Volatile Substances of Chinese Traditional Jinhua Ham and Cantonese Sausage JFS:

advertisement

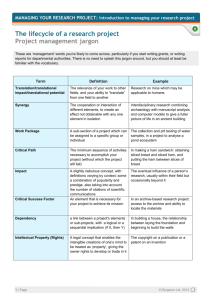

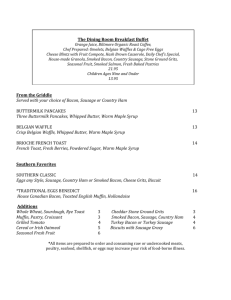

JFS: Food Chemistry and Toxicology Volatile Substances of Chinese Traditional Jinhua Ham and Cantonese Sausage Abstract: The relationship between volatile substances and manufacturing procedures of Chinese traditional Jinhua ham and Cantonese sausage were determined. Ethanol and its alcohol esters were the major volatiles of Cantonese sausage suggesting that ethanol added to meat at the formulation stage was the most important factor for the characteristic flavor of Cantonese sausage. Small amounts of fatty acid and amino acid breakdown products were also detected in Cantonese sausage. In Jinhua ham, alkanes and alkenes were the major volatiles, but branched aldehydes and sulfur compounds were also detected. This indicated that many complicated chemical reactions occurring in Jinhua ham during ripening contribute to its characteristic flavor. Keywords: volatile composition, meat, jinhua ham, Cantonese sausage Introduction T HERE ARE NUMEROUS TRADITIONAL Chinese-style semi-dry sausages in Chinese traditional market and found that they varied in thiobarbituric acid reactive substances ( TBARS) values and nitrite concentrations. There is no similar product of Chinese-style semidry sausages in other parts of the world. The large quantity of wine added into Cantonese sausage during manufacturing may contribute much of its specific flavor to the product. No lactic acid bacteria starter culture is added to Cantonese sausage, which therefore differs from most fermented sausages elsewhere. Addition of large amounts of sugar may also contribute to the flavor formation in the Chinese-style sausage products. Lin and others (2000) showed that adding 7 to 9% of sugar in Chinese-style sausage was conducive to proteolysis than adding 5% of sugar. So far, almost no published report on the volatiles of Cantonese sausage is available. The aim of this study was to determine the volatile substances of these 2 important traditional Chinese meat products using purge-and-trap dynamic headspace/gas chromatography-mass spectrometry (GC-MS) and to assess the possible relationship between these volatiles and manufacturing procedures of these meat products. Further, this work may help stimulate interest in studies on traditional Chinese-style meat products. meat products in China and Southeast Asia, but Jinhua ham and Cantonese sausage are the most famous and popular (Dong and others 1999). These products have strong characteristic flavors enjoyed by most Chinese consumers. The characteristic flavors of these products are considered to be derived from their volatile substances. However, almost no information on the characteristics of these substances is available. Jinhua ham is a dry-cured ham produced through a long ripening period during which lipids and proteins are degraded by natural enzymes in meat, producing free fatty acids, free amino acids and volatile compounds ( Wagu and others 1995; Berdague and others 1993a). Jinhua ham is quite similar to Western-style dry-cured hams where numerous reports have been published on the volatiles of those products (Berdague and others 1991; Garcia and others 1991; Barbieri and others 1992; Sabio and others 1998). Differences in volatile substances between Jinhua and Westernstyle dry-cured hams, however, are expected because of different manufacturing procedures. Chinese Cantonese sausage is one of the most famous Chinese-style semi-dry sausages. The common ingredients in Chinese-style semi-dry Materials the