MEAT

SCIENCE

Meat Science 67 (2004) 643–649

www.elsevier.com/locate/meatsci

Temperature abuse affects the quality of irradiated pork loins

M.J. Zhu a, A. Mendonca b, D.U. Ahn

b

a,*

a

Department of Animal Science, Iowa State University, 2276 Kildee, Ames, IA 50011-3150, USA

Department of Food Science and Human Nutrition, Iowa State University, 2312 Food Science Building, Ames, IA 50011-3150, USA

Received 25 September 2003; accepted 9 January 2004

Abstract

The influence of temperature abuse on the quality of irradiated pork loins was investigated. Pork loins were obtained directly

from a local packing plant, sliced and vacuum-packaged. Pork loins were randomly separated into 3 groups, sliced, and assigned to

receive 0, 1.5, or 2.5 kGy electron-beam irradiation. Then, each chop was further cut into three equal pieces and assigned to three

temperature treatments: Trt I was placed in a refrigerator directly after irradiation; Trt II was left at room temperature for 3 h before

refrigeration; and Trt III was exposed at room temperature for 1 h three consecutive days with intermittent storage at 4 °C between

exposures. Before irradiation, each loin pieces were vacuum-packaged. Color, 2-thiobarbituric acid reactive substances (TBARS),

and volatiles were measured after 0, 14, 28 and 42 days of storage, and water-holding capacity and sensory characteristics of the

loins were measured after 0, 14 and 28 days of storage. Temperature abuse had no significant effect on color, oxidation, and volatiles

of irradiated pork loins. However, temperature abuse improved water-holding capacity of meat, which could be caused by the

accelerated hydrolysis of muscle proteins at higher temperature. Irradiation increased redness, sulfur contents in volatiles and offodor of pork loin. Off-odor and redness induced by irradiation sustained during storage. Among sulfur compounds, the content of

dimethyl disulfide decreased gradually while the level of thiourea remained relatively constant. Irradiation also increased water loss,

which might be related to the structural damage in membrane during irradiation. This study shows that temperature abuse has little

effect on the quality of irradiated pork.

Ó 2004 Elsevier Ltd. All rights reserved.

Keywords: Pork loin; Water-holding capacity; Color; Volatiles; Temperature fluctuation; Irradiation

1. Introduction

During large-scale distribution and handling of meat,

especially in export of meat to foreign markets, there are

numerous opportunities for meat to be temperature

abused. These opportunities include loading and unloading of meat at shipping ports and subsequent

transportation by trucks (refrigerated or unrefrigerated)

to retail outlets where the meat has to be unloaded again

and stacked for storage. Therefore, it is inevitable for

meat products to be exposed to fluctuating temperatures

during irradiation, transportation and subsequent storage, which may promote the growth of microorganism

*

Corresponding author. Tel.: +1-515-294-6595; fax: +1-515-2949143.

E-mail address: duahn@iastate.edu (D.U. Ahn).

0309-1740/$ - see front matter Ó 2004 Elsevier Ltd. All rights reserved.

doi:10.1016/j.meatsci.2004.01.005

including pathogens and accelerate quality changes in

meat (Labuza & Fu, 1995).

Reducing the incidence of foodborne pathogens and

decreasing the numbers of microorganisms in meat

products is a major objective of many meat processor in

the United States. Irradiation is an attractive method to

eliminate pathogens in meat products, but changes color

and generates irradiation off-odor (Ahn, Jo, & Olson,

2000). In order to minimize quality change, low irradiation dosage is frequently used in meat processing. The

bacteriocidal action of ionizing irradiation is largely

linked to damage of bacterial DNA from the production

of free radicals during the irradiation process some bacteria in meat products can repair the damage, and recover

and proliferate during product transport and storage,

especially during temperature abuse (Lee, Sebranek,

Olson, & Dickson, 1996). Lucht, Blank, and Borsa (1998)

demonstrated that a temperature of 14–22 °C is optimal

for the recovery of irradiation-injured pathogens.

