Transfer of The Development Process and ... U.S. B.Eng., Urban Engineering The University of Tokyo

advertisement

Transfer of The Development Process and Project Organizational

Systems Between Japan and the U.S.

by

HIDEO OBITSU

B.Eng., Urban Engineering

The University of Tokyo

(1976)

Submitted to the Department of

Urban Studies and Planning

in Partial Fulfillment of the

Requirements for the Degree of

Master in City Planning

at the

Massachusetts Institute of Technology

May 1987

@ Hideo Obitsu

1987

The author hereby grants to MIT permission to produce and to

distribute copies of this thesis document in whole or in part.

Signature of Author

0

Department of Urban studies and Planning

May 11, 1987

A-.

Certified by

,.

Bernard J. Frieden

Professor, City Planning

Thesis Supervisor

Accepted by

Phillip L. Clay

Director fthe MCP Program

MASSACHUSE TTS INSTITUTE

OF TECHNOLOGY

JUN o 8 1987

LIBRAR'Ir-

FRdo

Transfer of The Development Process and Project Organizational

Systems Between Japan and the U.S.

by Hideo Obitsu

Submitted to the Department of Urban Studies and Planning

on May 11, 1987 in partial fulfillment of the

requirements for the Degree of Master in City Planning

ABSTRACT

The main subject of this thesis is the development project

process and the differences in project organizational systems in

different environments. Through the case study of the Toyota

Kentucky (KY) Project and three other comparable projects, Nissan

Smyrna (Tennessee), Toyota Tahara (Japan), and Fuji Gunma

(Japan), the differences in project development systems between

Japan and the U.S. are examined. It is found that the American

development environment is more flexible and dynamic, especially

because of the possibility of a fast-track program, than the

Japanese environment.

Specifically, differences and similarities in the project

organizational systems, such as, traditional, design-build, and

construction management, between the two countries are studied.

A framework of the project organizational systems is built and

used to analyze the project organizations in the four automotive

plant projects as well as to define the differences and

similarities between the two countries. The influence on the

project organization of a fast-track program to achieve the

shortest possible project duration time is examined in the Toyota

KY Project. For the base of the analysis of the four project

organizational systems, a theoretical model developed by Minden

is used and its validity is simultaneously evaluated by the

applicability to the projects. Additionally, the organizations

of the client (Toyota Motor Corporation) and the design-builder

(Ohbayashi Corporation) for the Toyota KY Project are analyzed.

Thesis Supervisor: Dr. Bernard J. Frieden

Title: Professor of City Planning

Acknowledgments

I would hereby like to acknowledge the following people for

their help and support with this thesis. The nature of my

research has required the cooperation and assistance of

professors, professionals in the field of building construction,

and my family.

Special thanks go to my thesis advisor, Professor Bernard

Frieden, and the readers, Professor Henry Irwig and Michael

Joroff, the Director of the Laboratory of Architecture and

Planning. I would like to thank Dr. James Womack for his

introduction to professors, professionals, and books regarding

automotive industry, and Dr. Chris Sawyer-Lancanno for his

careful English editing.

Special thanks go to many professionals and managers in the

Toyota KY Project for Ohbayashi Corporation, Mr. Ohba, Mr.

Mizoguchi, Mr. Robert Jordan, Mr. Suzuki, Mr. Nagashima, Mr.

Muro, Mr. Muramatsu, Mr. Kanai, Mr. Matsunaga, and many managers

and engineers. I would like to thank Mr. Noma for the

information on OHB in the U.S. and Mr. Robert Lefebvre for the

information on Giffles Associates. I am especially grateful for

the support of many managers and engineers from Ohbayashi

Corporation in Japan, Mr. Tanabe, Mr. Sato, Mr. Osaki regarding

the Toyota Tahara Project, Mr. Kuroki, Mr. Kujirai, Mr. Imagawa,

regarding the Fuji Gunma Project, Mr. Hanzawa, Mr. Kataoka, Mr.

Harada, Mr. Shouda, Mr. Aoyagi, and other managers and engineers

who provided much information about Japanese construction. I am

as well grateful to Dr. Koshizuka and Mr. Mizushima regarding

information about local governments' incentives for corporations

in Japan.

Ohbayashi Corporation also deserves special thanks for its

full financial support for our family's stay in Cambridge for two

years.

Finally, I am deeply indebted to my family, Hiromi, my wife,

and Sayaka, our daughter, and our parents who arranged a

comfortable and cheerful environment that is the real reason for

completing this thesis.

3

IFigures and Project Summairies

Lstf Tables,

Tabes

and

Projects

2-3-1:

Factories

2-3-'2:

Outline of History

2-3:

Subsidiaries

2-3-4:

Outl ine

3-2.

2-1:

Staties'

-2-:

Reouired

Host

if

Differences

1-1:

-actors

Importarit

of TMC

TMC

of

the U..

of TMC in

of

Companies

(roup

Toyota

for

Incentives

for

Permissions

Auto

Japanese

KY-

in

Projects

Manufacturers

IFiguresMarket

Construction

I-1:

International

1-2:

Where Top

I -3:

Japanese Contractors'

1-4:

Major

1 -5:

International

2-4-1-1-a:

Schematic

2-4--1-1-b:

Section

2-4-1-1:

Development

2-4-1-2:

Toyota Tahara Project

2-4-1-3:

Outline

of

2-4-1-4:

TMC' s

Organization

2-4-1-5:

OH's Site

2-4-2-1-a:

Schematic

2-4-2-1-b:

Section of Assembling

2-4-2--i:

Develtopment

2-4-2-2:

Fuji

2-4- 2-:

Outl ine

of

Tahara

in

of

Tahara

Toyota

Tahara

Tahara

Toyota

for

Tahara

Gunma

Fuji

Shop

Chart

Process

Project

Contractors

Project

Toyota

of

Toyota

for

Organization

Proj

Tahara

Organization

of

6

Schedule

Project

Plan

Top

Project

Chart

Process

Contractors

Japanese

O-f

Press Shop

of

Gunma

of

ects

International

Japanese

Contracts

Plan

Proj

Overseas

For

Market

Contracts

Foreign

250 Won

in

of

Fuji

Gunma

G unma

Fuji

Schedule

ect

Organization

4

of

Fuji

Gunma

Fi

ur g an i z at i on

C

2-4

2-4--4:

E - sr

OHb

gar i z at i on

2-4-1

Scherati

c

24-31:

2-4-3-2:

2-4 -3-3:

4:

2-4

Nissan

2-4-3-6:

Schedule

Project

Schedule

of

Plan

Schematic

3-1-c:

KY

Toyot a

Toyota KY

in

of

Drawing

Perspective

Smyrna

1987

Jan.

