Lipid Oxidation, Color, Volatiles, and ... Characteristics of Aerobically Packaged and

advertisement

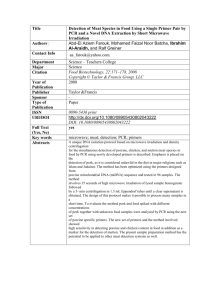

JFS: Sensory and Nutritive Qualities of Food Lipid Oxidation, Color, Volatiles, and Sensory Characteristics of Aerobically Packaged and Irradiated Pork with Different Ultimate pH K.C. NAM, D.U. AHN, M. DU, AND C. JO ABSTRACT: Irradiation and storage increased lipid oxidation of normal and pale-soft-exudative (PSE) muscles, whereas dark-firm-dry (DFD) muscle was very stable and resistant to oxidative changes. Irradiation increased redness regardless of pork-quality type, and the increases were proportional to irradiation dose. Irradiation increased the production of sulfur-containing volatiles, but not lipid oxidation products. The total volatiles produced in normal and PSE pork were higher than the DFD pork. Some volatiles produced in meat by irradiation evaporated during storage under aerobic packaging conditions. Nonirradiated normal and DFD pork had higher odor preference scores than the nonirradiated PSE, but irradiation reduced the preference scores of all 3 pork-quality types. Key Words: irradiation, pork ultimate pH, color, lipid oxidation, volatiles I technology to control microorganisms and parasites and to extend shelf life in raw meats. Nutritional disadvantages of irradiation have not been reported other than that thiamin is reduced in irradiated beef; more thiamin, however, is lost when beef is cooked than irradiated (Giroux and Lacroix 1999). Many researchers have reported that irradiation induces oxidative chemical changes, the formation of off odor, and color changes. Irradiation also increases 2-thiobarbituric acid (TBARS) values in meats. Initiators of lipid oxidation in irradiated meat are considered to be hydroxyl radicals generated by the interaction of ionizing energy with water molecules in muscle tissues or in meat products (Thakur and Singh 1994). Regardless of packaging type, irradiated raw pork patties produced more volatiles than nonirradiated ones and developed a characteristic aroma immediately after irradiation (Ahn and others 1998). Hashim and others (1995) showed that irradiating uncooked chicken breast and thigh produced a characteristic bloody and sweet aroma that remained after the thighs were cooked, but was not detectable after the breasts were cooked. Millar and others (1995) reported that the redness of chicken breast increased after ionizing irradiation in oxygen-permeable film. The changes in meat color after irradiation were highly dependent on animal species, muscle type, and location in a muscle (Nanke and others 1998). © 2001 Institute of Food Technologists The impacts of irradiation on meat color could be related to oxygen availability and the amount of free radicals formed at the time of irradiation. The ultimate pH of meat is also known to be a crucial factor for meat quality. Pork, depending on the ultimate pH, can be classified as normal, pale-soft-exudative (PSE), or darkfirm-dry (DFD); and each classification has its own distinctive color, texture, and flavor characteristics. The distribution and proportion of free and bound water in normal, PSE, and DFD pork are different. PSE pork upon irradiation would be more susceptible to oxidative changes and produce more off-flavor volatiles than irradiated normal or DFD meat due to its denatured muscle structure. Chen and Waimaleongora-Ek (1981) reported that the lower the pH value in the raw chicken meat sample, the higher the TBARS values. Silva and others (1999) showed that DFD pork was more susceptible to bacterial spoilage and was less flavorful