Meat Science 51 (1999) 355±361

Lipid oxidation, color changes and volatiles production in irradiated

pork sausage with dierent fat content and packaging during

storage$

C. Jo, J.I. Lee, D.U. Ahn*

Department of Animal Science, Iowa State University, Ames, IA 50011-3150, USA

Abstract

Eects of irradiation on lipid oxidation, color and volatiles production in pork sausages with dierent fat content and packaging

were determined. Sausages (with 4.7, 10.5 and 15.8% fat content) were sliced and vacuum-packaged either in oxygen-permeable or

impermeable bags, irradiated (0 or 4.5 kGy) and stored at 4 C for 7 days. Lipid oxidation, color and volatiles productions were

analyzed at 0, 3 and 7 days of storage. TBARS (2-thiobarbituric acid reactive substances) values of cooked pork sausages increased

with the increase of fat content regardless of storage, irradiation or packaging types. Irradiated samples had higher TBARS than

nonirradiated at 0 day but the dierence disappeared during storage in both packaging types. Lightness of sausages (Hunter Lvalue) increased with the increase of fat content and storage time but was not aected by irradiation. In aerobic packaging, irradiation reduced Hunter a-values of pork sausages at 0 day but irradiation eect on a-value disappeared during storage. In vacuum

packaging, however, irradiated samples had higher Hunter a-values than nonirradiated samples. Irradiation increased 1-heptene

and total volatiles, but the amount of 1-heptene was not associated well with TBARS values of pork sausages. In both irradiated

and nonirradiated pork sausages, aerobic packaging produced more volatiles than vacuum packaging during storage. It was concluded that irradiation and fat content had signi®cant eects on lipid oxidation, color and volatiles production of cooked pork

sausages during storage but that oxygen availability had a stronger eect than irradiation and fat content. # 1999 Elsevier Science

Ltd. All rights reserved.

1. Introduction

Low-dose (<10 kGy) irradiation can kill at least

99.9% of salmonella in poultry and an even higher percentage of Escherichia coli 0157:H7 (Olson, 1998). But,

irradiation is known to generate hydroxyl radicals that

can initiate chain reactions of lipid oxidation in aqueous

and oil emulsion systems. Irradiation could produce a

large amount of hydroxyl radicals in meat because over

75% of muscle cells are composed of water (Thakur &

Singh, 1994). Thayer, Boyd, and Jenkins (1993) reported

that irradiation-induced chemical changes are dose

dependent and the generation of characteristic o-odor

and color changes in meat is almost instantaneous after

irradiation. Both raw and cooked meats produce o-odor

after irradiation but the sources and mechanisms of oodor production in irradiated meats are not yet known.

* Corresponding author. Tel.: +1-515-294-6595; fax: +1-515-2942401; e-mail: duahn@iastate.edu

$

Journal paper no. J-17966 of the IA Agriculture and Home Economics Experiment Station, Ames, Iowa 50011-3150, USA. Project

no. 3322, and supported by Hatch Act and the Food Safety Consortium.

Ahn et al. (1998b) observed that aerobic-packaged

irradiated raw pork had signi®cantly higher TBARS

values than those of control. Less stable displays of

color were noted for samples irradiated in aerobic

packaging (Luchsinger et al., 1996). Akamittath,

Brekke, and Schanus (1990) suggested that discoloration and lipid oxidation are interrelated and pigment

oxidation may catalyze lipid oxidation. However, irradiation had no detrimental eects on the color or ¯avor

of cured meat with nitrite or a nitrite-free curing system.

Polyphosphates had a bene®cial eect on lipid oxidation

but a detrimental eect on color stability in irradiated

meat (Shahidi, Pegg, & Shamsuzzaman, 1991).

Lynch, Mac®e, and Mead (1991) reported that irradiated turkey breast ®llets produced unpleasant odor

notes when stored in oxygen-impermeable ®lm and the

odor notes were dierent from those developed from

corresponding nonirradiated samples. Heath, Owens,

Tesch, and Hannah (1990) and Hashim, Resurreccion,

and MacWatters, (1995) also showed that irradiating

uncooked chicken meat produced a characteristic

bloody and sweet aroma that remained after the meat

was cooked. Reineccius (1979) suggested that carbonyl

compounds are important for irradiation odor and that

0309-1740/99/$Ðsee front matter # 1999 Elsevier Science Ltd. All rights reserved

PII: S0309 -1 740(98)00134 -X

356

C. Jo et al./Meat Science 51 (1999) 355±361

Table 1

Eect of fat content and irradiation on lipid oxidation of cooked pork sausages with dierent packaging a

