6 .33 0.0 7912 4.51 8 0.32 29 0.82 0.0 0.49 0.10 .161 16.1 6.3 5.0 .67 0.0 7912 4.5 8 0.32 30 0.82 0.0 0.49 0.10 .161 16.6 6.2 4.9 0.0 79121 4.5!, 8 0.21 31 0.61 0.0 0.49 0.10 .161 15.7 6.4 5.1 0 0.0 79121 0.45 3.8 6 0.59 0.61 0.0 0.49 , 0.10, .161. 15.2 6.4 5.1 .33 0.0 7912 3.8 6 32 1.0 1.0 0 1.0 . 0.41 TABLE 4-1 (CONTINUED) EXPERIMENTAL DATA OF PARAMETRIC STUDY 33 0.61 0.0 .49 0.10 .161 14.9 Non-Dimensional Parameters /T h e x /D H/W IF IF z/H v/u o o o H 0 6 3.8 7912 5.2 .67 0.0 6.5 34 0.61 0.0 .49 0.10 .161 15.7 6.4 5.1 1.0 0.0 7912 36 0.31 0.0 .49 0.10 .161 16.8 6.3 5.1 0.0 7912 37 0.31 0.0 .49 0.10 .161 17.8 6.0 4.8 .5 0.0 7912 - 38 0.31 0.0 .49 0.10 .161 15.2 6.7 5.3 1.0 7912 - 50 0.40 0.060 1.13 0.07 .106 17.8 16.3 12.9 0 .049 12017 51 0.40 0.060 1.13 0.07 .106 16.9 17.1 13.6 1.0 .049 12017 54 0.47 0.047 0.82 0.08 .125 0 .058 10191 55 0.47 0.047 0.82 0.08 .125 16.7 11.2 8.9 1.0 .058 10191 56 0.61 0.036 0.49 0.10 .161 17.0 6.0 4.8 0 .074 7912 57 0.61 0.036 0.49 0.10 .161 16.8 6.0 4.8 1.0 .074 7912 60 0.40 0.060 1.13 0.07 .106 17.4 16.5 13.0 0 .020 12017 61 0.40 0.060 1.13 0.07 .106 16.3 17.4 13.7 1.0 .020 12017 64 0.47 0.047 0.82 0.08 .125 16.7 11.2 8.9 0 .023 10191 65 0.47 0.047 0.82 0.08 .125 16.4 11.3 9.0 1.0 .023 10191 66 0.61 0.036 0.49 0.10 .161 16.4 6.1 4.8 0 .030 7912 67 0.61 0.036 0.49 0.10 .161 16.2 6.1 4.8 1.0 .030 7912 Physical Parameters Run H No. (ft) u D AT (fps) (fps) (ft) (ft) 0 (*F) V H 0 00 - Experimental Results max 0 AT0 .41 3.8 6 .32 0.88 1.9 3 .57 1.9 3 .57 1.9 3 .42 1.25 3.8 6 .22 3.8 6 .14 0.78 3.8 6 .25 3.8 6 .19 0.45 3.8 6 .48 35 00 I - - - 0 0.0 - 3.8 6 1.25 3.8 6 .34 3.8 6 .22 0.78 3.8 6 .28 3.8 6 .20 0.45 3.8 6 .48 6 .32 -- 3.8 - 4.2 Single-port Discharge Without Crossflow 4.2.1 Near-Surface Discharge Preliminary Obserat tons In the absence of ambient currents the most critical parameters governing the near-surface discharge behavior are the Froude number F and the relative water depth H/D 1 and 2, . At Froude numbers between the jet mixing is observed to be restricted to the lateral surface and the heated discharge is essentially "floated" on to the receiving water. At higher Froude numbers, increased mixing results in a greater volume of entrained water causing the jet penetrate deeper and become attached to the bottom. to The jet remains attached until buoyant forces overcome the effects of the entrainment. In relatively shallow depths, the results indicate substantial deviation of temperature distributions from those corresponding to the ideal conditions of unrestricted water depth characterizing Stolzenbach's (1971) predictive model for surface discharges. Centerline and Areal Dilutions Figures 4-1 to 4-4 are plots of centerline temperature rise versus longitudinal distance. Figures 4-5 to 4-7 are plots of excess temperature contours versus enclosed surface area. These figures illustrate that in shallow water the temperature dilution is dependent upon the interrelationship between the relative water depth and the Froude number. has important physical meaning. The shape of the curves Note that with increasing -39- 1.0 I I F I 0 I I I I I ~ 14.0 ..v/uu o Run 1 0 0 H/D O 6.3 14.2 13.7 15.1 14.4 6 Run 5 4.5 o Run 9 3.8 9 Run 13 1.9 h max /H 0.75 1.00 1.34 2.55 Stol2zenbach S(3 h max &13a .10 0 AT Sc AT - o h /H - 1.34 max ao a0 /H - 2.55 max/H o h max /H 0 .01 101 . Figure 4-1: I I . . . I I I I - 1.00 - 0.75 I . I . . 103 x L 2 Do Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant:F 0~ 14.0 -40- 1.0 1 F I a I 9.0 0 z/H v/u - I H/D o Run 16 6 Run 20 0 0 Run 24 0 a 0 IF I I h 0 6.3 3.8 1.9 9.1 8.7 8. 7 Stolzen bach I 1 1 /H max 0.42 0.78 1.54 0 0 h 0 0 0 0 AT 0 h max max /H - 1.54 /H - 0.78 00 00 Sc AT, oh max /H 0 .01 I I . I b I . 0.42 = I I I 9t i2 10ol1 x 0 Figure 4-2: Surface Centerline Temperature Rise vs. Longitudinal Distance with ConstantIF 0 -41- 9.0 a i IF a I 1 1 1 I 5 0 Z/H v/u H/D m0 - 0 P0 0 00 O Run 27 5.0 4.9 6 Run 31 3.8 5.1 36 1.9 5.1 0)Run I I h max /H 0.33 0.45 0.88 Stolzenba ch n0 0 '~,0omax 03 h /H - 0.88 h /H - 0.45 h /H = 0.33 .10AT sc AT 0 .01 i I i t I 101 I I I - - - - 102 x D 0 Figure 4-3: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant IF 0 -42- 5.0 1.0 hmax/H 0.80 z/H = 0 v/u 0 = 0Run o'Run 1 20 6Run 36 13- H/D IF 6.3 3.8 1.9 19.2 8.7 5.1 x/H h 0.75 0.80 0.85 Stolzenbach IF =5.1, H/D =1.9 .10 Mn 10 AT 00- 8.7, H/D 0-3.8 BC AT 0 0 IF oo-14.2, H/D -6.3 .01 102 101 xD 0 Figure 4-4: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant hmax /H % 0.80 -43- 103 1.0 V * 7V -010 z/H 0 0 Run 1 v/U 0 0 6 Run 5 0 Run 9 V Run 13 .