Scientific & Technical Report The Partnership of the Minimate™ TFF

advertisement

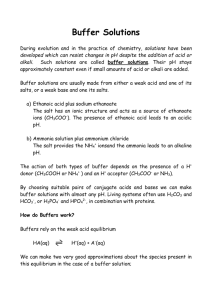

Scientific & Technical Report PN33339 The Partnership of the Minimate™ TFF Capsule with Liquid Chromatography Systems Facilitates Lab-scale Purifications and Process Development Through In-Line Monitoring Introduction Tangential Flow Filtration Tangential flow filtration (TFF) is an effective method for both diafiltration and concentration operations in purification strategies for biomolecules.1,2 The TFF process recirculates sample flow over the surface of a membrane, controlling gel layer formation and effectively reducing fouling. The operator develops an effective and reproducible process by optimizing flow rates and controlling transmembrane pressure. This results in improved flux rates and productivity.3 A TFF process developed on lab-scale devices can be readily scaled to larger process volumes. Traditionally, TFF separations have used peristaltic pumps and flexible tubing to provide the needed pressure and flow. Although standard lab pump systems are sufficient for most TFF applications, the use of high-performance liquid chromatography (LC) systems can offer some additional advantages with respect to process development and control. This paper describes the novel use of an LC system as the control platform for performing TFF using a Minimate TFF capsule. Liquid Chromatography and TFF Protein purification is rarely a simple process and almost never a single step. Instead, it requires an ordered sequence of purification steps assembled into a process compatible with the biochemistry of the target protein to achieve the required purity. Purification protocols include a variety of separation techniques that may include general filtration/ clarification, size exclusion chromatography, affinity chromatography, ion exchange chromatography, ultrafiltration, and possibly a sterilization step. TFF is frequently used in a process before chromatographic steps to desalt and buffer exchange (diafiltration) the sample into a suitable state for binding or to adjust the sample concentration. It may also be applied as a bridge between chromatographic steps when the elution buffer at the end of one process is incompatible with the binding conditions of a subsequent step. At the end of a process, it may be used to adjust the final concentration and ionic strength of the product as required. Few protein chemists are without access to an LC pump system that has pumping capacities approaching 100 mL/min. These systems can serve as robust alternatives to the use of a peristaltic pump for TFF protocols with significant additional benefits. Here we report the use of an ÄKTA Explorer◆ liquid chromatography system (GE Healthcare) to operate the Minimate TFF capsule. Specific advantages of using an LC pump system to drive TFF are: • Use of chromatography equipment already in place saves equipment cost, benchspace, and training time. • Precise control of pressure and flow rate assures uniform development of the gel layer to improve reproducibility between runs. • Ability to monitor and record process parameters in real time (pH, conductivity, absorbance, temperature, feed flow rate, valve positions, system pressure) gives a researcher an auditable trail for process validation. • Reduction in system working volume with narrow bore PEEK◆ and Tefzel◆ tubing allows greater concentration factors. • Operation of system valves to multiplex purification procedures using the same pumping system (sequential operations on multiple cartridges and columns). TFF devices can be sanitized in place while other column operations are underway. steps. An optimized fluid path minimizes hold-up and working volumes and allows easy scale up to larger TFF systems like Centramate™ and Centrasette™ systems. The Minimate TFF capsule and larger devices utilize consistent materials of construction to assist in process validation. Finally, each pharmaceutical grade Minimate TFF