Section of Main Shop

31 -b:

KY

Toyota

Si te Plan of Toyota KY

3--d:

Toyota KY

Si te Plan of

Toyota KY Project

2-1

:

3-2-2:

Toyota

Diagr am of

of

Merit

Diagram

of Saturn

Outline

of

Project

(2)

Shop

Pact

Project

Oroanization

OHB's Organization Chart

Flow Chart

4- 1--2:

Outline

of

Framework

4-1-4:

Minden's

of

for

of

Classification

Toyota

Organi zati

Project

in

Deinition

5

KY

Toyota KY

Project

Contractual

Alternative

of

of

for Toyota KY

OHB's Site Organization Chart

4-1-1:

KY

Toyota

Schedule

Schedule

Project

KY

(2)

Process Chart

Development

3-1-

in

Nissan

Smyrna

Nissan

for

Organization

Toyota KY Project

3-1-a

of

Nissan Smyrna

for

Organization

Daniel's

(2)

Organization

Project

of

Outline

Smyrna

Ni ssan

Smyrna Project

Nissan Smyrna

NMMC's

of

Process Chart

Development

a

Gunma

Fu.j i

f or

Gun

Lu

i

Nissan Smyrna

of

Pl an

f or

the

Systems

Approach

onal

Framework

Systems

4.-1 -5

1--- i :

4-

c i ic L O rg a n i Zt

Pr (-:- r

eent

i on a L

Method

St-

DeF;i an

o

1odel

Four

i

Pro

Var-i abI eE

52-1:

C n

5-2-2-a:

Application

of

the

5-2-2-b:

Application

of

the Matrix

for

5-2-2-c:

ApDlication

of

the Matrix

for Toyota Tahara

5-2-2-d:

Appl i cati

the Matri

-for Fuj i

5-2- 3

iotnency Factors of

ActLUal

on -of

and Optimal

Four

Pro

a

ctS

ects in

the Mat ri

-For Toyota KY

latrix

Systems a-f

Nissan Smyrna

G unma

the Projects in

the

Fr amewor k

15-2-

Japanese Project

Fr amewor k

5-3-1:

Cost

Mechanism

Control

Mintzbergr s

Organizational

Framework

5--:

TMC

5-4-1:

OHB's Organization -or

in

for

Systems

Toyota

Organizational

and Nissan's Organization

Toyota

Schematic IPIroject Summaries

2--4-1-1:

1K.Y

Project

Summary

of

Toyota Tahara

2-4-2-1:

Project

Summary

of

Fuji

2-4-3-1:

Project

Summary

of

Nissan Smyrna

3-1

Project

Summary

of

Toyota

Gunma

KY

for

KY

and

the

in

Nissan

SmVrna

Analysis

the Projects

and

Projects

in

Japan

TARLE OF CONTENTS

Aic know l edgments

Li st

of

Tabl es.

F gures and

Proj ect SLmmar ies

1 I ntroduct i on

2

Back grouind

2-1

Trade

Toyota Kentucky

i nf ormationOf:

2-2 History of The Ohbayashi

2-4 Other

2-4-1

automotive

2-4-1-1

Project

2-4-1-2

Devel opment

Project

2-4-2-2

Development

Smyrna

Outline

of

Ni ssan

9

P.

18

P.

33

Corporation

P.

41

P.

52

F.

68

P.

32

Japan)

and

Organi

zati on

the U.P.)

Motor

Developmen t

Proc ess

Kentucky

and organization

(in

U.S.iA.

Manufact uring

and Organi z ati

Project

on

P. 102

summary

Process and Schedule

3-2- 1 Pl anni ng /F'r e-desi gn

3

F.

and

the U.S.

Japan)

Corporation

3-2 Development

3-2-2

(in

Project

2-4-3-2

Project

Toyota Motor

(in

Proc ess

Project suIMMarV

3-1

4

summary

2-4.-3-1

Toyota

in

constructions

Process

Project

Gunma

2-4-2--1

2-4-3-

P.

Summary

2-4-3 Nissan

3

plant

Tahara Project

Toyota

2-4-2 Fuji

Corporation

the History of

2-3 Outline of

investment,

3

(::ntractors

international

Japanese

direct

Japanese

friction,

Project

F'.

Design

st age

stage

Procurement

stagre

7

P. 109

3 --- 4 Con

r"t uc t. i on- st ce

SPr-oj ect

4

Procurement

Alternative

(includii-g4

Systems

of

Evaluation

Proj ect

5--1

Proj ect (Organizational

classi-fication

of

the Development

Organizational

Difff erences

in

construction

Evaluation

System of

in

systems for

Japan and

the

four

P. 167

automotive

Process And

the Toyota KY

Tovotaa's

P. 183

Project

process and

P. 186

an automotive plant

the U.S.

of the four automotive

construction procurement

5-3 Anal ysi s of

Project

the development

rganizational

5-2

Methods/

projects)

pl ait

5

P. 159

aion

rgaz.

r

plant

P. 192

methods

strategy for the Toyota KY

P. 201

Proj ect

5-4

Analysis

of

Ohbavashi's

strategy

for

the Toyota KY

P .214

Project

6

Conc1 usi onEs

and

Further

Research

P. 222

Ref e r en c es

P. 229

Bibli ography

P. 235

1

P. 241

A-ppendi x 2

P. 249

Appendi

P. 252

Appendix

x

A p p end i x

P. 256

4

8

INTRODCTION

The meeting of two different cultures is a significant

character

Project,

(KY)

of the Toyota Kentucky

the first

$800

million direct investment in the U.S. by Toyota Motor Corporation

The

(TMC/Toyota), the biggest Japanese automobile manufacturer.

main subject of

thesis is

this

and the differences in

different

leadership applying the Toyota

with Japanese management

plant,

systems in

organizational

Toyota is trying to build a Toyota style auto-

environments.

Total

the development project process

Quality Control

(TQC) system to the construction using a

Japanese construction manager, Ohbayashi Corporation

using American general

and sub contractors in

This thesis analyzes this

examining

1)

What

are the differences in

Japan and in

What

and

the U.S.

as a core case study

the following questions:

organizational

2)

project

(OHB),

the development process and

system for an automotive plant construction in

the U.S.?

kind of

project organizational

members' internal

system (including project

organization) do TMC and OHB build to cope- with

uncertainties, such as many change orders caused by a fast-track

program?

3)

What

kind of conceptual

project organizational

model

and design methodology of

systems should be used or developed for

future projects?

In

addition to these main

process in

questions,

TMC

the new business environment,

technology transfer

in

and OHB's

learning

and the difficulties

the construction industry are

9

of

cupple: I cent a Iy

uncertai ntie

in

the new

Ktky Project,

i

first

the

by the Toyota

of

one

the

project

Lsino

tLlrnkl::ev

contract

to

eCla

the

fst-trac.k

mi

125

ion

Because the

S out of

i

events . ab:::oL.t

be

wi

:construction

The

y i -Far plant;

with

such

as

ca

i

cs

a c:nstruction

4)

the U.S.

Corporation,

manages

the

by

manager

more

get

Toyota

than

and

or

$900

for

Ohbvasihi

construc:tion

of

th

of

t h

S.tud i ed

of

labor

beginni ng

i n the

thei

of

of

on

of

D)ecemriber

s...

in the

ieSccr i pt. i on

infli..enc:e

the end

conlstructio:4n.

r el aion

the

t he ir

as

under

on the

1abor

. c.

cat i on.s and

KY Project

still

isvcigqned

PA) i s- not

proj cct

i mpIrt ant

the projiect

ed

the

and

TMC

OHiB as.sociatedc w it h t.he pr oj ec t

4 ast--track

manaement,

Japanece

cocntractors,

AFL-CIO

Toyota

anli:

c-Ocets for

the proiject site,,

CIO.

r

the

labor rel

nresceItc:

those

of

f cuE

New"

are

-From

()

into

K.:entuc ki.y qovernment

i aid

i i

complete

the

the Tovota

in

Toyota will

the project

off

was

:i mpact

lthouLh the

case,

The Ohbavashi.

2)

3)

is analyzes thhe

"A

man c ae

to

construction.

though

1937.

