Error Analysis Module I Table of Contents Error

Error Analysis Module I

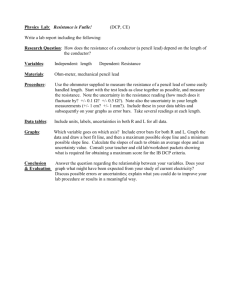

UCCS Physics Labs

Table of Contents

Parallax 3

FYI

FYI

If you attempted to count to stars in ONE galaxy at a rate of one every second it would take around

3,000 years to count them all. There are billions of galaxies in the known universe.

Error Analysis I - 1

Error Analysis

Error analysis is the study of error and how it affects experimental results.

The best way to describe error is by a simple example. Imagine if you needed to know the length of a pencil and all you had to make the measurement was a ruler marked-off in millimeters (Figure 1).

The pencil is definitely longer than 3 cm, but not quite 3.1 cm, so the actual length has to be somewhere in-between.

In real life no one would care how long a pencil is to the nearest fraction of a millimeter. What about a critical engine part? A small difference in its length means the difference between the engine running or not running and leaving you stranded out in the middle of nowhere. Now, keeping that in mind, we can return to finding the “best” measurement of our pencil.

Since the divisions on the ruler are in millimeters and our pencil is in-between marks, we will have to give an “educated guess” at the next digit in the length. We know it has to be somewhere between 3.0 and 3.1 cm, and it looks almost halfway between the two marks. Why not call it a length of 3.05 cm.

Now since we guessed at the last digit there has to be some uncertainty (error) in its value. This uncertainty also has to be recorded to let others know that 3.05 is not the exact length of the pencil. Not knowing what other errors are present and the limited accuracy of the ruler, it would be safe to say that the length could be a half of a millimeter higher ( to be higher we would add, +0.5 mm, to the measurement) or lower

(this would mean we need to subtract, -0.5 mm, from the measurement) than what we wrote down. To represent this fluctuation we use the symbol (

±

). The (+) will represent how much could be added to the measurement. The (-) will reflect by how much the value could be adjusted below the measured value. So the final answer would be 3.05

±

0.05 cm.

Use this rule of thumb to find the uncertainty in most, but not all, measurements:

Uncertainty =

±

1

2

the smallest division on the instrument.

Error Analysis I - 2

Parallax

This is another source of error that you will have to be aware of while taking measurements.

Parallax (par-al-laks) n. - the measure of the change in the relative position of an object caused by the motion of the observer.

From the First edition of “Scott’s New

World Dictionary of Physics”, 1998

Scientist’s just love boring definitions. Instead of trying to explain further, how about seeing an example of what I’m talking about? Let’s look at the example of the pencil measured by looking from three different positions (Figure 2).

This pencil is a different length than the one in the

first example, but you can still get the idea.

Each of the different positions will give a drastically different reading. Ranging from about 4.2 cm (position 1) to about 5 cm (position 3), there is a variation of 0.8 cm!

If you do nothing to reduce the effects of parallax on your measurement you should record 0.8 cm as your error for this length measurement. However, we can do something about parallax if we take a little extra time to make a correct measurement.

Error Analysis I - 3

The correct way to reduce parallax is to take your reading along the perpendicular line-of-sight with the ruler (position 2), which gives the measured length as 4.6

±

0.05 cm. The error recorded in this measurement,

±

0.05 cm, is due to the inaccuracy of the ruler and still has to be accounted for in the result.

The best way to reduce parallax is to place the ruler as close to the object as possible. In figure 3, the ruler is touching the object and parallax has been eliminated. It does not matter what angle you are looking at the ruler from, the measurement is the same.

Each of these errors will depend on the situation and it will be up to you to use your best judgment. As you perform more and more measurements this idea of recording your uncertainty will become easier and possibly second nature. Don’t worry if you have problems with error in the beginning.

Remember, when taking measurements keep the accuracy of the equipment and the possibility of parallax in the back of your mind.

Uncertainty of the human response

The hardest thing to quantify is the “human error” involved in a measurement.

Everyone has different hand-eye reaction times and even for one person this number can vary. Let’s take the example of starting and stopping a stopwatch. We will have to come up with an uncertainty in the measurement from a stopwatch. The best way I have found is to try to stop the counter on a specific number (like 1.00 seconds). Make several attempts and keep track of your results. Take an average of these results and subtract it from the target number. This will be the rough uncertainty in all further measurements.

Error Analysis I - 4

Uncertainty of a digital readout

The most commonly used piece of equipment you will be using this semester with a digital readout will be the electronic balance so let concentrate on it.

If the range of the reading will only give you 1 decimal point (e.g. 12.4 g) then your uncertainty has to be in the next decimal point (e.g. 0.0

x g). If this last decimal point were as high as 12.46 g or more the scale would round up the reading to 12.5. It has to be less than 0.06. If the reading were any lower than 12.35 g, the reading would round down to 12.3 g. Therefore our range of possible weights is from 12.35 g to 12.45 g. To put this in terms of uncertainty, our recorded weight should be:

12.4

±

0.05 g

This type of measurement falls under the rule-of-thumb that the uncertainty is

±

½ the next digit.

Uncertainty of Computer sensors

A common problem with modern equipment is that they are “black boxes” you plug them into a digital readout or computer and they give you a result. The methods it uses to obtain this result are hidden from you, so how are you supposed to record an uncertainty in this measurement? Well it is rather simple; the manufacturer will supply you with the uncertainty. Caution!

With most simple solutions there is a catch. For the uncertainty to be valid the instrument must be treated with care, operated within certain atmospheric conditions, calibrated properly, not dropped or damaged, etc.

Error Analysis I - 5