Sources and Mechanisms of Carbon Monoxide Production by Irradiation

advertisement

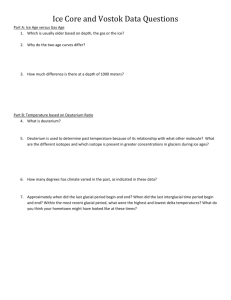

JFS: Food Chemistry and Toxicology Sources and Mechanisms of Carbon Monoxide Production by Irradiation ABSTRACT: The sources and mechanisms of gas production by irradiation were determined using model systems prepared with fatty acid, phospholipids, oil, sugars, glycolysis and TCA cycle intermediates, nucleic acids, amino acid monomers and homopolymers, and proteins. The model systems were irradiated at 0, 2.5, 5, or 10 kGy using a linear accelerator and the amounts of CO, CO2, and CH4 produced were determined using gas chromatography. The productions of CO, CO2, and CH4 in all samples were irradiation-dose dependent. Glycine, asparagine, and glutamine were the major sources of CO production among amino acids, and glyceraldehydes, pyruvate, and ␣-ketoglutarate were the major sources of CO among glycolysis intermediates. Phosphatidyl choline, phosphatidyl ethanolamine, and lysophosphatidyl choline produced the greatest amounts of CO among the phospholipids. The major sources of CO2 production were pyruvate, threoine, and methionine, and those of CH4 were methionine and acetone. The amounts of CO produced from these sources were significant, and the production of gas compounds via radiolytic degradation appears to be closely related to the structure of molecules. Keywords: carbon monoxide, carbon dioxide, methane, model system, irradiation Introduction C olor is a major sensory attribute determining consumer accep tance of meat. Consumers expect the color of uncured cooked light meats such as oven-roasted poultry breast meat or poultry breast rolls to be white. Therefore, if those meats show pink or red color, consumers suspect that they are contaminated or undercooked. Millar and others (1995) found that irradiated chicken breasts had a definite color change from the usual brown/purple to a pink/red, but the degree of redness varied depending upon various factors such as irradiation dose, animal species, muscle type, and packaging type (Satterlee and others 1971; Shahidi and others 1991; Millar and others 1995; Luchsinger and others 1996; Nanke and others 1998). Nanke and others (1998) proposed the color compound in irradiated meat to be an oxymyoglobin-like pigment. However, the red pigment cannot be oxymyoglobin because the red color formed by irradiation is mainly produced under anoxic conditions, and the increase of redness was dose-dependent (Jo and others 2000). Nam and Ahn (2002a, 2002b) characterized the pink pigment formed in irradiated raw and cooked turkeys as CO-myoglobin (CO-Mb). Furuta and others (1992) and Woods and Pikaev (1994) reported that a considerable amount of CO was produced by radiolysis of organic components in irradiated frozen meat and poultry. CO has a very strong affinity to heme pigments and thus easily forms CO-Mb complex, which increases the intensity of red meat and blood color significantly. The affinity of CO to heme pigments is significantly influenced by the valence of heme iron and the oxidation-reduction potential (ORP) of meat determines the status of iron in heme pigments. Our preliminary study indicated that irradiation of meat decreased ORP (increased reducing potential) and produced gaseous compounds that can act as a 6th ligand of myoglobin (Hannah MS 20040079 Submitted 2/10/04, Revised 3/15/04, Accepted 4/5/04. Authors Lee and Ahn are with the Dept. of Animal Science, Iowa State Univ., Ames, IA 50011-3150. Direct inquiries to author Ahn (E-mail: duahn@iastate.edu). © 2004 Institute of Food Technologists Further reproduction without permission is prohibited and Simic 1985; Nam and Ahn 2002a,b). Therefore, irradiation generates favorable conditions for CO-Mb complex formation, which intensifies the redness of heme pigments. Although CO-Mb was considered as the major pigment responsible for pinking in irradiated meat, no attempt has been made to elucidate the sources and mechanisms of CO production by irradiation. In addition to CO, this study also was expected to show the production of other gas compounds such as CO2 and CH4 because the production of these compounds may provide significant clues in understanding the mechanism of CO production in irradiated meat. The