Microwave Joining — Part 1: ClosedLoop Controlled Microwave Soldering of WELDING RESEARCH

advertisement

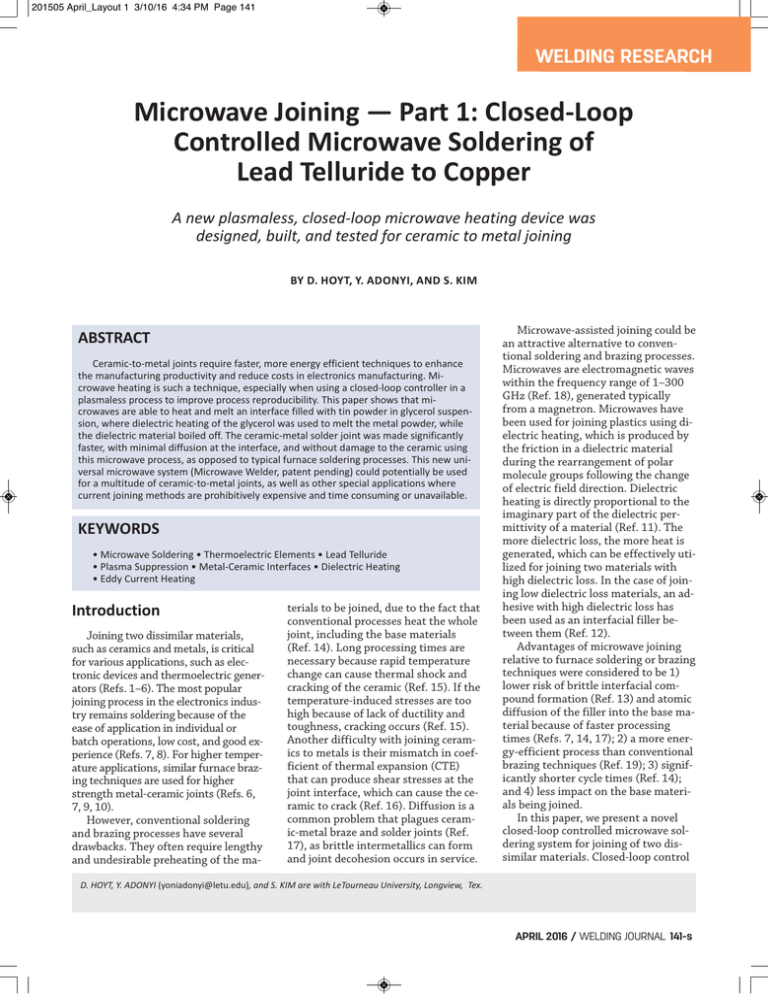

201505 April_Layout 1 3/10/16 4:34 PM Page 141 WELDING RESEARCH Microwave Joining — Part 1: Closed­Loop Controlled Microwave Soldering of Lead Telluride to Copper A new plasmaless, closed­loop microwave heating device was designed, built, and tested for ceramic to metal joining BY D. HOYT, Y. ADONYI, AND S. KIM ABSTRACT Ceramic­to­metal joints require faster, more energy efficient techniques to enhance the manufacturing productivity and reduce costs in electronics manufacturing. Mi­ crowave heating is such a technique, especially when using a closed­loop controller in a plasmaless process to improve process reproducibility. This paper shows that mi­ crowaves are able to heat and melt an interface filled with tin powder in glycerol suspen­ sion, where dielectric heating of the glycerol was used to melt the metal powder, while the dielectric material boiled off. The ceramic­metal solder joint was made significantly faster, with minimal diffusion at the interface, and without damage to the ceramic using this microwave process, as opposed to typical furnace soldering processes. This new uni­ versal microwave system (Microwave Welder, patent pending) could potentially be used for a multitude of ceramic­to­metal joints, as well as other special applications where current joining methods are prohibitively expensive and time consuming or unavailable. KEYWORDS • Microwave Soldering • Thermoelectric Elements • Lead Telluride • Plasma Suppression • Metal­Ceramic Interfaces • Dielectric Heating • Eddy Current Heating Introduction Joining two dissimilar materials, such as ceramics and metals, is critical for various applications, such as electronic devices and thermoelectric generators (Refs. 1–6). The most popular joining process in the electronics industry remains soldering because of the ease of application in individual or batch operations, low cost, and good experience (Refs. 7, 8). For higher temperature applications, similar furnace brazing techniques are used for higher strength metal-ceramic joints (Refs. 6, 7, 9, 10). However, conventional soldering and brazing processes have several drawbacks. They often require lengthy and undesirable preheating of the ma- terials to be joined, due to the fact that conventional processes heat the whole joint, including the base materials (Ref. 14). Long processing times are necessary because rapid temperature change can cause thermal shock and cracking of the ceramic (Ref. 15). If the temperature-induced stresses are too high because of lack of ductility and toughness, cracking occurs (Ref. 15). Another difficulty with joining ceramics to metals is their mismatch in coefficient of thermal expansion (CTE) that can produce shear stresses at the joint interface, which can cause the ceramic to crack (Ref. 16). Diffusion is a common problem that plagues ceramic-metal braze and solder joints (Ref. 17), as brittle intermetallics can form and joint decohesion occurs in service. Microwave-assisted joining could be an attractive alternative to conventional soldering and brazing processes. Microwaves are electromagnetic waves within the frequency range of 1–300 GHz (Ref. 18), generated typically from a magnetron. Microwaves have been used for joining plastics using dielectric heating, which is produced by the friction in a dielectric material during the rearrangement of polar molecule groups following the change of electric field direction. Dielectric heating is directly proportional to the imaginary part of the dielectric permittivity of a material (Ref. 11). The more dielectric loss, the more heat is generated, which can be effectively utilized for joining two materials with high dielectric loss. In the case of joining low dielectric loss materials, an adhesive with high dielectric loss has been used as an interfacial filler between them (Ref. 12). Advantages of microwave joining relative to furnace soldering or brazing techniques were considered to be 1) lower risk of brittle interfacial compound formation (Ref. 13) and atomic diffusion of the filler into the base material because of faster processing times (Refs. 7, 14, 17); 2) a more energy-efficient process than conventional brazing techniques (Ref. 19); 3) significantly shorter cycle times (Ref. 14); and 4) less impact on the base materials being joined. In this paper, we present a novel closed-loop controlled microwave soldering system for joining of two dissimilar materials. Closed-loop control D. HOYT, Y. ADONYI (yoniadonyi@letu.edu), and S. KIM are with LeTourneau