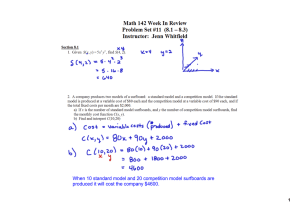

PASSIVE SOLAR HOUSING

advertisement