Fat content

0 day

0 kGy

Aerobic packaging

(%)

4.7

10.5

15.8

SEM

Vacuum packaging

(%)

4.7

10.5

15.8

SEM

a

b

c

d

4.5 kGy

3 day

SEM

0 kGy

4.5 kGy

7 day

SEM

0 kGy

4.5 kGy

SEMb

mg Malondialdehyde equivalents/kg Meat

1.6

1.6 bc

1.8 b

0.07

1.8

2.2 a

2.2 a

0.07

0.08

0.07

0.07

±

3.3 d

5.1 c

4.4 c

0.36

3.9 d

4.9 c

4.4 c

0.17

0.41

0.11

0.18

±

6.6

6.5

5.9

0.30

5.8

5.9

5.7

0.35

0.21

0.21

0.44

±

1.1 dd

1.4 bc

1.5 bc

0.04

1.2

1.6 ac

1.7 ac

0.04

0.05

0.04

0.03

±

1.2 e

1.5 d

1.7 c

0.04

1.3 e

1.6 d

1.8 c

0.04

0.04

0.04

0.05

±

1.4 d

1.6 c

1.7 ac

0.05

1.2

1.6

1.5 b

0.10

0.12

0.03

0.05

±

Irradiated at 0 or 4.5 kGy dose. n=4.

SEM: standard error of mean.

Dierent letters within a row are signi®cantly dierent ( p < 0.05).

Dierent letters within a column are signi®cantly dierent ( p < 0.05).

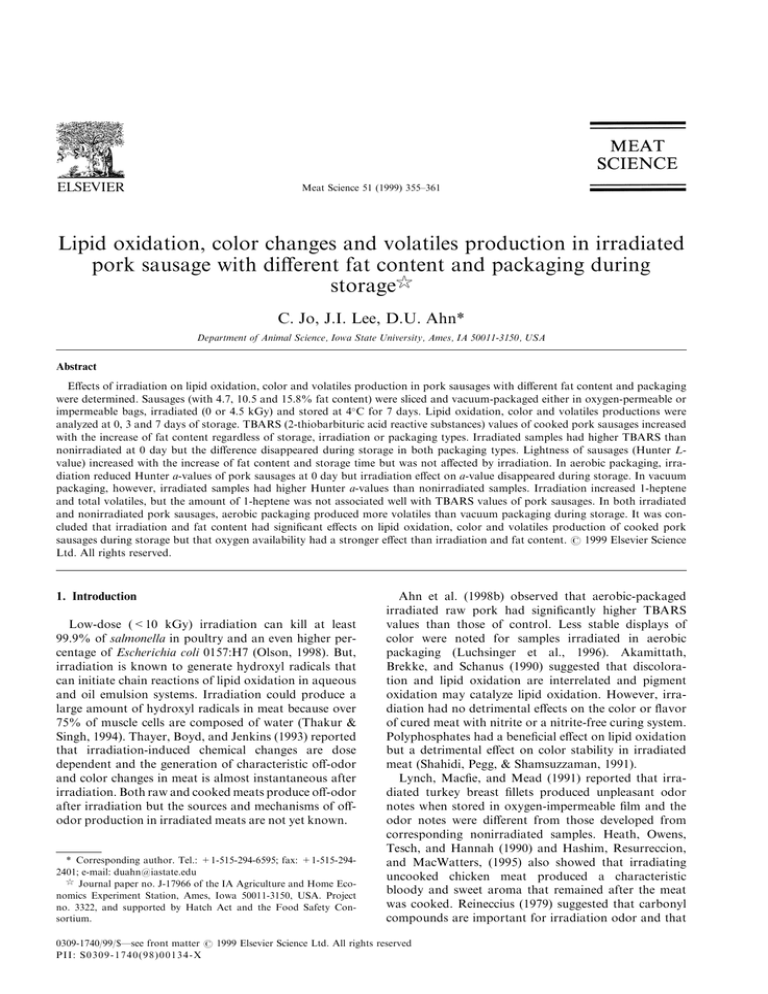

Fig. 1. Color changes of cooked pork sausages with aerobic packaging during storage (&), nonirradiated pork sausage with 0% fat added; (^),

nonirradiated pork sausage with 10% fat added; (*), nonirradiated pork sausage with 20% fat added; (&), irradiated pork sausage with 0% fat

added; (^), irradiated pork sausage with 10% fat added; (*), irradiated pork sausage with 20% fat added). a±c Dierent letters within a storage

day are signi®cantly dierent ( p < 0.05). NonIR, nonirradiated; IR, irradiated.