644

M.J. Zhu et al. / Meat Science 67 (2004) 643–649

Our study showed that the temperature abuse greatly

accelerated the growth of Listeria monocytogenesis in

ready-to-eat turkey meat products (Bisha, Mendonca,

Sebranek, & Dickson, 2003). Apart from the proliferation of microorganisms in meat, fluctuating temperature

accelerates a number of enzymatic and chemical reactions that can influence the shelf life of irradiated meat.

Exposure of meat to increased temperature conditions

undoubtedly accelerates proteases activity to breakdown

muscle protein into small molecular weight peptides,

and long term storage of meat is often associated with

extensive softening of meat and color change independent of microorganism (Gill, 1996; Tewari, Jayas, &

Holley, 1999). Lipid oxidation may also be accelerated

under the elevated temperature conditions. However, no

information on quality changes in irradiated meat by

temperature abuse is currently available. Since two most

frequent temperature abuses are delay at room temperature after irradiation and temperature fluctuation

during transporting products from one location to another, meats were treated with a 3-h exposure to room

temperature after irradiation and 1 h per day for three

consecutive days of exposure to room temperature to

simulate temperature fluctuation conditions in industry.

To avoid the quality changes caused by microbial

growth, the pork loins used in this study were directly

purchased from a local packing plant where loins were

dissected under strict hygiene conditions. A great care

was taken to avoid microbial contamination during

transportation and further packing. The objective of this

study was to determine the effect of temperature fluctuation on the quality of irradiated pork loins.

2. Materials and methods

III) were exposed at room temperature for 1 h three

consecutive days with intermittent storage at 4 °C between exposures. In each step of meat handling, care

was taken to avoid microbial contamination.

Loin pieces were vacuum-packaged individually in

low oxygen-permeable bags (nylon/polyethylene, 9.3 mL

O2 /m2 /24 h at 0 C; Koch, Kansas City, MO) before irradiation. The energy and power level used for irradiation were 10 MeV and 10 kW, respectively, and the

average dose rate was 88.3 kGy/min. To confirm the

target dose, 2 alanine dosimeters per cart were attached

on the top and bottom surface of a sample. The alanine

dosimeter was read using a 104 Electron Paramagnetic

Resonance Instrument (Bruker Instruments Inc., Billerica, MA, USA). The range of actual dosage for

1.5 kGy was 1.414–1.810 kGy and the range for 2.5 kGy

was 2.34–3.12 kGy. Color, volatiles and lipid oxidation

were analyzed after 0, 14, 28 and 42 days of storage, and

water-holding capacity and sensory characteristics were

evaluated after 0, 14, and 28 days of storage.

2.2. Water-holding capacity

Measurement of water-holding capacity was performed by centrifugation method (Bertram, Andersen,

& Karlsson, 2001). Samples were cut parallel to the

muscle fiber direction, which is about 2.0 cm long and

0.5 0.2 cm in cross-sectional area. The samples were

weighed and placed in test tubes with a filter paper

(Whatman No. 1) cushion. The tube was sealed with

parafilm then centrifuged at 400g at 4 °C for 60 min.

After centrifugation the sample were weighed again.

Water-holding capacity was calculated as the percentage

of the difference in weight before and after centrifugation. Two meat samples were taken from each loin piece

and the average data was used for statistical analysis.

2.1. Sample preparation

2.3. Color measurement

Twelve pork loins fabricated under strict hygienic

conditions were obtained directly from a local packing

plant. Chops from three different loins were pooled and

used as one replication. The upper portion of each loin

was sliced into 2.5-cm thick chops for water-holding

capacity measurement. The rest was sliced to 1.0-cmthick chops and the chops were used for color, volatiles

and 2-thiobarbituric acid reactive substances (TBARS)

assays. Chops within each replication were randomly

separated into three groups, and each group was

assigned to receive 0, 1.5, or 2.5 kGy electron-beam

irradiation using a Linear Accelerator (Circe IIIR;

Thomson CSF Linac, Saint-Aubin, France). Each chop

within a group was further cut into three equal pieces to

make three sub-groups: one sub-group were refrigerated

(4 °C) immediately after irradiation (Trt I); another subgroup was kept at room temperature (22 °C) for 3 h

before refrigeration (Trt II); and the last sub-group (Trt

The surface color of sliced pork loins was measured

in package using a Hunter LabScan Colorimeter

(Hunter Laboratory, Inc., Reston, VA) that had been

calibrated against black and white reference tiles covered with the same packaging materials as used for

samples. The CIE L (lightness), a (redness), and b

(yellowness) values were obtained using an illuminant A

(light source). Two color readings were taken from each

side of a sliced loin.