Methods sausages are wine and sugar, added in large quantities. The amounts of wine and sugar added, however, vary de- Sample preparation pending upon the fermentation conFour packages each of Jinhua ham ditions and the addition of spices. (Zhejiang Cereals, Oil & Foodstuffs I/E Chou and Liu (1996) surveyed the Corp. Ltd., Hangzhou, China) and © 2001 Institute of Food Technologists Cantonese sausage (Guangdong Foodstuffs I/E Corp., Guangdong, China) were purchased from different stores in Beijing, China. The bags of ham and sausage were cut open, divided into small portions, repackaged in oxygenimpermeable vacuum bags (O 2 permeability, 9.3 mL O2/m2/24 h at 0 8C), and then stored at –20 8C until used. Before analysis, samples were stored at 4 8C overnight. Lipid extraction Lipids were extracted from samples according to the method of Folch and others (1957). Two grams of ham or sausage sample, butylated hydroxytoluene (BHT; 50 mL, 7.2%), and 30 mL Folch 1 solution (chloroform:methanol = 2:1) were added to a 50-mL test tube and homogenized with 3 volumes of deionized distilled water using a Polytron (Brinkman Instruments, Inc., Westbury, N.Y., U.S.A.) for 20 s at high speed. The homogenate was filtered through a Whatman No. 1 filter paper (Whatman Inc., Clifton, N.J., U.S.A.) into a 100-mL graduated cylinder, and the filter paper was rinsed twice with 10 mL of Folch 1 solution. After addition of 8 mL of 0.88% NaCl solution to each cylinder, the cylinder was capped with a glass stopper and the content mixed. The inside of the cylinder was washed twice with 2 mL of Folch 2 solution (chloroform: methanol: water = 3:47:48). After phase separation, the lipid layer volume was recorded, and the upper layer (methanol and water) of the solution was completely and carefully siphoned off so as not to contaminate the chloroform layer. This organic layer was put in a glass scintillation vial and dried under nitrogen flow. Vol. 66, No. 6, 2001—JOURNAL OF FOOD SCIENCE 827 Food Chemistry and Toxicology M. DU AND D.U. AHN Volatiles of Chinese Ham and Sausage . . . Food Chemistry and Toxicology GC determination of fatty acid composition Table 1—Fatty acid composition and TBARS values of Chinese Cantonese sausage and Jinhua1 ham Twenty-five mg of extracted oil, transferred into a 20-mL test tube with cap, was used for methylation. One mL of methylating reagent (boron trifluoride-methanol; Sigma Chemical Co. St. Louis, Mo., U.S.A.) was added and incubated in a 90 8C water bath for 1 h. After this was cooled to room temperature, 2 mL hexane and 5 mL water were added, mixed thoroughly, and left at room temperature overnight for phase separation. The top hexane layer containing methylated fatty acids was used for fatty acid analysis using a GC (HP 6890; Hewlett Packard Co. Wilmington, Del., U.S.A.). A ramped oven temperature condition (180 8C for 2.5 min, increased to 230 8C at 2.5 8C/min, then held at 230 8C for 7.5 min) was used. Temperatures at both the inlet and detector were 280 8C. Helium was the carrier gas at linear flow of 1.1 mL/min. Flame ionization detector air, H 2, and make-up gas (He) flows were 350, 35, and 43 mL/ min, respectively. Fatty acids were identified by MS and GC retention times were compared with known standards. Relative quantities were expressed as wt% of total fatty acids. Item Volatile analysis A purge-and-trap dynamic headspace GC/MS system was used to identify and quantify the volatile compounds. One-half gram of ham or sausage sample was placed in a 40-mL sample vial, and the vial was flushed with helium gas (99.999%) for 5 s at 40 psi. After capping with a Teflon-lined, open-mouth cap, the