C. Jo et al./Meat Science 51 (1999) 355±361

357

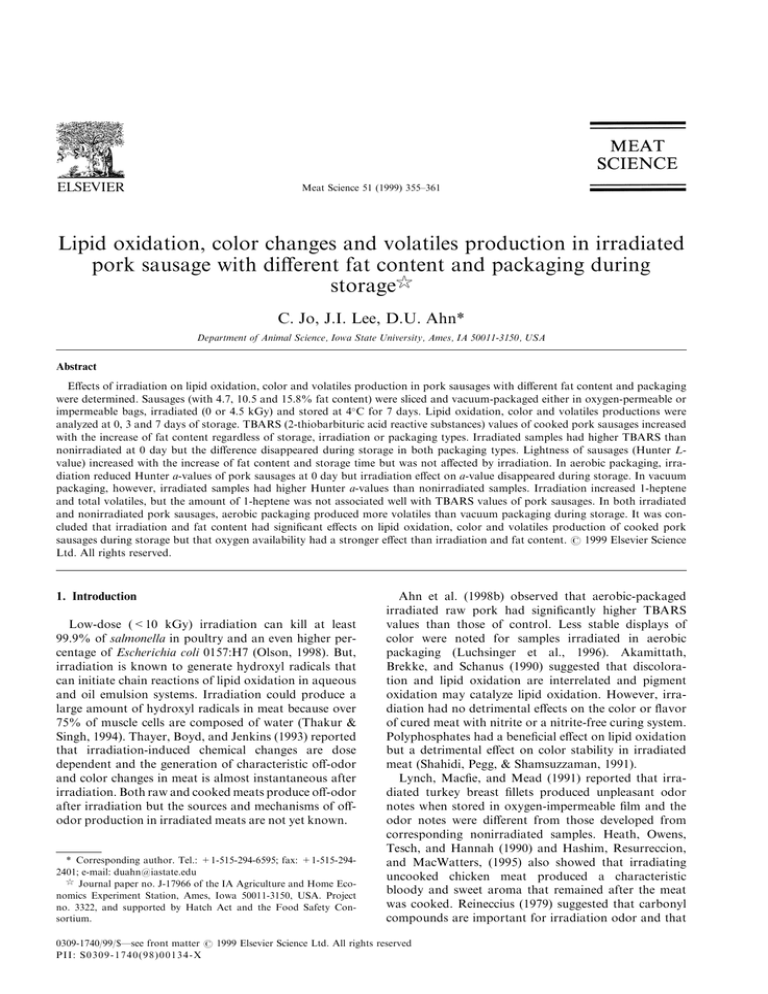

Fig. 2. Color changes of cooked pork sausages with vacuum packaging during storage (&), nonirradiated pork sausage with 0% fat added; (^),

nonirradiated pork sausage with 10% fat added; (*), nonirradiated pork sausage with 20% fat added; (&), irradiated pork sausage with 0% fat

added; (^), irradiated pork sausage with 10% fat added; (*), irradiated pork sausage with 20% fat added). a±c Dierent letters within a storage

day are signi®cantly dierent ( p < 0.05). NonIR, nonirradiated; IR, irradiated.

Table 2

Eect of fat content on the production of volatiles in irradiated aerobic-packaged pork sausages after 0 day of storage at 4 C a

Volatiles

1-heptene

Propanal

2-methylpropanal

2-methylbutanal

Pentanal

3-pentanone

Hexanal

1-butanol

1-pentanol

Nonanal

Decanal

1-heptanol

Aldehydes + ketones

Alcohols

Total volatiles

a

b

c

d

Nonirradiated

4.7%

10.5%

15.8%

1.0 b

9.6 c

19.8

16.8

25.7

98.6 a

157.8

7.8

11.7

1.0

nd d

1.0

329.1

20.5

350.5

5.6 a

12.7 b

14.1

21.0

27.5

81.7 ab

141.2

5.1

12.5

1.0

nd

1.0

299.2

18.6

323.4

9.0 a

17.6 a

17.8

12.7

25.2

54.5 b

157.6

4.5

13.0

1.0

nd

1.0

286.5

18.4

313.9

Irradiated at 0 or 4.5 kGy dose.

