THE IMPROVEMENT OF WIND TUNNEL DIFFUSER Cr~PACTERISTICS HENRY

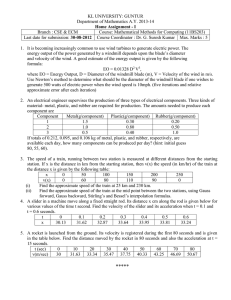

advertisement

THE IMPROVEMENT OF WIND TUNNEL

DIFFUSER Cr~PACTERISTICS

By

HENRY G. WEBB JR.

B.Ae.E.,

Rensselaer

Polytechnic

1942

Institute

and

ZUP~~ICK

JOSEPH E.

B.S. University

of Pittsburgh

1943

SUBMITTED IN PARTIAL FULFILLMENT OF THE

REQUIfiEMENTS FOR THE DEGREE OF

MASTER OF SCIENCE

IN

AERONAUTICAL ENGINEERING

From the

MASSACHUSETTS

INSTITUTE OF TECHNOLOGY

1949

Signature

of Authors:

HenryjG.

Webb Jr.

{Vose~h E. uubadick

Certified

by:

De#artment

of Aeronautical

Engineering,

Chairman,

Sept. 2, 1949

Department

~vraduate Students

,:"

"

.~

I

l

Committee

on

Sept. 2, 1949

Prof. Joseph S. Newell

Secretary

of the Faculty

Massachusetts

Cambridge

39,

Dear Professor

Institute

of Technology

Massachusetts.

Newell:

In accordance

with the requirements

of the faculty, we

hereby submit a thesis entitled,

THE IMPROVEMENT OF \~fJND TUNNEL

DIFFUSEH

ln partial

fulfillment

Master of Science

CHARACTERISTICS

of the requirements

in Aer~nautical

for the Degree of

Engineering.

/fHenry G. Webb,

Joseph E.~nick

j?

.

ACKNOWLEDGMENT

The authors

sincere

thanks

the preparation

to express

to the following

their

persons

tunity of working

Joseph

Bicknell

on the project

1n

for g1v1ng

us the opporduring

the

of the work.

Wright

for his aid in the construction

obtaining

necessary

the Aeronautical

machine

work

test equipment.

Machine

involved

Shop

during

To the sponsors

making

and

who were of assistance

and his suggestions

To Mr. Hatry Hilberg'of.the

Staff

appreciation

of this thesis.

To Professor

course

wish

the funds available

Also

to Mr.

for his splendid

J.R.

Wind Tunnel

and 1n

Maddox

cooperation

of

on the

the project.

of the Diffuser

Research

for the construction

To the typist Eleanor

the Vari-Typer.

Brothers

of the equipment

Mugnai

Project

for

of the equipment.

for her work performed

on

TABLE OF CONTENTS

Page

I

Purpose

II

Summary

III

IV

V

Introduction

Description

1

.

3

of Apparatus

A.

The Tunnel and Diffuser

3

B.

Nacelles

4

C.

The Windmills

D.

Damping Screen

5

E.

Instrumentation.

5

.

4

1.

Pressure Measurements

5

2.

Direction

5

3.

Tuft Studies

4.

Miscellaneous

Indicator

6

.

6

7

Test Procedure

A. Pressure Measurements

B. Wind Direction

and Windmill

7

Speed

8

Measurements

9

C. Tuft Studies

VI

Test Results

A. Velocity

and Discussion

.

. .

10

Surveys

11

B. Pressure Recovery

C. Turbulence

D. Tuft Studies

10

.

.

. . .

12

13

Page,

VII

VIII

IX

Conclusions

14

. . . • .

A.

General

B.

Recommendation

14

Remarks

for Further

Study

14

References

16

Appendix

17

A.

Nomenclature

B.

Pitot Tube Calibration

19

C.

Direction

20

D.

Pressure

Recovery

E.

Velocity

Surveys

F.

Run Index

G.

Figures

17

.