2.4. 2-Thiobarbituric acid reactive substances measurement

Five grams of minced loin were weighed into a 40-mL

test tube and homogenized with 50 lL butylated hydroxyanisole (7.2%) and 15 mL of deionized distilled

water (DDW) using a Polytron homogenizer (Type PT

M.J. Zhu et al. / Meat Science 67 (2004) 643–649

10/35, Brinkman Instruments Inc., Westbury NY, USA)

for 15 s at high speed. One milliliter of the meat homogenate was transferred to a disposable test tube

(13 100 mm) and then thiobarbituric acid/trichloroacetic acid (15 mM TBA/15% TCA, 2 mL) was added.

The mixture was vortex mixed and incubated in a boiling water bath for 15 min to develop color. The sample

was cooled in cold water for 10 min, mixed again using a

vortex mixer, and centrifuged for 15 min at 2500g at

4 °C. The absorbance of the resulting supernatant

solution was determined at 531 nm against a blank

containing 1 mL of DDW and 2 mL of TBA/TCA

solution. The amounts of TBARS were expressed as

milligrams of malonaldehyde per kilogram of meat.

2.5. Volatiles analysis

A purge-and-trap dynamic headspace GC/MS system

was used to identify and quantify the volatiles compounds. Three grams of minced loin meat was put in a

40-mL sample vial and flushed with helium gas

(99.999%). After capping with a Teflon-lined, openmouth cap, the vial was placed in a refrigerated (4 °C)

sample tray. Samples were purged at 40 °C with helium

gas (40 mL/min) for 11 min. Volatiles were trapped with

a Tenax/charcoal/silica trap column at 20 °C, desorbed

for 2 min at 220 °C, concentrated using a cryofocusing

unit at –90 °C, then desorbed into a GC column for 60 s

at 220 °C. An HP-624 column (15 m, 250 lm i.d., 1.4 lm

nominal), an HP-1 column (60 m, 250 lm i.d., 0.25 lm

nominal), and an HP-Wax column (7.5 m, 250 lm i.d.,

0.25 lm nominal) were combined using zero-volume

connectors and used for volatiles analysis. A ramped

oven temperature was used: the initial oven temperature

was set at 0 °C for 2.5 min, then increased to 10 °C at 5

°C/min, to 45 °C at 10 °C/min, to 110 °C at 20 °C/min,

to 210 °C at 10 °C/min, and held for 2.5 min. Liquid

nitrogen was used to cool the oven below ambient

temperature. Helium was the carrier gas at constant

pressure of 22 psi. A mass selective detector (MSD) was

used to identify and quantify volatiles compounds in

irradiated samples. The ionization potential of MS will

be 70 eV, scan range was between 19.1 and 350 m=z. The

identification of volatiles was achieved by comparing

mass spectral data with those of the Wiley Library. The

peak area was reported as the amount of volatiles released (Ahn, Jo, Du, Olson, & Nam, 2000).

2.6. Sensory evaluation

sensory characteristics and was assigned a score ranging

from 1 (none) to 9 (extremely strong), respectively. All

samples were labeled with random three-digit numbers

and presented randomly to panelists.

2.7. Statistical analysis

A split-plot design was used in this study. Chops from

different loins were first split into three irradiation dosages, and then individual chops were cut into three

pieces and assigned to three temperature treatments.

Data were processed by the general linear model (GLM)

of statistical analysis system (SAS, 2000). The differences

in the mean values were compared by the Tukey’s

multiple range test, and mean values and standard error

of the means (SEM) were reported (P < 0:05).

