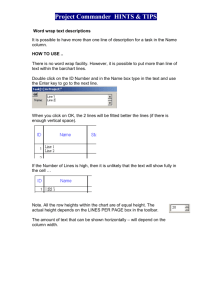

EverGuard® Square Tube Wrap Detail EverGuard® Square Tube Wrap are designed to be wrapped around square

advertisement

EverGuard® Square Tube Wrap Detail EverGuard® Square Tube Wrap are designed to be wrapped around square or rectangular tubing. The Square Tube Pipe Wrap comes in three Sizes 4” x 4”, 4” x 6”, 6” x 6”, but can also be custom made to whatever size is needed. Before installing, four Drill‐Tec™ plates and fasteners must be installed around next to the pipe. NOTE: If the plate and fasteners intrude into the boot flange area, then a target must first be installed over the plates and fasteners before boot installation. Dry‐fit the square tube pipe wrap in place and mark on the penetration where the wrap terminates. Remove the wrap and install EverGuard® Water‐Block Sealant or FlexSeal™ Caulk Grade Roofing Sealant slightly below the marks. Fit the square tube pipe wrap in place and lift up the flap area at the bottom of the curb corner overlaping the adjacent lap to create a T‐Joint intersection. Using the base of square penetration for stability, we are going to weld starting at the angle change of the flashing first. The membrane at the angle change can be softened with a little hot air from the welder on the outside. This will make welding the angle change easier to complete. Once the angle change area has been welded, we need to weld the vertical weld. NOTE: Overheating the membrane can cause distortion, which can produce an improper weld and ultimately lead to a leak Where these areas meet along the base, you need to cut the bottom underlying piece back at a 45 degree angle or “dog ear” it back, this will help to crease this T‐Joint intersection when it is welded. Begin with welding down the underlying flap area first. Then weld the top flap. You want to ensure that the T‐Joint area is creased in properly. Finish welding the remainder of the base flange starting near the penetration and working your way to the edge. Next install the pipe clamp. Since the pipe clamp will only compress on the corners of the square tube, we will first need to install slivers of GAF walk way pad, or scrap membrane on the 4 flat sides of the square tube between the flashing, and the clamp to ensure there is proper compression all the way around the square tube. Tighten the clamp and trim the excess clamp material down to one inch. Caulk over top of the clamp and the top edge of the wrap to finish off the detail.