SEM: standard error of mean.

Dierent letters within a row are signi®cantly dierent ( p < 0.05). n =12.

nd: n=Not detected.

Irradiated

SEMb

4.7%

Area (pA s)

1.1

57.8

0.9

15.7 c

1.7

24.6

3.3

32.4

2.5

30.9

9.9

107.7 a

7.7

201.4 a

1.4

6.2

0.5

15.1 a

ÿ

6.2 a

ÿ

0.8

ÿ

1.0

16.6

419.5 a

1.5

22.3 a

17.2

499.6 a

10.5%

15.8%

SEM

44.0

20.5b

32.7

26.4

32.5

61.8 b

177.0 ab

7.4

14.8 a

3.3 b

nd

0.5

354.2 b

22.3 a

420.5 b

60.2

26.0 a

23.6

28.5

34.3

47.2 b

144.6 b

5.1

10.1 b

1.0 b

nd

0.3

305.2 b

15.4 b

380.8 b

6.0

1.5

3.6

2.5

3.0

11.9

13.0

1.4

1.0

0.8

0.1

0.2

19.3

1.6

22.6

358

C. Jo et al./Meat Science 51 (1999) 355±361

O2/m2/24 h at 0 C; Koch, Kansas City, MO) and stored

in a 4 C refrigerator overnight. Irradiation was conducted the next day at 0 or 4.5 kGy dose (97 kGy/min)

using a Linear Accelerator (Circe IIIR, Thomson CSF

Linac, France). For the aerobic packaging treatment,

vacuum packaging bags were opened before irradiation.

Samples were stored in a 4 C refrigerator immediately

after irradiation and 0-day samples were analyzed 3 h

after storage.

the intensity of irradiation odor is dependent upon

oxygen content during irradiation. El Magoli, Laroia,

and Hansen (1996) indicated that 2-butanone, 2-pentanone and 3-hydroxy-2-butanone increased with the

increase of fat content from 11 to 22% in beef patties,

and Ahn et al. (1998b) reported that propanal, pentanal, hexanal, 1-pentanol and total volatiles correlated

highly ( p < 0.01) with TBARS values of cooked meat.

Although lipid is the most important substance for

quality changes in meat, the eect of fat content on the

development of lipid oxidation, color changes and

volatiles production in irradiated meat is limited.

The objective of the present research was to determine

the in¯uence of irradiation on lipid oxidation, color

change and volatile production in cooked pork sausages

with dierent fat content and packaging during storage.

2.2. Measurements of lipid oxidation, color and fat

content

Lipid oxidation was determined using a spectrophotometer (Gilford Instrument Laboratories, Oberlin,

OH) as described in detail by Jo and Ahn (1998a).

TBARS values were expressed as mg malondialdehyde

(MDA) equivalents per kg meat. A CIE Lab color

[lightness (L), redness (a) and yellowness (b)] of sausages

was measured using a Hunter Colorimeter (Hunter

Associates Laboratories, Reston, VA). Total fat content

was determined by the Folch's extraction method

(Folch, Less, & Sloane-Stanley, 1957).

2. Materials and methods

2.1. Sample preparation

Lean pork was obtained from a local packer and

ground twice through a 9-mm plate. Pork sausages batters were prepared with the lean ground meat, back fat

(0, 10 or 20% of meat weight), NaCl (2%) and ice water

(10%). The batters were stued into cellulose casings (3

cm thickness) and cooked in a smoking chamber to an

internal temperature of 72 C. After cooling by a cold

water shower, the sausages were sliced to 2 cm-thick

pieces (approximately 30 g), vacuum-packaged into

oxygen-impermeable nylon/polyethylene bags (9.3 ml

2.3. Volatiles analysis

Precept II and a Purge-and-Trap concentrator

(Model 3000, Tekmar-Dohrmann, Cincinnati, OH)

were used to purge and trap volatiles, and a gas chromatography (GC) (Hewlett Packard, Model 6890, Wilmington, DE) equipped with a ¯ame ionization detector

(FID) was used to analyze volatiles from pork sausages.