3. Results and discussion

3.1. Water-holding capacity

Water-holding capacity is an important quality

characteristic of pork loins. These results demonstrated

that irradiation significantly increased the loss of water

from loins (Table 1). For the control samples with no

temperature abuse (Trt I), both irradiation at 1.5 and

Table 1

Water-holding capacity influenced by irradiation and treatments of

pork loins

Characteristics

Trt I

Trt II

Trt III

0 kGy

1.5 kGy

2.5 kGy

0 day

8.1b

11.3a

10.9a

8.9b

10.2a

10.0a

–

–

–

SEM

0.9

0.9

–

0 kGy

1.5 kGy

2.5 kGy

14 day

8.1bx

9.0ab

10.2ax

8.6x

10.0

9.9x

6.4y

8.6

6.8y

0.5

0.9

0.8

SEM

0.5

0.6

0.4

2.3

0 kGy

1.5 kGy

2.5 kGy

28 day

5.7b

6.4ab

8.0ax

7.4

6.9

6.2y

6.0

6.3

6.4y

0.6

0.7

0.4

SEM

0.6

0.6

0.6

x;y

Twelve trained sensory panelists characterized the

smell of irradiated loins under different temperature

fluctuation. Panelists were trained to familiarize with

irradiation odor, the scale to be used, and the range of

intensities likely to be encountered during the study.

A 9-point category scale was used to describe the

645

SEM

0.5

1.2

0.9

Means within a row with different superscript differ significantly

ðP < 0:05Þ; n ¼ 4.

a–c

Means within a column with different superscript differ significantly

(P < 0:05).

Trt I, refrigerated immediately after irradiation; Trt II, kept at

room temperature for 3 h before refrigerated storage; Trt III, were

exposed at room temperature for 1 h at three consecutive days with

intermittent storage at 4 °C between exposures.

646

M.J. Zhu et al. / Meat Science 67 (2004) 643–649

2.5 kGy significantly increased centrifugation loss

compared to that of non-irradiated samples. This result

is in agreement with a previous report about increased

centrifugation loss and reduced water-holding capacity

of pork chops after irradiation (Zhao & Sebranek,

1996). The mechanism for irradiation-induced centrifugation loss in pork loins is not clear, but two possible

theories exist: (1) irradiation may damage the integrity

of membrane structure of muscle fibers (Lakritz, Carroll, Jenkins, & Maerker, 1987) and (2) irradiation may

denature the muscle proteins, thus lowering waterholding capacity (Lynch, Macfie, & Mead, 1991). After

14 days of refrigerated storage, samples from three

consecutive days of exposure to room temperature (Trt

III) had lower centrifugation loss than other treatments

(Table 1). Since the meat used in this study is at postrigor stage, the water-holding capacity of meat is gradually improving during storage due to hydrolysis of

muscle proteins. Therefore, the improved water-holding

capacity observed in this study could be due to accelerated hydrolysis of proteins during temperature abuse,

since high temperature increases protease activity (DeTable 2

Color a of pork loin effected by irradiation and treatments after

storage

Irradiation dose

Trt I

Trt II

Trt III

0 kGy

1.5 kGy

2.5 kGy

0 day

13.0b

14.6a

15.2ay

13.2c

14.3b

15.6ax

–

–

–

SEM

0.4

0.2

–

0 kGy

1.5 kGy

2.5 kGy

14 day

12.8b

15.1ax

15.9a

12.6c

14.1by

16.8a

12.5c

14.5bxy

15.9a

SEM

0.3

0.3

0.4

0 kGy

1.5 kGy

2.5 kGy

28 day

14.4b

15.5a

16.2a

14.6b

15.5a

15.9a

13.3b

16.1a

16.3a

SEM

0.3

0.2

0.4

0 kGy

1.5 kGy

2.5 kGy

42 day

–

14.9b

16.1a

–

15.3

16.0

–

14.7b

16.3a

SEM

0.3

0.4

0.2

a–c

SEM

0.4

0.2

0.1

0.3

0.2

0.3

0.4

0.3

0.3

–

0.3

0.3

Means within a column with different superscript differ significantly

ðP < 0:05Þ; n ¼ 4.

x;y

Means within a row with different superscript differ significantly

ðP < 0:05Þ.