capsule is 100% integrity tested during manufacture to ensure reliable performance. Technical Data Effective Filtration Area Recommended Crossflow Rate Operating Temperature Range Maximum Operating Pressure pH Limits Product Hold-up Volume (feed/retentate) 50 cm2 (0.05 ft2) 30-80 mL/min (0.6-1.6 L/min/ft2) 5-50 °C (41-122 °F) 4 bar (400 kPa, 60 psi) at 20 ºC (68 ºF) 1-14 ~1.6 mL Ultrareservoir™ Container, 500 mL The Ultrareservoir container is designed to hold up to 500 mL of sample and give efficient mixing of product. The sloped bottom and optimally located feed and return ports reduce the system hold-up volume, which allows high concentration factors to be achieved. The reservoir lid seals tightly, allowing additional sample volume or diafiltration solution to be drawn into the reservoir by vacuum that is created as filtrate is generated through the TFF device. This allows continuous diafiltration to be performed without the need for a transfer pump. Minimate TFF Capsule with LC Pump System Materials and Methods Minimate TFF Capsule Minimate TFF capsules contain Omega™ polyethersulfone membrane with an effective filtration area of 50 cm2. The Omega ultrafiltration (UF) membrane, available in a wide range of molecular weight cut-offs, offers low adsorption characteristics resulting in high product recoveries. Sample batch sizes of up to 1 liter can be desalted and subsequently concentrated to volumes as low as 5 mL with little user intervention. The reusable/disposable capsule can perform single or sequential concentration/diafiltration steps using the same device in a closed loop connection, saving time and avoiding product loss associated with transfer 2 Equipment and Reagents 1. ÄKTA Explorer Chromatography Workstation with Unicorn◆ 4.0 Software (GE Healthcare) 2. Digital Pressure Gauges (Cole Parmer, Model 1200) 3. 1XPBS (phosphate buffered saline) Solution (Invitrogen, Carlsbad, CA) 4. 1M NaCl in PBS 5. Bovine Serum Albumin (BSA) solution: 1 mg/mL dissolved in PBS with 1M NaCl 6. 0.5M sodium hydroxide in water 7. 0.1M sodium hydroxide in water Step-by-Step Procedures Table 1 Parts List for Connecting the Minimate TFF Capsule to ÄKTA Explorer FPLC System Description Qty Tefzel tubing, 1/8" (use the minimal amount of tubing) PEEK tubing (green), 0.030 x 1/16" (use the minimal amount of tubing) Tefzel tubing, 1/16" (use the minimal amount of tubing) Adapter assembly, 1/8" NPT to 5/16, 24 flat bottom female Tubing connector, 1/8" male Ferrule for 1/8" tubing (use the minimal amount of tubing) Union, 5/16" female 1/16" male Fingertight connector, 1/16" Pressure gauge TEE Digital pressure gauge, 0-300 psi range 10-32 female to male luer assembly Micro-metering valve, 1/16" 10-32 female to female luer assembly 3 ft 3 ft 3 ft 3 each 3 each 3 each 1 each 12 each 3 each 3 each 2 each 2 each 2 each Set-up 1. Connect an outlet valve line from the ÄKTA (e.g., F8) to the “From Device” outlet of the Ultrareservoir container. 2. Connect a buffer valve line from the ÄKTA (e.g., A18) to the “To Pump” outlet of the Ultrareservoir container. 3. Choose a column valve position from ÄKTA (e.g., position 4) for the Minimate capsule. Connect bottom column valve to a digital pressure gauge (P1) and then connect P1 to one of the “Feed/ Retentate” ports of the Minimate TFF capsule. Connect top column valve to a digital pressure gauge (P2) and then connect P2 to the other “Feed/Retentate” port of the capsule. Orient the capsule in a vertical position with the end connected to the top valve facing up. Connect the upper “Permeate/Drain” port of the capsule to a digital gauge (P3). Connect a length of tubing to the outlet from the pressure gauge and put the other end in a waste container. Connect the other “Permeate/Drain” port to a three-way valve connector. Use the valve to close off the port. 4. Put separate buffer valve lines from the ÄKTA into the following solutions: A13: PBS A14: 0.5M sodium hydroxide A12: 0.1M sodium hydroxide A11: BSA solution Membrane Equilibration and Line Flushing 1. Using manual instruction, set the flow path to the following: Column Position: 4 Outlet Valve: Waste F1 Buffer Valve: A13 Flow Direction: Up Flow 2. Start the pump by setting a flow rate of 20 mL/min. Increase flow rate until the feed pressure reaches 2.7 bar (40 psi). 