vial was placed in a refrigerated (4 8C) sample tray. The maximum sample holding time in the sample tray before determination of volatiles was less than 10 h to minimize oxidative changes (Ahn and others 1999). The meat sample was purged with helium gas (40 mL/min) for 15 min. Volatiles were trapped at 20 8C using a Tenax/silica gel/charcoal column (Tekmar-Dohrman, Cincinnati, Ohio, U.S.A.) and desorbed for 2 min at 220 8C. The desorbed volatiles were concentrated at –90 8C using a cryofocusing unit (Tekmar-Dohrman, Cincinnati, OH), thermally desorbed and injected (30 s) onto a capillary column by increasing the temperature to 220 8C. An HP-624 column (7.5 m, 0.25 mm i.d., 1.4 mm nominal) and an HP-1 column (52.5 m, 0.25 mm i.d., 0.25 mm nominal; Hewlett-Packard Co.) were connected using a zero dead-volume Jinhua ham Cantonese sausage Identification Total fat content 20.84 6 0.14 31.73 6 0.20 Fatty acid composition ———————— (%) ———————— Tetradecanoic 1.22 6 0.08 1.21 6 0.08 Hexadecenoic 2.34 6 0.31 2.51 6 0.07 Hexadecanoic 23.25 6 0.75 22.86 6 0.22 Heptadecenoic 0.22 6 0.04 0.22 6 0.04 Heptadecanoic 0.24 6 0.06 0.23 ± 0.06 Octadecadienoic 8.98 6 1.40 9.12 ± 1.54 Octadecenoic 44.07 6 2.19 44.55 6 1.44 Octadecatrienoic 3.90 6 0.54 4.23 6 0.23 Octadecanoic 12.39 6 1.29 11.66 6 0.26 Eicosatetrenoic 1.36 6 0.25 1.35 6 0.20 Unidentified 2.03 6 0.28 2.06 6 0.27 Total saturated fatty acid 37.10 35.96 Total unsaturated fatty acid 60.87 61.98 TBARS value ———mg malonaldyde/kg meat——— 1.14 6 0.12 4.78 6 0.32 MS/RT2 MS/RT MS/RT MS MS/RT MS/RT MS/RT MS/RT MS/RT MS/RT 1n=4. 2 MS: identified by mass spectrometry; RT: identified by retention time of standards. column connector ( J&W Scientific, Folsom, Calif., U.S.A.). Ramped oven temperature was used to improve volatile separation. The initial oven temperature of 0 8C was held for 2.50 min. After that the oven temperature was increased to 10 8C at 2.5 8C per min, increased to 80 8C at 10 8C per min, increased to 150 8C at 20 8C per min, and then increased to 180 8C at 10 8C per min and was held for 2 min at that temperature. Constant column pressure at 20.5 psi was maintained. The ionization potential of the mass selective detector (Model 5973; HewlettPackard Co.) was 70 eV, and the scan range was 33.1 to 350 m/z. Identification of volatiles was achieved by comparing mass spectral data of samples with those of the Wiley library (Hewlett-Packard Co.). Standards, when available, were used to confirm the identification by the mass selective detector. The area of each peak was integrated using ChemStation software (Hewlett-Packard Co.), and the total ion count 3 104 was reported as an indicator of volatiles generated from the meat samples. Statistical analysis Four packages of ham and sausage each were used to analyze volatile and fatty acid composition. Data were analyzed as 8 replications using SAS software (SAS Institute Inc. 1989). The generalized linear model (GLM) procedure was used to calculate the means and standard errors. Results & Discussion T HE FATTY ACIDS OF C HINESE J INHUA ham and Cantonese sausage were 828 JOURNAL OF FOOD SCIENCE—Vol. 66, No. 6, 2001 very similar ( Table 1). Both products contained about 61 to 62% of total unsaturated fatty acids and 36 to 37% total saturated fatty acids. Their major fatty acids were octadecenoic acid, hexadecenoic acid, and octadecanoic acid, in descending order. However, Cantonese sausage had 4-fold higher TBARS than the Jinhua ham (Table 1). The high TBARS value of Cantonese sausage could be related to the grinding and fermentation steps and high fat content in Cantonese sausage. The fat content of Cantonese sausage was 