Trt I, refrigerated immediately after irradiation; Trt II, kept at

room temperature for 3 h before refrigerated storage; Trt III, were

exposed at room temperature for 1 h at three consecutive days with

intermittent storage at 4 °C between exposures.

vine, Wahlgren, & Tornberg, 1999). During storage,

water-holding capacity increased for all loins with various irradiation doses and temperature treatments (Table 1). This may also be due to the hydrolysis of muscle

proteins during storage, a continuation of the postmortem changes in muscle (Koohmaraie, 1994).

3.2. Color values and TBARS values

As shown in Table 2, irradiated samples have higher

redness (a value) than control samples, which is in

agreement with the previous results (Ahn et al., 2000).

Temperature abuse had no effect on the redness of pork

loin. No significant changes in redness occurred during

storage. As for lightness (L value) and yellowness

(b value), no changes were observed for both temperature abuses and during storage (data not shown).

Overall, the temperature fluctuations had no effect on

the color values of irradiated pork loins. Temperature

fluctuation, irradiation and storage had little influence

on TBARS of pork loins (data not shown). Minimal

irradiation and temperature fluctuation effects on

TBARS were expected because the loin chops were

vacuumed packaged.

Table 3

Irradiation off-odor as influenced by irradiation and treatments of

pork loins

Irradiation dose

Trt I

Trt II

Trt III

0 kGy

1.5 kGy

2.5 kGy

0 day

1.5b

5.7a

6.0a

1.4b

6.2a

7.0a

–

–

–

SEM

0.4

0.5

–

0 kGy

1.5 kGy

2.5 kGy

14 day

1.3b

6.9a

7.1a

1.5c

5.6b

7.6a

1.7b

6.8a

7.3a

SEM

0.4

0.3

0.5

0 kGy

1.5 kGy

2.5 kGy

28 day

1.4c

6.2b

7.3a

1.2b

5.4a

6.3a

1.7b

4.7a

5.7a

SEM

0.4

0.5

0.6

a;b

SEM

0.3

0.6

0.6

0.3

0.4

0.5

0.4

0.5

0.6

Means within a row with different superscript differ significantly

ðP < 0:05Þ; n ¼ 12.

Trt I, refrigerated immediately after irradiation; Trt II, kept at

room temperature for 3 h before refrigerated storage; Trt III, were

exposed at room temperature for 1 h at three consecutive days with

intermittent storage at 4 °C between exposures.

Twelve trained sensory panelists characterized the smell of irradiated loins stored under different temperature conditions. A 9-point

category scale was used to describe the sensory characteristics and was

assigned a score ranging from 1 (none) to 9 (extremely strong), respectively.

M.J. Zhu et al. / Meat Science 67 (2004) 643–649

50

45

40

35

30

25

20

15

10

5

0

Thiourea contentin volatiles of 0 kGy

irradiated prok loins

10000

Trt 1

Trt 2

Trt 3

0

14

28

Thiourea content (x10 4)

Ion counts (x10000)

Dimethyl disulfide in volatiles of 0 kGy

irradiated pork loins

42

Trt 1

8000

Trt 2

6000

Trt 3

4000

2000

0

-2000

0

Storage (days)

trt1

7000

6000

5000

Trt 2

Trt 3

4000

3000

2000

2000

0

0

14

28

28

42

Thiourea content in volatiles of 2 kGy

irradiated pork loins

30000

Thiourea content (x10 4)

9000

8000

14

Storage (day)

Dimethyl disulfide in volatiles of 1.5 kGy

irradiated pork loins

Ion counts (x10000)

647

Trt 1

25000

Trt 2

20000

Trt 3

15000

10000

5000

0

42

0

Storage (days)

14

28

42

Storage (day)