than the normal pork. In addition, the response of normal, PSE, and DFD muscles to color changes upon irradiation could be different from each other. However, little work has been done to determine the effect of irradiation on the quality changes of raw pork with different ultimate pH. The objective of this study was to determine and compare the effects of irradiation on lipid oxidation, off-odor volatiles, and color of aerobically packaged normal, PSE, and DFD pork during refrigerated storage. Materials and Methods Sample preparation Twenty-four pork loin (Longissimus dorsi) muscles, 8 each of normal (pH 5.7 to 5.8), PSE (pH 5.4 or less) and DFD (pH 6.2 to 6.8) meat, were purchased from a local packing plant. The pork loins were trimmed of all fat from the surface, and the lean muscle was sliced to 3-cm thick steaks and packaged in polyethylene oxygen permeable bags. After packaging, they were stored overnight at 4 ⬚C and then irradiated using a Linear Accelerator (Circe IIIR, Thomson CSF Linac, SaintAubin, France). The target doses of irradiation were 0, 2.5, and 4.5 kGy. The energy and power level used were 10 MeV and 10 kw, respectively, and the average dose rate was 92.0 kGy/ min. The max/min ratio was approximately 1.12 for 2.5 kGy and 1.15 for 4.5 kGy. To confirm the target dose, 2 alanine dosimeters per cart were attached to the top and bottom surfaces of the sample. The alanine dosimeter was read using a 104 Electron Paramagnetic Resonance Instrument (Bruker Instruments Inc., Billerica, Mass., U.S.A.). The pork steaks were stored at 4 ⬚C for up to 10 d. The pH of meat samples was measured after 0, 5, and 10 d of storage after homogenizing samples with 9 vol. of deionized distilled water (DDW). Color and lipid oxidation in aerobically packaged irradiated pork loins were determined at 0, 5, and 10 d, volatile production at 0 and 10 d, and sensory analysis at 7 d of storage. Vol. 66, No. 8, 2001—JOURNAL OF FOOD SCIENCE 1225 SensoryandNutritiveQualitiesofFood Introduction RRADIATION IS THE BEST AVAILABLE Irradiation Impact on the Quality of Pork with Different Ultimate pH . . . Table 1—The pH of aerobically packaged normal, PSE, and DFD pork Longissumus dorsi muscle affected by irradiation dose and storage time at 4 ⬚C Storage 0 kGy 2.5 kGy 4.5 kGy time Norm PSE DFD Norm PSE DFD Norm PSE Day 0 Day 5 Day 10 SEM2 5.69b 5.63b 5.64b 0.04 5.47c 5.46bc 5.45cd 0.04 6.39a 6.42a 6.53a 0.06 5.64b 5.60b 5.59bc 0.03 5.46c 5.40c 5.40d 0.03 6.35a 6.42a 6.47a 0.06 5.67b 5.50c 5.66b 5.46bc 5.58bc 5.49bcd 0.04 0.02 DFD SEM1 6.32a 0.04 6.30a 0.05 6.40a 0.04 0.05 a-dDifferent letters within a row are different (P ⬍ 0.05), n = 8. 1 SEM: Standard errors of the mean among different meat type x irradiation within a storage time. 2 SEM: Standard errors of the mean among different storage time within a meat type. Color measurement Color measurements were conducted on the surface of samples with a LabScan spectrophotometer (Hunter Associated Labs. Inc., Reston, Va., U.S.A.) that had been calibrated against white and black reference tiles. Hunter L- (lightness), a- (redness), and b- (yellowness) values were obtained (American Meat Science Assn. 1991) using a setting of D65 (daylight, 65-degree light angle). An average value from 2 random locations on each sample surface was used for statistical analysis. TBARS value SensoryandNutritiveQualitiesofFood The fluorometric 2-thiobarbituric reactive substances (TBARS) method (Jo and Ahn 1998) was used to determine the extent of lipid oxidation in raw meat. Minced sample (3 g) was weighed and placed in a test tube (50 mL). Nine mL of deionized distilled water (DDW) was