--- 01 i, 10 6.3 0.75 4.5 1.00 3.8 1.34 1.9 2.50 IWStolzenbach HID 2 10 10 10 0 Figure 4-5: Excess Temperature Contours vs. Enclosed Surface Area with Constant IF 14.0 0 .10 .10 AT sc IF 0 /H / 00 9.0 0Run 0 0- 3 0 0 hmx/H H/D oRun 16 0.42 6.3 20 ORun 24 0.78 1.54 3.8 1.9 0 Stolzenbach .01 10 Figure 4-6: 102 2 A/ A/D 10 3104 Excess Temperature Contours vs. Enclosed Surface Area with Constant IF 9.0 0 -44- 1'.0 I I I h I P a I~ l ii I .10 AT AT S 0 5.0 S0F z/H H/D 0 0 v/u WO h /H O Run 27 0 Run 31 5.0 3.8 0.33 0.45 8 Run 36 1.9 0.88 - Stolzenbach .01 .1 # . & ,1 ,~.I ,A 1 I 1 1 '[C A/D 2 Figure 4-7: Excess Temperature Contours vs. Enclosed Surface Area with Constant F = 5.0 0 -45- distance from the discharge the curves become flat. Hence, a large increase in distance or surface area results in a small incremental decrease in the temperature rise, AT /AT . 5 0 The results show that where horizontal inertial forces dominate, temperature dilutions increase with increasing Froude number or increasing water depth. The centerline temperature rises show increasing agreement and the areal temperature rises show fair agreement with Stolzenbach's model as H/D Obviously, increases. the theoretical results give unrealiztically low temperature concentrations at low water depths with the discrepancy increasing with decreasing relative water depth, (see Figures 4-1 to 4-3). What "deep water" is depends on the relative magnitude of the Froude number. This can be reflected in the relative jet h penetration parameter, x which is defined in Chapter II h max = 0.42 F 0 ' hb (2-41) 00 Note the magnitude of hmax/H in Figures 4-1 to 4-4, for those discharge configurations that show good agreement with Stolzenbach's prediction, i.e., "deep water" situations. that for a given Froude numb-er, The results suggest there is a critical depth of water, beyond which the bottom does not significantly restrict jet entrainment. For the circular outfall, this critical configuration can be parameterized as -46- h ( ) H crit = f (F The importance of h 0 , H/D) (4-3) 0 /11 with respect to temperature dilutions will be investigatcd further in the next section. The fact that there is good agreement between the experimental results and Stolzenbach's prediction in "deep water" suggests that the hydraulic model was capable of simulating a semi-steady state condition before basin boundary effects dominated the flow pattern. Such a state is of short duration however. Figure 4-8 is a plot of the relative maximum jet penetration depth, h /H. Both experimental results and theoretical prediction are presented. Figure 4-9 shows a typical vertical section of a surface jet. The isotherm AT/ATO = 0.0 is used to define the boundary of the jet's penetration in the experimental results. These results show good agreement with Stolzenbach's et al (1972) prediction of the jet's maximum penetration h max Q,42 IF ' H 0 Ab ( (44 0 0 H and the maximum penetration of a round near-surface jet is accurately predicted by Equation (4-4) when ]F (D/H) < 3.1 (4-5) -47- A a 2.55 Z/H - 0 v/u - 0 0z // 16 0I 00 14 <1 . > <1.0> <. 61 0 0 0~ 12 0~ 10 <1.0> > 0 F 0 0<.5> 8 'z-I o 6 <1. 0>0 <.4> <. 0 0 4 2 D F 0 ) < 3.1 -- o Experimental Results Stolzenbach (Criteria for Full Penetration) 0 1 2 3 4 5 6 H/D Figure 4-8: Maximum Jet Penetration Depth of Surface Discharge -48- Depth (Ft) 0.18 0.15 0.12 0.09 Sz ~~....6 ... .4 8 3 AT = 0.0 0 5 Figure 4-9; 10 x(Ft) Schematic of Isotherms AT/AT 15 20 in the Vertical Plant, y 25 = 0. Run No. 5 Stable Region Dilutions Figure 4-10 characterizes the performance of a given discharge configuration (F AT temperature rise ( s. , H/D ) in terms of the stable centerline The stable centerline temperature is 0 in principle the asymptotic limit of the ATsc /AT see Figures 4-1 to 4-3. H/D vs x/D curve; The asymptotic values of (ATsc AT) as oo are obtained from Stolzenbach's model which is applicable - in deep water. This is given by the inverse of Equation (2-40) AT ( l/IF Sc (4-6) 0 These values are indicated on the right-hand side of the plots. lines (AT /AT ) The - constant can be obtained by interpolating between the experimental values and then-connecting the asymptotic points. Three separate regions can be distinguished. Region I: The flow pattern resembles that of the unrestricted water depth condition. Consider a fixed value of 1F0 representing a given discharge condition. For increasing values of H/D0 , the stable centerline temperature rise (AT a maximum value of (H/D ) crit. Sc /AT ) 0s decreases down to This indicates the dividing line between Regions I and II, and represents the point at which the assumption of an infinite extent of the ambient water becomes valid. The equation of the line in terms of hmax is: Hrt 3.3 mn( ax -50- (4-7) h max H 20 19 18- 45 D 3.3H/D H4i- h max-1. H 17 16 tp 15 .13 06 0 14 13 .06 12 IF AT sc 07 11 0 0 0 9. 8 -.08 S.09 .4.09 10 7.11 7 6 5 4 3. 2 0 1 21 2 .12 413 14 16 20 .. 