University, Longview, Tex. APRIL 2016 / WELDING JOURNAL 141-s 201505 April_Layout 1 3/10/16 4:34 PM Page 142 WELDING RESEARCH Fig. 1 — A diagram of the Microwave Welder showing key components. Fig. 2 — The Microwave Welder with key components labeled. Note, the generator control panel and most of the touchscreen panel are hidden from view in this image. Fig. 4 — A schematic of the actual closed­loop control system used by the Microwave Welder. Fig. 3 — A COMSOL simulation of the electric field distribution in the microwave waveguide with a reflecting backwall. and arc suppression were to be used to ensure repeatable joining of different coatings, semiconductors, and metals, two specific features of our system for which a patent is pending. We attempted to validate the concept of dielectric heating by microwaves and the use of this heating mechanism at the interface of a ceramic-metal joint to melt the metal filler powder used to bond the joint. Objectives For the purpose of demonstrating the dielectric heating mechanism and joining two dissimilar materials with the proposed system, we chose ceramic thermoelectric elements (lead telluride and bismuth telluride) and copper (Cu). Joining these thermoelectric materials to Cu substrate is crucial for thermoelectric generators. A microwave joining system has been designed, built, and tested, as no commercial systems were available. Safe and reproducible operation was to be ensured by using a plasma-dischargefree environment, although metals were involved in the joining process. Experimental Procedures A conceptual schematic of the system is shown in Fig. 1, while Fig. 2 shows the third prototype of the system with key components labeled. The microwave generator produces a 2.45-GHz microwave guided through a WR-340 waveguide that has a cross section of 3.4 × 1.7 in. and supports only the TE10 mode. The waveguide is connected first to the isolator (which diverts the reflected wave), then to a dual-power coupler that measures forward and reverse power, third to the sample chamber where heating occurs, and finally to the movable backwall where reflection happens. A FLIR T300 thermal camera is used to observe the temperature of the sample, which is fed to a computer running a LabVIEW program that contains the closed-loop control platform. This controller uses temperature and heating rate to control magnetron power and backwall position, respectively. A touchscreen computer interface allows the operator to input parameters, such as sample mass and material 142-s WELDING JOURNAL / APRIL 2016, VOL. 95 properties, and observe runtime results, such as temperature of the sample and magnetron power. For the theoretical modeling of this microwave system in terms of electromagnetic field distribution in the waveguide, we employed the COMSOL multiphysics software. A typical calculated electric field norm (V/m) along the waveguide is shown in Fig. 3. Due to the reflected wave from the backwall, constructive and destructive interferences between the forward and the reflected waves occurs, and a standing wave pattern is formed inside the waveguide. At the peak locations, the magnitude squared of electric field is doubled from that of the forward wave only case while, at valleys, it becomes zero. Therefore, the backwall is used to produce a variation of intensity levels at a desired location in the waveguide depending upon the backwall’s location (Refs. 21, 22). The dielectric heat is directly proportional to the magnitude squared of electric field (|E0|2), as shown in Eq. 1. Note the dielectric heat is also proportional to the dielectric loss term (”), which is a unique material characteristic of the target. 201505 April_Layout 1 3/10/16 4:34 PM Page 143 WELDING RESEARCH A B Fig. 5 — A COMSOL simulation plot of the heating of bismuth tel­ luride in the Microwave Welder, demonstrating the difference in final temperature for two different backwall locations. Fig. 6 — Experimental results from a microwave heating experi­ ment that validated the COMSOL simulation of Bi2Te3 heating. Fig. 7 — PbTe­Cu solder joint configuration in the Microwave Welder. dialectric = 2 0”|0|2 (1) where is the 2.45 GHz frequency of the wave, and 0 is the permittivity of free space. Control of the electric field intensity distributions and modulation of magnetron power provides closed-loop control of the heat delivered to the sample using temperature of the sample as feedback into the control system. This dual parameter control (backwall position and power) coupled with continuous temperature monitoring using a thermal camera provides the means for the actual closed-loop control for stable heating at a joint interface — Fig. 