Indicator

(Drawings

Characteristics

and Data

and Data

22

26

30

and Photographs)

32

I

This experimental

to determine

investigation

was conducted

the effect of freely rotating windmills

and time variations

Wind Tunnel

PURPOSE

of velocity

diffuser.

optimum position

on the space

in a model of the Wright Brothers

It is required to determine

and blade configuration

the lowest turbulence

primarily

both the

of the windmill

level and most uniform velocity

to give

distribution

at the diffuser exit.

A further characteristic

to be considered

loss associated with each. diffuser windmill.

windmills

is the energy

Thus a comparison

of

with damping screens or other devices capable of produc-

ing the improvements

mentioned

above may be made.

II SUMlv1ARY

windmills

The installation

of several

in two positions

~n a model of the Wright Brothers

Wind Tunnel diffuser was tested.

distribution,

turbulence,

by the proper selection

single configuration

types of freely rotating

It was found that the velocity

and energy losses could all be reduced

of windmill

was optimum

location

and blade form.

for the simultaneous

No

achievement

of all three effects.

A description

diffuser

characteristics

velocity distributions

q (Y~U2) variation

variation

behavior

included.

is given.

employed

Data are presented

for the

at the tailpipe exit, and also as a weighted

Turbulence

results, but attention

in their determination.

measurements

The interpretation

are given as

is called to the inaccuracies

Diagrams

of tufts placed on the diffuser

used to estimate

to study the

in the form of contour plots of the

with duct radius.

quantitative

involved

of the methods

illustrating

the

and tailpipe walls are

of a modified

diffuser

efficiency,

energy losses, is explained.

Specific

c~nclu~ions "to be drawn from these tests are

made and recommendations

for further investigation

are given.

III

INTRODUCTION

The work contained

herein

tion of the effects of a windmill,

velocity

distribution

is an experimental

placed

and turbulence

The existing

problem

investiga-

in a diffuser,

level of the stream.

that brought

the work in this

thesis about was that the flow in the Wright Brothers

Tunnel

is of such a nature

as to produce

is these eddies that make it impossible

steady stream required

for the testing

the flow is satisfactory

by R.A. Summers,

a honeycomb

the maximum

of flutter models,

restrained.

type of testing

This problem

~ethod of attacking

or a series of damping

section.

The damping

screens

of fluid passing

through it, since the resistance

the velocity

variations

to the square of the local wind velocity,

although

in which

at or near

pressure

of the stream

is proportional

the high speed areas

losing more total head than the low speed regions.

flow is thereby

improved

velocity

the section

across

turbulent

motions

scale.

in two respects,

is reduced

The effect of damping

has been investigated

Schubauer,

ref. 6.

Nevertheless,

transf~s

screens

speed regions

as required.

flow in this manner

speeded-up

flow is subjected

is relatively

by the screen is reduced

In addition

to delay and possibly

to a positive

prevent

pressure

- 1 -

to

to adopt a device

to 'smoothing'

in the boundary

diffuser.

of

and G.B.

from high speed regions

the velocity

the

on. wind tunnel

section

it is more efficient

excess energy

in

them to motions

by H.L. Dryden

low, the amount of energy dissipated

The

along with decreasing

Since the speed in the maximum

a minimum.

the variation

of large scale by reducing

turbulence

which

and

is by

screen with a uniform

reduces

smaller

It

is discussed

the problem

drop coefficient

therefore

eddies.

ref. 5.

The standard

placing

undesirable

Wind

to have the uniform

for the present

a rigid model is completely

on the

out the

layer can be

seperation

gradient,

to the low

where

the

such as in a

A windmill

of appropriate

design, placed in a diffuser

and allowed to rotate freely is one such device capable of

producing

the same effects as the damping screen.

The windmill

is driven by the high speed regions and drives the low speed

regions producing

turbulence

an even velocity distribution.

in a manner analogous

It acts on the

to a rotating cutter.

If a

piece of wire fed into the cutter were such that the blade came

around at the same time the cut in the wire did the resulting

pieces would be the same as the ones fed in.