198. the

cr

the

This c thes

January

in

agrcement

durino

HB

inves.tment

program

wit h Toyota

a project

un:i on

di rect

Japanese Cengi reer

Five

seeveralc

an, alyes

follows:

indi-vidual

milion ar-id 200000

made

the core

Iotor Corooration;

Bi g

and

by vIl

of

as

are

the thesis

l

environment.

coharacteritics

Special

This

F i na.

empoyoed

trategiec

alternative

1)

ned. e-

eai'

program,

turnk:y

and labor

dcision

c:ontract,

reiations

making

10

cost-plu-fe

tate

i ncenti ves

thOsie wiith

includino

ystem ,

contract

lon

for

AFL-

t eI- m r el at ion ship

between clients

and contractors, and TQC program are unusual

factors in the American construction industry.

Comparative studies using

the Nissan Smyrna Project,

Toyota Tahara Project, and the Fuji

find answers to the main questions.

would be an ideal

Gunma Project will

the

be done to

The Toyota Tahara project

comparable project in Japan with the Toyota KY

Project because they have many common factors, such as building

type, client, and prime contractor.

Therefore, the difference

between the U.S. and Japan's development process and organization

will be extracted.

special

The Fuji

Gunma Project will be used to check

features of Toyota's methods for its construction by

comparing the project with the Toyota Tahara Project.

This

comparison will be important to define the Japanese style of

development process and organization for

automotive plant

construction.

The Nissan Smyrna Project would be an

comparison

of the Toyota KY Project in

differences between the TMC's

risky

projects.

points:

the clients,

large direct

order to examine the

strategy and Nissan's in

Toyota and Nissan,

both projects are the

investment in the U.S. by Toyota and Nissan;

in

Tennessee;

Robert B.

the project manager,

in

are the two largest

car manufacturers;

the location of each project is

Ohbayashi

regard to

These two projects also have many similar

Japanese international

first

ideal project for the

the mid-South,

Jordan,

Toyota KY was the project manager

Construction in the Nissan Smyrna Project.

features or roles of Ohbayashi

11

in

for

Kentucky and

working for

Daniel

Therefore, special

the Toyota KY Project will

be

etr

acte(j

by the compar iso:r

of

Toy'ota KY with the Nissan

3Irvyrna

Prjcl I ect

Tabl e

1 -1

s umnmar i

i mportant

most

es the

factors.

pro

The

ects

di fferences;

process a nd organi Zati on w i

liie

will

be

Thu1h

T'

traditional

as

organi zati

on

fast-track

analvzed in

for

many

factors

seem

to

needs

to

analye

dc

ici

on

the

i nC rea'

the

necesity

of

procram

5.

c

a oart

its

of

w el l

development

the policy,

Namely,

of

Further,

and

ost -pl

cost

of

the

-fle1xibility

of

a

for

rime.s c ontr ad i :tsi=

TMC

coS.t

i nt.ensi ve

s TQCU procgram,

because

to el i mi nate

spare

cont

and

beciusi:e the

orders

used

use

of

or

ystem

to

quiCk

chancie or ders

the

the

ast-track

value eng i neer i no

excessive us

space

during

does not

Moreover

r.

.

in

a

OHB and

r act

manv

pilan

pln

desig

much

decisiion

:is not

us-fee

ffinal

bae

TMC

change

and

as

as the use of

uSes a giroup

probl ems,

the c

pajroicct

TMC

Japan

wivth

for

marv

to use

STC

orocess and

such

are undesirable

the

horiZontal

be

in

and a cost-p-olus--fee contract

stace.

tends

ngineering

ect may

const.ructi on

the

uncertai ntv

TMC

pro

I

plant

decisions

f inal

e1t

of

the

and

the

above

4

var ious factors-

guarant

factors sho..twn

Chapter

instant

mak: i n ..

b

the double

They

conStruc:tion

devel opment

belov

contradict

con tractors.

fast-track

each

Factors

s pol i cy for

rgram

ceneral

as

nes.

methods

ossible.,

the

li

in

Ie Iricc-s of the

d i 4'ff

be ep1 ai ned frai nl

differences bet ween t hese i mportant

dcuble horiz-ontal

t he

and

. L.e

o.fV

the posi

bsibility of

future changes.

TMc

s short constructi

urnc er t ai nty

of

the

future

c:'n

schedul e,

c omp act

12

c ar

probab

m11ar k et

in

v

due

to the

the U.

.. .

creates

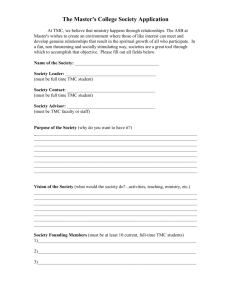

TAB 1-

PR O

EC 1

PRO JECTC

T

5

AND

DI FFERENCES

i-TYOT A

KENTUCKY

LOCAT 1IN

'Ol0ST

OF

NISSANr

SMYRNfNA

U. SU.

I MF O RT ANT

TOY OTA

FU J I

TAHARA

GUNMA

JAPAN

JAAN

NAT I ONAL~ Y

CLIEN 1T, TYOTA

JAPANESE

YES

AMEiR ICAN

A

NO

JAPANESE

YES

PRIMEl

fOH BA YASHI

DAN IEL

OHBAYASHI

C'ONTRACTFOR,

STAZF

NOTIONALTY

Ame.':

FACTORS

Jap.

Ame.

A E

(OHBAYASHI)

GIFFLES

KAHN

PROJ ECT SIZE

(FLO:R AREA)

370, 000 SM

00,

1APANE

NO

OHBAYASHI

Jap.

Jap.

TOYOTA

(OHBAYASHI)

C) SM

73 000 SM

(FUJI)

OHBAYASHI

30, 000 SM

USI)

SS

ONSHIPS

LONG TERM

CLIENT &< CONTRACTOR!

RELA'

T

(MONTH)

CONTFUCTION

CONE

PERIOD

(PLAN)

22

(FAST

PROJ

CT

ORGA"C

IZ(AT ION

PHASED

DES I GN-

CT TYPE

< PRM. CONT.

METHED TO SELECT

PRIME CONTRACTOR

SELFE DERFORM BY

F'RTK CONTRACTOR

RELiATIONS

TOTA

QUALITY

6

TRADITIONAL

Cc)nt r ac tor

MlANAGE Const.

TRD IT I ONAL DESIGN-UILD

Mngt. (OWNER

COS T PLUS

FEE

:NEGOTIATION NEGOTIATION

NO

S

LUMP

SUM

SELECTIVE

BIDDING

Y YEYES

(:TRUCTURAL

MERI T SHOP

TO

YES

TRiD I TIONAL

'A/E)

COST PLUS

FEE

CLOSED

(BUILDING)

TRACK::)

FRAME WORKS)

LAPBD

LONG TERM

11

TRACK<I) (FAST

(TRUNKEY)

CONT

.L IE'

LONG TERM

(BUILDING)

(20)

METHOD PHASED

-UCTION

SHORT TERM

SELECTIVE

BIDDING

YES

(TEMFORARY

WORKS)

MFIT SHOPF MULTI--LAYER

(OPEN SHOP) SB-

SHOP

LUMP SUM

(TEMFORARY

WORKS)

MULTI--LAYER

SUB-

CONTFCT I NG CONTRACT I NG

NO

YES

NO

n.a.

ni.