4. Sample heating is accomplished by control of magnetron power and backwall position and set by a target heating rate. The thermal camera measures the temperature of the sample, which is fed back into the control algorithm (implemented on a LabVIEW platform) along with instantaneous heating rate in two feedback loops. The first feedback loop controls magnetron power by feeding the desired temperature as a set point and the actual temperature as the process variable into a proportional-integral controller, the output of which is scaled to the magnetron’s power output range. Fig. 8 — Magnetron power, the temperature set point, and the ac­ tual temperature of the interface as a function of time for the Cu­ PbTe soldering experiment. The second feedback loop finds the heating rate error and multiplies it by a set point using the dielectric character of the target, which specifies the volume fraction of the target that is composed of a dielectric substance versus a metal. The product is used to calculate the target wall position, which is fed into a proportional-integral-derivative (PID) controller with appropriate constants optimized for speed and accuracy. This design allows the control system to select between heating the dielectric portion of a target with use of a local electric field maximum or heating of metallic particles by the use of a local magnetic field maximum. The position of these field maxima are adjusted by the movement of the backwall. The advantage of this closed-loop controlled device lies in the combination of a feed-forward component — the dielectric character — with a double-nested loop design feedback component utilizing the temperature and heating rate for control of the magnetron power and the backwall position (Ref. 22). The dielectric character defines the composition of the target being heated — what portion is a dielectric material versus a metal. The magnetron input power and the backwall positions are constantly adjusted to maintain the desired heating rate of the sample. Results and Discussion Dielectric Heating Validation To demonstrate the microwave heating of a dielectric material, a simulation was performed using a Bismuth Telluride Bi2Te3 block by placing it in a waveguide terminated by a movable backwall. As shown in Fig. 5, the Bi2Te3 block is heated with microwave energy mostly by the dielectric mechanism. Figure 5A shows the temperature of the Bi2Te3 for a backwall position giving particularly low electric field intensity at the sample location. Figure 5B shows the temperature developed in the Bi2Te3 block for a backwall position extended by 0.38 cm. It is obvious that the Bi2Te3 temperature is different and depends upon the relative location of the movable backwall due to the standing wave pattern produced in the waveguide, which in turn shows the controllability of the sample heating using the backwall. APRIL 2016 / WELDING JOURNAL 143-s 201505 April_Layout 1 3/10/16 4:34 PM Page 144 WELDING RESEARCH Fig. 10 — Electron­dispersive x­ray spectrum of the solder interface material. ing process, a microwave solder joint was made between lead telluride (PbTe) and Cu, a common conductor material in the electronics industry. Both of these materials have a low susceptibility to microwave heating as defined in Eq. 1, which means that selective heating will exist at the interface. Minimal heating of the base materials is key for ceramic-metal joining as it reduces the stresses induced by disparities in the CTEs of the materials and thermal shock in the ceramic. A dielectric liquid, glycerol, was identified as having a much greater dielectric loss factor than bismuth telluride. In addition, antimonious tin powder (Sn) was selected as the metal filler, having a low melting point and being commonly used in the soldering industry. A 90% mass tin/10% mass glycerol interlayer paste composition was selected for its viscosity. The joint configuration was placed on a metal stage within the Microwave Welder, as shown in Fig. 7. The magnetron power and temperature data for the experiment is shown in Fig. 8. In this example of microwave soldering, the closed-loop control system favored modulation of the magnetron power over backwall adjustment. Thus, there was no significant movement of the backwall during the experiment. The inset image in Fig. 8 shows the sample used in this experiment. As shown, the actual heating rate of 5.41°C per second (red solid line) outpaced the expected heating rate of 3°C per second (orange dashed line) while the magnetron power is gradually increased from 0 to 1400 W (green dotted-dashed line). While the mismatch between the actual heating rate and the