added, and the mixture homogenized with a Brinkman polytron (Type PT 10/35, Brinkman Instrument Inc., Westbury, N.Y., U.S.A.) for 15 s at high speed. The meat homogenate (0.5 mL), sodium dodecylsulfate (8.1% 200 L), hydrochloric acid (0.5 M, 1.5 mL), thiobarbituric acid (20 mM, 1.5 mL), butylated hydroxytoluene (7.2%, 50 L), and DDW (250 L) were added in a test tube. The sample was vortexed and heated in a 90 ⬚C water bath for 15 min. After cooling for 10 min in cold water, 1 mL of DDW and 5 mL of n-butanol/pyridine solution (15:1, v/v) were added. The sample was vortexed and centrifuged 3000 ⫻ g for 15 min, and the resulting upper layer was read by a fluorometer (Model 450, Barnstead/ Thermolyne, Dubuque, Iowa, U.S.A.) with 520 nm excitation and 550 nm emission. The amounts of TBARS were expressed as milligrams of malondialdehyde per kilogram of meat. Volatiles compound analysis A 1226 purge-and-trap apparatus (Pre- cept II and purge-and-trap 3000, Tekmar-Dohrmann) connected to a gas chromatograph/mass spectrometry (GC/MS, Hewlett-Packard) was used to analyze the volatiles responsible for the off odor in samples. Two-g of minced sample and 1 pack of oxygen absorber (Ageless type Z-100, Mitsubishi Gas Chemical America Inc., New York, N.Y., U.S.A.) were placed in a 40-mL sample vial. The vials were then flushed with helium gas (99.999%) for 5 s. The maximum holding time in a refrigerated (4 ⬚C) sample tray before analysis was less than 10 h to minimize the oxidation during the holding time. The meat sample was purged with helium gas (40 mL/ min) for 11 min. Volatiles were trapped at 30 ⬚C using a Tenax/Silica gel/Charcoal column (Tekmar-Dohrmann) and desorbed for 2 min at 220 ⬚C, focused in a cryofocusing unit at –100 ⬚C, and then thermally desorbed into a column for 30 s at 220 ⬚C. A combined column—an HP-624 (8 m, 250 m i.d., 1.4 m nominal) column with an HP-1 column (44 m, 250 m i.d., 0.25 m nominal) using a zero dead-volume column connector—was used for volatile analysis. Ramped oven temperature was used (0 ⬚C for 2.5 min, increased to 10 ⬚C at 2.5 ⬚C/min, increased to 80 ⬚C at 10 ⬚C/ min, increased to 150 ⬚C at 20 ⬚C/min, increased to 180 ⬚C at 10 ⬚C/min, and held for 1 min). Inlet temperature was 180 ⬚C. Liquid nitrogen was used to cool the oven below ambient temperature. Helium was the carrier gas at a constant pressure of 20.5 psi. The ionization potential of MS was 70 eV, and the scan range was 18.1 to 300 m/z. Identification of volatiles was achieved by comparing mass spectral data of samples with those of the Wiley library (Hewlett-Packard) and standards, when available. The area of each peak was integrated using ChemStationTM software (Hewlett Packard), and the total peak area (pA*sec) ⫻ 10 4 was reported as an indicator of volatiles JOURNAL OF FOOD SCIENCE—Vol. 66, No. 8, 2001 generated from the meat samples. The peaks produced by mass spectral data were grouped into 5 major volatile classes—ketones, alcohols, aldehydes, sulfur (S)-containing compounds, and hydrocarbons—and reported. Sensory analysis The intensity of off odor and preference for the odor of meat samples were determined at 7 d of storage using 76 sensory panelists. For evaluation of odor, samples containing 3-g muscle in coded, capped glass scintillation vials were presented to each panelist in isolated booths. A 15-cm linear hedonic scale, anchored at opposite ends with the words “no off odor” and “very strong odor,” and “not preferable” and “highly preferable,” was used to rate the samples on the intensity of irradiation odor and on the preference for the irradiation odor. The responses from the panelists were