objectives of this study were to determine the sources of CO production and to elucidate the mechanisms of CO production in meat by irradiation. Materials and Methods Sample preparation Model systems were prepared with various components generally found in meat: fatty acids and oils (oleic acid, linoleic acid, linolenic acid, phosphatidyl choline, corn oil, and fish oil), carbohydrates (glucose, fructose, starch, and glycogen), glycolysis and citric acid (TCA) cycle intermediates (glucose-6-phosphate, acetone, pyruvate, lactate, ␣-ketoglutarate, citrate, oxaloacetate, glyceraldehydes, adenosine-5′ triphosphate, and 3-phosphate glycerol), nucleic acids (adenine, guanine, cytosine, uracil, and thymine), amino acid monomers (glycine, leucine, threoine, lysine, histidine, tyrosine, tryptophan, glutamate, aspartate, asparagine, cysteine, and methionine), amino acid homopolymers (glycine, leucine, threonine, lysine, tyrosine, glutamate, aspartate, asparagine, glutathione, and met-gly-met-met), and proteins (albumin and hemoglobin). All chemicals were purchased from Sigma Chemical Co. (St. Louis, Mo., U.S.A.). For fatty acids and oils, oil-in-water emulsion systems were prepared by blending (Waring blender; 22000 rpm for 2 min; Dynamics Corp. America Co., New Hartford, Conn., U.S.A.) 0.8 g of fatty acid or oil with 80 mL deionized distilled water. PhosVol. 69, Nr. 6, 2004—JOURNAL OF FOOD SCIENCE C485 Published on Web 7/27/2004 Food Chemistry and Toxicology E.J. LEE AND D.U. AHN Mechanism of carbon monoxide production . . . Table 1—The production of CO, CO2, and CH 4 from fatty acids and oils by irradiationa,b Unit (ppmd) 0 kGy 2.5 kGy 5 kGy Food Chemistry and Toxicology CO Oleic acid Linoleic acid Linolenic acid Phosphatidyl choline Phosphatidyl ethanolamine Lysophosphatidyl choline Corn oil Fish oil S.E.M. 18.98 y 12.58 by 26.57 y 28.20 dy 24.73 cy 63.45 cx 34.38 y 22.56 by 5.75 20.93 z 26.57 az 22.78 z 276.90 cw 130.69 by 195.77 bx 47.72 z 37.42 az 9.11 20.39 z 25.81 ayz 30.37 yz 399.68 bv 177.87 ax 207.48 bw 31.78 yz 48.05 ay 5.75 CO2 Oleic acid Linoleic acid Linolenic acid Phosphatidyl choline Phosphatidyl ethanolamine Lysophosphatidyl choline Corn oil Fish oil S.E.M. 179.28 bx 180.37 cx 155.42 bxy 133.41 dxy 97.61 dy 128.53 bxy 108.46 dxy 116.38 cxy 17.03 466.70 awx 316.70 by 199.35 bz 509.22 cw 611.17 cv 174.95 bz 440.35 cwx 368.76 bwy 30.37 493.28 axy 413.23 abxy 385.58 ay 703.36 bvw 785.25 bv 163.23 bz 604.12 bwx 485.14 bxy 51.08 CH4 Oleic acid Linoleic acid Linolenic acid Phosphatidyl choline Phosphatidyl ethanolamine Lysophosphatidyl choline Corn oil Fish oil S.E.M. 0.00 0.00 0.00 b 0.00 c 0.00b 0.00 0.00 0.00 0.00 0.00 0.00 0.00 b 0.00 c 0.00b 0.00 0.00 0.00 0.00 0.00 y 0.00 y 0.00 by 11.06 bx 0.00 by 0.00 y 0.00 y 0.00 y 1.74 10 kGy S.E.M.c 16.81 z 20.07 abz 37.96 z 472.13 ax 185.79 ay 608.46 aw 37.20 z 36.66 az 9.54 3.04 2.49 6.07 10.30 7.16 14.32 4.01 3.58 548.81 az 468.00 az 423.86 az 1253.80 ay 1624.51 ax 3219.64 aw 731.02 az 778.74 az 122.67 42.08 36.66 40.46 55.75 42.84 150.76 35.14 39.05 0.00 z 0.00 z 4.34 ay 23.64 aw 13.34 ax 0.00 z 0.00 z 0.00 z 0.54 0.00 0.00 0.33 2.93 0.22 0.00 0.00 0.00 aDifferent letters (a-d) within a row with the same sample indicate statistically significant difference (P < 0.05). phatidylcholine, phosphatidylethanolamine, or lysophosphatidyl choline (100 mg dissolved in chloroform) was evaporated from chloroform to a thin film on the wall of a 40-mL sample vial. The vial was placed under a stream of nitrogen to remove any chloroform. Phospholipid liposome systems were prepared by hydrating each phospholipid with 10 mL water by gently shaking for 15 min. The milky suspension was then vortex-mixed to disperse the phospholipid before use. For water-soluble compounds, an aqueous solution of each component (10 mg/mL) was prepared. Four 5-mL portions of 1% solutions (1 from each replication) were transferred to scintillation vials and irradiated at 0, 2.5, 5, or 10 kGy using a linear accelerator (Model 10/15; San Diego, Calif., U.S.A.). The energy and power level used were 10 MeV and 30 kW (2 parallel 15 kW e-beams), respectively, and the average dose rate was 99.3 kGy/min. The max/min ratios were 1.05, 1.02, and 1.04 (average) for 2.5, 5, and 10 kGy, respectively. To confirm the target dose, 