expected heating rate shows that certain miscalibration still exists in the system, the actual heating rate was linear, demon- Fig. 9 — SEM images of the Cu­PbTe interface showing each component of the joint and an absence of cracking, although a few voids exist between the tin interlayer and the ceramic. An experiment with the actual Microwave Welder machine prototype was performed to validate the simulated heating at the backwall location producing the maximum temperature in the Bi2Te3 block. The block of Bi2Te3 was placed on a stage within the waveguide to center it in the waveguide. Figure 6 shows the heat generated in the sample for a 120-s run. The final temperature on the block at the backwall position producing maximum heating (the electric field hotspot) was 69.9°C, while the final temperature from the simulation for heating Bi2Te3 in the electric field hotspot was 74°C. This represents an error of 4.1°C, or only about 6%. The experiment shown in Fig. 6 demonstrates the ability of the system to heat a dielectric material using a movable backwall. It also validates the simulation results used to predict the wave pattern generated in the Microwave Welder’s single mode waveguide. Indeed, finite element analysis (FEA) simulation was used to find the backwall location for which the greatest heat would be generated in the dielectric target — the backwall position for which the hotspot would exist at the target’s location. The temperature developed in this simulation was closely correlated to an experimental result using the same operating parameters as existed in the simulation. Thus, the Microwave Welder was shown to work as designed, with more or less degrees of accuracy, and more work will be required to perfect the system. Microwave Soldering Validation Experiment To validate the ceramic-metal join- 144-s WELDING JOURNAL / APRIL 2016, VOL. 95 strating the efficacy of the closed-loop control. The temperature reached the boiling point of glycerol at about 40 s, at which point the Sn solder melted and formed a bond while the glycerol evaporated. The interface temperature started to drop after the Sn melted because the dielectric liquid was no longer present, removing the primary source of microwave heating. Figure 9 shows a scanning electron microscope image of the Cu-PbTe joint. Complete bonding to the copper base material was achieved, while partial bonding to the ceramic occurred. This is due to the absence of pressure on the joint during the soldering process. With addition of joint pressure, complete wetting to the ceramic could be achieved, which will improve joint strength. Most importantly, no cracking is observed in the PbTe, indicating that the copper and lead telluride base materials were not unevenly overheated to produce stresses induced by their disparity in thermal expansion. In addition, this figure shows some Pb diffusion into the Sn interlayer. However, although the Sn interlayer is only about 100 microns thick, no PbCu intermetallics formed because the speed of the joining process prevented the base materials from mixing chemically. Note the entire microwave soldering process was completed in 75 s, as opposed to the typical 3600 s used during furnace soldering of this specific joint (the reason for the long soldering cycle is that lead telluride has very low thermal conductivity and any rapid heating or cooling via convection will crack the ceramic). An EDS (electron-dispersive x-ray spectroscopy) scan at a point in the interlayer close to the Cu base material is shown in Fig. 10, revealing no appreciable amount of lead. This indicates that atomic diffusion was insufficiently rapid to produce the defects that are common to this kind of 201505 April_Layout 1 3/10/16 4:34 PM Page 145 WELDING RESEARCH joint in longer duration processes. Again, when compared to a furnace soldering process on the order of an hour, this nearly minute-long microwave soldering approach apparently did not allow time for brittle intermetallics to form. Finally, some adjustments to the system could improve this joint, such as eliminating the voids at the ceramic side of the interface. With the addition of pressure upon the sample during the microwave soldering process, complete wetting to the ceramic could be achieved, which will improve bond strength. In addition, if the dielectric liquid could be replaced completely by a metal soldering composition, then higher temperature soldering and brazing could be accomplished with this same microwave process. Eddy currents and magnetic hysteresis are both mechanisms by which microwaves interact with metals to produce heat, paramagnetic metals only utilizing the first and