expressed in numerical values ranging from 0 (no off odor or not preferable) to 15 (very strong odor or highly preferable) to the nearest 0.1 cm. Statistical analysis The experimental design was to determine the effects of different meat type, irradiation, and storage time on lipid oxidation, volatiles content, and color changes in samples during the 10d storage. Data were analyzed using SAS software (SAS Institute Inc. 1985) by the generalized linear model procedure; the Student-Newman-Keul’s multiple range test was used to compare differences among means. Mean values and standard error of the means (SEM) were reported. Significance was defined at P ⬍ 0.05. Results and Discussion pH The pH values for the nonirradiated and irradiated normal, PSE, and DFD pork (Table 1) showed that irradiation had no effect on the pH of all 3 quality types of pork Longissimus dorsi muscle with aerobic packaging. The original ultimate pH of normal, PSE, and DFD meat has been maintained throughout the 10-d storage. Color The lightness, redness, and yellowness of 3 different grades of pork loins with aerobic packaging were compared by irradiation dose and storage time (Table 2). The most important factor influencing L-values was meat type (P Irradiation Impact on the Quality of Pork with Different Ultimate pH . . . Storage time L-value Day 0 Day 5 Day 10 SEM2 a-value Day 0 Day 5 Day 10 SEM2 b-value Day 0 Day 5 Day 10 SEM2 0 kGy Norm PSE 48.1by 51.3bcx 48.9cy 0.8 2.5 kGy 4.5 kGy DFD SEM1 DFD Norm PSE DFD Norm PSE 54.9a 53.5ab 51.9bc 0.9 42.3c 41.9d 44.8d 1.1 49.5b 52.1b 51.7bc 1.0 56.7a 55.9bc 58.1a 1.0 37.0dy 43.1ax 44.6dx 1.4 47.5b 49.5c 50.2bc 1.0 54.9a 52.8abc 53.1b 1.0 42.2c 42.2d 42.1d 0.9 7.1dey 9.1ay 9.8abcx 0.4 6.6ey 7.8abcxy 9.1bcx 0.5 7.0dey 5.6dy 9.1bcx 0.5 8.6cdy 7.9abcy 10.3abx 0.3 8.9cdx 6.5cdz 7.8cy 0.2 10.5bcx 7.0bcy 12.0ax 0.7 13.2ax 8.9az 11.1aby 0.6 11.9abx 7.3bcz 9.5bcy 0.5 12.5ax 0.5 8.5aby 0.4 11.8ax 0.6 0.7 11.0by 13.2abx 13.6abx 0.2 12.7az 13.8ay 14.6ax 0.2 9.5cdy 10.9bz 9.8cy 13.4aby 11.8cx 14.4ax 0.5 0.2 12.7ay 14.1ax 14.9ax 0.3 8.6dy 10.0cy 12.6bcx 0.5 11.0bz 12.5by 14.4ax 0.3 12.6az 13.6aby 14.6ax 0.3 10.2bcy 0.4 9.8cy 0.3 11.7cx 0.4 0.3 1.1 0.9 1.1 a-e Different letters within a row are significantly different ( P ⬍ 0.05), n = 8. x-z Different letters within a column of same color value are significantly different (P ⬍ 0.05). 1 SEM: Standard errors of the mean among different meat type x irradiation within a storage time. 2 SEM: Standard errors of the mean among different storage time within a meat type. Table 3—TBARS values of aerobically packaged normal, PSE, and DFD pork Longissumus dorsi muscle affected by irradiation dose and storage time at 4 ⬚C Storage 0 kGy 2.5 kGy 4.5 kGy time Norm PSE DFD Norm PSE DFD Day 0 Day 5 Day 10 SEM2 0.10cy 0.10cy 0.10c 0.10cy 0.12aby 0.10c 0.24bx 0.25bx 0.04 0.20bxy 0.09c 0.23bx 0.09b 0.03 0.01 0.32ax 0.26aby 0.35abx 0.64ax 0.06 0.10 0.11c 0.11b 0.01 Norm 0.13ay PSE DFD SEM1 0.13aby 0.10cy 0.01 0.28abxy 0.28abxy 0.12cx 0.04 0.38abx 0.47abx 0.12bx 0.09 0.07 0.07 0.01 a-c Different letters within a row are significantly different ( P ⬍ 0.05), n = 8. x-y Different letters within a column are significantly different ( P ⬍ 0.05). 