If the same rate of

feed was kept and the cutter rotated faster the resulting

pieces

would be smaller.

the

resulting

Similarly,

turbulence

in the case of the windmill

is a function of what goes into the windmill

and the R.P.M. of the windmill

There occurs two classes of turbulence,

termed 'coarse grained' and 'fine grained'.

the 'coarse grained' turbulence

turbulence

windmill

differentiating

The wind mill reduces

but allows the 'fine grained'

to pass through unaffected.

is analogous

generally

The blade pitch of the

to the mesh of the damping screen in

between the scale of turbulence which will be

reduced and that which will not.

The use of a windmill

employed

to any great extent.

subject is by A.R. Collar,

cal and assumes a small

velocity

distribution.

to improve the flow has not been

The only report available

ref. 3.

on the

Most of the work is theoreti-

steady variation

from a uniform

Very little test data is presented.

- 2 -

IV

A.

The Tunnel

DESCRIPTION

and Diffuser.

The tunnel

of and assembled

and diffuser,

in following

section,

the setting

section,

the diffuser,

pipe,

figures

TD 1n notation,

order:

chamber,

the blower,

the bell mouth,

and the 22.3

is comprised

the expansion

15 inch constant

the

inch constant

section

tail

66, 56, 57 and 58.

The power

It is an American

cubic

OF APPARATUS

source

High

for the tunnel

Speed Blower,

feet per minute.

is a centrifugal

No. 245 and rated

blower.

11,000

at

The tunnel was run at a constant

R.P.M.

1780, since the driving motor is a 3 phase induction motor.

The outlet of the blower is a rectangular section of 19 x 26~

of

inches with

the centrifugal

impeller

e

to the right viewing

offset

into the stream.

To prevent

blower

gap of ~ inch exists

The flexible

seal,

between

figure

vibrations

from being

the blower

57, between

strip of ~ inch by 4 inch rubber

transmitted,

and the expansion

section.

these two is made with

bolted

to the flange

a

a

of the

8

blower

and to the flange

the irregular

series

of

velocity

distribution

section.

produced

To improve

by the blower

a

6 screens, 16 mesh and .009 inch dia, are evenly spaced

1n the expansion

section,figure

to the last screen

expansion

of the expansion

section

66.

in this section.

A series

of tufts were

The construction

is of ~ inch plywood

and tapers

tied

of the

from a

19 x 26~

4

inch rectangular

blower

flats at the settling

The settling

8

outlet

to a regular

octagon,

4 foot across

chamber.

chamber

is also of ~ inch plywood

construc-

4

tion with

circular

holes

a tuft observation

port of 8 inches

port on the top for the light

are located

the regular

on the vertical

octagon

at station

The bell mouth

by

source.

and horizontal

12

The

inches

and a

four static

centerline

of

1, given by figure 66.

and all of the tunnel

of .042 inch gage steel with welded

- 3 -

joints

aft 1S constructed

on each particular

section.

The contraction

satisfactory

cone surfaces

are not completely

because of warping and generally

poor fabrication.

The 15 inch constant section contains

equally spaced on the periphery

4 static holes

at station 2, given by figure 66.

This section and the 4~o

half angle diffuser

section

are a scaled down model of the Wright Brothers Wind Tunnel.

to the lack of rigidity of the gage of the metal a plywood

was used to bring the diffuser

Due

frame

section into round at the wind-

mill.

B.

Nacelles.

The forward nacelle,

figures 59 and 67, is a scale

model of the Wright Brothers Wind Tunnel

and supports.

fan drive motor fairing

A scaled down model of the propeller

in the full

size tunnel is not present in this set up, since the blower

produces

nacelle

the stream in this case.

is removable

to take the

A cone at the end of the

%

{nch shaft of the windmill

hub,

figure 66 and 71.

The aft, nacelle,figure

68,does not exist in the Wright

Brothers Tunnel but is used here as a mount for the large aft

windmill.

c.

Windmills.

The forward and aft windmill

chord and diameter

are made of ~

16

are very similar except ~n

of the blade figures 69 and 70.

inch 17ST dural having a constant

chord, with the

leading edge rounded and the trailing edge tapered.

taper being about 15% of the chord.

The blades

The width of

The blades are riveted to a

threaded steel shank which in turn mounts

into the wind mill hub,

figure 71.