Table 3

Eect of fat content on the production of volatiles in irradiated vacuum-packaged pork sausages after 0 day of storage at 4 C a

Volatiles

1-heptene

Propanal

2-methylpropanal

2-methylbutanal

Pentanal

3-pentanone

Hexanal

1-butanol

1-pentanol

Nonanal

Decanal

1-heptanol

Aldehydes + ketones

Alcohols

Total volatiles

a

b

c

d

Non irradiated

4.7%

10.5%

15.8%

4.1

12.1

13.8

17.4

24.5

73.3

136.3

2.4

12.0

1.0

nd d

1.0

303.3

15.4

297.8 bc

6.3

13.7

15.7

18.5

27.0

75.4

156.3

2.3

13.5

1.0

nd

1.0

307.6

16.8

331.1 a

8.2

16.1

13.0

17.1

26.3

72.2

143.2

6.2

10.1

1.0

nd

1.0

288.8

17.3

314.3 ab

Irradiated at 0 or 4.5 kGy dose.

SEM: standard error of mean.

Dierent letters within a row are signi®cantly dierent ( p < 0.05). n=12.

nd: not detected.

Irradiated

SEMb

4.7%

Area (pA s)

1.3

59.3

1.1

17.6 b

0.7

17.8

2.4

25.8

1.4

26.1 b

6.2

55.1

8.1

224.9 a

1.5

7.6

1.5

14.1 a

ÿ

6.8 a

ÿ

nd

ÿ

nd

15.2

374.2 a

1.7

22.6 a

8.2

456.1 a

10.5%

15.8%

SEMb

63.8

22.2 a

18.0

32.1

33.6 a

55.4

171.9 b

5.6

12.6 ab

1.0 b

nd

nd

334.3 ab

18.2 ab

416.3 ab

50.2

23.9 a

16.3

26.4

32.7 a

38.9

149.7 b

2.9

11.1 b

1.0 b

nd

nd

289.0 b

14.0 b

353.2 b

4.8

0.9

0.6

1.7

1.6

11.3

7.0

1.4

0.7

0.1

ÿ

ÿ

20.1

2.0

21.3

C. Jo et al./Meat Science 51 (1999) 355±361

359

Meat (2 g) was sampled into a vial (40 ml) and analyzed

using the conditions described in detail by Ahn et al.

(1998a). The area of each peak was integrated and

reported as an indicator of volatiles generated from the

meat samples.

15.8% fat content in vacuum packaging. The TBARS

values of vacuum-packaged pork sausages were very

similar throughout storage indicating that oxygen

availability is the most critical factor in the development

of lipid oxidation.

2.4. Statistical analysis

3.2. Color

Experimental design was constructed to determine the

eect of irradiation and fat content on lipid oxidation,

color changes and volatile production in cooked sausages stored in two packaging conditions. Analyses of

variance (SAS Institute, 1988) were used to ®nd dierences and the Student±Newman±Keul's multiple range

test was used to compare dierences among mean

values. Mean values and standard errors of the mean

(SEM) were reported.

Irradiation had no eect on Hunter L-values of sausages both with aerobic and vacuum packagings (Figs. 1

and 2). Pork sausages with high fat produced lighter

color than low-fat sausages. Storage increased Hunter

L-values of pork sausages with both packagings but, the

changes of Hunter L-values in vacuum-packaged sausages were smaller than those of the aerobic-packaged.

Irradiation reduced a-values of aerobic-packaged pork

sausages at day 0 but had no eect on those at day 3.

Nonirradiated pork sausages with 10% backfat added

had higher a-value than that of the irradiated sausages

with 20% backfat added at day 7. However, there were no

dierences in a-values between irradiated and nonirradiated sausages within a same backfat treatment at

day 7. The Hunter a-values of aerobic-packaged pork

sausage gradually decreased in all treatments as storage

time increased. The a-values of all pork sausage were the

highest in vacuum-packaged irradiated sausages and the

lowest in aerobic-packaged nonirradiated sausages.

Therefore, packaging type (oxygen availability) was again

an important factor for maintaining the color of sliced

pork sausages during storage. Irradiation reduced Hunter

b-values of vacuum-packaged sausages but had no eect

on Hunter b-values of the aerobic-packaged product.