4 alanine dosimeters per cart were attached to the top and bottom surfaces of a sample vial. The alanine dosimeter was read using a Bruker e-Scan II (Bruker Instruments Inc., Billerica, Mass., U.S.A.). Four replications were prepared for all model systems. Table 2—The production of CO, CO2, and CH4 from carbohydrates by irradiationa,b Unit (ppmd) 0 kGy 2.5 kGy CO Glucose Fructose Starch Glycogen S.E.M. 15.08 c 13.67 d 13.77 c 13.88 d 2.39 37.42 bcy 53.47 cx 40.46 ay 54.23 cx 3.47 CO2 Glucose Fructose Starch Glycogen S.E.M. 75.92 by 136.44 bx 146.42 dx 128.85 cx 11.17 259.00 ay 294.47 axy 340.35 cx 295.88 bxy 16.59 CH4 Glucose Fructose Starch Glycogen S.E.M. 0.00 0.00 0.00 0.00 b 0.00 0.00 0.00 0.00 0.00 b 0.00 5 kGy 10 kGy SEMc 57.48 aby 85.47 ax 86.55 bx 116.92 ax 33.95 bz 32.00 by 74.62 bx 115.51 ax 4.45 14.32 9.76 8.79 1.95 4.77 292.30 a 359.33 a 474.51 b 317.57 b 55.64 373.97 ay 394.25 ay 960.20 ax 434.71 ay 61.39 54.12 35.68 32.00 24.84 0.00 0.00 0.00 0.00 b 0.00 0.00 y 0.00 y 0.00 y 3.69 ax 0.22 0.00 0.00 0.00 0.11 aDifferent letters (a-d) within a row with the same sample indicate statistically Determination of gas compounds To identify the gaseous compounds produced by irradiation, CO gas was purchased from Aldrich (Milwaukee, Wis., U.S.A.), and CH4, and CO2 were purchased from Praxair (Danbury, Conn., U.S.A.). The standard gases were analyzed using a gas chromatograph (GC, Model 6890; Hewlett Packard Co., Wilmington, Del., U.S.A.) with a flame ionization detector (FID). The method of Furuta and others (1992) was modified for the detection of carbon-related gases. The control or irradiated sample (5 mL) was placed in a 20-mL glass vial. C486 JOURNAL OF FOOD SCIENCE—Vol. 69, Nr. 6, 2004 significant difference (P < 0.05). bDifferent letters (x-z) within a column with the same irradiation dose indicate statistically significant difference (P < 0.05). cS.E.M., standard error of the means (n = 4). dGas concentration in headspace (19 mL) from 5 mL 1% sample solution. To minimize experimental errors due to air incorporation, the vials were flushed with helium gas (40 psi) for 5 s before irradiation. In our previous study, irradiated turkey meat samples were microwaved to release gas compounds from meat (Nam and Ahn 2002a, URLs and E-mail addresses are active links at www.ift.org Mechanism of carbon monoxide production . . . Table 3—The production of CO, CO2, and CH4 from glycolysis intermediates by irradiationa,b Unit (ppmd) 2.5 kGy 46.64 cx 17.79 by 14.43 by 27.44 bxy 45.88 bx 22.02 xy 14.53 dy 36.12 dxy 22.56 abxy 14.43 dy 6.18 87.64 by 27.98 bz 37.96 bz 25.27 bz 73.75 aby 24.40 z 29.83 cz 168.44 cx 24.73 az 28.74 cz 9.87 58.57 dy 114.75 bcy 408.68 by 186.33 by 368.00 dy 176.25 cy 309921.00 ax 194.47 dy 41.00 ay 169.74 dy 8283.42 0.00 0.00 d 0.00 b 0.00 b 0.00 0.00 0.00 b 0.00 b 0.00 b 0.00 0.00 5 kGy 114.43 by 26.36 by 46.64 by 22.02 by 68.87 aby 20.39 y 41.21 by 345.23 bx 15.51 by 42.62 by 23.21 10 kGy 171.15 aw 45.88 axyz 91.97 axy 38.50 ayz 99.57 ax 22.02 yz 63.77 axyz 740.24 av 21.15 abyz 91.43 axy 13.12 SEMc 9.54 3.36 10.30 3.15 9.22 3.47 3.47 36.98 2.06 3.80 154.01 cy 216.92 by 2508.46 by 198.81 by 2280.70 cy 1964.21 by 277911.00 ax 495.45 cy 35.25 ay 301.30 cy 1484.93 295.34 by 210.74 by 5106.62 by 184.17 by 4089.81 by 2802.39 by 290112.00 ax 648.92 by 43.17 ay 524.95 by 1671.69 413.56 az 350.11 az 15352.50 ay 252.71 az 6870.72 az 4328.10 az 316309.00 ax 992.95 az 48.05 az 932.54 az 2931.35 20.72 30.26 2040.46 11.93 193.28 334.06 12653.70 29.07 3.80 41.00 0.00 z 30.37 cx 0.00 bz 3.04 by 0.00 z 0.00 z 0.00 bz 0.00 bz 0.00 bz 0.00 z 0.43 0.00 z 58.57 bw 5.86 bx 3.36 by 0.00 z 0.00 z 0.00 bz 0.00 bz 0.00 bz 0.00 z 0.65 0.00 z 130.69 ax 27.98 ay 10.74 az 0.00 z 0.00 z 4.23 az 27.12 ay 4.12 az 0.00 z 4.88 0.00 2.71 6.18 1.19 0.00 0.00 0.11 1.08 0.22 0.00 a Different letters (a-d) within a row with the same sample indicate statistically significant difference (P < 0.05). b Different letters (v-z) within a column with the same irradiation dose indicate statistically significant difference (P < 0.05). cS.E.M., standard error of the means (n = 4). d Gas concentration in headspace (19 mL) from 5 mL 1% sample solution. 