31.73%, much higher than that of the Jinhua ham (20.84%; Table 1). The color of TBARS samples from Cantonese sausage was orange-red, not a typical red color, indicating that the major TBARS were not malonaldehyde but rather other oxidation compounds including ethanol and aldehydes. Many compounds can react with thiobarbituric acid (TBA) to produce chromatic products. Kosugi and others (1987) reported that alkanals and alkenals reacted with TBA and produced yellow (455 nm) and orange (495 nm) pigments. Supporting the interpretation, alkanals detected in volatiles indicated that large amounts of alkanals and alkenals were formed in Cantonese sausage, probably via the extensive degradation of lipids during the fermentation of Cantonese sausage. This also suggested that the TBARS measurement, determined at 531 nm, underestimated the real oxidation status of Jinhua ham. Ethanol and ethyl esters of fatty acids were the dominant volatile components (76% of total volatiles) in Chinese Cantonese sausage ( Table 2). In Cantonese sausage, a large amount of Volatiles of Chinese Ham and Sausage . . . Table 2—Volatiles in Chinese Cantonese sausages Volatiles Ion counts (×104) Ethanol and methyl/ethyl ethers Ethanol Acetic acid ethyl ester 1-Propene, 3-ethoxy-2-methyl ester Propanoic acid ethyl ester Propanoic acid 2-methyl-ethyl ester Butanoic acid 2-methyl ethyl ester Butanoic acid 3-methyl ethyl ester Pentanoic acid, ethyl ester Hexanoic acid, ethyl ester Peptanoic acid, ethyl ester Total ethanol-related volatiles Alkanes and alkenes Hexane Heptane 1-Octene Octane Total alkanes, alkenes Aldehydes 2-Methyl propanal 3-Methyl butanal 2-Methyl butanal Pentanal Hexanal Total aldehydes Ethyl butanoate Methyl cyclopentane Chloroform Benzene 2-Pentanone 1,1-Diethoxy ethane 4-Heptanone Methyl benzene 4-Heptanone Total other volatiles Total volatiles Percentage Identification 133319 6 27109 33760 6 13781 515 6 153 2779 6 1073 3030 6 926 216 6 192 222 6 286 316 6 260 3440 6 1252 320 6 73 177917 57.38 14.53 0.22 1.20 1.30 0.09 0.10 0.14 1.48 0.14 76.58 MS/RT 2 MS/RT MS MS MS MS MS MS/RT MS/RT MS/RT 2677 6 728 1499 6 465 265 6 222 1143 6 505 5584 1.15 0.65 0.11 0.49 2.40 MS/R MS/RT MS/RT MS 244 6 77 1107 6 327 449 6 120 663 6 347 1911 6 1774 4374 40674 6 19048 353 6 118 809 6 189 180 6 46 265 6 217 1170 6 930 513 6 101 345 6 145 156 6 45 44465 232337 6 43747 0.11 0.48 0.19 0.29 0.82 1.88 17.51 0.15 0.35 0.08 0.11 0.50 0.22 0.15 0.07 1.63 100.00 MS MS/RT MS/RT MS/R MS/RT Other volatiles MS/RT MS MS/RT MS/RT MS/RT MS MS/RT MS MS/RT 1 n=4. 2 MS: identified by mass spectrometry; RT: identified by retention time of standards. China. Briefly, the temperature of the ripening chamber is raised 4 8C per mo for the first 6 mo to 26 8C, then the temperature is lowered 4 8C per mo for 4 mo. Large amounts of n-alkanes, branched alkanes, aldehydes, and ketones were found in Jinhua ham, but ethanol and its derivatives were not detected. The sources of n-alkanes were not clear, but they were probably derived from lipids. 1-Pentene, 2-pentene, 1-octene, and 2-octene could be formed from the degradation of unsaturated fatty acids by a similar mechanism as n-alkanes, and hams contained large amounts of unsaturated fatty acids, as shown in Table 1. Many branched alkenes also were detected in Jinhua ham. This was in agreement with findings by Garcia and others (1991) who reported on the volatile components of Iberian dry-cured ham. It is difficult to derive the mechanisms of branched-alkene formation, but the most probable pathway for the forma- tion of branched alkenes in Jinhua ham could be through the degradation and intermolecular rearrangement