CONT ~LD ( T QC)

I N C 1STRUCT I ON

INCE YTIVES

CLI. EJ5

BY

FOR

STATES

$125

mi

$19

mil

those undesirable

unintentionally because the schedule

factors

requires the fast-track program,

which needs the cost-plus-fee

contract.

The separation of the construction management function from

the use of the company's own forces

construction)

is

performance of

OHB's decision based on the policy and capacity,

but the decision basically fits

turnkey contract with OHB.

to many American

trade friction

(self

TMC's strategy which employs a

OHB tries

to distribute

the project

contractors to avoid unnecessary blame for

in

the construction

have enough Japanese staff

industry,

to use self

new

and OHB does not

performance in

addition to

construction management.

KY's incentives for TMC have influenced the strong reaction

by the AFL-CIO

they try

workers'

This is

(construction union)

to use local workers

against TMC and OHB because

(75"4 non-union)

labor relations rather

regardless of the

than only union contractors.

based on the local business conventions and probably is

based on the best effort

The difficulties

Quality Control

the difficulties

base agreement

of

between TMC and KY.

the implementation

program on the American

of American

managers'

of TMC's Total

construction system,

and

associating with TMC's

Japanese-style group decision process show the difference

in

business conventions and the potential difficulties for American

contractor's entry to the Japanese construction market.

There are many variables that affect

and organization

size

in

a development

(physically or monetary),

project;

a development

building type,

construction schedule,

14

process

project

location,

and contract type are important variables,

participants in

government,

manager,

a project,

such as a client,

an architect and engineer

a general

as are the

contractor,

a state or local

(A/E),

a construction

subcontractors,

and labor

union.

Environmental conditions around the project are important ,too,

such as political,

legal,

economical,

social conditions, and

business conventions.

To be more specific, differences and similarities of

construction management

or project procurement

Japan arid the U.S.

be studied.

will

methods between

Despite many text books and

articles

about construction management, they do not have a

rational

general

theory of the selection for an optimal

procurement method, and each author sets his/her individual

definition or terminology of alternative project management

methods,

Similarly,

transfer

process in

such as construction management

although there are many studies about technology

of construction in

the broad transfer of

the context of the developing areas,

no study about technology transfer

of

and design-build.

development process in

Construction

Management

is

there is

almost

(including management systems)

developed countries.

popularity and explicitness,

1

the development

Because of

the

Barrie and Paulson's Professional

used

as the text

book

to

alternative construction management methodologies.

define

Based on

B&<P's definition, the author develops a framework of project

organizational

For

systems in

a theoretical

38

model is employed

a triangular

framework,

shape in

Figure 4-1-3.

Minden's procurement

to define theoretically

15

optimal

decision making

project

organizational systems of the four automotive plant projects

because of this is probably the first and firm attempt to develop

a theoretical

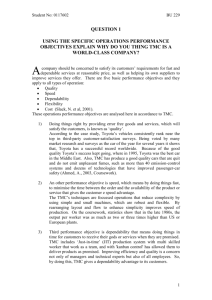

procurement methodology.

applying the decision making model

projects,

the validity

of the model

At the same time,

for the four automotive

will

be evaluated.

Additionally for a framework for organizational

analysis of

TMC and OHB for the Toyota KY Project, the concepts built by

9

Mintzberg, Bronfman Professor of Management Policy at McGill

University is used.

This theory provides a framework for the

classification of organizations and for defining independent

variables known as contingency factors, to change or formulate

27

organizational structure.

Irwig's summary of Mintzberg's

framework is used to show the results of the analysis of TMC and

OHB's organization for the Toyota KY Project on

Irwig's pentagon

diagram after Mintzberg.

Finally,

the strategy of TMC and OHB for the project to cope

with uncertainties is analyzed.

actual

Several

alternatives of the

strategy are examined.

The thesis structure is

Chapter 2:

as follows:

Background information of the project.

includes four sections.

The first section presents historical

background on the economic and political

the U.S.

situation of Japan and

The second section describes the history of OHB in the

U.S.

The third

TMC.

The

last

section presents an outline and the history of

section describes three projects comparable with

the Toyota KY Project:

Smyrna,

This chapter

Toyota Tahara, Fuji

are explained respectively.

16

Gunma,

and Nissan

Chapter 3:

project

Toyota Kentucky Project.

summary,

The project

organization.

used

and

development

process and

summary

schedule section

presents

The project

events.

a detailed

project

important

factors

description

process

of

events on

of these

reasoning

describes the

section

organization

and

development

The

stage and the possible

each development

includes a

schedule,

presents

outline.

describe the project

to

This chapter

organizational structure and contract types of the project, and

Chapter

4:

systems

(including classification

Alternative procurement methods/project organizational

projects).

A new

presented.

Alternative

framework

of

of

procurement

Paulson's definition

automotive

the

5:

methods

systems is

comparing Barrie

and

38

and

plant

Minden's one

project

Evaluation

organizational

are

explained here.

organizations

will

The

be classified

process and

Project

are analyzed.

the organizational

about these points and

Several

studied.

in

OHB.

possibly

Chapter

Gunma

6:

the

in

projects,

Conclusions

between

strategies

Japan

procurement

using

and

the U.S.

Further

17

to

find

by TMC

methodology

for

TMC

OHB

to

and

Toyota Tahara,

these answers.

Research.

and

are examined

the Nissan Smyrna,

are used

and

the Toyota KY

employed

the new environment

studies

The development

strategies employed by TMC and OHB are

the optimal

Comparative

Fuji

process and the project

systems of

Differences

alternative

manage uncertainties

define

of the development

systems of the Toyota KY Project.

project

and

organizational

framework.

Chapter

to

the four automotive plant

project

1

four

the project.

of OHB's organization of

explanation

2.

Back groumd infatrnation of

Toyota Kentucky Project

This section includes on account of the general

situation between Japan and

the Toyota KY Projects.

history

of trade

operations.

The first part explains the brief

and

the U.S.,

Japanese

and Japanese international contractors

The next part describe the outline and history of

the Ohbayashi

of

the U.S. in projects comparable with

friction between Japan

direct investment,

economic

Corp.

in the U.S.

the Toyota Motor Corp. will

Then, an outline of the history

be explained.

Finally, three

projects, Toyota Tahara, Fuji Gunma, and Nissan Smyrna, will

described.

These projects will

Projects

section

in

2-1 Trade friction,

be

be compared with the Toyota KY

four.

Japanese direct investment,

and Japanese

inter-national contractors.

Special

of

features of

the study about

transfer

developed countries will

thesis.

of

the

current

increase

of

relationship

period was

support the importance of

is

in

the first

1976 to 1978;

features of

the

a symbolic event in the context

between

the U.S.

the project is

and Japanese

a symbol

of

the rapid

engineering

the U.S.

friction between

periods:

process between

the share by Japanese international

companies

Trade

development

definitely

At the same time,

construction

Special

of

The Toyota KY Project

industry.

three

the Toyota KY Project and the scarcity

the U.S.

period

was

the third

and

Japan is classified

1971

period

to

is

1972;

1981

into

the second

to date.

the third period is the sophistication of the

18

items that cause the trade friction.

In the first period, the

textile industry was the major problem.

period, the steel

Then in the second

industry was discussed.

Now the items are

expanded to automobiles, color televisions, semiconductors and

financial

services.

