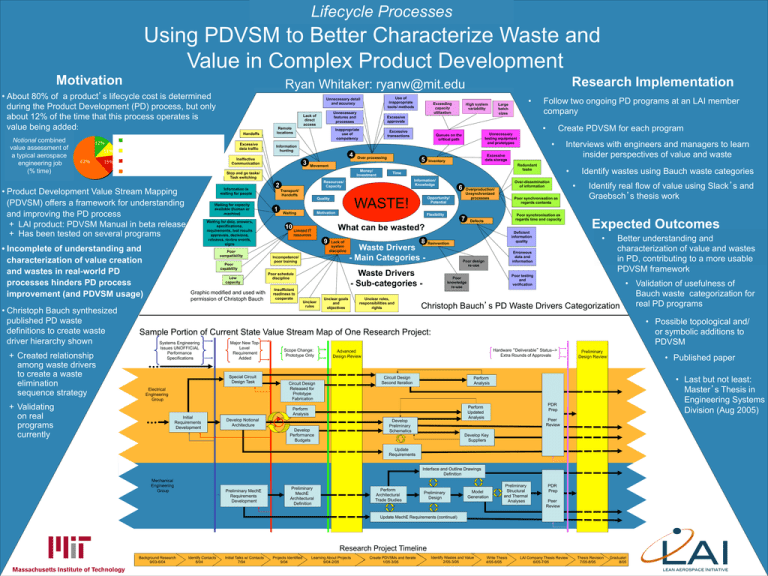

Motivation

advertisement

Lifecycle Processes Using PDVSM to Better Characterize Waste and Value in Complex Product Development Motivation • About 80% of a product’s lifecycle cost is determined during the Product Development (PD) process, but only about 12% of the time that this process operates is value being added: 12% 11% 62% 15% Value-added activity Job idle Remote locations Information hunting 4 3 Information is waiting for people Waiting for capacity available (human or machine) Waiting for data, answers, specifications, requirements, test results approvals, decisions, releases, review events, signs Poor compatibility Poor capability Low capacity Graphic modified and used with permission of Christoph Bauch Excessive transactions 1 High system variability 5 Transport/ Handoffs Inventory Time WASTE! Motivation Waiting 6 Opportunity/ Potential Flexibility Lack of system discipline Incompetence/ poor training 7 Waste Drivers - Main Categories - Unclear rules Unclear goals and objectives Unclear roles, responsibilities and rights Interviews with engineers and managers to learn insider perspectives of value and waste • Poor synchronisation as regards time and capacity Defects Deficient information quality Reinvention Identify wastes using Bauch waste categories • Identify real flow of value using Slack’s and Graebsch’s thesis work Expected Outcomes • Erroneous data and information Poor design re-use Waste Drivers - Sub-categories - Poor schedule discipline Insufficient readiness to cooperate 8 • Poor synchronisation as regards contents resources 9 Create PDVSM for each program Over-dissemination of information Overproduction/ Unsynchronized processes What can be wasted? 10 Limited IT • Redundant tasks Information/ Knowledge Quality Follow two ongoing PD programs at an LAI member company Excessive data storage Movement Resources/ Capacity • Large batch sizes Unnecessary testing equipment and prototypes Queues on the critical path Over processing Money/ Investment 2 Exceeding capacity utilization Excessive approvals Inappropriate use of competency Stop and go tasks/ Task switching • Incomplete of understanding and characterization of value creation and wastes in real-world PD processes hinders PD process improvement (and PDVSM usage) + Created relationship among waste drivers to create a waste elimination sequence strategy Unnecessary features and processes Lack of direct access Ineffective Communication • Product Development Value Stream Mapping (PDVSM) offers a framework for understanding and improving the PD process + LAI product: PDVSM Manual in beta release + Has been tested on several programs • Christoph Bauch synthesized published PD waste definitions to create waste driver hierarchy shown Excessive data traffic Necessary non-value added activity Pure waste activity Use of inappropriate tools/ methods Unnecessary detail and accuracy Handoffs Notional combined value assessment of a typical aerospace engineering job (% time) Research Implementation Ryan Whitaker: ryanw@mit.edu Poor testing and verification Poor knowledge re-use Better understanding and characterization of value and wastes in PD, contributing to a more usable PDVSM framework • Validation of usefulness of Bauch waste categorization for real PD programs Christoph Bauch’s PD Waste Drivers Categorization • Possible topological and/ or symbolic additions to PDVSM Sample Portion of Current State Value Stream Map of One Research Project: Systems Engineering Issues UNOFFICIAL Performance Specifications Major New TopLevel Requirement Added Special Circuit Design Task Electrical Engineering Group + Validating on real programs currently Initial Requirements Development Scope Change: Prototype Only Hardware “Deliverable” Status--> Extra Rounds of Approvals Advanced Design Review Circuit Design Second Iteration Circuit Design Released for Prototype Fabrication • Last but not least: Master’s Thesis in Engineering Systems Division (Aug 2005) PDR Prep Perform Updated Analysis Develop Preliminary Schematics Develop Performance Budgets • Published paper Perform Analysis Perform Analysis Develop Notional Architecture Preliminary Design Review Peer Review Develop Key Suppliers Update Requirements Interface and Outline Drawings Definition Mechanical Engineering Group Preliminary MechE Requirements Development Preliminary MechE Architectural Definition Perform Architectural Trade Studies Preliminary Design Model Generation Preliminary Structural and Thermal Analyses PDR Prep Peer Review Update MechE Requirements (continual) Research Project Timeline Background Research 9/03-6/04 Identify Contacts 6/04 Initial Talks w/ Contacts 7/04 Projects Identified 9/04 Learning About Projects 9/04-2/05 Create PDVSMs and Iterate 1/05-3/05 Identify Wastes and Value 2/05-3/05 Write Thesis 4/05-6/05 LAI Company Thesis Review 6/05-7/05 Thesis Revision 7/05-8/05 Graduate! 8/05