of fatty acids. This conclusion is similar to that reported by Ruiz and others (1999) who detected high amounts of n-alkanes and branched-alkanes in dry-cured Iberian ham. Sabio and others (1998) also showed that Iberian ham had a high amount of medium-chain hydrocarbon compounds, similar to our results with Jinhua ham. However, the volatile components of Bayonne, light Italian country, and Parma ham were somewhat different from the Jinhua ham (Sabio and others 1998). The common characteristic processing method of Iberian ham and Jinhua ham is a very long aging time. During this aging period, a large number of alkanes should be formed through various reactions including lipid oxidation. Numerous branched aldehydes were also detected in Jinhua ham. The branched aldehydes might be produced by enzyme-cata- Vol. 66, No. 6, 2001—JOURNAL OF FOOD SCIENCE 829 Food Chemistry and Toxicology wine (approximately 8% of meat, ethanol content about 15%) is usually added at the beginning of the sausagemaking process. Sausages are fermented and oven-dried at about 50 8C for 3 days, with relative humidity of about 70%. High amounts of ethanol and ethyl esters indicated that ethanol and its derivatives played a central role in the formation of the characteristic flavor of Cantonese sausage. Chen and others (1997) also reported that wine is important for the flavor development of Chinese-style sausage. The purpose of using a large amount of wine in Cantonese sausage is: to produce characteristic flavor and to prevent the spoilage of sausage during the fermentation process. Because no lactic acid starter culture is added in Cantonese sausage manufacture, as in other fermented sausages, bacteria would grow quickly if a large amount of ethanol, which inhibits bacterial growth, was not added. In sausages fermented with lactic acid bacteria, the strains of lactic acid bacteria influence the generation of volatile components substantially (Berdague and others 1993b). Loury (1972) suggested that n-alkanes might come from the oxidation of unsaturated lipids. About 30 volatile compounds were detected in the Cantonese sausage. Hexanal has been suggested as the oxidation product of linoleic acid, and the detection of hexanal among the volatiles indicated that there was a certain degree of lipid oxidation in the Cantonese sausage. This was in agreement with the TBARS values shown in Table 1. Branched aldehydes could come from the degradation of amino acids by oxidative deamination-decarboxylation of amino acids via the Strecker degradation (Garcia and others 1991). Other volatiles, such as octane, heptane, pentane, heptanone, octane, and hexane, could be formed via the degradation of unsaturated fatty acids or amino acids. Endogenous enzymes in meat and enzymes from microorganisms, and the degradation of sugar and its reaction with amino acids or lipids during fermentation, also could have contributed to the formation of these volatiles. The volatiles in Jinhua ham are quite different from those of the Cantonese sausage (Table 3). Processing of Jinhua ham involves a long ripening process (10 mo) at a relative humidity of about 70 %. The temperature during the ripening periods changes along with the climate changes in the Jinhua area of Volatiles of Chinese Ham and Sausage . . . Table 3—Volatiles in Chinese Jinhua ham1 Volatiles Ion counts (3 3 104) Percentage Identification 0.08 30.44 1.75 7.42 11.70 13.37 1.12 0.24 0.86 66.97 MS/RT 2 MS/RT MS MS/RT MS/RT MS/RT MS MS MS Food Chemistry and Toxicology n-Alkanes and alkenes Butane 70 6 56 Pentane 25907 6 5341 2-Pentene 1490 6 478 Hexane 6312 6 1096 Heptane 9956 6 3442 Octane 11378 