3. Results and discussion

3.1. Lipid oxidation

Regardless of storage time, irradiation or packaging

types, TBARS values in sausages increased with the

increase of fat content (Table 1). Fat content of sausages prepared with 0, 10 and 20% backfat added were

4.7, 10.5 and 15.8%, respectively. Irradiation increased

the lipid oxidation of sausages with 10.5 and 15.8% fat

content in both aerobic and vacuum packaging at day 0.

However, the irradiation eect on lipid oxidation disappeared during storage except for the sausages with

Table 4

Eect of fat content on the production of volatiles in irradiated aerobic-packaged pork sausages after 7 days of storage at 4 C a

Volatiles

1-heptene

Propanal

2-methylpropanal

2-methylbutanal

Pentanal

3-pentanone

Hexanal

1-butanol

1-pentanol

Nonanal

Decanal

1-heptanol

Aldehydes + ketones

Alcohols

Total Volatiles

a

b

c

d

Nonirradiated

4.7%

10.5%

15.8%

9.6

16.0

68.8

9.9

33.3 a

93.8

369.6 a

8.2

29.8 a

7.0 a

4.7

6.8 a

602.9 a

41.8 a

654.3 a

9.9

20.2

63.5

13.4

26.9 a

79.0

228.7 b

7.5

25.3 a

3.8 b

3.9

4.3 b

439.5 b

37.1 b

486.5 b

13.5

13.4

120.0

15.3

20.1 b

60.3

200.7 b

7.1

21.5 b

3.0 c

5.5

2.9 c

138.0 b

31.5 c

483.0 b

Irradiated at 0 or 4.5 kGy dose.

SEM: standard error of mean.

Dierent letters with in a row are signi®cantly dierent ( p < 0.05). n=12.

nd: not detected.

Irradiated

SEMb

4.7%

Area (pA s)

1.6

60.1 a

2.3

26.9 b

19.0

60.8 c

1.6

22.1 a

2.1

35.5 a

9.8

81.8

9.4

349.7 a

0.3

7.6

0.6

24.6 a

0.2

6.1 a

1.1

1.0 a

0.2

5.4 a

24.6

583.8 a

0.9

37.6 a

24.0

681.5 a

10.5%

15.8%

SEMb

21.3 b

21.2 c

152.7 a

18.1 b

18.9 b

50.7

202.3 b

7.7

18.1 b

3.6 b

0.3 b

3.2 b

467.7 b

29.0 b

518.0 b

55.3 a

34.6 a

89.8 b

24.9 a

35.6 a

54.8

195.8 b

6.7

15.0 b

2.9 b

nd d

2.2 c

437.8 b

24.0 c

517.2 b

2.6

1.3

4.5

1.0

1.6

9.3

14.9

0.5

1.1

0.3

0.1

0.3

25.2

1.2

27.1

360

C. Jo et al./Meat Science 51 (1999) 355±361

3.3. Volatiles

hydrocarbons. The Cnÿ1 has one carbon atom less than

the parent fatty acid, and the Cnÿ2:1 has a double bond

in position 1 and is two carbon atoms less than the

parent fatty acid. Therefore, 1-heptene (C7:1) would be

a product from nonane (C9:0) that oxidized and cleaved

from oleic or other n ÿ 9 fatty acids during irradiation

and storage. The productions of nonanal, decanal or 1heptanol in vacuum-packaged pork sausages (both

irradiated and nonirradiated) were very small. The

amount of total volatiles in irradiated cooked pork

products was signi®cantly higher than the amount in the

nonirradiated products. In addition to the amount of

identi®ed volatiles, many unknown volatiles with short

retention time also were found in irradiated samples.

This means that irradiation increased not only volatiles

production but also the number of volatile compounds.

Most probably, these volatiles would be nonpolar small

hydrocarbons and could be important for irradiation

odor but were excluded from the calculation of total

volatiles.

More volatiles were produced as the development of

lipid oxidation in pork sausages progressed during

storage (Tables 2±5). Shahidi and Pegg (1994) observed

that the content of hexanal, an index of lipid oxidation

and meat ¯avor deterioration, declined markedly upon

extended storage of meat. They indicated that the reactions of hexanal with meat components or its further

oxidation to hexanoic acid were responsible for the

reduction of hexanal in meat during storage. The present study showed decrease of hexanal in pork sausages

after 7-day storage only in vacuum packaging. The

reason for hexanal change in vacuum-packaged pork

sausages during storage cannot be explained.