Japanese direct

friction.

investment overseas is

to trade

The first period of the direct investment boom was

1972 to 1973.

invested in

At this time, mostly the manufacturing industry

developing areas,

Only trading and financial

developed

related

countries.

such as Asia and South America.

service industries invested in

In 1973,

the investment yielded $3.5

billion due to the favorable environment for the direct

investment because of the scarcity of the domestic

(Japanese)

labor supply and the strong yen created by the "Nixon shock."

Backed up this

environment,

the textile

electric manufacturers invested

areas.

But

industry and some

in South east Asia and other

on the other hand, Japanese manufactures were not

strong enough to go to developed countries, such as the U.S. and

Europe.

The second direct

investment boom, begun

since 1980, has

been accelerated by the strong yen against U.S. dollar.

Compared

with the first period, the contents of the investment and the

target areas are very different.

electric, and mechanical

The transport machine,

industry have increased

Especially, in VTRs, semi-conductors, computers,

their share.

and

communication devices, which Japan has a technical

increasing.

advantage, are

In the automobile industry, after Honda and Nissan,

Toyota decided to invest in the U.S.

19

Mazda, Mitsubishi, Fuji,

and

ISuZu are following,

Because of

too.

the slow economic growth

Japan and the

in

economic slump in developing countries, the Japanese construction

target

industry has recently turned their

by Japanese corporations

investment

U.S.

in

to the direct

developed countries.

market

has become the most attractive

for them.

This total

in 1984.

Japanese contractors and their

The total

yen which was

contract amount overseas in 1985 was 11 billion

% more than

The

10

includes direct contract by

overseas subsidiaries.

Contracts

by the overseas subsidiaries have been increasing every year

8

since 1979.

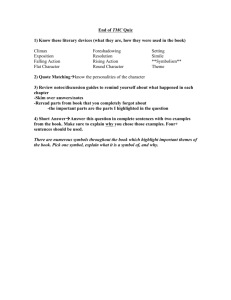

Figure

1-1 shows the market trend of the international

and the share of Japanese contractors in

construction market

Figure

These graphs indicate the declining market

foreign contracts.

North America.

not still

contractors won

1-2 shows where the Top 250 international

of the Middle East

it.

and Asia,

and the relatively

steady market

of

The increasing share of Japanese contractors is

but it appears stable compared with the big

significant

ups and downs of the whole market.

Figure

1-3 shows

overseas operations.

13 years trend of Japanese contractors'

It

shows rapid expansion of

operations by Japanese contractors

The regional

in this decade.

share of the contract is

share of Asia has shrunk drastically,

international

changing.

North America,

While the

Europe,

Pacific region are increasing and occupy 46% of the total

overseas contract.

1)

The U.S.

The top five countries are as follows:

except Hawaii,

199 billion

20

yen;

and

-

L-

-..-.---

--

F~

C-.-

.4.:

-

'11

Ii.

R)

-

-

-I

LIJ

.

.

.,.....*

--

.

1

I

*

'1

-*

F

F"

Ljq rl

F

IijI~i:

.. I.

~,

r- r7.-

SOURCE: ENR

TOP 250 INTERNATIONAL CONTRACTORS

I

I

I

~*-,

I

:9..

-4K-

7.

-r

N)

N)j

S . . *- - * * *

*

-t

......- -

*

- -

..

1-.*,-1

~.

I~i

A7-5CA

r4

p

Ft ..f , - - ':r

T

- .- *-*-.'

*ThFh

SOURCE: ENR

TOP 250 TNTERNATTONA, CONTRAC'TORS

F IONJFPE 1

,J AF

~

"'4

F. J

M-SE

-T-.A.- f 'j1:§

Ff.,

E13 17

-

I.

I

I

r..

.

r

-/

I

-

r~~~

'e

7:1-

i ..e.

elI

lee".

-z

lo,

~1

.0

ei~

el

de

r

-

1*~

.e...-

ee

I

e-

e

I .-..

e

.0.I

....

e-

74

IOM t.1

:0

.

'I

}.*

el-eI

' 1e* :10 1i

t

.....

II

r

r :j

FCc

A

ee

I

j

-I

re'1'

i

t

LI.. I

11'

-

re.

ell

1 1

II

..

.

err

-j

7

I

SOURCE: THE WHITE PAPER OF CONSTRUCTION

JAPAN'S MINISTRY OF CONSTRUCTION

l

2)

Australia,

3)

Hongkong,

4)

Singapore, 86 billion yen;

5)

Hawaii,

Figure

176 billion

yen;

yen;

106 billion

77 billion yen.

1-4 shows the recent

change of major

market

international

for Japanese contractors.

1-5 shows the recent trend

Figure

of overseas operations by

the Japanese Big Five contractors plus Kumagai-gumi.

gumi

Kumagai-

has extended its business drastically, and the Big Five seem

to be starting new steps in the international market.

The Japan's ministry of Construction explains that the

reason for

the decline of contract

contractors from 59%

economy of ASEAN

in

84 to 36%

in

'85 is due to the inactive

(Association in South East Asian Nations) and

The reason for the increase of

the decrease of new projects.

contract

share of Asia for Japanese

share in the U.S. and Australia for Japanese contractors

is the increase of Japanese plants and offices in the U.S.

26

associated with the direct investment by Japanese corporations.

Additionally, the rapid increase of real

estate development by

Japanese contractors in the U.S. and Australia is another reason

for

the increased share in these areas for Japanese contractors.

The Ministry of Construction forecasts that the U.S. and

Australia will

continue to be major overseas markets for Japanese

contractors.

Reaction by the U.S. against the current

Japanese contractors'

gradually.

operations in

the U.S.

Because of the imbalance in

24

increase of

has begun to change

contracts between

[7i[

1

ii

'12

'-I

1-.!:

N)

-.7:

34

17A

NORTH AMERICA

-k

:

AUSTRALIA

S,

A

MALAYSIA

D

SINGAPORE

SOURCE: THE WHITE PAPER OF CONSTRUCTION

P

*

4.7:'

4

R)

(3)

Fi

5

[77

A

OHBAYASHI

~I]

KAJIMA

1

rx-r- r~i

5.

SHIMIZU

F

TAISEI

TAKENAKA

SOURCE:

KUMAGAI

TOP 250 INTERNATIONAL CONTRACTORS

Japanese contractors in

Japan,

the U.S.

market,

nothing in

'85.

and American

contractors in

government has asked Japan to open up its

construction market.

the U.S.

the U.S.

Japanese contractors got

yen

280 billion

in

but on the other hand, American contractors got

The Kansai

International Airport Project is the

first target by the U.S. government.

Though there is little

visible movement in the Japanese government, Japan has a new

potential

problem in the construction industry in

1986.

Topics about Japanese contractors in the U.S. have recently

appeared both in professional

construction magazines such as

Engineerinq News record and national newspapers in the U.S.

Engineering News Record, Sep. 20,

'84, reports the recent rush of

Japanese contractors into the U.S. market comparing it with the

29

previous Canadian movements.

It explains the attractiveness of

the U.S. market as much space, political

loose restriction.

for

The magazine describes the general

Japanese international

activities

stability, relatively

situation

contractors and states their

as contractor developers in

the U.S.

for Japanese contractors has become the first

The U.S.

in

'84,

market

from the

fifth in '83.

In The New York Times, Bennet writes "Now, Japan

Inc. Wears

a Hard hat:

Japanese builders are beginning to win some big

17

contracts in the U.S."