1 SEM: Standard errors of the mean among different meat type x irradiation within a storage time. 2 SEM: Standard errors of the mean among different storage time within a meat type. 0.01). PSE pork, which has low pH, had the highest L-value, whereas DFD pork had the lowest L-value among the 3 meat types. Irradiated pork loin had (P ⬍ 0.01) greater a-values than nonirradiated pork chops regardless of meat type, and the increase in a-values was proportional to irradiation dose. Furthermore, the redness was not decreased during the 10-d storage period even in aerobic packaging conditions. Although there have been several inconsistent results (Satterlee and others 1971; Luchsinger and others 1996) in terms of the stability of increased redness in irradiated meat, the red/pink pigment formed by irradiation in this experiment was not easily oxidized. Therefore, irradiation could have a desirable effect on improving the color of PSE pork, which has a detrimental pale color and reduced pigment stability (Livingston and Brown 1981; Sorheim and others 1997). The b-values of PSE loin meats were higher (P ⬍ 0.01) than the normal and DFD samples at 0 d of storage. Color b-value increased during storage in all 3 pork types, but yellowness usually does not have much impact on the overall color of meat. Irradiation had no effect on the b-values of pork loin. TBARS values Meat type, irradiation, and storage time all influenced lipid oxidation of aerobic-packaged pork loin (Table 3). Irradiation and storage time increased (P ⬍ 0.01) the TBARS values of normal and PSE loin muscles, whereas DFD loin was not influenced by irradiation. DFD loin was very stable and resistant to the quality changes by irradiation and storage. DFD meat has high water holding capacity and intact membrane structure, which can act as a barrier against the attack of free radicals, such as hydroxyl radicals. Therefore, irradiation could be more useful for DFD meat than for the normal and PSE meats. Because DFD meat is more susceptible to bacterial spoilage than other pork types, its use as a meat ingredient or for retail cuts is highly limited. However, if combined with irradiation, DFD meat could be an excellent meat source for further processing or for retail cuts. PSE pork was more susceptible to lipid oxidation than the normal and DFD porks when irradiated and stored under aerobic conditions (Table 3). Our result agreed with Yasosky and others (1984) who reported that the ultimate pH of ground pork was negatively correlated with the TBARS values after 12 d of storage at 2 ⬚C. Cooked meat is highly susceptible to lipid oxidation because the cooking process denatures antioxidant components, damages cell structure, and exposes membrane lipids to the environment (Ahn and others 1998). The antioxidant effect was more notable when the irradiated raw turkey patties were loosely packaged than when they were vacuum-packaged (Ahn and others 1997). As in cooked meat, the membrane structure of PSE pork would be leaky because of protein denaturation by low pH and high carcass temperature at early postmortem. Through the holes generated by denatured membrane proteins, water molecules can easily get into membrane bilayers. Along with the water, free ionic iron and iron proteins confined inside of cells under normal conditions may also get into membrane bilayers and promote oxidative reactions when free radicals are available. Hydroxyl radicals can be formed from water molecules in all meat conditions upon irradiation, and the reaction of hydroxyl radicals is site specific because of their short halflife (10 –6 s). Therefore, the distribution of water and its location are critical for the irradiation-dependent initiation of lipid oxidation. Also, the susceptibility of muscle tissues to lipid oxidation is closely related to the nature, proportion, degrees of unsaturation of the fatty acids in the lipids, and the composition of phospholipids in the cell membrane (Gray and others 1996). Volatile compounds Meat type as well as storage time affected (P ⬍ 0.05) the production