3 4 H/D Figure 4-10: 5 6 7 8 9 0 Stable Region Temperature Rise Near Surface Discharge -51- 10 and If 3.3 L> D - If < n(--!) h .45D D = f (F n h. Ds ) (4-9) o s- (4-9) -,HD 0 0 for Froude numbers 5 to 15. D is surface temperature dilution, AT s ( SC D s AT 0 Region II: The effect of decreasing relative water depth is to decrease temperature dilution and increase the areal distribution of the induced temperature rise. The ambient water does not remain stagnant since measureable currents are generated to replace the entrained water. From dye studies conducted in the model, large symmetrical opposing eddies are observed in the area 120 from the discharge; of x/D 0 see Figures 4-11 and 4-12. The jet is observed to be two dimensional in character as greater lateral entrainment combined with buoyant surface spread leads to re-entrainment of the heat. This phenomena results in a limited recirculation thus decreasing the validity of the equation of heat h conservation (2-15). Note the position of the line max = 1. It H is significant since it shows that for a fixed value of IF0 the bottom boundary affects jet behavior at depths of water greater than the depth of the jet's penetration. Region III: (ATSC/AT ) on IF In this region there is little when H/D is small. dependence of The water along the longitudinal axis of the discharge approaches fully mixed condition. -52- 25sT =0 .0 AT .08 20- 15- .10 I~j .11 10- 13 Recirculatiorn 5- 5 Figure 4-11: ld b Surface Horizontal Temperature Distribution. Run No. 16, z/H n 0 25AT /AT 5 0.15 0 20- .16 15- 0.17 10 8 5 .30 Recirculation 15 10 Figure 4-12: 5 0 5 Surface Horizontal Temperature Distribution-. 10 Run No. 31, z/H 15 0 in this region D s - f(H/D ) 4.2.2 (4-10) 0 Discharaes with Variable Submergence Preliminary Observations With increasing submergence, the observed effect of buoyancy is to deflect the jet trajectory toward the free surface and the greater the Froude number, the longer the trajectory. relatively low water depths, H/D Due to the < 6.3, the jet intersects the water surface at an angle ranging from 0* for near surface discharge to less than 90* as the discharge submergence approaches near bottom. Thus, the jet generally has a substantial horizontal velocity component at the surface which, for constant submergence, increases with increasing F 0 Surface Centerline Dilutions Figures 4-13 to 4-22 are plots of centerline temperature rise versus longitudinal distance. They show the effect of relative submergence z/H on temperature dilution with constant Figures 4-13 to 4-16 can be grouped with constant H/D ranging from 6.3 to 1.9. IF and H/D . 'F 11, 14.0 and 0 Similar groupings are possible for Figures 4-17 to 4-19 and for Figures 4-20 to 4-22 with IF0' and 5.0, respectively. The following phenomena are noted: -55- 9.0 1.0 V F 0 v/u 0- 14.0 0 H/D 0 -U 0A Run 1 6.3 V Run 4 z/H 3F 0.0 0.33 0.66 1.00 14.2 13.9 13.3 14.1 0 Stolzenbach /0 0 .10 / 0 sc AT z /H 3 t3 C31 0 0( 0n r - AT z/H z/H 0 .66 .33 0.0 0 V V% -01 I I I I I 101 .,.~, x I I AI I z/H = 1.0 I 102 D0 Figure 4-13: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant F 0 ~14.0, H/D - 6.3 0 -56- " - 1.0 , I IF 0 ~ 14.0 v/u -0 o Run 5 * Run 6 H/D 0 - 4.5 o Run 7 V Run 8 -- .10 - AT Sc / / z/H F 0.00 0.33 0.67 1.00 13.7 15.7 13.8 13.5 0 ' 13 a% (WO 0 .01 101 10 2 D 0 Figure 4-14: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant F ~ 14.0, H/D = 4.5 -57- ~ A... S I F 00 5 I 5 I Ij I ~5.0 H/D 0 3.8 v/ - 0 10 x I 8 z/H F 0 Run 9 0.00 15.1 0 Run 11 0.33 5 1- F -- O Runl11 0.67 14.5 V Run 12 1.00 14.9 .10 AT AT Sc 0 .01 102 D0 Figure 4415: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant IF0 15.0, H/D0 - 3.8 -58- 103 1 I V0 V/u I 4 14.0 H/D 0 6 *1 4 I 0 1.0 0 Run 13 6 Run 14 Run 15 W 0 0 I 1 I I z/H IFT 0.0 0.5 1.0 14.4 13.6 14.5 I I ~I ,I V 1 1--tjJ 9 0 .10 AT sc AT 0 a . . .01 10 2 101 a 10 0 Figure 4-16: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant IF -59- 14.0 1.0 .I IF I I* i ~9.O z/H H/D 0 6.3 V/u 0 0 I o Run 16 0.00 Run 17 0.33 0.67 DRun 18 V Run 19 0 1.00 I I IF 9.1 9.3 NG 8.8 9.0 0\0 S00 .10 003 VVV 0 0 D30 -S-C A~T v9 O C[ 0 .01 . j I. . . . . o j z/H - 0.00 z/h - 0.66, z/h = 1.00 I I- ic x 0 Figure 4-17: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant IF0 9.0, H/D = 6.3 - ~ .0 hID= 6. -60- I I I I I 90 H/D 0 9 V/U O Run 20 21 eRun 22 V Run 23 - 3.8 aRun 0 aC Z/H IF 0.00 0.33 8.7 8.7 0.67 9.1 1.06 8.7 M D V .1 o 087 AT ):1- SI 101 I 10 I I 2 0 Figure 4-18: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant 9.0, H/D0 = 3.8 F0 -61- I 1.O Mi .. -- --- . T , 9.0 0 H/D 0 8v/u0 I I IC, I F z/H - 1.9 o Run 24 6 Run 25 o Run 26 -0 I 0.0 0.5 1.0 1 - 1 0 8.7 8.7 8.8 0 200 00 0 6 0 6 00 Q .10 0 00 6o 6 0 z/H 0.0 = z/H - 0.5, z/H = 1.0 AT Sc ZT 0 .01 i Ie a r II n'a,, C I 10. 0 0 I I I .I 10 Z x D 0 Figure 4-19: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant 9.0, H/D - 1.9 IF 0 0 0 -62- I #I 103 I I . 1.0 F i I I I 5.0 0 H/D 5.0 0 v/u 0 -0 0 9 Run 30 4.9 4.6 5.0 4.9 o oo z/H- 0.00 o Run 27 * Run 28 * Run 29 U U z/H r 0.00 0.33 0.67 1.00 H 0 0 0 0 000 e 7 .10i AT 0 D Sc I/H - 0.66 4VV V VV z/H - 0.33 az/H - 1.00 AT 0 .01 A . . I a 6 a 1 a a I I 101 x 0 Figure 4-20: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant IF = 5.0, H/D - 5.0 -63- aa aa ~a 0 1.0 1 F 0 - dq 1. 