20000

18000

16000

14000

12000

10000

8000

6000

4000

2000

0

Thiourea content involatiles of 3 kGy

irradiated prokloins

Trt 1

Trt 2

Trt 3

0

14

28

42

Storage (days)

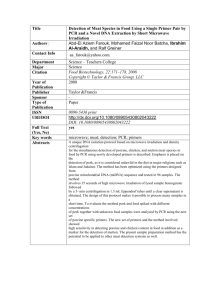

Fig. 1. Effects of temperature fluctuation and storage on dimethyl

disulfide contents (104 counts) in volatiles of pork loins under

different irradiation conditions. Trt I, pork loins were refrigerated (4

°C) immediately after irradiation; Trt II, irradiated pork loins were

kept at room temperature (22 °C) for 3 h before refrigeration; Trt III,

after irradiation, pork loins were exposed at room temperature for 1

h three consecutive days with intermittent storage at 4 °C between

exposures. Pork chops were irradiated at 0, 1.5 or 2.5 kGy. Volatiles

were analyzed after storage at 4 °C for 0, 14, 28, and 42 days. A

purge-and-trap dynamic headspace GC/MS system was used to

identify and quantify the volatiles compounds. A mass selective detector (MSD) was used to identify and quantify volatiles compounds

in irradiated samples. The identification of volatiles was achieved by

comparing mass spectral data with those of the Wiley Library. The

peak area (104 ion counts) was reported as the amount of volatiles

released (n ¼ 4).

60000

Thiourea content (x10 4)

Ion counts (x10000)

Dimethyl disulfide involatilesof 2.5 kGy

irradiated porkloins

Trt 1

50000

Trt 2

40000

Trt 3

30000

20000

10000

0

0

14

28

42

Storage (day)

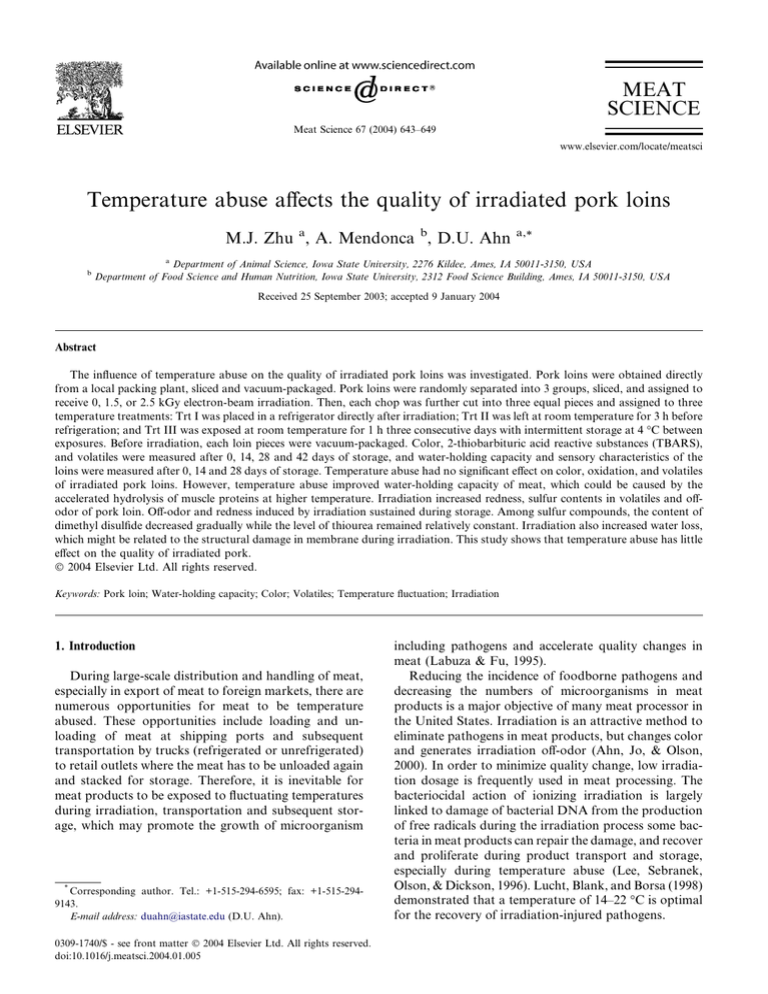

Fig. 2. Effects of temperature fluctuation during storage on thiourea

content (104 counts) in irradiated pork loins. Trt I, pork loins were

refrigerated (4 °C) immediately after irradiation; Trt II, irradiated pork

loins were kept at room temperature (22 °C) for 3 h before refrigeration;