and the composition of volatiles in aerobically packaged pork loins (Table 4). At d 0 of storage, nonirradiated normal pork loins produced the higher amount of ketones than the PSE and DFD porks, but PSE pork produced the higher amount of alcohols and total volatiles than the normal and DFD porks. The Vol. 66, No. 8, 2001—JOURNAL OF FOOD SCIENCE 1227 SensoryandNutritiveQualitiesofFood Table 2—Color L-, a-, and b-values of aerobically packaged normal, PSE, and DFD pork Longissumus dorsi muscle affected by irradiation dose and storage time at 4 ⬚C Irradiation Impact on the Quality of Pork with Different Ultimate pH . . . Table 4—Relative production of volatiles in aerobically packaged normal, PSE, and DFD pork Longissumus dorsi muscle affected by irradiation dose at different storage times at 4 ⬚C also influenced by irradiation, but their changes by irradiation were not as severe as those of other volatile groups. Storage 0 kGy 2.5 kGy 4.5 kGy As storage time increased, the comtime Norm PSE DFD Norm PSE DFD Norm PSE DFD SEM1 position of volatiles in pork changed significantly. Large amounts of ketones Peak area (pA*sec) ⫻ 104 from nonirradiated normal and alcoDay 0 hols from nonirradiated PSE pork after Ketones 15867a 550c 3041c 761c 195c 335c 5308b 189c 218c 733 10 d of storage were found in aerobicb a b b b b b b b Alcohols 2402 26350 4014 160 1192 0 420 370 52 86 Aldehydes 1055bc 763bc 1863a 472bc 844bc 684bc 633bc 1161b 399c 156 packaging conditions. After 10 d of storS-compounds 185d 1738c 65d 10037a 4643b 1274c 5143b 2979bc 2684c 592 age, the amounts of most volatile Hydrocarbons 2167c 2066cd 1991cd 3918a 2403bc 1049e 3174ab 3112ab 1183de 253 groups (except for ketones) decreased Total volatiles 23145b 32796a 11639cd 16905c 9830d 3727d 16125c 7379d 4937d 1944 (P ⬍ 0.05) from those at d 0, and the Day 10 differences in irradiation effect by meat Ketones 6040b 196c 3517bc 4357bc 0c 5718b 13128a 536c 1562bc 1248 type decreased. In particular, the Alcohols 127c 7664a 3067bc 165c 4913b 1199c 238c 1608c 131c 879 amounts of S-containing volatiles in irAldehydes 276c 388ab 470ab 239c 845a 445ab 390ab 781ab 341bc 106 radiated samples decreased drastically, S-compounds 139d 182d 112d 267d 632c 2146a 448c 387c 1169b 94 Hydrocarbons 1305c 1679c 1291c 1713c 5203a 1395c 1959c 3031b 1768c 294 and their differences among meat types Total volatiles 8411b 10579ab 9294ab 7124b 12391ab 12519ab 16853a 7070b 6128b 1853 also disappeared except for the DFD samples irradiated at 2.5 kGy. This result a-e Different letters within a row are significantly different (P ⬍ 0.05), n = 4 SEM: Standard errors of the mean among different meat type x irradiation within a volatile group. indicated that the volatiles produced by irradiation were escaped during storage under aerobic-packaging conditions. The disappearance rate of S-containing volatile compounds of irradiated DFD Table 5—Sensory characteristics of aerobically packaged irradiated normal, pork was slower than that of the normal PSE, and DFD pork Longissumus dorsi muscle refrigerated for 7 d or PSE pork. Irradiation Off-odor intensity3 0 kGy 2.5 kGy 4.5 kGy SEM2 Preference for the meat odor4 0 kGy 2.5 kGy 4.5 kGy SEM2 Norm PSE DFD 2.90by 4.00ay 3.12by 6.91x 7.33x 0.32 6.72x 7.32x 0.34 6.47x 6.79x 0.32 9.12ax 7.12y 6.37y 0.33 8.14bx 6.75y 6.56y 0.33 9.36ax 7.44y 7.06y 0.34 SEM1 Sensory characteristics 0.26 0.35 0.36 0.33 0.31 0.35 a-b Different letters within a row are significantly different (P ⬍ 0.05), n = 76. x-yDifferent letters within a column of the same question are significantly different ( P ⬍ 0.05). 