1 1 1 1 1 IF ~ 5.1 0 H/D - 3.8 o Run 31 0 Run 32 6 Run 33 9 Run 34 v/u 0 -0 C 0 1 0 z/H 5.1 0.00 5.1 U.J3 0.66 1.00 5.1 5.1 0 0000000 0 00 6 z/H - 0.00 z/H - 0.33, 9 .10 0.66 z/H - 1.00 AT SC AT 0 .01 3 101 .3.3.1 MOMONNObSOMWAM i i x 0 Figure 4-21: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant IF 0 ~5.1, H/D 0 3.8 -64- ! 2 . . d=W 1.0 I U 5.0 0 v/u 0 5.0-6.3 - o Run 36 6 Run 37 ) Run 38 -0 . IF z/H 5.1 4.8 5.3 0.0 - . 1.0 0 00o 00 z/H - 0.0 z/H - 0.5 z/H - 1.0 sC AT 0 A b .01 101 i ' a I I I I I x D 0 Figure 4-22: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant IF 0 5.0, H/D = 1.9 0 0 -65- I - 0.5 r( 4 dDo 13 AT 0 H/D . - hull I 1) For increasing values of W 0, the temperature dilutions increase with constant discharge submergence z/H. 2) For increasing values of relative water depth H/D , temperature dilutions increase with constant Froude number, IF. 0 3) For a discharge configuration ( IF and H/D0 ), increasing values of z/H significantly increase the temperature dilution in the immediate vicinity of the discharge. There is observed a positive tendency for surface dilutions to increase in the stable region. This becomes less apparent as the relative water depths decrease. 4) Maximum observed surface temperatures decrease with increasing relative discharge submergence. Figures 4-23 to 4-28 are plots of centerline temperature rise versus longitudinal distance for near-bottom discharges, z/H N 1.0. Figures 4-23 to 4-25 illustrate the effect of relative water depth H/D0 on temperature dilution, while Figures 4-26 to 4-28 show the effect of Froude number IF0 on temperature dilution. Temperature dilution increases with increasing Froude number and increasing water depth. There is less dependence on IF0 with decreasing H/D. 4.2.3 Summary In general, with decreasing relative water depth, two major phenomena interfere with jet entrainment and turbulent development: -66- 1 1. A .V I1 . - v/u 0 .10 I 1.0 z/HH/D - a 0 /3 -M M 6.3 6.3 5.0 A 0 AT 14.1 9.0 4.9 o Run 4 6 Run 19 0 Run 30 I H/D 0 5.0-6.3 I caa 00 0d IF 00 0 - 4.9 W0 -9.0 o0 0 I. &........ o oo .F 0 14.1 I 101 x 10 2 0 Figure 4-23: Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H - 1.0, H/D 0 - 5.Q-6.3 -67- 1I 1 -UI 1. 0 - I z/H - 1.0 0 - - IF 0 H/D - 3.8 v/u - - o Run 12 6 Run 23 0 o Run 14.9 8.7 5.1 34 -~\ A .10 AT AT Il 0 0 A e' ^ 6 E oo 63e n o oo AA A S~c 2' 7o -55 $0 .1, IF -14 .9 8.7 0 0 .015 .01 . 10 a I . x k a . . I i I a I 1 I 6 I 102 D0 Figure 4-24: Surface Centerline Tepperature Rise vs. Longitudinal Distance with z/H = 1.0, H/D - 3.8 -68- . . . 1.01 Z/H - 1.0 0 H/D - 1.9 0 v/u 0 M 00 0 Run 15 tun 26 tun 38 14.5 8.8 5.3 *00 0 000)0MOr 6 S6 .10 AT 8 = 5.3, F0 = 14.5 IF = 8.8 0c .01 a .I . 10 aSI , . I 10 x 0 Figure 4-25: Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H = 1.0, 'H/D - 1.9 -69- 1.0 P 0 = 14.0 H/D0 0 o Run 4 * Run 8 O Run 12 V Run 15 z/H - 1.0 v/u - 0 0 14.1 13.5 14.9 14.5 6.3 4.5 3.8 1.9 9o 0 .10 - - AT ii 0r0 6A 0 3p 0 0 A H/D - 1.9 H/D - 3.8 6 6 H/D - 0 - 4.5 .00 LT0 0 0 0 0 o o o H/D0 - .01 I I I x I I I II I p 6.3 f 102 0 Figure 4-26: Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H - 1.0, P = 14.0 -70- p * I 1.0 F - 5.0 0 H/D z/H - 1.0 ORun 30 4.9 5.0 0 aRun 34 D Run 38 5.1 5.3 3.8 1.9 0 0M - 1.9 H/D 0 - 3.8 v/u 0 F - 0 a e9 0 H/D 4 0 .10 a 0 00 ac 000 0 00 H/D - 5.0 0 .01 i . . . , , A I, i . 10 102 x 0 Figure 4-27: Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H - 1.0, P 0 5.0 -71- 1.0 I V0 9.0 0 - O Run 19 -Run 23 0Run 26 0 H/D 9.0 8.7 6.3 I I I I a I I IT 3.8 1.9 8.8 n 0 0 IF 0 -/H1.0 v/u I 0 66 CD .10 "M AT 8c 00 00 0 t 31 a n 000 H/D - 1.9 - 3.8 0 c6c6 H/D 0-0 - 6.3 H/D . 10 0 0 .01 1 10 . - L . . -I. I .1 I I I 102 x D 0 Figure 4-28: Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H - 1.0, F0 = 9..0 -72- 1) Observations using dye injection suggest that the effect of bottom friction on the velocity distribution and entrainment rate becomes more pronounced in shallow water. 2) Because of the increasing restriction on the extent of the ambient water, will the entrainment of the latter by the jet generate appreciable currents to replace the entrained water and eventually part of the heated surface layer will be re-entrained by the jet. This re-entrainment increases the temperature concentration at the surface. 4.3 Single-port Discharge with Crossflow 4.3.1 Near-Surface Discharge The non-dimensional relative jet penetration parameter h ax is important in characterizing the phenomena observed with ambient crossflows. All results of laboratory experiments presented were conducted at constant relative water depth, H/D increasing Froude number and H/D - 3.8. With constant, the water depth becomes "relatively" shallow due to increasing bottom interaction with the flow of ambient entrainment into the jet. Figures 4-29 to 4-32 are plots of centerline temperature rise versus longitudinal distance. Figures 4-33 and 4-34 are plots of excess temperature contours versus enclosed surface area. They show the effect of Froude number and crossflow strength on temperature dilution. This is reflected in the relative jet h penetration parameter max, since H -73- 1.0 h max o H O Run 60 1 2.9 .1.25 .020 a Run 64 8.9 0.78 .023 ORun 66 4.8 0.45 .030 -S tolzenbach z/H - 0 H/D - 3.8 ao & o94.8I 1 3 -13. 