The article begins with Ohbayashi Corp.'s

tunnel

construction for

the I-10 highway in

using the favorable comments for Ohbayashi

the American

joint

venture partner

Phoenix

and concludes

by Shank-Artukovich,

of Ohbayashi

for

the project.

Bennet explains the basic situation of the U.S. construction

27

market

$4

the more than $100

of

billion

the

('86),

"This year

as

no far- bellow the $5 billion

by Bechtel,

that

"some

John P.

last year

in domestic contracts won

construction companies'

In the

reactions

others are profiting."

builders are bitter,

American

Boone,

Companies,

American contracts -

in

billion

one of the nations top three builders."

he states American

article,

companies may capture

(Japanese)

senior vice president of

the Dallas based Vantage

one of the nation's largest private developers,

described briefly that "It

is a two way street.

While they are

learning about doing business here, we can tap technology from

Japan."

This statement seems to point out the essential

relationship between the U.S. and Japan's construction industry

to date,

though differences of building construction technology

between these countries seem to be little.

Though the drainage tunnels construction for the I-10

Japanese builder,

work

it

is

still

an exceptional

for Japanese contractors in

Japanese clients

or

event

in

the U.S.

terms of public construction done by a

in

industry

construction

a sensational

is

highway by Ohbayashi

the U.S.

case to date.

comes from their

Business

leading Tokyo-based construction firm

Inc.,

Information

and expanding along with leading firms

such as Ohbayashi

Hann and Krizan summarize this

that the bulk of the U.S.

a

says that medium-size

Japanese contractors are now setting up subsidiaries in

and offices

A

from development projects by themselves.

report prepared by international

and Kajima Corp.

Most

the U.S.

Corp.

report and

say

contracts have been for the factories

of Japanese companies setting

28

up shops in

the U.S.

including

24

Toyota, Nissan, Cannon, and Nippon Denso.

Bennet says

that the Japanese construction companies have strong ties

other Japanese corporations, because the traditional

with

Japanese way

of doing business insures long-lived relationships between

17

Actually this is the main reason why

builders and their clients.

Corp.

the Ohbayashi

the

Kentucky Project from

got the Toyota

important

Toyota Motor Corporation, one of Ohbayashi's most

clients.

Supplementally the following part of this section presents

the discussion about Japanese contractors' general

structuring

general

they are trying

capture overseas projects by Japanese investors,

manufacturers and financial

to

such as auto-

But competition among

institutions.

contractors is

Japanese contractors and local

unavoidable.

Therefore cooperation with the local construction

industry is

President Ohbayashi

to avoid new trade friction.

contracts like

the Toyota KY Project should be

with the local construction

actively used to ease friction

44

industry.

joint

Historically,

popular method for

and

ventures have been a traditional

Japanese engineering

construction companies to

Joint

avoid or reduce business risks

in

unfamiliar countries.

ventures are also very popular

in

the Japanese construction

industry,

from

says

venture with local contractors,or construction

that a joint

management

As a

a project organization especially in the U.S.

policy of Japanese contractors,

important

strategy of

though the emphasis of their

the usual

joint

venture concept,

29

merits are quite different

the distribution

of

business risks.

popular

Joint

because it

projects

to

small

venture construction

is

a convenient

or

mid-size

local

in

way to

Japan

is

distribute

public

companies maintaining

high quality guaranteed by the joint venture sponsor,

This type of

construction company.

engineering

very

the

a big

joint

venture

is

an effective way to transfer technology from a big and advanced

or

company to a small

medium sized

local

construction companies.

Another purpose of joint venture in Japan is coordination

for construction companies

by a client

construction companies themselves.

or sometimes by

For instance, when a

manufacturing company decides to rebuild its main factory, the

company

will

choose

some contractors who are usually building or

maintaining the company's facilities.

among contractors for

much.

If

Historically, the share

the manufacturing

the rebuilding project

manufacturing company may well

is

company does not

unusually big,

arrange

vary so

the

a joint venture whose

participating ratio will be similar to the historical

distribution

of

much

Through

international

demerits.

factor of

experience of

Diversification of

the joint

venture

important

local

purposes

venture with

between

for

of

application

international

the U.S.

and Japan,

in

it

is one of

contractors

construction

30

risks is

overseas construction

business conventions

a local

Japan,

Japanese

its merits as well

construction

in

the company.

for

venture in

joint

contractors are aware of

Knowledge about

difference

the contractors

despite the unusual

contractors

joint

among

contracts

company.

and their

to

an

as

important

for Japanese

Japan.

the most

structure

Considering

matured

a

the

industry,

construction

business conventions

companies without

knowledge of

in each country must get help to secure

their operations in the new environment.

from local

sufficient

The necessity for help

companies reduces as a company accumulates the know-

how of operations in

the new market.

Information about local

trade or jurisdiction of the

construction industry in the U.S. is very important to manage a

project effectively and successfully.

organization

including subcontracting in a reasonable way is a

key factor to achieve project goals.

traditional

Structuring project

Either

through a

construction process or construction management style

construction,

the input of

local construction conventions into

design and procurement is critical

Information about the local

and not an easy task.

construction industry in Japan

is important, too, because even in open shop areas in the U.S.,

local

It

information is

very important

may not be appropriate to describe the labor

Japan as open shop,

however,

Japanese labor relations

unions,

relations.

relations in

it has many similarities

and the open shop in

instance, the Japanese construction

in

including labor

so trade or jurisdictional

between

the U.S.

For

industry has no industrial

arrangement

is

not necessary

Japan.

Ohbayashi

tool

Corp.

for American

has used the joint

construction business as well

business risks since its first operation

some examples in

Kyoto

Inn Hotel

venture as a learning

Ohbayashi's history in

construction

in

31

as avoiding some

in the U.S.

the U.S.

There are

such as the

1974 and the Evertrust office

building in

a joint

to

1985.

Ohbayashi

did this

venture with American

avoid

In

construction by structuring

contractors to learn

business and

some risks.

the context of both the Japanese and American

construction

industry,

a Japanese construction

a greater reputation by doing construction management

contracting

as a sponsor

of

a joint

the construction management for

venture.

gain

than by

This is

because

Japanese contractors is

contracting style and challenging subject for them.

risky for

could

company

a new

It is too

unexperienced Japanese construction contractors who

seeking for Japanese clients

have come recently to the U.S.

because of the difficulty of getting information and hiring good

American

managers.

32

2-2 Chatline and the history of Ohbayashi Corporation in the U.S.

Ohbayashi

Corp. has been in

worked on relatively small

Coast until

1982.

the U.S. since

projects in Hawaii

1966, having

and on the West

It has gradually undertaken bigger projects,

primarily the building of factories and warehouses for Japanese

23

companies setting up operations in the U.S.

Ohbayashi began to

attach importance to the U.S.

to get heavy construction in

Though Ohbayashi

recently in

the U.S.,

Corp.

it

is

market

around

80

the U.S.

began

almost unknown except very

has been famous as one of the Big Five

engineering construction companies in

is

1982 because it

Japan.

The outline of

it

as follows:

1) name; Ohbayashi corporation,

2) head office;

3, 2-chome, Kanda Tsukasa-cho, Chiyoda-ku,

Japan,

3) establishment; Jan. 25, 1892,

4) capital assets; 32.6 billion yen (Mar. 31, 1986)

5) employees; 9,915 (ave. 39.4 years old) (Mar. 31, 1986)

6) subsidiaries in the U.S.