1 SEM: Standard errors of the mean among different meat type within an irradiation dose. 2 SEM: Standard errors of the mean among different irradiation dose within a meat type. 3 Off-odor intensity: 0, no odor; 15, very strong odor. 4 Preference for the meat odor: 0, not preferable; 15, highly preferable. SensoryandNutritiveQualitiesofFood amounts of ketones and alcohols in meat decreased significantly after irradiation. The production of sulfur-containing volatile compounds in pork increased by irradiation, but no difference in S-compounds between 2.5 kGy and 4.5 kGy was observed. DFD pork produced the least amount of Scontaining volatiles among the 3 meat types at each irradiated and nonirradiated conditions (Table 4). The pH of the meat system could have an important role in producing S-containing volatile compounds by irradiation. Shu and others (1985) reported that a vigorous thermal degradation of cysteine into volatile components was occurring at the isoelectric point of cysteine. The major S-containing volatile compounds found in irradiated pork include mer1228 captomethane, dimethyl sulfide, carbon disulfide, methyl thioacetate, and dimethyl disulfide. Patterson and Stevenson (1995) found that dimethyl trisulfide is the most potent off-odor compound, and the changes that occur following irradiation are distinctively different from those of the warmed-over flavor in oxidized meat. Ahn and others (2000) reported that S-containing volatiles such as 2,3-dimethyl disulfide produced by radiolytic amino acids were responsible for the off odor in irradiated pork. They also assumed that the off-odor volatiles in irradiated pork were the result of compounding effects of volatiles from lipid oxidation and other reactions, such as radiolysis of amino acid side chains. The production of aldehydes and hydrocarbons in pork were JOURNAL OF FOOD SCIENCE—Vol. 66, No. 8, 2001 Meat type and irradiation dose affected (P ⬍ 0.05) the intensity of off odor and the preference for a meat odor (Table 5). The off-odor intensity of PSE was higher than normal and DFD meats in nonirradiated samples. Irradiation increased (P ⬍ 0.05) the intensity of irradiation odor, which was not significantly different among irradiated normal, PSE, and DFD meats. The preference for a meat odor also was consistent with the result of intensity of off odor. As the off odor in meat became more intense, the preference for the meat odor decreased because most trained panelists considered irradiation odor as an off odor. Huber and others (1953) reported that meat sterilized by irradiation developed a characteristic odor, which has been described as metallic, sulfide, wet dog, wet grain, or burnt. In nonirradiated samples, the preference for a meat odor for normal and DFD meats was higher than the PSE meat. After irradiation, however, there was no difference in odor preference for the 3 pork types. Ahn and others (2000) reported that sensory characteristics of irradiated meat were described as having a barbecued corn-like odor, and sensory panels showed no objection to the odor. However, irradiation of pork at the 2.5 kGy level decreased (P ⬍ 0.05) the odor preference for all 3 pork types in this study. Irradiation Impact on the Quality of Pork with Different Ultimate pH . . . I RRADIATION INCREASED TBARS AND off odor in aerobically packaged pork. But DFD pork, which usually is underutilized because of its microbial susceptibility, was more stable and resistant to lipid oxidation and off-odor production by irradiation than the normal pork. This suggests that irradiation can significantly increase the utilization of DFD pork, and can greatly benefit pork and beef industries. References Ahn