2002b). To provide the same conditions as in irradiated meat, all samples were microwaved for 10 s at full power. Ten minutes after microwave heating, the headspace gas of each sample (200 L) was withdrawn using an airtight syringe and injected into a splitless inlet of a GC (Model 6890; Hewlett Packard Co.). A Carboxen-1006 Plot column (30 m ⫻ 0.32-mm inner dia; Supelco, Bellefonte, Pa., U.S.A.) was used. Helium was used as a carrier gas at a constant flow of 1.8 mL/min and oven conditions were set at 120 ⬚C. A FID equipped with a nickel catalyst (Hewlett Packard Co.) was used for the methanization of CO and CO2, and the temperatures of inlet, detector, and nickel catalyst were 250 ⬚C, 280 ⬚C, and 375 ⬚C, respectively. Detector (FID) air, H2, and make-up gas (He) flows were 350, 35, and 40 mL/min, respectively. The identification of gaseous compounds was achieved using standard gases and a gas chromatography/mass spectrometer (GC/MS), and the area of each peak was integrated by using Chemstation software (Hewlett Packard Co.). To quantify the amount of gases released, peak areas (pA * second) were converted to the concentration (ppm) of gas in the sample headspace (15 mL) using CO2 concentration (330 ppm) in air. Statistical analysis Data were analyzed using the generalized linear model procedure of SAS software (SAS Inst. 1995); Student-Newman-Keul’s URLs and E-mail addresses are active links at www.ift.org multiple range test was used to determine significant differences between the mean values of treatments. Mean values and standard error of the means (SEM) were reported. Significance was defined at P < 0.05. Results and Discussion Sources of gas production by irradiation The production of CO, CO2, and CH4 in samples prepared with fatty acid, phospholipid, or plant oil were irradiation-dose dependent (Table 1). Ionizing radiation is known to generate hydroxyl radicals in aqueous (Thakur and Singh 1994) or oil emulsion systems (O’Connell and Garner 1983). The hydroxyl radical is the most reactive oxygen species. It can initiate lipid oxidation by abstracting a hydrogen atom from a fatty acyl chain of a polyunsaturated fatty acid and form a lipid radical. After the initial cleavage at the weakest bond of fatty acids or their esters by irradiation, a variety of compounds are formed by the subsequent chemical reactions. The scission at the acyl-oxygen bond among typical compounds accounts for the formation of a major aldehyde, CO, and alcohol or water and that of the alkyl-oxygen bond generated free fatty acid, CO2, the Cn–1 alkane, and, possibly, some short-chain hydrocarbons (Josephson and Peterson 2000). Vol. 69, Nr. 6, 2004 —JOURNAL OF FOOD SCIENCE C487 Food Chemistry and Toxicology CO Glucose-6-phosphate Acetone Pyruvate Lactate /alpha/-Ketoglutarate Citrate Oxaloacetate Glyceraldehyde Glyceraldehyde-3-phosphate Adenosine-5-triphosphate S.E.M. CO2 Glucose-6-phosphate Acetone Pyruvate Lactate /alpha/-Ketoglutarate Citrate Oxaloacetate Glyceraldehyde Glyceraldehyde-3-phosphate Adenosine-5-triphosphate S.E.M. CH4 Glucose-6-phosphate Acetone Pyruvate Lactate /alpha/-Ketoglutarate Citrate Oxaloacetate Glyceraldehyde Glyceraldehyde-3-phosphate Adenosine-5-triphosphate S.E.M. 0 kGy Mechanism of carbon monoxide production . . . Table 4—The production of CO, CO2, and CH4 from nucleic acids by irradiationa,b 0 kGy Unit (ppmd) 2.5 kGy 5 kGy Food Chemistry and Toxicology CO Adenine Guanine Cytosine Uracil Thymine S.E.M. 11.28 13.12 b 14.64 c 15.73 b 12.58 b 2.06 16.05 19.31 ab 24.19 b 27.98 b 22.23 ab 3.04 CO2 Adenine Guanine Cytosine Uracil Thymine S.E.M. 147.29 w 49.13 cy 28.20 bz 131.24 cw 110.95 cdx 6.40 179.83 y 48.59 cz 30.37 bz 271.69 bx 180.37 bcy 12.15 170.61 y 73.21 bz 37.42 az 305.64 bw 221.26 bx 14.86 CH4 Adenine Guanine Cytosine Uracil Thymine S.E.M. 0.00 0.00 b 0.00 b 0.00 b 0.00 b 0.00 0.00 0.00 b 0.00 b 0.00 b 0.00 b 0.00 0.00 0.00 b 0.00 b 0.00 b 0.00 b 0.00 16.16 y 22.34 abxy 30.91 bx 29.61 bxy 16.81 aby 3.25 Table 5—The production of CO, CO2, and CH4 from amino acid monomers by irradiationa,b Unit (ppmd) 10 kGy SEMc 15.73 z 28.20 ayz 44.25 ay 69.74 ax 29.83 ayz 4.77 2.39 3.04 2.71 3.80 3.80 0 kGy CO Glycine Leucine Threonine Lysine Histidine Tyrosine Tryptophan Glutamate Aspartate Asparagine Glutamine Cysteine Methionine S.E.M. 2.5 kGy 15.51 cyz 15.73 byz 20.07 bcxyz 19.52 xyz 31.45 w 23.10 bwxyz 25.27 wxyz 23.64 wxyz 27.66 