(1985)

a. Ohbayashi America Corporation, California

b. United Development Corporation, Washington

c. J. E. Roberts-Ohbayashi Corporation, California

d. Ohbayashi Hawaii Corporation, Hawaii

e. Ohbayashi Associates Hawaii Inc., Hawaii

f. Citadel Corporation, Georgia

7) Overseas office in the US.

(1985)

a. New York

b. Los Angels

c. San Francisco

d. Chicago

e. Atlanta

f. Honolulu

Important events of Ohbayashi

Tokyo,

corp. in the U.S. are as

follows:

1966-1971;

the first operation of Ohbayashi

the Surfrider hotel

in Honolulu, Hawaii.

Corp.

After

in the U.S. was

Ohbayashi got a

negotiated contract from a Japanese overseas subsidiary, Kyouya,

'33

Ohbayashi

registered as a foreign corporation, and then received

a contractor's licence in

construction was in

The completion of the

1967.

In addition, Ohbayashi

1969.

got an

enlarging and remodeling construction contract for the PrincessKailua Hotel,

and completed it in

Ohbayashi started real

construction in Hawaii.

estate development as well

Ohbayashi

(SM) parcel in downtown Waikiki

acquisition of overseas real

Ohbayashi

in 1971.

This acquisition was

set up its

(Japan)

regarding

the

estate for Japanese corporations.

in

local office

opened its

as

acquired a 1600 square meters

permit by the Ministry of Finance

the first

1972;

1969.

overseas subsidiary,

Honolulu in

Ohbayashi

Hawaii

1971.

Then,

Corp.,

in

it

1972.

Ohbayashi started its operations in North America by

setting up the overseas subsidiary, Ohbayashi America Corp. in

Los Angels

(L.A.).

It received a licence of a general

contractor

in the U.S. in 1973.

1973;

Ohbayashi set up the Department of Overseas Business in

the Tokyo Head Office.

opened a local

Besides Ohbayashi

America Corp.,

it

office, which mainly dealt with heavy construction

in Los Angeles.

1974-1975;

After two years of market research, Ohbayashi

started active operations on the West Coast.

construction of Hotel

The completion of

Kyoto

America

It got the

Inn from America Kintetsu Kougyou.

the construction was in 1975.

Ohbayashi chose

J.E.Roberts Co. as the joint venture partner for the

construction.

Actually, Ohbayashi

did not make a profit

it gave too many incentives to the partner.

34

Since then,

because

Ohbayashi

America

has gotten many projects mainly from Japanese

companies or their

subsidiaries.

construction by itself

Ohbayashi did this

with little

profit,

but

it

learned

the

construction business through these experiences.

1976-1977;

Ohbayashi America expanded

Angels to San Francisco

(S.F.)

project is

located in

network from Los

and Seattle.

took on a big project,

America

its

Then,

the Milcreak Project.

a suburb of Seattle,

Ohbayashi

manage the project.

project in

America

got

which does not exist

In

with Adlian Wilson Co.,

a big American

America's

Consequently,

it

it

for

America's

the first

time

company through competitive bidding with

construction business.

order

Nov.

1976,

in

Ohbayashi

America hooked up

design firm,

organization to manage

constructed the L.A.

the Japanese

office

and arranged

a turnkey program.

of American Komatsu

by turnkey contract.

Ohbayashi chose J.E.Roberts Co. as a strategic partner

to expand Ohbayashi's operations

into

public facility

construction because J.E.Roberts had much experience in

field.

to

project from an American

This event was a milestone in Ohbayashi

construction bonds,

1978;

Corporation

1988.

from an American

Ohbayashi

and

The corporation plans to complete the

history because Ohbayashi

Forklift,

Tokyuu Group.,

Corp.,

Ohbayashi got the Koncho Building

company.

on

facilities

investors set up the United Development

American

This

and developed about

3,200 private residents and various recreational

1,085 acres wilderness.

Ohbayashi

J.E.Roberts-Ohbayashi

succeeded

35

in

the

getting a public

in

housing project

in

north San

Ohbayashi

Department.

Francisco from the Federal

began to manage the Wilshire Building

this

one of the Ohbayashi's properties,

L.A.,

a sophisticated tunnel

both in

sensational

Japan,

Record,

the U.S.

came back to the U.S.

Sep.20,1979,

and Japan because of

which once the U.S.

from Japan.

advanced

had exported to

Ohbayashi's portrait

on

topic about Ohbayashi Corp.

public heavy

tunnel project was the first

because this

its

EngineerinQ News

used the president,

and wrote a special

the cover,

This project was

construction method.

engineering technology,

civil

year.

Construction Method,"

proposing "Slurry Shield Tunnel

Francisco,

in

got a sewage project of the City of San

Ohbayashi

1979-1980;

Housing

construction project done by a Japanese contractor in the U.S.

Ohbayashi

1982;

was to get business

purpose of opening the New York office

especially for American

information

Soon after some efforts

to Japan.

information,

The original

opened the New York office.

managers in

the office

companies that

to get such kind of

realized that someone who

does not give anything cannot get anything in

The first

Ohbayashi

success was the NEC

contracted this

the lump sum contract.

Hawaii,

Information's Boston factory.

Doing

the construction,

its

Ohbayashi

using

Ohbayashi

began

business relations.

the head of the New York office,

this relationship.

Then,

project with Turner Construction

to get business information through

Noma,

business.

began to get projects on the East Coast.

the office

managers in

planned to go

gave an example of

When a typhoon destroyed Ohbayashi's hotel

getting

had difficulties

36

insurance money.

An

in

the NEC project,

of

an underwriter

introduced a construction

for Ohbayashi.

insurance specialized lawyer

money from the insurance company than it

Ohbayashi

had not done business in

N.Y.,

80

Noma added.

such an appropriate person,

1983;

Ohbayashi

Urban Renewal

corp.

asked to introduce

which Ohbayashi

at Hartford,

inlLSUrance broker

It

received more

had expected.

If

it would not have found

got a public housing project from the L.A.

Department.

This was the first case for a Japanese

It

contractor to get a public building construction project.

also got the Westside Pump Facility from the City of

Francisco, and a condominium, Tokyo Villa in L.A.,

San

through

competitive bidding.

1984;

Ohbayashi Corp.

Ohbayashi got the drainage tunnel

17

It also got a big (324,000 SF)

I-10 in Phoenix.

Rothchild Realty Group,

construction for

high rise

(17F)

agreed to business cooperation with The

office

Ill.

building from Evertrust,

a subsidiary of

Ever Line, in Jersey City, New Jersey, on just the other side of

the river from

Manhattan.

This was the first case for a

Japanese contractor to get a project from a non-Japanese company

in

the greater New York

area.

Ohbayashi chose Sordoni,

in

New Jersey

( about one tenth of

joint venture partner.

from Ohbayashi

a medium size construction company

Turner

Turner Construction),

as a

Construction rejected the offer

Corp. to be the joint venture partner though

Turner had contracted the NEC Boston project with Ohbayashi.

According

to Noma,

the head of the N.Y.

office,

because Ohbayashi

tried to get involved in the construction and to learn the

37

business on the East Coast,

lump sum contract with an American

cautious enough

it

N.Y.

in

had not enough experience on

Why Ohbayashi could not do construction in

the East Coast.

despite

Ohbayashi was

was afraid of unforseen problems during and

the construction because it

Jersey,

contractor.

to avoid doing construction individually

At the same time, it

after

venture rather than

chose joint

it

in

doing construction individually

New

L.A.,

is

that the concessions related construction business especially in

construction union is one of the special

features of the

Noma explains that even

construction business in Manhattan.

