Evaluation of Assembly Simulators Used in

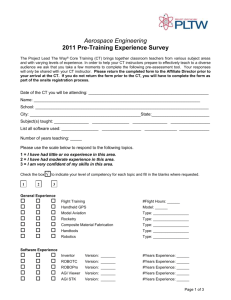

advertisement