This one hub is used for both the forward and aft

windmills.

The twist was put into the blades by the device.

shown in figure 65.

This allows for a given increment

per inch of the blade.

the protractor

of twist

The total twist was then checked with

arrangement

of figure 60, which was also used to

set the blade angle for the various configurations.

- 4-

The windmills

D.

are tested with their respective

Damping Screen.

An 18 mesh .010 inch diameter

the

nacelles.

3

4

screen S was tacked to

inch plywood frame at the end of the tailpipe.

was made with this configuration

to determine

One run

the effects of

screen on turbulence.

E.

Instrumentation.

1.

Pressure

measurements.

The velocity

nacelle were obtained

distributions

ahead of the forward

by a pitot static tube mounted on the

survey rake, pitot tube and wind direction

figure 66.

The diffuser

readings.

obtained

indicator

and tail pipe were removed

The data for the velocity

distributions

suppor~

for these

was

from a 31 tube survey rake, figure 63 and 72.

total head tubes and 2 static tubes were connected

vertical c;llcohol

manometer

board, all pressures

relative

pressure.

to

atmospheric

in inches of water.

The 29

to a

being measured

The scale is calibrated

The average velocity was obtained

readings of the {our static holes in the settling

from

chamber,

figure 66 and the four static holes in the 15 inch constant

section, figure 66 and 58, connected

to the same mpnometer

board as the survey rake.

2.

Wind Direction

Indicator

By following

vane direction

scale

indicator

d.isturhance

in flow direction,

can be used to measure

in the flow.

shall, for the purposes

including

the variations

The definition

of turbulence

as

these large scale disturbances.

to build a single vane

indicator with an oil damper proved unsuccessful

the large effect of temperature

upon.

the large

of this report, be interpreted

After several attempts

indicator

a

employing

on the oil viscosity,

only aerodynamic

of air speed.

A disadvantage

ing ratio must be used if the natural

- 5 -

an

damping was decided

This would have the added advantage

independent

because of

of a damping ratio

is that a low damp-

frequency

is to be high

enough to respond

to a reasonable

range of disturbance

frequencies.

The final design,

Sec. IX-C had stability

fig. 73, described

up to a deflection

above which the indicator

was slightly

more fully in

of about 40°,

unstable.

The three vanes are made of .005 inch brass shim

stock while the supports

tubing

are of hollow stainless

.034 inch outside diameter.

The vertical

.020 inch dia. piano wire with conical

is assembled

by soldering

two adjustable

pivot,

3.

screws

tips.

and is mounted

steel

pivot 1S

The indicator

in a fork with

that hold, act as bearings

for the

fig. 64 and 73.

Tuft Studies

A series of 2 inch tufts were attached

scotch tape to the surface of the diffuser

fig. 62.

With the large windmills

necessary

to use the Strobotac-Strobolux

the tufts 1n the diffuser,

and tailpipe,

installed

especially

with

on N2

it was

apparatus

to see

for the high windmill

speeds.

4.

Miscellaneous

Ihe windmill

speeds were measured

Radio Co. Strobotac-Strobolux

the same reason the ambient

pressure

were recorded

the Wright Brothers

for references

air temperature

for each run made.

together with all pressure

with a General

measurements

Wind Tunnel.

- 6 -

purposes.

For

and atmospheric

These

data,

etc. are on file at

V

A.

TEST PROCEDURE

Pressure Measurements

and Windmill

Speed

Before any runs were made all connections,

tunnel static orifices,

from the

pitot tube, and rake, to the manometer

board were checked for leaks.

With the single pitot tube installed on the support

traverses

in four directions

were made for a complete

velocity at the end of the 15 inch dia. constant

survey of

area section.

Dynamic pressure heads were recorded and corrected

for instru-

ment error.

The variation of static pressure

over the cross section

of the tailpipe exit was checked with the single pitot tube.

Since the variation was found to be small all subsequent

were made with the survey rake incorporating

tubes.

two static pressure

The position of the static holes was adjusted

error caused by proximity

to the adjacent

runs

till the

total head tubes was

eliminated.