High-fat sausages produced more propanal but less 1pentanol, nonanal and 1-heptanol than low-fat products

(Tables 2±5). The amounts of aldehydes, ketones and

alcohols were the highest in pork sausages with 4.5% fat

and the lowest in sausages with 15.8% fat. Among

individual volatile compounds, only propanal showed

the same trend as TBARS values, which increased with

the increase of fat content (Table 1). This indicated that

there would be certain interactions between fat content

and production of volatiles in pork sausages. Recently,

Ahn et al. (1998b) reported that cooked pork patties

from L. dorsi, which had about 2.5 to 3 times higher fat

content than those from R. fermoris, produced less hexanal and total volatiles than those from R. fermoris at

the same TBARS value. Jo and Ahn (1998b) con®rmed

this trend using an oil emulsion study. Their results

suggested that if the amount of volatiles is used as an

indicator of lipid oxidation or o-¯avor generation in

cooked pork products, the fat content of samples should

be taken into consideration.

Irradiation increased the amount of 1-heptene in pork

sausages signi®cantly but storage or packaging type

did not (Tables 2±5). Although very small amounts of

1-heptene were found in nonirradiated pork sausages,

1-heptene was an excellent indicator for irradiation

treatments. Villavicencio, Mancini-Filho, Hartmann,

Ammon, and Delincee (1997) suggested the use of

hydrocarbons to detect radiation treatment in the processing of beans. Nawar et al. (1996) reported that irradiation breaks chemical bonds in triacylglycerides and

produces carbonyl compounds such as Cnÿ1 and Cnÿ2:1

Table 5

Eect of fat content on the production of volatiles in irradiated vacuum-packaged pork sausages after 7 days of storage at 4 C a

Volatiles

1-heptene

Propanal

2-methylpropanal

2-methylbutanal

Pentanal

3-pentanone

Hexanal

1-butanol

1-pentanol

Nonanal

Decanal

1-heptanol

Aldehydes + ketones

Alcohols

Total volatiles

a

b

c

d

Nonirradiated

4.7%

10.5%

5.3 b

7.5 c

14.4

15.1

18.2

51.3

109.3

6.3

10.2

0.5

nd d

0.5

216.3

17.1

238.7

6.9 ab

11.5 b

13.2

18.1

18.2

59.9

100.7

5.3

10.2

0.3

nd

0.3

221.9

15.7

244.5

15.8%

9.1 a

15.1 a

14.3

19.4

22.9

57.4

103.9

4.6

9.5

nd

nd

nd

233.0

14.0

256.1

Irradiated at 0 or 4.5 kGy dose.

SEM: standard error of mean.

Dierent letters within a row are signi®cantly dierent ( p < 0.05). n=12.

nd: not detected.

Irradiated

b

4.7%

10.5%

15.8%

Area (pA s)

0.7

53.5

0.7

11.5 b

0.6

17.6

6.0

28.1 c

3.4

23.3 b

5.7

79.9

4.6

131.9 a

0.6

6.0

0.3

9.7 a

0.2

2.2 ab

ÿ

nd

0.2

1.4 a

16.2

294.5

1.0

17.0 b

16.8

365.1

50.5

16.8 a

17.6

42.4 a

29.5 a

82.7

122.7 ab

6.8

10.9 a

1.7 ab

nd

1.0 a

313.4

18.7 a

382.6

55.2

20.1 a

16.4

36.3 b

30.6 a

66.8

102.3 b

5.4

7.5 c

1.2 b

nd

0.3 b

267.2

12.4 c

341.9

SEM

SEMb

1.7

1.1

0.4

1.9

1.7

10.1

7.3

0.4

0.3

0.2

ÿ

0.2

19.0

0.5

19.4

C. Jo et al./Meat Science 51 (1999) 355±361

Ahn et al. (1998b) observed that oxygen exclusion

from meat after cooking was more important in preventing lipid oxidation of cooked meat than raw meat

treatments. The authors reported that lipid oxidation

was not catalyzed by the cooking process but by subsequent oxygen contact with cooked meat during storage. Packaging types had the most in¯uence on the

production of volatiles, lipid oxidation and color changes in cooked pork sausages during storage. It was

concluded that keeping oxygen from meat was more

important than irradiation and fat content in maintaining a high quality of meat after cooking.

References

Ahn, D. U., Olson, D. G., Jo, C., Chen, X., Wu, C., & Lee, J. I.