6 3F 09.0 .10 AT 0 0 0 0 Sc 0T & .01 101 Figure 4-29: a a .. x D ... I . 102 Surface Centerline Temperature Rise vs. Longitudinal Distance with near Constant v/u 0.^ 0.060, H/D = 3.8 -74- 1.0 z/H - 0 H/D - * hmax 7 0 12.9 8.9 4.8 o Run 50 0 Run 54 3.8 13 Run 56 -- v/u H 1.25 0.78 0.45 .049 .058 .074 - Stolzenbach 1Fu-4.8 IF 0- 9.0 0 .10 AT 0 sc 0 - 13.0 0 0 - AT .01 I C I 101 x I I - 0 Figure 4-30:' Surface Centerline Temperature Rise vs. Longitudinal Distance with Near Constant v/u "' .025, H/D - 3.8 0 1 -75- 0 I C eq mum 1.0 o o max v/u0 64 66 9 20 13.7 8.9 4.8 12.5 9.0 1.25 0.78 0.45 1.25 0.78 .020 .023 .030 0 0 31 5.0 0.45 0 0 Run 60 Z/H - 0 HID o 0 a Run o Run *Run 0 £Run *Run 3.8 F oa-N OUM Ae 0.0 0 00 cA&4$ .10 A * *c- AT 8C 0 La- .01 L01 x LU 0 Figure 4-31: Surface Centerline Temperature Rise vs. Longitudinal Distance with Variable v/u 0 , H/D - 3.8 -76- Sam" 1.0 M a I I * 1 z/h -0 H/D - o A o * * * 3.8 I & em 0 6% AU 9 20 31 &M .074" 0 0 0 RON E o 0 'S .10 ola L .0 0 0 0 8C AT . .01 .. A . .. I I f I I 102 101 D Figure 4-32: I 0 Surface Centerline Temperature Rise vs. Longitudinal Distance with v/u - 0 to .074, H/D - 3.8 -77- 0 .049_ .058 1.25 0.78 0.45 1.25 0.78 0.45 ~*I AU AT 12.9 8.9 4.8 12t5 9.0 5.0 50 54 56 M A^ .- ~ Run Run Run Run Run Run 1max v/u a a II 1.0 H/D 0 3.8 z/H 0 0 Run 60 6 Run 64 o Run 66 Do c13 max H 1.25 0.78 0.45 Fo 13.7 8.9 4.8 v/uo.02Q .023 .01 ~Oj 0o a00 .10 . 0 T0 .01 1 2 10 1 Figure 4-33: 1.0 11 Excess Temperature Contours vs. Enclosed Surface Area with v/u0 .025 -' T T ~1 1 ~IJ- H/D0 0. - 0 z/H 0 0 A/D0 2 IF 0 3.8 & o Run 50 a Run 54 o Run 56 0 0 0 13.5 8.8 4.8 II h v/u max H 1.25 0.78 0.45 .049 .058 .074 61 0 .10 S 0 0. AT sc AT 0 .01 I d. I 10 I 1 0 A I I I I I .1111 i I I 0, I 1 10z Figure 4--34: A/D 2 Excess Temperature Contours vs. Enclosed Surface Area with v/u \. .060 0 -78- I a I A I in 0.42 A 1 4 or hb (4-10) - a constant for these tests H0] and 0.42 A /4 h H 0x-- b (4-11) 0 Thus, effectively h S- f (F) (4-12) Figures 4-29 and 4-30 show that there is poor agreement of the crossflow configuration with Stolzenbach's prediction. In part, this is due to the relative shallow water depth at which the crossflow experiments were run. The observed phenomena can be divided into two parts according to the magnitude of the jet penetration parameter h /H. h max 1 is an indication that the jet has become attached to the H h bottom. 1) For - < 1, the following observations are noted: As compared with the non-crossflow case, increased entrainment on the outer face of the jet due to a small crossflow increases dilution. 2) See Figures 4-31 and 4-32. A further increase in crossflow v/u induces a small but positive increase in temperature dilution. 3) Temperature dilution increases with increasing Froude number. 4) The jet deflection increases with increasing Froude number. See Figures 4-35 to 4-37. -79- 25- T 20-- .17 15- 00 0 105 5- 15 10 Figure 4-35: 5 0 5 Surface Horizontal Temperature Distribution. 10 Run No. 66, IF 15 = 4.8 25- AT 0. 05 200 20- .06 15- .07 10.08 5- 15 .10 Figure 4-36: 5 0 5 Surface Horizontal Temperature Distribution. 10 Run No. 64, IF 15 =8.9 25- AT /AT 0 S 0.10 0 15 10- .11 .1 .1 5- 15 10 Figure 4-37: 5 0 5 Surface Horizontal Temperature Distribution. 10 Run No. 60, IF 15 = 13.0 5) Semi-steady state conditions in the hydraulic model can be achieved. With increasing IF0 , (v/u - constant, H/D 0 0 - constant), the jet's vertical penetration increases, effectively causing increased blockage of the crossflow. See Figure 4-38. The result is a decrease in the volume of ambient crossflow that penetrates beneath the plume. A large re-entrainment eddy on the lee side of the jet develops and intensifies. See Figure 4-39. The results suggest that increasing the Froude number has a positive effect on h temperature dilution until max 1. hH For max > 1, the jet'becomes attached to the bottom. Increasing IF increases the area of jet attachment and all of the crossflow is prevented from passing to the lee side of the plume. The temperature concentrations in the re-entrainment eddy increases until a steady state is achieved. Increasing IF further in- creases the re-entrainment causing the temperature concentrations to increase. 4.3.2 Near-Bottom Discharge The results presented were conducted at constant relative water depth, H/D - 6. Figures 4-40 and 4-41 are plots of excess temperature contours versus enclosed surface area. They illustrate the effect of Froude number and crossflow on temperature dilution. The results suggest that: -83- y v'7 y h max< H H V x-const ;7 47 7 or T7 or ,o- ' V max > H H V xnconst. Figure 4-38: Typical Vertical Cross-section of Isotherm, x - constant, constant H/D and v/u , z/H = 0 00 -84- 20 - 15 z=O CO Ln AT 10- =08 .09 .10 5- Recirc ulation Eddy I 5 I. 10 Figure 4-39: 0 5 Typical Plane View of Discharge in a Crossflow, h z/H = 0, Run No. 50 10 /H > 1, r I. 1.0U a H/D - . I 91 O Run 51 6 Run 55 * Run 12 0 I IF0 v/u0 13.0 8.8 14.9 .049 .058 0 3.8 1 z/H - . 