Value Chain Challenges of The Biobased Economy Corn stover Sugarcane

advertisement

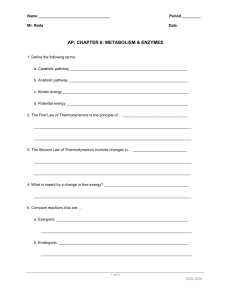

Value Chain Challenges of The Biobased Economy 9 October, 2007 ESF Forest Biorefinery Conf. Jack Huttner Vice President, Biorefinery Business Development Switchgrass Corn stover Sugarcane AGENDA • Background on Genencor • Strategic Commercial Drivers • Strategic Technology Developments • Genencor’s Commercial Strategy 2 Genencor Division at a Glance Develops and produces enzymes for industrial applications ¾ History traced to 1982 ¾ May 2005: Danisco–Genencor Division: responsible for production, innovation, marketing and sales of industrial enzymes. ¾ 9 Bioproducts manufacturing sites ¾ Proven innovator ~3500+ owned and licensed patents and patent applications ¾ Approximately 1200 Employees Worldwide 3 Genencor’s Products In Everyday Life Innovative and Cost Effective Catalysts for Many Major Industrial Segments Delivering on the Promise of Biotechnology for Over a Two Decades! – Cleaning – Textiles – Carbohydrate Processing – Fuel Ethanol – Brewing – Leather – Baking – Pulp and Paper – Food and Specialties – Biorefineries 4 Our Vision of the Biobased Economy We envision a future where biotechnology fulfills many unmet needs… – – In development and deployment of industrial enzymes In the production of fuels, chemicals and materials We envision a future where biotechnology helps create sustainable industrial activities We envision a future where biorefineries take their place alongside oil refineries 5 AGENDA • Background on Genencor • Strategic Commercial Drivers • Strategic Technology Developments • Genencor’s Commercial Strategy 6 Fuel Ethanol Market Drivers • Environmental – – – – Carbon constraints Positive energy balance Ecological efficiency, sustainability Cellulosics replace starch from food crops • Societal – Desire to reduce foreign fuel supply dependence – Rural economic development – Desire for local farmer co-ops to become more vertically integrated • Economic – – – – – High crude oil and gasoline cost Solid return on investment Improved economics of production Tax Incentives Technological advances and process improvements 7 Why Biofuel from Cellulosics? US gasoline replacement 160 BGPY gasoline 140 Bush SOTU target: 30% (45BGPY) 120 100 80 12-15 BGPY limit for starch ethanol 60 40 20 0 0 20 40 60 80 100 120 % Gasoline Replacement. (All USA information.) 8 McKinsey (Riese) Slides BIO World Congress – March 2007 9 A New Industry Needs A New Paradigm Cellulosic ethanol will not be like starch ethanol • Enzyme solutions will be specific to each substrate & integrated solution • Enzyme dosing is 50-100x higher than for starch – Biomass much more recalcitrant to hydrolysis (speed) • Transportation costs are a significant factor for raw materials, incl. enzymes Enzyme production should be proximate or co-located with biorefineries – Optimal catchment area? • Readily available (collected) substrates likely early winners 10 Renewable Carbon: Theoretical Ethanol Yields Feedstock ethanol yield / dry ton* Gallons Liters Cane bagasse 112 424 Corn stover 113 428 Rice straw 110 416 82 310 Hardwood sawdust 101 382 Mixed paper 116 439 Forest thinnings Note: Cellulose & hemicellulose utilized (C6 & C5 sugars) 11 Biomass Value Chain Integration Status Corn stover, bagasse, pulp, etc. FEEDSTOCK Mechanical or thermo chemical PRETREATMENT ENZYME HYDROLYSIS Current GCOR role No infrastructure for some No collection implements Process choice needed Complex sugars to simpler sugars FERMENTATION Yeast to ethanol (C-6) END PRODUCTS FEEDSTOCK PRETREATMENT Enzymes tuned to feedstock & pretreatment ENZYME HYDROLYSIS Need to utilize C5 sugars Ethanol and other biochemicals FERMENTATION END PRODUCT 12 Value Chain Implications • Feedstock: – Crop residues • First plants will be built near existing facilities • Close ties to conservationists will be required to study effects/maximize yield – Producers’ share (biomass delivered price @ biorefinery gate???) – Existing collected biomass feedstocks – will require new business models in mature industries – Higher yielding biomass crops will be the natural trajectory • Enzymes: – Capacity • Not likely be built on speculation • Most likely built near the point of use • Advances will lower the capacity required over time – Enzymes technology will have a greater impact than just “cost of enzyme/gal EtOH” • Total enterprise capital • Pretreatment and ethanologen design & efficiency • Operating cost (e.g. energy and raw materials) 13 McKinsey (Riese) Slides BIO World Congress – March 2007 14 AGENDA • Background on Genencor • Strategic Commercial Drivers • Strategic Technology Developments • Genencor’s Commercial Strategy 15 35 0.8 30 0.7 0.6 25 0.5 20 0.4 15 0.3 10 ETOH Cost, USD/Litre Sugar Cost, US Cents/Lb Context: Sugar & Ethanol Costs Sugar Cost ETOH Cost 0.2 5 0.1 0 0 EU USA IND ZAF AUS THA BRA Source: Itau Corretora, Sugar & Ethanol Sector Report. 