(1998). Eect of muscle type, packaging, and irradiation on lipid

oxidation, volatile production, and color in raw pork patties. Meat

Science, 49, 27±39.

Ahn, D. U., Olson, D. G., Lee, J. I., Jo, C., Wu, C., & Chen, X.

(1998). Packaging and irradiation eects on lipid oxidation and

volatiles in pork patties. Journal of Food Science, 63, 15±19.

Akamittath, J. G., Brekke, C. J., & Schanus, E. G. (1990). Lipid oxidation and color stability in restructured meat systems during frozen storage. Journal of Food Science, 55, 1513±1517.

El Magoli, S. B., Laroia, S., & Hansen, P. M. T. (1996). Flavor and

texture characteristics of low fat ground beef patties formulated

with whey protein concentrate. Meat Science, 42, 179±193.

Folch, J., Less, M., & Sloane-Stanley, G. M. (1957). A simple method

for the isolation and puri®cation of total lipids from animal tissues.

Journal of Biological Chemistry, 226, 497±509.

Hashim, I. B., Resurreccion, A. V. A., & MacWatters, K. H. (1995).

Disruptive sensory analysis of irradiated frozen or refrigerated

chicken. Journal of Food Science, 60, 664±666.

Heath, J. L., Owens, S. L., Tesch, S., & Hannah, K. W. (1990). Eect of

high-energy electron irradiation of chicken on thiobarbituric acid

values, shear values, odor, and cook yield. Poultry Science, 69, 313±319.

361

Jo, C., & Ahn, D. U. (1998). Fluorometric analysis of 2-thiobarbituric acid reactive substances in turkey. Poultry Science, 77, 475±

480.

Jo, C., & Ahn, D. U. (1998b). Fat reduces volatiles production in oil

emulsion system analyzed by purge-and-trap dynamic headspace/

gas chromatography (unpublished).

Luchsinger, S. E., Kropf, D. H., Garcia-Zepeda, C. M., Hunt, M. C.,

Marsden, J. L., Rubio Canas, E. J., Kastner, C. L., Kuecker, W. G.,

& Mata, T. (1996). Color and oxidative rancidity of gamma and

electron bean-irradiated boneless pork chops. Journal of Food Science, 61, 1000±1004, 1093.

Lynch, J. A., Mac®e, H. J. H., & Mead, G. C. (1991). Eect of irradiation and packaging type on sensory quality of chill-stored turkey

breast ®llets. International Journal of Food Science and Technology,

26, 653±668.

Nawar, W. W., Zhu, Z., Wan, H., Degroote, E., Chen, Y., &

Aciukewicz, T. (1996). Progress in the detection of irradiated food

by measurement of lipid derived volatiles. In: C. H., McMurray,

E. M. Stewart, R. Gray, J. Pearce (Eds.), Detection methods for

irradiated foods (pp. 241±249). Cambridge: Royal Society of

Chemistry.

Olson, D. G. (1998). Irradiation of food. Food Technology, 52, 56±62.

Reineccius, G. A. (1979). Symposium on meat ¯avor. O-¯avors in

meat and ®sh ± A review. Journal of Food Science, 44, 12±21.

SAS Institute. (1988). SAS user's guide1. Cary, NC: SAS Institute.

Shahidi, F., Pegg, R. B., & Shamsuzzaman, K. (1991). Color and oxidative stability of nitrite-free cured meat after gamma irradiation.

Journal of Food Science, 56, 1450±1452.

Shahidi, F., & Pegg, R. B. (1994). Hexanal as an indicator of the ¯avor

deterioration of meat and meat products. American Chemical

Society Symposium Series, 558, 256±279.

Thakur, B. R., & Singh, R. K. (1994). Food irradiation. Chemistry

and applications. Food Review International, 10(4), 437±473.

Thayer, D. W., Boyd, G., & Jenkins, R. K. (1993). Low-dose gamma

irradiation and refrigerated storage in vacuum aect microbial ¯ora

of fresh pork. Journal of Food Science, 58, 717±719, 733.

Villavicencio, A. C. H., Mancini-Filho, J., Hartmann, M., Ammon, J.,

& Delincee, H. (1997). Formation of hydrocarbons in irradiated

Brazilian beans: Gas chromatographic analysis to detect radiation

processing. Journal of Agricultural and Food Chemistry, 45, 4215±

4220.