Trt III, after irradiation, pork loins were exposed at room temperature

for 1 h three consecutive days with intermittent storage at 4 °C between

exposures. Pork chops were irradiated at 0, 1.5 or 2.5 kGy. Volatiles

were analyzed after storage at 4 °C for 0, 14, 28, and 42 days. A purgeand-trap dynamic headspace GC/MS system was used to identify and

quantify the volatiles compounds. A mass selective detector (MSD) was

used to identify and quantify volatiles compounds in irradiated samples. The identification of volatiles was achieved by comparing mass

spectral data with those of the Wiley Library. The peak area (104 ion

counts) was reported as the amount of volatiles released (n ¼ 4).

648

M.J. Zhu et al. / Meat Science 67 (2004) 643–649

3.3. Sensory evaluation and volatiles analysis

Irradiation induced strong off-odor (Table 3). After

irradiation, off-odor intensity increased from around 1.5

points to above 5 points on a 9-point scale. This irradiation off-odor was a pungent, cooked corn like odor

that has been reported in previous research (Ahn et al.,

2000; Du, Hur, & Ahn, 2002). Temperature fluctuation

and storage had no significant effect on irradiation

off-odor (Table 3).

Irradiation induces sulfur-containing volatiles, which

are the main compounds for irradiation off-odor (Du

et al., 2002; Kim, Nam, & Ahn, 2002). Dimethyl disulfide was almost undetectable in non-irradiated samples,

but the amount of dimethyl disulfide dramatically increased after irradiation (Fig. 1). During storage, the

content of dimethyl disulfide gradually reduced and

became barely detectable after 28 days of storage

(Fig. 1). This suggested that dimethyl disulfide might not

be the only sulfur volatile contributing to irradiation offodor because strong irradiation off-odor was still apparent by sensory panelists after 28 days of storage

(Table 3). However, no significant amounts of other

sulfur volatiles were detected in this study. In another

study, dimethyl disulfide content was shown constant in

volatiles of irradiated vacuum-packaged pork during

storage (Ahn, Nam, Du, & Jo, 2001).

Irradiation odor seems to be more related to thiourea

content in volatiles than other sulfur compounds

(Fig. 2). After 42 days of storage, significant amounts of

thiourea still remained in meat. This result was in

agreement with the sensory data where a sulfur-like offodor was noted (Table 3). Thiourea content in volatiles

enhanced greatly by irradiation, and increased slightly

after 14 days refrigerated storage before decreasing at

42 days of storage (Fig. 2). There was no overall difference in thiourea content among different temperature

fluctuation. Combining with sensory evaluation data,

this result showed that temperature abuse did not

influence the irradiation off-odor of pork loins.

4. Conclusion

Mild temperature fluctuation had minor effect on

color, oxidation, and volatiles of irradiated pork loins.

However, temperature fluctuation improved waterholding capacity of meat. Irradiation increased redness,

sulfur contents in volatiles and off-odor of pork loins.

During storage, the content of dimethyl disulfide decreased gradually while the level of thiourea remained

relatively constant. Irradiation also increased centrifugation loss that was partly reversed during refrigerated

storage, which could be due to the hydrolysis of muscle

proteins. This result shows that the quality changes induced by temperature abuse are not a major concern.

However, temperature abuse is expected to promote

recovery and proliferation of bacteria in irradiated

meats and extensive microbial growth can affect the

quality of meat, when meats with poor hygienic conditions are used.