wx 26.03 dwxyz 15.18 cy 26.90 awxy 21.48 bwxyz 2.39 49.53 by 17.68 bz 31.45 abyz 28.20 yz 22.02 z 47.72 ay 22.56 z 31.45 yz 20.39 z 80.26 cx 48.27 by 18.44 bz 21.15 bz 5.31 195.23 yz 136.44 az 41.76 az 677.66 ax 324.30 ay 49.67 19.85 4.66 1.95 40.89 28.20 0.00 y 4.66 ax 3.80 ax 3.80 ax 3.80 ax 0.33 0.00 0.22 0.11 0.00 0.00 CO2 Glycine Leucine Threonine Lysine Histidine Tyrosine Tryptophan Glutamate Aspartate Asparagine Glutamine Cysteine Methionine S.E.M. 154.56 dxy 126.14 cy 132.65 cxy 134.82 cxy 141.54 cxy 143.49 bxy 172.99 bx 154.88 dxy 164.32 dxy 165.40 dxy 84.60 dz 169.52 dx 146.42 dxy 8.68 1191.22 cw 177.12 bz 3261.72 bu 317.25 byz 223.43 cz 375.05 ayz 264.97 bz 875.27 cx 1301.30 cw 972.89 cx 538.83 cy 393.71 cyz 2633.73 cv 66.49 Phosphatidyl choline (PC), phosphatidyl ethanolamine (PE), and lysophosphatidyl choline (LPC) produced the highest amounts of CO among fatty acids and oils. The greatest amounts of CO2 were generated from PC, PE, and LPC, and the production of CO2 from LPC at 10 kGy were about 10 times greater than that at 0 kGy. Small amounts of CH4 were detected only in linoleic acid, PC, and PE after >5 kGy irradiation. The proposed mechanism of CO and CO2 production from phosphoglycerides is that hydroxyl radical generated by high-energy radiation breaks the ester bonds between fatty acids and glycerol 1st, and then the -CO- group or carboxylic group of fatty acids is further degraded to produce either CO or CO2 gas. A glycerol backbone, 2 fatty acid chains, or a fatty acid and a hydrogen, a phosphate, and a choline or ethanolamine, are the common denominators of PC, PE, and LPC. The susceptibility of certain bonds to radiolytic degradation or any other chemical reactions is decided by bond strength or bond dissociation enthalpy. The bond strength in a molecule is dependent on its component atoms, and the bond strength of a double bond is greater than that of a single bond because of electron localization (Atkins 1979; Halliwell and Gutteridge 1989a). This, in turn, weakens the bond strength of adjacent atoms with single bonds. Because of the C = O double-bond in the carboxyl end of a fatty acid, the ester bonds of fatty acids to the glycerol backbone are the most susceptible to radiolytic degradation in phosphoglycerides. Triglycerides such as corn oil and fish oil produced much lower amounts of CO and CO2 than phosphoglycerides because triglycerides are nonpolar and have no direct contact with water molecules, whereas phosphoglycerides have a polar end, which allows direct contact with water. This provides an important explanation of why phosphoglycerides in a liposome system (aqueous) produce greater amounts of CO and CO2 than triglycerides and free fatty acids in an oil-in-water emulsion system. Irradiation produces CH4 Glycine Leucine Threonine Lysine Histidine Tyrosine Tryptophan Glutamate Aspartate Asparagine Glutamine Cysteine Methionine S.E.M. 0.00 b 0.00 d 0.00 c 0.00 d 0.00 b 0.00 b 0.00 0.00 b 0.00 b 0.00 0.00 0.00 b 0.00 d 0.00 0.00 bz 6.62 cz 0.00 cz 23.32 cy 0.00 bz 0.00 bz 0.00z 0.00 bz 0.00 bz 0.00 z 0.00 z 0.00 bz 245.66 cx 2.82 aDifferent letters (a-d) within a row with the same sample indicate statistically significant difference (P < 0.05). bDifferent letters (x-z) within a column with the same irradiation dose indicate statistically significant difference (P < 0.05). cS.E.M., standard error of the means (n = 4). dGas concentration in headspace (19 mL) from 5 mL 1% sample solution. C488 JOURNAL OF FOOD SCIENCE—Vol. 69, Nr. 6, 2004 5 kGy 10 kGy SEMc 52.39 bx 72.13 ax 15.51 bz 26.36 ayz 30.37 abyz 41.21 ay 21.69 yz 26.36 yz 22.23 yz 31.78 yz 38.29 axyz 38.83 ayz 20.93 yz 23.32 z 20.39 yz 32.00 yz 40.13 xy 38.29 yz 97.61 bw 123.10 aw 55.31 bx 72.99 ax 19.85 byz 32.32 ayz 20.61 byz 37.42 ayz 5.10 3.58 3.90 1.95 3.90 3.25 2.93 4.23 2.82 4.99 7.27 3.47 5.31 1.95 2.39 1715.84 bv 2531.78 awx 62.91 172.45 bz 248.92 az 11.82 3954.99 bt 10868.60 au 459.44 299.13 bz 472.13 az 12.26 740.78 bxy 2416.49 awx 118.76 375.05 az 435.47 az 24.73 218.87 bz 379.61 az 25.38 1080.26 bw 2011.39 axy 57.48 1681.13 bv 3426.03 aw 113.23 1805.86 bv 3391.33 aw 125.49 863.34 bwx 1511.17 axyz 47.29 518.76 byz 1112.58 ayz 34.16 3260.09 bu 7074.68 av 110.63 97.94 304.45 0.00 bz 11.39 bx 3.04 by 43.38 bw 0.00 bz 0.00 bz 0.00 