After allowing the motor to accelerate

ning speed on 220 V. the windmill

rotational

to normal run-

speed was taken

with a Strobotac-Strobolux.

The hub and one blade were marked

to allow quick determination

of the true speed.

ings were then taken.

approximately

read-

The total head orifices on the rake were

1 inch inside the tailpipe

the large downstream

Pressure

windmill

installed

for most runs, but with

some pressures

were

taken with the rake pushed inside the tailpipe up almost to the

windmill.

No trouble was experienced

with vibration

of the rake

in either position due to the rigidity of the mount.

level in the manometer

atmospheric

nearest

pressure

the horizontal,

was adjusted till the tube connected

read zero.

.01 inch water.

All heads were measured

pressure was measured.

to

to the

The rake was set at four angles from

_45°, 0°, + 45°, and

were read and recorded

The alcohol

~o,

individually.

and pressure

Thus a time average

If the flow was very unsteady

might take as long as 10 seconds, but usually

7

heads

each reading

all heads were

read for each rake position

in ahout35

seconds.

line total head was read four times during

variation

of the average

time interval.

The variation

pressure

heads

alcohol

density,

increased

B.

flow velocity

since

accuracy

ment

taken.

instrument

although

were estimated

most

oscillations

deflection

the following

oscillated

sinusoidally

oscillations

fairly

the averaging

elsewhere

simple

Readings

finding

amplitude

-

of many

detected.

a time average

If the vane

of

~ + 6°.

i

10°, the

If the

-

superposed

and varying

but with

can be made.

time interval

The

10 seconds.

the deflections

The

frequency,

is not as simple,

different

were

can he read

case may be taken.

7T

the instru-

were readily

behind

for

deflections

at its natural

as true flow direction

ful only in comparing

angular

the instrument.

he (~)(~100)

was approximately

in this report

was vertical

the movement

a constant

is composed

estimate

to he interpreted

of

and the

By viewing

into

the reasoning

would

the process

accurate

built

frequently

with

deflection

movement

visually.

of lower frequency

To illustrate

indicator

The

variation

be small,

and maximum

lighting,

to the protractor

oscillated

time average

would

of the indicator

The average

from above, w~th proper

by reference

to be negligible.

Measurements

The axis of rotation

of the indicator

over this

is not required.

Wind Direction

all readings

each run the time

for temperature

the correction

the center-

could be checked

was found

are not corrected

Since

practice

As pointed

presented

used

for

out

herein

variations,

a

are not

hut are use-

configurations.

taken with

the instrument

at the following

positions,

--

- 8 _

1----

HOR.

t.

c.

Tuft Studies

By means

of tufts placed

the type of flow along

following

in the diffuser

the wall was placed

and tailpipe

in one of the three

categories,

1.

Relatively

2.

Rough,

smooth

unseparated

but with

scale turbulence

3.

Separated

- 9-

considerable

large

VI

A.

Velocity

TEST RESULTS AND DISCUSSION

Surveys

Fig. I shows a nearly uniform

the diffuser

inlet.

The velocity

velocity

decreases

wall on the left side, facing upstream.

the slightly

eccentric

irregular

outlet

distribution

at

more rapidly near the

Whether

this is due to

fairing of the bell mouth or to the

from the centrifugal

fan is uncertain.

result is that the flow tends to separate

more readily

The

on this

side of the diffuser

The data obtained

the tailpipe

Appendix.

has been plotted

q or q20

or average,

is a quantity

from the duct centerline,

the horizontal

Appendix.

LP

11

~)12

satisfies

The quantity~,

distribution

duct to regions

energy

the energy

from

in the

q2D at any radius r

lS,

at the radius

of mass, but introduces

the equation

for conservation

the great change

is transferred

near the wall.

Fl.

of

from Eqn. 14.

in the velocity

At the low blade

from the center of the

Unfortunately

the section

at these high rotational

of the

speeds

losses.

To reduce the energy

blades were twisted

position

or the mean q is calculated

blade near the hub is stalled

thus increasing

on the radius

heads obtained

caused by the small windmill

angles considerable

This

2

the continuity

Fig. 2 shows clearly

fig. 6

(I)

a slight error by not satisfying

energy.