3. Inspect the line connection to make sure there is no leak. 4. Run for at least 5 minutes or until the pH, conductivity, and absorbance signals flatten out. 5. Stop pump. Diagram 1 Partnership of TFF with Column Chromatography A Minimate TFF capsule is installed between the top and bottom column valves. Pump flow is directed into the TFF feed port, and the retentate flow goes through the analysis sensors and back to the Ultrareservoir container. Pressure sensors or gauges upstream and downstream of the capsule monitor pressure, and a third gauge is placed along the filtrate path to monitor backpressure. In diafiltration mode, the Ultrareservoir container is connected to the diafiltration buffer vessel. In concentration mode, the Ultrareservoir container is left open to the atmosphere. www.pall.com/lab 3 Buffer Exchange A buffer exchange protocol was developed using 1M NaCl in PBS as the starting sample. This solution was diafiltered with PBS to remove salt and then back to high salt with a solution of 1M NaCl in PBS. Once the process conditions were developed, the process was repeated using a starting solution of 1 mg/mL BSA, 1M NaCl in PBS. 1. Equilibrate the Minimate TFF capsule according to the procedure described in the preceding section. 2. AutoZero the UV absorbance monitor of the ÄKTA and set the column position to “Bypass.” 3. Set the buffer valve line to A11 and pump flow rate to 50 mL/min. Fill the Ultrareservoir container with 200 mL BSA solution (1 mg/mL dissolved in PBS with 1M NaCl). 4. Put the diafiltration buffer feed line (connected to the top part of the Ultrareservoir) into a flask containing PBS. 5. Using manual instruction, set the flow path to the following: Column Position: 4 Outlet Valve: F8 Buffer Valve: A18 Flow Direction: Up Flow 6. Start the pump at 20 mL/min. Adjust the flow rate so that the feed pressure (P1) is just under 2.7 bar (40 psi). Note: Flow will start from the permeate tube. Diafiltration solution will start to be drawn into the Ultrareservoir container in a few minutes. If this does not occur, check that the reservoir lid is completely inserted and sealed. 7. Stop the pump once the conductivity signal reaches a plateau. 8. Put the diafiltration buffer feed line into a flask containing 1M NaCl in PBS solution. 9. Repeat steps 5-7. Sample Concentration After the buffer exchange is complete, a sample can be concentrated by opening the diafiltration buffer feed line to air. This will break the vacuum generated under the diafiltration mode. 4 1. Leave the diafiltration buffer feed line open to air. 2. Using manual instruction, set the flow path to the following: Column Position: 4 Outlet Valve: F8 Buffer Valve: A18 Flow Direction: Up Flow 3. Start the pump at 20 mL/min. Adjust the flow rate so that the feed pressure (P1) is just under 2.7 bar (40 psi). 4. Collect the permeate in a graduated cylinder. (This will allow the permeate volume to be measured and concentration factor to be determined.) 5. Stop the pump once the desired concentration is reached. Washing, Regenerating, and Storing the Minimate Capsule 1. Using manual instruction, set the flow path to the following: Column Position: 4 Outlet Valve: Waste F1 Buffer Valve: A13 (PBS) Flow Direction: Up Flow 2. Start the pump by setting a flow rate of 20 mL/min. Increase flow rate until the feed pressure reaches 2.7 bar (40 psi). 3. Wash the system until the UV, pH, and conductivity signals stabilize. 4. Switch the buffer valve line to A14 (0.5M sodium hydroxide). 5. Wash the system until the UV, pH, and conductivity signals stabilize. 6. Stop the pump. Let the Minimate capsule soak in 0.5M sodium hydroxide for 1 hour. 7. Switch the buffer valve line to A12 (0.1M sodium hydroxide). 