6 4217 1-Octene 951 6 325 1-Pentene 207 ± 122 2-Octene 735 6 246 Total alkanes and alkenes 57006 Branched alkanes and alkenes Methyl cyclopentane 417 6 79 Methyl cyclohexane 196 6 50 2,5-Dimethyl hexane 297 6 95 2,4-Dimethyl hexane 752 6 230 2,3,4-Trimethyl pentane 1488 6 441 2,3,3-Trimethyl pentane 1320 6 377 2,3-Dimethyl hexane 456 6 137 3-Methyl heptane 407 6 116 3-Methyl-2-heptene 1797 6 555 Total branched alkanes and alkenes 7130 Aldehydes 2-Methyl propanal 2668 6 866 3-Methyl butanal 5304 6 2052 2-Methyl butanal 4225 6 1425 Pentanal 518 6 349 Hexanal 143 6 93 Total aldehydes 12715 Sulfur compounds Methanethiol 117 6 36 Thiobis methane 122 6 102 Thiourea 59 6 20 2,3-Dimethyl disulfide 735 6 208 Total sulfur compounds 1033 Other volatiles 2-Methyl furan 212 6 62 Chloroform 2880 6 835 Benzene 127 6 81 2-Ethyl furan 413 6 100 Methyl benzene 388 6 96 1,2 Cyclohexanedione 2938 6 877 Ethyl benzene 59 6 31 1,4 Dimethyl benzene 73 6 39 Total other volatiles 7090 Total volatiles 85116 6 17873 0.49 0.23 0.35 0.88 1.75 1.55 0.54 0.48 2.11 8.38 MS MS MS MS M MS MS MS MS 3.13 6.23 4.96 0.61 0.17 15.11 MS MS/RT MS/RT MS/RT MS/RT 0.14 0.14 0.07 0.86 1.21 MS/RT MS/RT MS/RT MS/RT 0.25 3.38 0.15 0.49 0.46 3.45 0.07 0.09 8.33 100.00 MS MS/RT MS/RT MS MS MS MS MS 1n=4. 2 MS: identified by mass spectrometry; RT: identified by retention time of standards. lyzed and other chemical reactions. Jose and others (1993) reported that muscle lipases and esterases in drycured ham are quite stable and active even after 15 mo of ripening, indicating that endogenous enzymes could have contributed to the formation of volatiles in dry-cured ham. Hinrichsen and Pedersen (1995) examined the relationship between microorganisms and volatiles formed in meat products and suggested that microorganisms contributed to volatile formation, especially those related to amino acid catabolism. About 15% of total volatiles in Jinhua ham were aldehydes. Because Jinhua hams were exposed to air for about 1 yr during the manufacturing process, large amounts of lipid oxidation products can be expected. Ruiz and others (1999) reported that the content of 2- and 3-methylbutanals, the degradation products of amino acids (leucine and isoleucine), were higher in aged hams. Aldehydes in drycured ham may be correlated to the aromas of ham and cured meats (Buscailhon and others 1994). Most of the volatile compounds found in drycured hams could be produced by lipid autoxidation and amino acid degradation (Sabio and others 1998). Four sulfur compounds were detected in the volatiles of Jinhua ham ( Table 3). Although the amounts of sulfur compounds were relatively small, they can 830 JOURNAL OF FOOD SCIENCE—Vol. 66, No. 6, 2001 be expected to play an important role in the overall taste/odor of ham, because their threshold values are much lower than those of other volatile compounds. Chloroform, benzene, and methyl benzene were found in both Cantonese sausage and Jinhua ham. These volatiles were not from the meat products but from the packaging materials. We observed the migration of these compounds from packaging materials to raw and cooked meat during storage (unpublished data). Conclusion T HIS STUDY INDICATED THAT THE MA- jority of volatiles from Cantonese sausage are alcohol derivatives. Only a small proportion of volatiles was generated from fatty acids and amino acids. The volatiles in Jinhua ham, however, were very different from those of the Cantonese sausage in that most of the volatile components were the breakdown products of fatty acids and amino acids. The alcohol-derived volatiles in Cantonese sausage should be related to the large amount of wine