J

8, the number of pressure

This equation

dependent

used to calculate

(h :

r.

q to the mean q.

line as is the data presented

rt~

=

in the

on fig. 2 through

but not on an angular

reference

The equation

on the curves

the effect of the fans on the q

the data has been plotted

as a ratio of a weighted,

wheren

directly

To show more readily

distribution

weighted

from the rake survey at the end of

loss caused

by blade stalling

to give the small windmills

- 10-

F3 and F5,

the

fig. 8.

With a twisted blade the effect of a change

is much less than that for an untwisted

clearly

in fig. 4.

uniform

twist, as for Fs, and a helical

obtained

blade.

This is shown

The twist of Fs is intermediate

twist.

between

a

The results

from Fs and Fs show that when the blade twist is close

to that of a helix a change

in pitch distribution

effect on the blade loading distribution

blade.

in blade angle setting

For this reason an analysis

of the blade element propeller

mounted

a fairly uniform

The blade angle setting

of the windmill

velocity

or approaches

and so the actual distribution

nacelle

distribution.

for the best average

is such that the flow still separates

the diffuser

q distribution

on the upstream

av~age

required

by any form

lead to large errors.

of the weighted

either of the three windmills

N1 will produc~

than for an untwisted

theory will

From a consideration

has a smaller

distribution

separation

in

is still not too

satisfactory.

The action of the windmills

end of the. diffuser

operates

uniform

is quite different.

in a flow having reached

velocity,

the windmill

mounted

Here the windmill

its greatest

and the tailpipe

helps further

following

to give a uniform

F2 has much the same effect

tion.

Windmill

behind

the hub and stalled

diviation

immediately

velocity

With F4 this loss is eliminated

distribution

is obtained

from a

behind

distribu-

as F1 but the wake

section of the blades

noticeable.

actual distribution

at the downstream

1S

more

and a good velocity

both as a weighted

average

and as an

for a blade angle of about 20~ as shown by

fig. 6 and fig. 53.

B.

Pressure

Recovery

The pressure

conversion

reflects

of kinetic

recovery

energy

both the relative

the diffusion

process,

a measure

to potential

magnitude

of the efficiency

energy.

As such it

of the total head loss in

velocity

distribution

at the

exit.

From fig. 7 it is seen that the tailpipe

pressur~

of

as well as the loss of static pressure

head rise caused by a non-uniform

tailpipe

1S

recovery

by about 6%.

increases

This is due to the improvement

- 11 -

the

in

velocity

distribution.

recovery

if the velocity

3%.

The possible

distribution

Thus the values of pressure

reflect primarily

pipe.

further

were uniform

recovery

in pressure

is only about

at the tailpipe

the total head loss in the diffuser

This loss is caused by skin friction

eddylos~es,

increase

and simil~

losses associated

exit

and tail-

on the duct wall,

with the nacelle-fan

group.

Windmill

settings

decreases

Fl

by reducing

the losses at large blade angle

the eddy losses,but

at low blade angles due to stalling

of the fan.

F2 has a limited effect on the diffuser

effect at all blade angle settings

and blade root.

this windmill

wall.

C.

near the hub

loss, and reduce the other losses considerably

less effect

The windmill

separation

at

than either F3 or F6•

recovery

This is caused by separation

and by earlier

directly

flow it has an adverse

due to stalling

The large drop in pressure

nacelle

Since windmill

All twisted blades on the other hand eliminate

low blade angles, F4 having

apparent.

loses its effectiveness

due to Nl

is

on the aft portion

of the

of the flow on the diffuser

has little effect on the losses associated

with the nacelle.

Turbulence

The direction

indicator,

fig. 73 which is described

Sect. "IV-E-2 and IX-C gives a visual

turbulence.

eliminating

promoting

The intensity

separation

dissipation

in smoothing

By preventing

begins

Furthermore

the turbulence

by smoothing

to increase

it again.

on the duct centerline,

ref. fig. 10.

the blade

windmill

Fl

stalling

is more apparent

Fig. 11 shows that the

obtained

chiefly

to the absence of blade stalling.

of turbulence

to that

torque.