z 0.00 bz 0.00 bz 0.00 z 0.00 z 0.00 bz 461.50 bv 0.54 4.12 az 22.56 ay 8.13 az 96.53 ax 4.77 az 4.45 az 0.00 z 5.53 az 4.12 az 0.00 z 0.00 z 4.66 az 888.61 aw 2.49 0.22 0.43 0.33 0.76 0.11 0.33 0.00 0.54 0.11 0.00 0.00 0.22 5.97 aDifferent letters (a-d) within a row with the same sample indicate statistically significant difference (P < 0.05). bDifferent letters (t-z) within a column with the same irradiation dose indicate statistically significant difference (P < 0.05). cS.E.M. = standard error of the means (n = 4). dGas concentration in headspace (19 mL) from 5 mL 1% sample solution. hydroxyl radicals by splitting water molecules and the half-life of the free radicals are very short (10–6 s) (Halliwell and Gutteridge 1989b). Therefore, the hydroxyl radicals produced by irradiation cannot travel far, and the chemical reaction should be instantaneous and site-specific. The productions of CO in glucose, fructose, and glycogen were irradiation dose–dependent, and the major sources of CO in carbohytrates were fructose and glycogen (Table 2). Starch was the major source of CO2 production, and glycogen was the only carbohytrate that generated CH4 gas at 10 kGy. Among glycolysis intermediates, glyceraldehyde was the major source of CO production, and much CO gas was also detected in glucose-6-phosphate, pyruvate, and adenosine-5-triphosphate by irradiation. Pyruvate, ␣-ketoglutarate, URLs and E-mail addresses are active links at www.ift.org Mechanism of carbon monoxide production . . . Table 6—The production of CO, CO2, and CH4 from protein and amino acid homopolymers by irradiationa,b Unit (ppmd) CO Albumin Hemoglobin Glycine homopolymer Threonine homopolymer Lysine homopolymer Tyrosine homopolymer Glutamate homopolymer Aspartate homopolymer Asparagine homopolymer Glutathione Met-Gly-Met-Met S.E.M. 22.02 dxy 39.91 dxy 15.18 dy 46.42 dx 26.36 cxy 21.48 bxy 32.86 bxy 24.19 cxy 31.24 dxy 47.18 abx 13.56 dy 6.51 CO2 Albumin Hemoglobin Glycine homopolymer Threonine homopolymer Lysine homopolymer Tyrosine homopolymer Glutamate homopolymer Aspartate homopolymer Asparagine homopolymer Glutathione Met-Gly-Met-Met S.E.M. 144.79 dz 252.71 dxyz 311.61 dwxy 429.50 dw 340.56 awxy 141.87 cz 170.28 bz 131.78 dz 345.99 cwxy 383.73 cwx 222.89 cyz 36.44 CH4 Albumin Hemoglobin Glycine Threonine Lysine Tyrosine Glutamate Aspartate Asparagine Glutathione Met-Gly-Met-Met S.E.M. 0.00 d 0.00 d 0.00 c 0.00 b 0.00 c 0.00 b 0.00 c 0.00 b 0.00 0.00 b 0.00 d 0.00 2.5 kGy 5 kGy 10 kGy SEMc 95.77 cyz 101.95 cy 46.64 cz 76.25 cyz 52.93 byz 50.43 ayz 70.28 ayz 78.63 byz 473.97 cx 43.17 bz 77.55 cyz 11.61 164.86 by 188.50 by 60.20 bz 91.43 bz 68.33 bz 47.72 z 67.03 az 77.33 bz 823.21 bx 48.81 abz 101.74 bz 13.45 227.22aw 259.00 av 77.87 az 146.42 ax 112.26 ay 65.94 z 77.01 az 122.34 axy 962.04 au 56.18 az 144.25 ax 8.89 9.54 11.71 3.47 2.60 6.62 6.94 3.15 4.77 24.08 2.60 4.34 279.07 cyz 492.19 cwx 531.45 cvwx 605.75 cvw 326.79 ay 459.33 bx 207.16 az 460.41 cx 628.31 bv 521.15 bvwx 428.20 bx 31.56 427.12 by 705.32 bvw 638.07 bwx 797.51 bvw 353.90 ay 498.37 bxy 228.85 az 832.43 bv 638.61 bwx 469.63 bcy 454.99 by 42.73 517.35 ay 908.89 auv 776.57 avwx 915.73 auv 472.67 ay 822.99 avw 244.36 az 1048.81 atu 1171.15 at 657.05 awxy 589.48 axy 54.01 28.74 39.70 20.17 29.07 50.00 47.61 11.93 45.77 52.82 36.33 31.67 35.03 bx 20.93 cxy 0.00 cy 0.00 by 0.00 cy 0.00 by 0.00 cy 0.00 by 0.00 y 0.00 by 369.04 cy 5.42 37.74 byz 45.01 by 2.28 bz 2.82 bz 6.18 bz 0.00 bz 9.87 bz 0.00 bz 0.00 z 0.00 bz 728.09 bx 8.79 68.87 ay 91.65 ax 5.31 az 10.74 az 9.44 az 6.18 az 14.64 az 5.75 az 0.00 z 4.66 az 1336.23 aw 6.18 8.46 3.58 0.11 0.87 0.65 0.33 0.43 0.33 0.00 0.11 15.18 Food Chemistry and Toxicology 0 kGy a Different letters (a-d) within a row with the same sample indicate statistically significant difference (P < 0.05). b Different letters (t-z) within a column with the same irradiation dose indicate statistically significant difference (P < 0.05). cS.E.M. = standard error of the means (n = 4). d Gas concentration in headspace (19 mL) from 5 mL 1% sample solution. citrate, and adenosine-5-phosphate were the major sources of CO2 production among glycolysis intermediates by irradiation and were closely related to their molecular structures (Table 3). Oxaloacetate, ␣-ketoglutarate, and citrate