8. Wash the system until the UV, pH, and conductivity signals flatten out. 9. Stop the pump. The Minimate capsule can be stored in 0.1M sodium hydroxide at 4-20 °C. B 60 250 50 40 150 30 20 50 0 A280 20 40 60 80 0 C Increasing Salt 100 450 90 400 Conductivity 350 70 60 250 50 200 40 150 30 100 20 50 10 A280 0 0 10 20 30 40 50 200 40 100 30 20 A280 50 60 70 80 Time (min) D 70 80 0 -10 Increasing Salt 100 90 80 350 70 60 250 50 40 150 30 20 50 10 0 -100 60 Conductivity Absorbance (mAU) 60 40 50 450 Conductivity (mS/cm) 70 Conductivity 30 80 300 80 20 10 Time (min) 90 10 120 140 -50 D 100 0 100 Conductivity (mS/cm) Decreasing Salt 300 Conductivity (mS/cm) 70 Conductivity Time (min) 400 Absorbance (mAU) 350 -50 500 0 90 80 Figure 1 Development of Buffer Exchange Parameters with In-line Monitoring A 100 Conductivity (mS/cm) A sequential buffer exchange back to the high salt buffer was possible without disconnecting the device D from the system by replacing the low salt (PBS) diafiltration buffer with a high salt buffer (PBS, 1M NaCl). Again, successful buffer exchange was detected in-line with the exchange of four buffer volumes (Figures 1C, 1D). Absorbance at 280 nm was monitored to act as a sample process control to determine if the absorbance readings are deflected by the changing salt concentrations. The ability to monitor and document the process “live” allows the researcher to save time and buffer, as well as provides a basis for future scale up decisions. Decreasing Salt 450 Absorbance (mAU) Continuous Diafiltration for Process Development To develop a process protocol, a mock bufferexchange protocol was created where a buffer-only sample (1N NaCL in PBS) was first diafiltered with PBS to reduce the salt concentration (Figures 1A, 1B). In-line monitoring allowed the documentation of salt concentration changes in real-time using the conductivity sensor and data acquisition program built into the ÄKTA Explorer. Consistent with previous observations,1 the passage of four volumes of diafiltration buffer was adequate to achieve > 98% buffer exchange. Absorbance (mAU) Results and Discussion 0 10 20 30 A280 40 50 -50 60 10 0 Time (min) Diafiltration (buffer exchange) processing was documented from high salt to low salt then back to high salt. Repeated runs using a 10K Minimate capsule were processed at 20 (graphs A and C) and 25 (graphs B and D) mL/min recirculation rates. Salt and protein (A280) concentrations were monitored using in-line sensors. www.pall.com/lab 5 C 60 Conductivity 40 30 0 20 -20 20 0 100 120 90 80 A280 70 80 60 60 50 C Conductivity 40 40 30 20 20 A600 0 0 10 20 30 40 50 60 -20 Time (min) 6 70 80 90 100 10 0 Conductivity (mS/cm) Absorbance (mAU) D Decreasing 140 100 40 30 50 0 10 20 20 A600 40 50 30 Conductivity (mS/cm) 50 A280 100 60 70 -50 80 90 100 10 0 Time (min) I D Increasing Salt C 100 90 300 80 70 I 250 60 200 50 150 C A280 40 100 30 50 20 A600 10 60 80 100 120 140 160 180 0 Time (min) 0 -50 0 20 40 Conducitivity (mS/cm) Conductivity Diafiltration (buffer exchange) processing was documented from high salt to low salt then back to high salt with a protein solution (1 mg/mL BSA). Repeated runs using a 10K Minimate capsule were processed at 25 (graphs A and C) and 20 (graphs B and D) mL/min recirculation rates. Salt, protein (A280), and turbidity (A600) were monitored using in-line sensors. Time (min) B 60 150 0 Absorbance (mAU) 80 Conductivity (mS/cm) Absorbance (mAU) 100 A600 40 60 80 100 120 140 160 180 200 70 350 180 80 80 Conductivity 200 400 120 A280 90 450 Decreasing 130 100 250 Figure 2 Validation of Diafiltration Parameters in the Presence of Protein A Increasing Salt 300 Absorbance (mAU) Buffer Exchange at Constant Protein Concentration Once a simple buffer-exchange protocol was developed, a second protocol was used to demonstrate diafiltration of a protein solution (1 mg/mL BSA) going first from high salt to low salt buffer (Figures 2A, 2B) and then back to a high salt buffer (Figures 2C, 2D). In addition to monitoring