1I 1 1 11' I I I C .10 0 n 06 A T -0 .01 k. I. i I i ll I I I A/D 0 II IaI I A I I 10 2 101 Figure 4-40. Excess Temperature Contours vs. Enclosed Surface Area with 1.0 /u0 I H/D - 0.06 I4 I I I II I 3.8 I 0 z/H - 1.0 0 2 Run 61 * Run 65 8.8 4.8 67 0 Run 0 v/u 13.0 O I .020 .023 .030 Do 6 O 0 .10 C3 a ZT.mc 0 I - .01 I 101 Figure 4-41: I I f I Ai I 102 r A/D I I 2 I Iia I 1 103 Excess Temperature Contours vs. Enclosed Surface Area with v/u o .025 .0 -86- ag I f 1) Increasing the crossflow velocity increases temperature dilution. 2) Near-bottom discharges show small but positive increase in temperature dilution as compared to near-surface discharge. Compare Figures 4-33 and 4-34 with Figures 4-40 and 4-41. 3) There is less dependence of dilution on the value of as compared with the near-surface discharge. as IF 0 is increased, the jet F However, meanders along the bottom, increasing blockage of the crossflow and re-entrainment on the lee side. -87- SUMMARY AND CONCLUSIONS V An experimental investigation of the temperature field induced by the heated effluent from a submerged single-port discharge is conducted. Primary emphasis is directed to the study of the interaction of a shallow water jet with the bottom and the free surface. The experimental program considers a discharge of heated water at temperature T pipe of diameter D 00 and density Q P0 from a circular at the edge of a receiving body of water of large extent, with temperature Ta, density pa and depth H are uniform. A uniform current v may be present in the receiving water and is parallel to the shoreline. number H/D F The densimetric Froude ranges between 4.9 and 15.7, the relative water depth ranges between 1.9 and 6.3, the relative crossflow V/u 0 ranges between 0.020 and 0.074, and the relative discharge submergence Z/H ranges between near surface (Z/H % 0) and near bottom (Z/H "- 1). Graphic dimensionless relationships among the pertinent parameters is presented to illustrate the jet's behavior and for use in the preliminary design of shallow water thermal out falls. In general, with decreasing relative water depth, two major phenomena interfere with jet entrainment and turbulent development. 1) The effect of bottom friction on the velocity distribution and entrainment rate becomes more pronounced in shallow water. 2) Because of the increasing restriction on the extent of the ambient water, the entrainment of the latter by the jet will generate appreciable currents to replace the entrained water and eventually part of the heated surface layer will be re-entrained by the jet. The re-entrainment increases the temperature concentrations at the surface. In the absence of ambient currents the most critical parameters governing the near surface discharge behavior are the Froude number W and the relative water depth H/D . In relatively shallow depths, the results indicate substantial deviation of temperature concentrations from those corresponding to the ideal conditions of unrestricted water depth characterizing Stolzenbach's (1971) predictive model for surface discharges. The jet penetration parameter h max /H defines the discharge conFor the range of figuration applicable to Stolzenbach's model. parameters here in studied, it is found that if H > h max '5> 3.3 kn( .45 o 0 the flow field is a function of the densimetric Froude number IF and Stolzenbach's model is applicable with respect to the assumption that the bottom does not interfere -with the jet's performance. However, if H ~ max < 3.3 kn() E-890 0 -89- then the flow field is a function of the densimetric Froude number IF and the relative water depth H/D . The theoretical results give unrealistically low temperature concentrations at low water depths with the discrepancy increasing with decreasing relative water depth. The experimental results show good agreement with Stolzenbach's et al prediction for the jet maxi- mum penetration depth in deep water. Varying the jet's relative submergence from near surface to near bottom significantly increases the near field temperature dilution and decreases maximum temperature concentrations. Dilutions in the stable region increase with submergence, but this becomes less apparent as relative water depths decrease. The non-dimensional relative jet penetration parameter h /H is important in characterizing the phenomena observed with ambient crosaflows. The jet's interaction with the crossflow can be divided into two parts according to whether h max /H is less than or greater than one, i.e., whether the jet is, or is not, attached to the bottom. The results suggest that maximum