have 2 or 3 carboxyl groups in their molecular structures. It was assumed that CO2 gas was originated from the carboxyl groups during irradiation. Oxaloacetate produced very high amounts of CO 2 in all irradiation treatments, but the amounts among irradiation treatments were not significant. This indicates that bond strength of carboxylic groups in oxaloacetate is weaker than others and can be broken even by relatively low energy radiation such as microwave heating. Acetone was the major source of CH4 gas, and small amounts of CH4 gas were also detected in pyruvate and lactate when irradiated at 10 kGy. Acetone, pyruvate, and lactate have 1 or 2 methyl groups in their molecular structures, and it was presumed that CH4 gas was produced from the methyl groups of these compounds via radiolytic processes. The nucleic acids adenine, guanine, cytosine, uracil, and thymine were more stable than other compounds and produced only limited amounts of CO, CO2, and CH4 gases (Table 4). Only very small amounts of CO were generated from nucleic acids and the amounts URLs and E-mail addresses are active links at www.ift.org of CO2 produced from uracil and thymine were irradiation dose– dependent. Small amounts of CH4 were detected only when nucleic acids were irradiated at 10 kGy. Table 5 shows the production of CO, CO2, and CH4 from amino acid monomers by irradiation. Large amounts of CO gas were detected in asparagine, glutamine, and glycine. This indicated that amino acids that contained amide as a side chain produced a large amount of CO gas after irradiation. Most amino acid monomers produced great amounts of CO2, but threoine and methionine produced the highest amount of CO2. Methionine, lysine, and leucine were the major sources of CH 4 production among amino acid monomers by irradiation. The amounts of CH4 produced from methionine were 10 times greater than those of lysine. Methionine and leucine have also 1 or 2 methyl groups in their molecular structures. The proposed mechanism of CO, CO2, and CH4 production by irradiation is that the methyl group in methionine can be broken down easily by irradiation because the bond energy of the methyl group bound to sulfur atom is weaker than that of others (Simic and others 1992). Therefore, methionine generated the largest amount of CH4 gas by irradiation, even though methionine has only Vol. 69, Nr. 6, 2004 —JOURNAL OF FOOD SCIENCE C489 Mechanism of carbon monoxide production . . . Food Chemistry and Toxicology 1 methyl group in its structure. This result agrees with the data from acetone, pyruvate, and lactate, which also have methyl groups. Amino acid homopolymers generated higher amounts of gases than others (Table 6). Asparagine homopolymer was the major source of CO among amino acid homopolymers, and the amount of CO in asparagine homopolymer was 10 times higher than those of asparagine monomer. Large amounts of CO were also produced from albumin and hemoglobin upon irradiation. The major sources of CO2 in amino acid homopolymers were aspartate homopolymer and asparagine homopolymer. Hemoglobin, albumin, threonine homopolymer, and glycine homopolymer also produced much CO2 gas. Met-gly-met-met was the major source of CH4 and albumin, and hemoglobin also generated much CH4. The results with amino acid homopolymers generally agreed with those of amino acid monomer. Conclusions A sparagine homopolymer, glyceraldehydes, and phospholipids produced the greatest amounts of CO gas by irradiation. The amounts of CO produced from these sources were large enough to react with most of the heme pigments present in light meats such as poultry breast and pork loin, and the production of gas compounds (CO, CO2, and CH4) via the radiolytic degradation was closely related to the chemical structure of molecules. References Atkins PW. 1979. Physical chemistry. San Francisco: Freeman and Co. p 102–20. Furuta M, Dohmaru T, Katayama T, Toratoni H, Takeda A. 1992. Detection of irradiated frozen meat and poultry using CO gas as a probe. J Agric Food Chem 40:1099–100. C490 JOURNAL OF FOOD SCIENCE—Vol. 69, Nr. 6, 2004 Halliwell BJM, Gutteridge C. 1989a. A consideration of atomic structure and bonding. In: Halliwell B, Gutteridge JMC, editors. Free radicals in biology and medicine. 