ferromagnetic metals utilizing both. Application of pressure to the sample is currently part of this ongoing research effort at LeTourneau University and is expected to generate further noteworthy results. This improvement will be presented in Part 2 of this paper series on microwave joining. Conclusions A novel plasmaless, closed-loop microwave heating device was designed, built, and tested for ceramic to metal joining. It was shown that furnace soldering could successfully be replaced by microwave soldering in a particular semiconductor/metal interface for thermoelectric generator application. The novelty consisted in delivering dielectric heating to melt a metal filler powder at the joint, which succeeded in avoiding thermal shock to the lowthermal conductivity lead telluride thermoelectric element and produced less brittle intermetallics at the joint interface. Accordingly, more efficient and longer lasting thermoelectric generators could be built in the future, as more work remains to be performed in implementing the technology from elements to full-scale modules. Acknowledgments This work was supported in part by the II-VI Foundation and by the American Welding Society. We are grateful to Allen Worcester who completed his MSc thesis work on this topic and the many LeTourneau University undergraduate students, such as Ithamar Glumac and others, who brought important contributions to this project. References 1. Santella, M. L., et al. 1996. Chapter 8: Ceramics. The Welding Handbook. American Welding Society. Volume 3, Part 1. pp. 390–401. 2. Jadoon, A. K., Ralph, B., and Hornsby, P. R. 2004. Metal to ceramic joining via a metallic interlayer bonding technique. Journal of Materials Processing Technology 152(3): 257–265. 3. Messler, R. W. 1995. The challenges for joining to keep pace with advancing materials and designs. Materials & Design 16(5): 261–269. 4. Wunderlich, W. 2014. The atomistic structure of metal/ceramic interfaces is the key issue for developing better properties. Metals 4(3): 410–427. 5. Min, G., and Rowe, D. M. 1999. Cooling performance of integrated thermoelectric microcooler. Solid-State Electronics 43(5): 923–929. 6. Passerone, A., and Muolo, M. L. 2004. Metal-ceramic interfaces: Wetting and joining processes. International Journal of Materials and Product Technology 20(5): 420–439. 7. Leblanc, S. 2014. Thermoelectric generators: Linking material properties and systems engineering for waste heat recovery applications. Sustainable Materials and Technologies 1–2. Elsevier B.V.: pp. 26–35. 8. DeVore, J. A., et al. 1989. Section 6: Soldering and mounting technologies. Elec- tronic Materials Handbook, Volume 1. ASM International, pp. 651–678. 9. Paponetti, C. A., and Sapp, M. 2007. Chapter 1: Basics of Brazing. Brazing Handbook. American Welding Society. 10. Roberts, P. 2013. Introduction to Furnace Brazing. 11. Callebaut, J. 2007. Section 7: Energy efficiency dielectric heating. Power Quality & Utilisation Guide. European Copper Institute & Laborelec. leonardo-energy.org. 12. Olson, D. L., et al. Welding of plastics. ASM Welding Handbook. Volume 6. 1054, 1055. 13. Liao, C. L., and Chen, W. 2007. Effect of interfacial compound formation on contact resistivity of soldered junctions between bismuth telluride-based thermoelements and copper. Electrochemical and Solid-State Letters 10(9): 23–25. 14. Beale, G. O., Arteaga, F. J., and Black, W. M. 1992. Design and evaluation of a controller for the process of microwave joining of ceramics. IEEE Transactions on Industrial Electronics 39(4): 301–312. 15. Carper, D. M., and Nied, H. F. 1993. Thermal Shock Resistance of Ceramic Matrix Composites. pp. 400–433. 16. Park, J.-W. 2002. A Framework for Designing Interlayers for Ceramic-to-Metal Joints. Massachuestts Institute of Technology. 17. Messler, R. W., and Savage, W. 1993. Joining of Advanced Materials. Chapter 15, Joining Dissimilar Material Combinations. 18. Liao, S. 1980. Microwave Devices and Circuits. Englewood Cliffs, N.J.: PrenticeHall, Inc. 19. Aravindan, S., and Krishnamurthy, R. 1999. Joining of ceramic composites by microwave heating. Materials Letters 38(4): 245–249. 20. Meredith, R. 2007. Chapter 13: Equipment safety. Engineers’ Handbook of Industrial Microwave Heating. The Institution of Engineering and Technology: London, United Kingdom. pp. 323–329. 21. Liboff, R., and Dalman, C. 1986. Transmission Lines, Waveguides, and Smith Charts. New York, N.Y.: Macmillian Publishing Company. 22. Worcester, A. C. April 2013. A method for feedback controlled microwave joining of ceramic-metal interfaces. Thesis. MSc Electrical Engineering. LeTourneau University. APRIL 2016 / WELDING JOURNAL 145-s