temperature dilu- tion is achieved with a crossflow when the discharge configuration satisfies the criteria h max H The deflection of the jet plume increases with increasing Froude number. Temperature dilutions also increases with an in- crease in the crossflow velocity y/u 0 , given that h constant. /H remains Stolzenbach's prediction with crossflows correlate -90- poorly with the experimental results, which is likely due to the shallow depths at which the tests were performed. -91- NO]MENCLATURE A discharge channel aspect ratio, h /b b local width of jet, 2-D b horizontal surface distance from core boundary to jet boundary, 3-D b one half the width of rectangular channel c coefficient in the exponent of Ellison and Turner's vertical entrainment velocity function cn concentration of heat in the plume in terms of density of water D dilution D0 outfall nozzle inside diameter F0 densimetric Froude number of the discharge IF 'a - ratio of flow in the jet to the initial flow characteristic Froude number - F A f a functional f similarity function for velocity g acceleration of gravity g' Ap /p g H maximum allowable penetration of the jet h vertical centerline distance from core boundary to jet - (1-C3/2 2 boundary hmax maximum value of h obtained in a heated discharge h0 depth of discharge channel K experimentally determined dimensionless coefficient describing the gross effects of the turbulent mixing process k coefficient of heat loss P pressure -92- - ....... . ..... - - , I-- ...... ..... Q discharge flow Q1 rate of entrainment of the ambient water per unit length of the jet r radial cylindrical coordinate r vertical distance from the jet centerline to the boundary of of the core region s longitudinal cylindrical coordinate s horizontal distance from the jet centerline to the boundary of the core region T mean local temperature t similarity function for temperature T' temperature fluctuations Ta ambient temperature of water Tc jet centerline temperature T temperature of water at jet Ts surface temperature Tsc jet AT the local temperature rise, T-T a AT C - (l-C)3/2 exit centerline temperature at the surface temperature rise at the centerline, T C -T a AT temperature difference between the discharge and the ambient water, T -T 0 a AT surface temperature rise, T.-Ta ATsc surface centerline temperature rise (AT) saverage fractional stable excess surface temperature rise in the jet (AT s u,v stable surface centerline temperature rise, Tsc mean velocities in s,r direction u'v' velocity fluctuations in s,r direction -93- a ujvw velocity components in the coordinate system relative to the centerline of a deflected jet uWvw velocity components in the fixed coordinate system u'v'w' turbulent fluctuating velocity components uc centerline jet velocity u0 discharge velocity - V,v ambient crossflow velocity v lateral velocity of the entrained flow at the jet boundary vs an internal velocity vb an internal velocity W,avertical Q0 /2h b velocity in the jet at z -- r and 0 < y < 8 wh internal velocity wr internal velocity xyz coordinate direction relative to the centerline of a deflected jet xFyz fixed coordinate direction experimentally determined entrainment coefficient lateral entrainment coefficient in non-buoyant jet (Iz vertical entrainment coefficient in a non-buoyant jet 8 coefficient of thermal expansion for water spread, db/dx of the turbulent region of a non-buoyant jet E spread, db/dx, of the turbulent region in an undeflected non-buoyant jet either of or r -94- Y Cz dimensionless width of the turbulent region of a jet, Iy1-s/b dimensionless depth of the turbulent region of a jet, z-v/h lateral jet stream line from the centerline in excess of the non-buoyant value G angle between x axis and s axis 0 angle between the jet centerline (x axis) and the - axis 00 angle between the discharge channel centerline and the y axis water surface elevation p mean local density of water Pa ambient density of water PC density of the jet centerline pO density of water at jet Ap difference between the ambient water density and the water density, p.-P APeCdensity exit deficit at the centerline, p C-P Ap0 difference between the ambient water density and the density of the heated flow at the discharge exit, paPO A experimentally determined dimensionless coefficients describing the gross effects of the turbulent mixing process V kinematic viscosity -95- LIST OF FIGURES Page Figure 2-1: Region of Physical Processes that Govern a Single-port Thermal Discharge 9 Figure 2-2: Definition Diagram for Round Buoyant Jet 11 Figure 2-3: Coordinate 19 Figure 2-4: Discharge Structure 20 Figure 2-5: Schematic of the Single-port Heated Discharge 26 Figure 3-1: Schematic of Heated Discharge 28 Figure 3-2: Experimental Setup 32 Figure 4-1: Surface Centerline Temperature Rise vs. Longitudinal Distance with ConstantIF 14.0 40 Definitions 0 Figure 4-2: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant F 9.0 0 