Acknowledgements

The research was supported by the Midwest Poultry

Consortium. The NASA FTCSC has funded the purchase of the Solartek 72 Multimatrix-Vial Autosampler

used for the volatile analysis in this study.

References

Ahn, D. U., Jo, C., Du, M., Olson, D. G., & Nam, K. C. (2000).

Quality characteristics of pork patties irradiated and stored in

different packaging and storage conditions. Meat Science, 56, 203–

209.

Ahn, D. U., Jo, C., & Olson, D. G. (2000). Analysis of volatile

components and the sensory characteristics of irradiated raw pork.

Meat Science, 54, 209–215.

Ahn, D. U., Nam, K. C., Du, M., & Jo, C. (2001). Volatile production

in irradiated normal, pale soft exudative (PSE) and dark firm dry

(DFD) pork under different packaging and storage conditions.

Meat Science, 57, 341–443.

Bertram, H. C., Andersen, H. J., & Karlsson, A. H. (2001).

Comparative study of low-field NMR relaxation measurements

and two traditional methods in the determination of water holding

capacity of pork. Meat Science, 57, 125–132.

Bisha, B., Mendonca, A., Sebranek, J., & Dickson, J. (2003). Efficacy

of sodium lactate and sodium diacetate alone or combinated with

pediocin for controlling Listeria monocytogenes in ready-to eat

turkey roll at 4 °C and 10 °C. In 2003’s IAFP – 90th Annual

Meeting, August 10–13, New Orleans, LA.

Devine, C. E., Wahlgren, N. M., & Tornberg, E. (1999). Effect of rigor

temperature on muscle shortening and tenderisation of restrained

and unrestrained beef m-longissimus thoracicus et lumborum.

Meat Science, 51, 61–72.

Du, M., Hur, S. J., & Ahn, D. U. (2002). Raw-meat packaging and

storage affect the color and odor of irradiated broiler breast fillets

after cooking. Meat Science, 61, 49–54.

Gill, C. O. (1996). Extending the storage life of raw chilled meats. Meat

Science, 43, S99–S109.

Kim, Y. H., Nam, K. C., & Ahn, D. U. (2002). Volatile profiles, lipid

oxidation and sensory characteristics of irradiated meat from

different animal species. Meat Science, 61, 257–265.

Koohmaraie, M. (1994). Muscle proteinases and meat aging. Meat

Science, 36, 93–104.

Labuza, T. P., & Fu, B. (1995). Use of time–temperature integrators,

predictive microbiology, and related technologies for assessing the

extent and impact of temperature abuse on meat and poultry

products. Journal of Food Safety, 15, 201–227.

Lakritz, L., Carroll, R. J., Jenkins, R. K., & Maerker, G. (1987).

Immediate effects of ionizing-radiation on the structure of unfrozen

bovine muscle-tissue. Meat Science, 20, 107–117.

Lee, M., Sebranek, J. G., Olson, D. G., & Dickson, J. S. (1996).

Irradiation and packaging of fresh meat and poultry. Journal of

Food Protection, 59, 62–72.

Lucht, L., Blank, G., & Borsa, J. (1998). Recovery of foodborne

microorganisms from potentially lethal irradiation damage. Journal

of Food Protection, 61, 586–690.

M.J. Zhu et al. / Meat Science 67 (2004) 643–649

Lynch, J. A., Macfie, H. J. H., & Mead, G. C. (1991). Effect of

irradiation and packaging type on sensory quality of chill-stored

turkey breast fillets. International Journal of Food Science and

Technology, 26, 653–668.

SASÒ Institute (2000). SAS user’s guide. Cary, NC: SAS Institute,

Inc.

649

Tewari, G., Jayas, D. S., & Holley, R. A. (1999). Centralized packaging

of retail meat cuts: A review. Journal of Food Protection, 62, 418–425.

Zhao, Y., & Sebranek, J. G. (1996). Physicochemical and sensory

qualities of fresh pork chops as affected by phosphate, ascorbate or

sorbate dipping prior to irradiation. Journal of Food Science, 61,

1281–1284.