protein and salt concentrations, in-line sensors documented the A600 values to ensure that the protein solution had not precipitated during processing. A precipitated protein solution would produce turbidity and cause a reading at A600. The use of in-line monitors allows the researcher to immediately trace the incident back to the salt concentration where protein precipitation first occurred, thus saving valuable time in troubleshooting. Precise Control of Sample Concentration In concentration mode, the Ultrareservoir container is left open to atmosphere. The concentration of the retained solute increases as permeate is removed, decreasing the process volume. The in-line monitors allow the researcher to track the progress of the concentration of the protein sample. While the salt concentration (which is 100% permeable to the membrane) remains constant, the protein solution concentration increases. The use of sensors allows the researcher to stop the process once the desired concentration is achieved. Documenting turbidity 25 200 80 70 700 60 Conductivity 50 500 A280 300 -100 40 30 80 20 A600 10 100 120 140 160 180 200 220 240 260 0 Time (min) 20 Conductivity 150 15 A280 100 10 50 A600 5 10 15 20 25 Conductivity (mS/cm) Absorbance (mAU) 90 900 100 250 0 100 1100 5 30 35 40 0 -50 Time (min) The concentration of a 1 mg/mL BSA solution was accomplished by leaving the diafiltration feed line open to air. The run using a Minimate 10K capsule was processed at 25 mL/min recirculation rate. Salt, protein (A280), and turbidity (A600) were monitored using in-line sensors. Sequential Buffer Exchange and Concentration An advantage of processing using in-line sensors was demonstrated by performing sequential processing operations. Diafiltration of the protein sample (1 mg/mL BSA) reduced the salt concentration by > 98% with about four volumes of buffer. As soon as the conductivity leveled off, indicating that desalting was complete, sample concentration was started by simply disconnecting the buffer line to the Ultrareservoir container. Concentration of retained solute increased as permeate was removed, decreasing the process volume. This process is facilitated using the features of an LC system, such as the multiport valves and in-line sensors. The ability to monitor “live” allows greater control over the process during the run and provides documentation that can be used to develop and validate the scale-up protocol. Sequential diafiltration followed by concentration was documented for a single run using a 1 mg/mL BSA solution in 1X PBS, 1M NaCl starting solution. The run using a Minimate 10K capsule was processed at 25 mL/min recirculation rate with the buffer exchange from high salt to low salt. The diafiltration buffer feed line was then opened to air, allowing the concentration of the sample. Salt, protein (A280), and turbidity (A600) were monitored using in-line sensors. Scalability TFF process development can be performed on a Minimate TFF capsule with a simple lab-scale system incorporating a peristaltic pump or with an LC pump and in-line monitoring system as described above. Both allow development of procedures that are ultimately scalable. The advantage of the LC system is greater control and documentation. The automation and documentation aspects simplify development of validated protocols and provide an audit trail for labs under Good Lab Practices (GLP). This is extremely useful in the scale-up process. While the Minimate TFF capsule is a valuable tool for small process volumes (typically under 1 liter), larger volumes can be processed by plumbing several Minimate TFF capsules in parallel. The Minimate TFF capsule was designed with the same flow path length as larger TFF devices (Centramate and Centrasette systems) allowing predictable performance and saving valuable optimization time when scaling beyond lab scale to volumes used in pilot and production plants. www.pall.com/lab 7 Conductivity (mS/cm) Figure 3 Precise Control of Protein Concentration