Figure 4-3: Surface Centerline Temperature Rise vs. Longitudinal Distance with ConstantWF 5.0 41 42 0 Figure 4-4: Figure 4-5: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant hm H ' 0.80 43 Excess Temperature Contours vs. Enclosed Surface Area with 14.0 ConstantIF 44 0 Figure 4-6: Excess Temperature Contours vs. Enclosed Surface Area with ConstantJF 9.0 0 Figure 4-7: Excess Temperature Contours vs. Enclosed Surface Area with Constant F 5.0 0 44 45 Page Figure 4-8: Figure 4-9: Figure 4-10: Figure 4-11: Figure 4-12: Figure 4-13: Maximum Jet Penetration Depth of Surface Discharge 48 Schematic of Isotherms AT/AT in the Vertical Plant, y-0. Run No. 5 49 Stable Region Temperature Rise Near Surface Discharge 51 Surface Horizontal Temperature Distribution. Run No. 16, z/H = 0 53 Surface Horizontal Temperature Distribution. Run No. 31, z/H = 0 54 Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant IF 14.0, H/D - 6.3 0 Figure 4-14: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant P0= 14.0, H/D0 - 4.5 Figure 4-15: Figure 4-16: Surface Centerline Temperature Rise vs. Longitudinal Distance with ConstantIF 15.0, H/D 1.8 0 0 Surface Centerline Temperature Rise vs. Longitudinal Distance with ConstantlF 14.0 0 Figure 4-17: 56 0 57 58 59 Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant Figure 4-18: Figure 4-20: - 6.3 60 Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant Figure 4-19: 0 = 9.0, H/D 0 9.0, H/D 0 3.8 61 Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant F = 9.0, H/D0 1.9 62 Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant F0 = 5.0, H/D 0 5.0 63 -97- Page Figure 4-21: Figure 4-22: Figure 4-23: Figure 4-24: Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant W = 5.1, H/D - 3.8 64 Surface Centerline Temperature Rise vs. Longitudinal Distance with Constant F0 = 5.0, H/D 0= 1.9 65 Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H - 1.0, H/D0 - 5.0-6.3 67 Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H 1.0, H/D - 3.8 68 Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H - 1.0, H/D - 1.9 69 0 Figure 4-25: Figure 4-26: Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H - 1.0, F Figure 4-27: Figure 4-28: = 14.0 Surface Centerline Temperature Rise - vs. Longitudinal Distance with z/H - 1.0, IF = 5.0 Figure 4-30: Figure 4-31: 71 Surface Centerline Temperature Rise vs. Longitudinal Distance with z/H = 1.0, F Figure 4-29: 70 = 9.0 72 Surface Centerline Temperature Rise vs. Longitudinal Distance with near Constant v/u0 I' 0.060, H/D - 3.8 74 Surface Centerline Temperature Rise vs. Longitudinal Distance with near Constant v/u 0I .025, H/D 0 3.8 75 Surface Centerline Temperature Rise vs. Longitudinal Distance with Variable v/u0 , H/D - 3.8 76 -98- Page Figure 4-32: Figure 4-33: Surface Centerline Temperature Rise vs. Longitudinal Distance with v/u 0to .074, H/D - 3.8 77 Excess Temperature Contours vs. Enclosed Surface Area with v/u '\' .025 78 0 Figure 4-34: Figure 4-35: Figure 4-36: Figure 4-37: Figure 4-38: Excess Temperature Contours vs. Enclosed Surface Area with v/u 0 .060 78 Surface Horizontal Temperature Distribution. Run No. 66,3F - 4.8 80 Surface Horizontal Temperature Distribution, Run No. 64, IF - 8.9 81 Surface Horizontal Temperature Distribution. Run No. 60,IF - 13.0 82 Typical Vertical Cross-section of Isotherm, x - constant, constant H/D and Figure 4-39: Figure 4-40: /u , Z/H-0 0 84 Typical Plane View of Discharge in a Crossflow, h /H > 1, z/H ~ 0, Run No. 50 max 85 Excess Temperature Contours vs. Enclosed Surface Area with v/u "v 0.06 86 Excess Temperature Contours vs. Enclosed Surface Area with v/u 0'o .025 86 0 Figure 4-41: -99- REFERENCES 1. Abraham, G., "Jet Diffusion in Stagnant Ambient Fluid", Delft Hydraulics Laboratory Publication No. 29 (1963) 2. Abramovich, G.N., The Theory of Turbulent Jets, The M.I.T. Press, M.I.T., Cambridge, Massachusetts (1963). 3. Fan, L.-N, "Turbulent Buoyant Jets into Stratified or Flowing Ambient Fluids", W.M. Keck Laboratory of Hydraulics and Water Resources, California Institute of Technology, Report No. KH-R-15, June (1967). 4. Partheniades, E., Beechley, B.C., and Jen, Y., "A Parametric Study for Surface Temperature Concentration Due to Submerged Heated Water Jets in Shallow Water", Coastal and Oceanographic Engineering Laboratory, College of Engineering, University of Florida, Technical Report No. 17, May, 1973. 5. Stolzenbach, K.D. and Harleman, D.R.F., "An Analytical and Experimental Investigation of Surface Discharges of Heated Water", Ralph M. Parsons Laboratory for Water Resources and Hydrodynamics, Department of Civil Engineering, M.I.T., Technical Report No. 135, February, 1971. 6. Stolzenbach, K.D., Adams, E.E., and Harleman, D.R.F., "A User's Manual for Three-Dimensional Heated Surface Discharge Computations", Ralph M. Parsons Laboratory for Water Resources and Hydrodynamics, Department of Civil Engineering, M.I.T., Technical Report No. 156, September, 1972. -100-