2nd ed. London: Clarendon Press. p 508–24. Halliwell BJM, Gutteridge C. 1989b. The chemistry of oxygen radicals and other oxygen-derived species. In: Halliwell B, Gutteridge JMC. editors. Free radicals in biology and medicine. 2nd ed. London: Clarendon Press. p 22–85. Hannah KW, Simic MG. 1985. Long-term preservation of bacon by high-energy electrons. Rad Phys Chem 25:167–71. Jo C, Jin SK, Ahn DU. 2000. Color changes in irradiated pork sausages with different fat sources and packaging during storage. Meat Sci 55:107–13. Josephson ES, Peterson MS. 2000. Preservation of food by ionizing radiation (II). Boca Raton, Fla.: CRC Press. p 102–3. Luchsinger SE, Kropf DH, Garcia Zepeda CM, Hunt MC, Marsden JL, Rubio Canas EJ, Kastner CL, Kuecher WG, Mata T. 1996. Color and oxidative rancidity of gamma and electron beam-irradiated boneless pork chops. J Food Sci 61:1000–5. Millar SJ, Moss BW, MacDougall DB, Stevenson MH. 1995. The effect of ionizing radiation on the CIELAB color co-ordinates of chicken breast meat as measured by different instruments. Int J Food Sci Technol 30:663–74. Nam KC, Ahn DU. 2002a. Carbon monoxide-heme pigment complexes are responsible for the pink color in irradiated raw turkey breast meat. Meat Sci 60(1):25–33. Nam KC, Ahn DU. 2002b. Mechanisms of pink color formation in irradiated precooked turkey breast. J Food Sci 67(2):600–7. Nanke KE, Sebranek JG, Olson DG. 1998. Color characteristics of irradiated vacuum-packaged pork, beef, and turkey. J Food Sci 63:1001–6. O’Connell MJ, Garner A. 1983. Radiation-induced generation and properties of lipid hydroperoxide in liposomes. Int J Radiat Biol 44:615–25. SAS Inst. 1995. SAS/STAT user’s guide. Cary, N.C.: SAS Inst. Satterlee LD, Wilhelm MS, Barnhart HM. 1971. Low-dose gamma irradiation of bovine metmyoglobin. J Food Sci 36:549–51. Shahidi F, Pegg RB, Shamsuzzaman K. 1991. Color and oxidative stability of nitritefree cured meat after gamma irradiation. J Food Sci 56:1450–2. Simic MG, Jovanovice SV, Niki E. 1992. Mechanisms of lipid oxidative processes and their solutions. Chapter 2. In: Lipid oxidation in food. Am Chem Soc. p 14–32. Thakur BR, Singh RK. 1994. Food irradiation—chemistry and applications. Food Rev Int 10(4):437–73. Woods RJ, Pikaev AK. 1994. Selected topics in radiation chemistry. Ch. 6. In: Woods RJ, Pikaev AK, editors. Applied radiation chemistry: radiation processing. New York: John Wiley & Sons, Inc. p 165–210. URLs and E-mail addresses are active links at www.ift.org If you paid for this article with a credit card, REMEMBER, just a few downloads a year quickly exceed the cost of a subscription. And with a subscription, you also get free access to back issues, free TOC-Alerts, your own print copy (if you wish) or personal JFS Website sign-on identification. And . . . with a full IFT Membership, you could be getting all these additional benefits, including ● Community ● Professionalism ● Advancement ● Knowledge ● Discounted IFT Events ● Local / Special Interest Groups ● Employment Referral Service ● Support and Involvement ● Recognizing Excellence ● and Discounted Student Membership. See www.ift.org Does your library subscribe to the Journal of Food Science? In these days of tight library budgets, librarians NEED TO KNOW who is using which journals to help them make educated subscription-purchasing decisions. ASK THEM to subscribe to the Journal of Food Science. It’s a great value, especially compared to the overpriced commercial journals covering the same field. With subject matter so broad ranging... We call it the “multipurpose food research tool!” They can subscribe at www.ift.org ?? ? Some Quick Questions . . . To help us serve you better, please give us your opinion regarding these downloaded articles . . . 1. How did you find this article/paper? 䊐 Google or other on-line search engine, 䊐 Link from other article, etc., 䊐 Search within IFT or JFS Website. 2. If you paid for this article with a credit card, was the purchasing process efficient and satisfactory? 䊐 Yes, 䊐 No 3. If you paid for this article, was the price what you expected? 䊐 Less than expected, 䊐 As expected, or 䊐 More than expected. Please check the boxes above and FAX this page to 312-416-7921. Thank you! TM Institute of Food Technologists ● 525 W. Van Buren St., Chicago IL 60607 USA ● 312-782-8424 ● www.ift.org