Figure 4 Sequential Operations for Diafiltration and Concentration Absorbance (mAU) (A600) provides a good diagnostic to determine experimentally the sample concentration limit prior to protein precipitation. The 1 mg/mL BSA solution could be concentrated over four-fold within 40 minutes without the formation of turbidity (Figure 3). While these conditions were chosen for this demonstration, in reality, much higher concentration factors for BSA can be achieved. Other protein solutions may precipitate more easily depending on solubility. References Literature Resources 1. L. Schwartz, 2003. Diafiltration: A Fast, Efficient Method for Desalting or Buffer Exchange of Biological Samples. Pall Scientific & Technical Report. • Product Data, Minimate Tangential Flow Filtration System and Minimate TFF Capsule, PN 33366 2. L. Schwartz, 2003. Desalting and Buffer Exchange by Dialysis, Gel Filtration or Diafiltration. Pall Scientific & Technical Report. 3. L. Schwartz and K. Seeley, 2002. Introduction to Tangential Flow Filtration for Laboratory and Process Development Applications. Pall Scientific & Technical Report, PN 33213. • Technical Article, Desalting and Buffer Exchange by Dialysis, Gel Filtration, or Diafiltration, available online at www.pall.com/lab • Technical Article, Diafiltration: A Fast, Efficient Method for Desalting or Buffer Exchange of Biological Samples, available online at www.pall.com/lab • Technical Article, Increased Productivity Using Minimate Capsules to Replace Stirred Cell Systems, PN 33342 • Technical Article, Introduction to Tangential Flow Filtration for Laboratory and Process Development Applications, PN 33213 Visit us on the Web at www.pall.com/lab E-mail us at LabCustomerSupport@pall.com Pall Life Sciences 600 South Wagner Road Ann Arbor, MI 48103-9019 USA 800.521.1520 USA and Canada (+)800.PALL.LIFE Outside USA and Canada 734.665.0651 phone 734.913.6114 fax To see how Pall is helping enable a greener, safer and more sustainable future, visit www.pall.com/green 10% Printed on paper containing 10% post consumer fiber. Australia – Cheltenham, VIC Tel: 03 9584 8100 1800 635 082 (in Australia) Fax: 1800 228 825 Austria – Wien Tel: 00 1 49 192 0 Fax: 00 1 49 192 400 Brasil – São Paulo, SP Tel: +55 11 5501 6000 Fax: +55 11 5501 6025 Canada – Ontario Tel: 905-542-0330 800-263-5910 (in Canada) Fax: 905-542-0331 Canada – Québec Tel: 514-332-7255 800-435-6268 (in Canada) Fax: 514-332-0996 800-808-6268 (in Canada) China – P. R., Beijing Tel: 86-10-6780 2288 Fax: 86-10-6780 2238 France – St. Germain-en-Laye Tel: 01 30 61 32 32 Fax: 01 30 61 58 01 Lab-FR@pall.com Germany – Dreieich Tel: 06103-307 333 Fax: 06103-307 399 Lab-DE@pall.com India – Mumbai Tel: 91 (0) 22 67995555 Fax: 91(0) 22 67995556 Italy – Buccinasco Tel: +3902488870.1 Fax: +39024880014 Japan – Tokyo Tel: 03-6901-5800 Fax: 03-5322-2134 Korea – Seoul Tel: 82-2-560-8711 Fax: 82-2-569-9095 Malaysia – Selangor Tel: +60 3 5569 4892 Fax: +60 3 5569 4896 Poland – Warszawa Tel: 22 510 2100 Fax: 22 510 2101 Russia – Moscow Tel: 5 01 787 76 14 Fax: 5 01 787 76 15 Singapore Tel: 65 6 389-6500 Fax: 65 6 389-6501 South Africa – Johannesburg Tel: +27-11-2662300 Fax: +27-11-3253243 Spain – Madrid Tel: 91-657-9876 Fax: 91-657-9836 Sweden – Lund Tel: (0)46 158400 Fax: (0)46 320781 Switzerland – Basel Tel: 061-638 39 00 Fax: 061-638 39 40 Taiwan – Taipei Tel: 886 2 2545 5991 Fax: 886 2 2545 5990 Thailand – Bangkok Tel: 66 2937 1055 Fax: 66 2937 1066 United Kingdom – Farlington Tel: 02392 302600 Fax: 02392 302601 Lab-UK@europe.pall.com © 2010, Pall Corporation. Pall, , Minimate, Omega, Centramate, Centrasette and Ultrareservoir are trademarks of Pall Corporation. ® indicates a trademark registered in the USA. Filtration.Separation. Solution.SM is a service mark of Pall Corporation. Cibacron is a trademark of CIBA-GEIGY LTD. *ÄKTA and UNICORN are trademarks of GE Healthcare. PEEK polymer is a trademark of Victrex plc. Tefzel is a registered trademark of DuPont. 4/10, 1.5k, AA GN09.3204 PN33339