added during manufacturing, while the volatiles in Jinhua ham would be related to the long aging process. References Ahn DU, Jo C, Olson DG. 1999. Headspace oxygen in sample vials affects volatile production of meat during the automated purge-and-trap/GC analyses. J Agric Food Chem 47(7):2776-2781. Barbieri G, Bolzoni L, Parolari G, Virgili R, Buttini R, Careri M, Mangia A. 1992. Flavor compounds of drycured ham. J Agric Food Chem 40(12):2389-2394. Berdague JL, Denoyer C, Quere JL, Semon E. 1991. Volatile compounds of dry-cured ham. J Agric Food Chem 39(7):1257-1261. Berdague JL, Bonnaud N, Rousset S, Touraille C. 1993a. Influence of pig crossbreed on the composition, volatile compound content and flavour of dry cured ham. Meat Sci 34:119-129. Berdague JL, Monteil P, Montel MC, Talon R. 1993b. Effects of starter cultures on the formation of flavour compounds in dry sausage. Meat Sci 35(3):275287. Buscailhon S, Berdague JL, Bousset J, Cornet M, Gandemer G, Touraille C, Monin G. 1994. Relation between compositional traits and sensory qualities of French dry-cured ham. Meat Sci 37(2):229243. Chen MT, Guo HL, Liu DC. 1997. Volatile compounds and some properties of Chinese-style sausage. Fleischwirtschaft 77(3):249-250. Chou CK, Lin KJ. 1996. Studies on nitrite residue and quality of Chinese-style semi-dry sausage on the traditional market. J Chin Soc Anim Sci 24(1):8794. Dong RC. 1999. Modernization of traditional Chinese meat products processing. Meat Res 11(2):36. Folch J, Less M, Slaone-Stanley GM. 1957. A simple method for the isolation and purification of total lipids from animal tissues. J Biol Chem 226(2):497509. Garcia C, Berdague JJ, Antequera T, Lopez-Bote C, Cordoba JJ, Ventanas J. 1991. Volatile components of dry cured Iberian ham. Food Chem 41(1):23-32. Hinrichsen LL, Pedersen SB. 1995. Relationship among flavor, volatile compounds, chemical changes, and microflora in Italian-type dry-cured ham Volatiles of Chinese Ham and Sausage . . . Loury M. 1972. Possible mechanisms of autoxidative rancdity. Lipids 7(10):671-675. Ruiz J, Ventanas J, Cava R, Andres A, Garcia, C. 1999. Volatile compounds of dry-cured Iberian ham as affected by the length of the curing process. Meat Sci 52(1):19-27. Sabio E, Vidal-Aragon MC, Bernalte MJ, Gata JL. 1998. Volatile compounds present in six types of drycured ham from south European countries. Food Chem 61(4):493-503. SAS Institute Inc., 1989. SAS User’s Guide, Cary, NC: SAS Institute Inc. Wagu Y, Kakuta T, Shindo H, Koizumi T. 1995. A study on Jinhua Huotui in China. I. General compounds, amino acid, 5’-nucleotide and microorganism of Chinese fermented food ‘Jinhua huotui’. J Japanese Soc Food Sci Tech 41(12):921-926. MS 20001582 Journal Paper Nr. J - 19121 of the Iowa Agriculture and Home Economics Experiment Station, Ames, IA 50011. Project Nr. 3322, supported by Hatch Act and State of Iowa funds. Authors are affiliated with the Animal Science Dept., Iowa State Univ., Ames, IA 50011-3150. Direct inquiries to author Ahn (E-mail: duahn@iastate.edu). Food Chemistry and Toxicology during processing. J Agric Food Chem 43(11):29322940. Jose MM, Fiedl T, Pablo N, Jose F. 1993. Muscle lipolysis phenomena in the processing of dry-cured ham. Food Chem 48(2):121-125. Kosugi H, Kato T, Kikugawa K. 1987. Formation of yellow, orange, and red pigments in the reaction of alk-2-enals with 2-thiobarbituric acid. Anal Chem 165(2):456-464. Lin KJ, Dhanapati N, Ishioroshi M, Samejima K. 2000. Myofibrillar ATPase activity of Chinese-style semidry sausage as affected by curing time and sugar concentrations. Food Sci Agri Chem 1(1):34-39. Vol. 66, No. 6, 2001—JOURNAL OF FOOD SCIENCE 831