Sordoni,

A very strong

extremely complicated.

New York is

greater

the joint venture partner, cannot do business in

Manhattan island.

To do construction business in Manhattan,

construction companies have to hire powerful project managers who

80

have much experience there and know who does what exactly.

Though several

for Japanese clients

Japanese contractors do tenant construction

in

Manhattan,

with American contractors,

usually by lump sum contract

Japanese contractors did not suffer

from obstructions by the union or others until

1985.

probably because the Japanese construction business is

for the union or others to pay it special

This is

too small

attention.

One of the reason that Ohbayashi does not do construction

independently on the East Coast

its

construction for

its

is

that Ohbayashi

Japanese clients.

cannot fail

in

Even in the U.S..,

failure of construction for Japanese clients causes a terrible

influence on Ohbayashi's business in

regard

their

Japan.

contracts with Ohbayashi for

38

Japanese clients

overseas projects as a

their long term relationships with Ohbayashi.

simple extension of

Ohbayashi

If

a Japanese client

in

fails

Japanese competitors will

for the client.

take some portion of Ohbayashi's share

At worst, Ohbayashi

for selective bidding of

and

may loose its reputation

it may loose chances even

advantage for the client;

historical

overseas,

project

the client's projects, which used to be

automatically contracted with Ohbayashi by negotiation.

Ohbayashi Corp. changed its operation system in the U.S.

1985;

It has

its first operation in the U.S.

after 20 years after

three main overseas offices in the U.S.,

N.Y.,

L.A.,

and S.F.

It

Ohbayashi added two other offices in Chicago and Atlanta.

completed the first full-turnkey project as a Japanese contractor

for the Sumitomo

Kinzoku Kouzan's semi-conductor factory in

Fremont.

Corp.

Ohbayashi set up Citadel

the increasing Japanese investment

necessity to set up an open

is

a closed

(union)

contract with open

area;

Atlanta,

a key city

The reason for setting up a new subsidiary in

Sun Bel t.

Belt is

in

(non-union)

in

the Sun

there and the

shop construction company.

shop company

the

in

the Sun Belt,

so it

Ohbayashi

cannot

shop companies which dominate

the

the contract between union and Ohbayashi prohibits

to use non-union contractors in

Ohbayashi

Sun Belt

is

contracted areas.

The

very popular for Japanese corporations partly because

it is largely non-union.

Japanese management tries to avoid

unfamiliar headaches which would be caused by labor unions.

Labor unions exist in

Japan,

too,

but most of them are individual

unions within their corporations rather than interindustry or

39

craft

is

unions.

Therefore, the concept of the labor union

Ohbayashi

the U.S.

in

from that

different

totally

in Japan

Corp. uses a so called

"Double Breast Strategy,"

that means the strategy for an owner of construction companies to

operational

possess two different

Most big American

companies.

in

strategy

closed and open shop

construction companies use this

the U.S.

A special

American.

companies,

feature of Citadel

Corp.

is

that all

management

Noma explains that because excellent American

is

managers

tend to avoid working under Japanese managers, Ohbayashi decided

to hire an American president for

its

new subsidiary.

Ohbayashi

simply gives policy but does not try to control the operations of

Citadel.

Though Citadel has gotten only small

1986, the top management of

Ohbayashi

projects as of

is looking for Citadel

to

get into the American construction market while Ohbayashi

provides business for it.

Management recognizes that the goal

of

its operations in the U.S. is to be able to get sufficient work

from American clients in all areas in the U.S.

At the end of

Citadel

1985, Ohbayashi

got the Toyota KY Project.

did a good job for Ohbayashi to gather information

regarding site selection or other project related matters, during

the planning stage of the project for Toyota Motor Corp.

Main

reason for Ohbayashi's success in getting the project was the

long-term relationships between Toyota and Ohbayashi

but the contribution

by Citadel

40

was significant

for

in Japan,

Ohbayashi.

2-3 History of Toyota Motor Corporation

This section has two parts:

the first

the second part

the history of TMC;

(T1C)

part is a summary of

a summary of the

is

historical relationship between TMC and Ohbayashi.

world

years.

famous

Toyoda)

1918 by Sakici

(established in

a

from Toyoda

independence

Since the

auto-manufacturer

TMC produced 3.4 million

1937,

Company

TMC has grown to

through ups

and downs

cars next to

the top,

during 50

GM's 5.7

1978 because its sales, and profit, both after

financing and taxes, were the most.

TMC has maintained the

in Japanese industry since

position

prestigious

then.

TMC

11 factories in Aichi prefecture in

employs 62,000 people and has

Japan.

in

Loom

TMC became the top Japanese manufacturing

million cars in 1984.

company in

Automatic

The products are automobiles, industrialized housing,

industrial

transporters,

The outline of

TMC

Name;

2)

Establishment;

3)

Location;

4)

Capital

5)

Employees;

parts.

is as follows

(1986):

Corporation

Toyota Motor

1)

and

28,1937

Aug.

I Toyota-Machi, Toyota City, Aichi

Assets;

Table 2-3-1

yen

133.2 billion

61,676

Prefecture, Japan

(m.:56,117, f.:5,579)

shows

its factories.

The Tahara

factory, one of

the comparable plants with the Toyota KY plant, is a relatively

new factory, the tenth factory of TMC.

oldest,

of

the dedication was

Toyota Motor

about one year after

Industry Co.

the TMC's plants in Japan.

The Honsha factory is the

Figure 2-3-1

the establishment

shows the

location of

All factories are located in Aichi

41

Factor-i.esE

Table r2--l

o+ TooaMotor

Cr.

EMFL.OYEES-

FLOOR

NA~ME'

DED I CA T' ION L AND

TAHAR

1979

3930

61 C)

H

1938

79C:

400

1959

1610

:,.

~73

1965

880

54

1966

1360

M I YOSH I

1968

0

1.40

TSUTSUMI

197C)

970

530

AKECH'

1973

30

140

AMA2

1.975

410

210

KOR 0MUR A

1978

820

230

TEIHCu

1986

320

90

MOTOMACHI

K MI GU

SHIMO

540)

PRODUCT S

4800 FPASS. CAF:.,

SMALL TRUCK

2400 TRUCK,:I Bus.

HOUS I NG

5200 PASS. CAR

3400 ENG INE,

TRANSMISSION

5 100 F'ASS. CAR

1900 SUSPENS ION.,

SMALL PARTS

5800 PA SS. CAR

900 DIECAST

PARTS

1600 ENGINE, ANTIPOLUT I ON DEV I CE

2300) TRANSMISSON,

POWER TRAIN

1400 MACHINE,

DI E

1985

AS OF DEC.

SOURCE: TOYOTA 1986 BY

42

TMC

LOcT

PL-ANTS

TM's

OF

ION

1. Location of Toyota City

2. Location of Takaoka Plant

Sanko 1 Honda-cho

t

bn

0m

~10ko

3km

3Oka

akaoka

67kma

ar

Toyota-shi Aichi-ken

6k

2k

2.5t

0565(52)1212

FIGURE 2-3-1

43

SOURCE: OUTLINE OF TAKAOKA PLAN'

BY TMC, 1983

Layout of T akaoka Plant

Monthly Production

Land space

50,000

1,370,000m 2 (336 acres)

510 ,000m2

Floor space

(5490,000 SF)