17 October, 2006 16 Advanced Cellulase Development Program • Project Structure and Funding – U.S. Department of Energy (DOE) funded >$15 million over a 4-year period beginning in June 2000 – Sub-contract through the National Renewable Energy Laboratory (NREL) • Goal: Improved Low Cost Cellulase for Biomass Conversion to Ethanol – Original program targeted a 10-fold cellulase cost reduction – Program achieved a 30-fold reduction • Awards – R&D Magazine, Top 100 Innovations, 2004 17 Cellulase Cost Reduction: Challenges • Multiple Enzymes with various weaknesses • • • Protein engineering challenges Novel catalyst identification challenges Strain assembly challenges • Pre-project cellulase strain (Trichoderma) production yield “best in the industry”…. yet cost of hydrolysis step was far from realistic commercialization goal • Limited knowledge of Trichoderma genomic sequence; limited toolset for host development • Complex, recalcitrant substrate 18 Integrated Plan of Action Production Strain Enzyme Performance • Choice of Organism • Regulation of Expression • Induction • De-repression • Genomics • Novel Cellulolytic Activities • Enzyme Discovery • Generation of Diversity • Protein Engineering • Assays and Screens Cellulase Cost Reduction Production Process • Host Engineering • Fermentation Process Development • Breakthrough Production Economics • Product Recovery Manufacturing Economics of Scale 19 500 450 Combined Enzyme step cost drop ~30X $/gal EtOH (NREL Metric) 400 350 300 250 2.3X 200 150 100 11X 50 20X 30X 0 0 10 20 30 40 50 60 Program Months 20 Biomass Products in the Pipeline • First true biomass enzyme for cellulosic ethanol production in the near term – Potent enzyme complex enhanced for broad substrate application – Ability to operate in simultaneous saccharification and fermentation (SSF) or two step sequential hydrolysis and fermentation (SHF) – Significantly enhanced performance over existing products • Target market: serving an unmet need – Process developers designing pilot and demonstration plants – Allows for process design around known enzyme parameters • Further improvements are on-going to meet the demand for – Improved performance – Lower cost 21 AGENDA • Background on Genencor • Strategic Commercial Drivers • Strategic Technology Developments • Genencor’s Commercial Strategy 22 System (Enterprise) Level Solution Enzyme hydrolysis is best deployed as part of an integrated solution….. 23 Ranking & Screening Opportunities • Focus on substrates already collected & processed – – – – Sugarcane bagasse Wood chips, paper pulp, short fiber pulp waste Grain fibers (corn, wheat, etc.) Sugar beet pulp • Efficient logistics needed for substrates that need collection – Corn stovers & corn cobs – Wheat straw – Energy crops 24 Exploring New Business Models Genencor’s value proposition: We will build and deliver to our partners a sustainable advantage in protein production and enzyme performance so that the biorefinery operates at optimal efficiency. • Enzyme production integrated into the biorefinery – Dedicated production capacity – Shared location & infrastructure • Sharing value – Enzyme improvements will reduce Capital Expenses & Operating Expenses and make the biorefinery more profitable 25 Complex Issues Now @ Forefront • Integration of all technologies….. • Supply Chain – – – What will drive raw material availability? What incentives or guarantees will be required? What is “value” of each player’s contribution • Demand Chain – – What in addition to ethanol will provide the best value to investors? What will it take for them to be accepted in the market? • Investment – – What is best mechanism to allow regional/local investors to participate? What is the role of investment types (angel, traditional, etc.) • Derisking funds – federal and state (pioneers face huge risk) 26 Conclusions • Most cellulosic biomass technology advancements now being done at the system level • New business models & value sharing schemes are needed • Enzymes: – Supply source will be critical – Tremendous room for improvement at system level • Feedstock: – “Chicken and egg” issue may lessen soon for uncollected feedstocks – Significant potential for improvement in crop residue and dedicated crops 27 Thank you. jack.huttner@danisco.com 28