DU, Jo C, Olson DG. 2000. Analysis of volatile components and the sensory characteristics of irradiated raw pork. Meat Sci 54:209-215. Ahn DU, Olson DG, Jo C, Chen X, Wu C, Lee JI. 1998. Effect of muscle type, packaging, and irradiation on lipid oxidation, volatile production, and color in raw pork patties. Meat Sci 49:27-39. Ahn DU, Sell JL, Jeffery C, Jo C, Chen X, Wu C, Lee JI. 1997. Dietary vitamin E affects lipid oxidation and total volatiles of irradiated raw turkey meat. J Food Sci 62:954-958. American Meat Science Association 1991. Guidelines for meat color evaluation. Available from: National Livestock and Meat Board, 444 N. Michigan Ave., Chicago, IL 606011 USA. 17 p. Chen TC, Waimaleongora-Ek C. 1981. Effect of pH on TBA 2-thiobarbituric acid values of ground raw poultry meat refrigerated storage. J Food Sci 46:1946-1947. Giroux M, Lacroix M. 1999. Nutritional adequacy of irradiated meat. Food Res Int 31:257-264. Gray JI, Gomaa EA, Buckley DJ. 1996. Oxidative quality and shelf life of meats. Meat Sci 43:S111-123. Hashim IB, Resurrecccion AVA, MacWatters KH. 1995. Disruptive sensory analysis of irradiated frozen or refrigerated chicken. J Food Sci 60:664-666. Huber W, Brasch A, Waly A. 1953. Effect of processing conditions on organoleptic changes in foodstuffs sterilized with high intensity electrons. Food Technol 7:109-115. Jo C, Ahn DU. 1998. Use of fluorometric analysis of 2thiobarbituric acid reactive substances in meat. Poultry Sci 77:475-480. Livingston DJ, Brown WD. 1981. The chemistry of myoglobin and its reactions. Food Technol 35:244252. Luchsinger SE, Kropf DH, Garcia-Zepeda CM, Hunt MC, Marsden JL, Rubiocanas EJ, Kastner C L, Kuecher WG, Mata T. 1996. Color and oxidative rancidity of gamma and electron beam-irradiated boneless pork chops. J Food Sci 61:1000-1005, 1093. Millar SJ, Moss BW, MacDougall DB, Stevenson MH. 1995. The effect of ionizing radiation on the CIE Lab color co-ordinates of chicken breast meat as measured by different instruments. Inter J Food Sci Technol 30:663-674. Nanke KE, Sebranek JG, Olson DG. 1998. Color characteristics of irradiated vacuum-packaged pork, beef, and turkey. J Food Sci 63:1001-1006. Patterson RLS, Stevenson MH. 1995. Irradiation-induced off-odor in chicken and its possible control. Br Poultry Sci 36:425-441. SAS Institute Inc. 1985. SAS User’s Guide. Cary, NC: SAS Institute Inc. 956 p. Satterlee LD, Wilhelm MS, Barnhart HM. 1971. Low dose gamma irradiation of bovine metmyoglobin. J Food Sci 36:549-551. Shu CK, Hagedorn ML, Mookherjee BD, Ho CT. 1985. pH effect on the volatile components in the thermal degradation of cysteine. J Agric Food Chem 33:442-446. Silva JA, Patarata L, Martins C. 1999. Influence of ultimate pH on bovine meat tenderness during aging. Meat Sci 52:453-459. Sorheim O, Erlandsen T, Nissen H, Lea P, Hoyem T. 1997. Effects of modified atmosphere storage on colour and microbiological shelf life of normal and pale, soft and exudative pork. Meat Sci 47:147-155. Thakur BR, Singh RK.1994. Food irradiation-chemistry and application. Food Rev Int 10:437-473. Yasosky JJ, Aberle ED, Peng ED, Mills EW, Judge MD. 1984. Effects of pH and time of grinding on lipid oxidation of fresh ground pork. J Food Sci 49:15101512. MS 20000509 Journal Paper Nr J-18852 of the Iowa Agriculture and Home Economics Experiment Station, Ames, IA 50011. Project Nr 3322, supported by the Food Safety Consortium. Authors are with the Animal Science Dept., Iowa State Univ., Ames, IA 50011-3150. Direct inquiries to author Ahn (E-mail: duahn@iastate.edu). Vol. 66, No. 8, 2001—JOURNAL OF FOOD SCIENCE 1229 SensoryandNutritiveQualitiesofFood Conclusion