This latter effect

results

added to the reduction

out large scale

in the diffuser,

from F6 are slightly

its scale by

might be compared

up to a point where

by

as well as by

by reducing

out an engine's

separation

of low frequency

can be reduced

of the turbulence

the action of the windmill

of a flywheel

reduces

of turbu~mce

in the diffuser" wall,

means of the windmill.

turbulence

indication

in

better

than with Fl, due

The damping

screen

for the few configurations

- 12 -

tested.

As shown in fig. 12, windmill

diffuser

has little net effect on the turbulence

since the

decrease

due to improved

offset by the

increaseq

turbulence

being twisted

turbulence,

the diffuser

D.

flow in the diffuser

generated

to a regular

although

F2 at the end of the

1S

by the blades.

Windmill

F4,

helix, gives a marked decrease

in

not as much as that given by F1 or Fs, since

separation

is not completely

eliminated.

Tuft Studies

The flow along the diffuser

and tailpipe

wall can be

studied by tufts.

The motion of the tuft indicates

whether

flow has separated

from the surface or is about to separate.

The flow is quite good with the large nacelle

With N1 in the flow separates

with the small windmill

being seen.

badly.

This is improved

N1 out.

greatly

F1 at low blade angles, no separation

The flow is almost equally

angles with windmill

the

F5•

The improvement

is not as great, considerable

separation

smooth at low blade

in flow with F2 and F4

occurring

on the left

side of the diffuser.

From a consid~ation

and pressure

recovery,

it is apparent

N1 is the largest component

of windmills

by reducing

of the tuft studies,

turbulence,

that the drag of nacelle

of the diffuser

head loss.

The use

does not reduce this loss, but does decrease

separation

in the diffuser.

by N1 and that associated

can be reduced

by

thp.

The turbulence

with flow separation

nroper choice of windmill.

- 13 -

losses

created

in the diffuser

ti

-J

2

et.

UJ

(f)

:J

U-

10

_.

..

lL t0

Z

<{ 0

}-

:l

~

Z ~et

0

r:JlL

2

CO

_0

Cf.v

U')

~

0

00

uJ

cf)

ell

W

uJ

d.

~

o ~

~;

UJ

d

UJ

:J

oCf.

V

O~H'Nl-t

m

o

~ri

Ci.

UJ

>-

~z

:J

°0 et

rZ

(/)

Gl

tU

~

uJ

~tO

g2

:::>

If)Ci.

o

~

I

-q-

C'J

0

I

~

I

~

,

\0

,

<0

FIG. I

(f)

UJ

u

1

I

2

en

0

:>

4

fi.

0

Z

:J

l-

..J

Z

uJ

c.J

UJ

U

W

£)

Ii

Z

uJ

et

w

W

LL

II

tL

aJ

rt oooooouJ

II

oooooocr

-en CO " \0 lO'V

Z2ZZZZZZ

m,...cocnQ=~-..r

211 1/" "

en ~cC..~~<C..~~

0

d)

~

>-

(()

C!C1aetetet

::>~:J:J:J::>:J::J

Cl

0<10t>0006

"b'/V\

N

0

lC

ro

-

guJ

(f)Q.

LL

Z

0

u

C)

:l

t<{

ct

0

z

CO

r-~"

ULL

00

--l

UjO

uJ

>2

~~

~

a

w

>

«

o

- - 2aQ,a

>-~r

o

FIG 2

cJ)

l1.J

<J

I

I

Z

en

:J

0

«

et

0

2

t::>

ro

~

J-LU

--

(f)

..J

0

cO

~

>en

1ft

I-

(/)0- u.

00. 2

..J 0

>-

t:~

z

0

ULL

00

~

.J

wo

u..J

OOV

000

"

II I'

1O~1f'\

c!Le.~

~lnu)

--ZZZ

£YO:

::l:J::J

(1

0<]0

"""'M

N

-

0

FIG 3

en

UJ

-zI

I

0

C)

<Il

~

:::>

U.

u

z

B

o

0

)2 :>a:

~~

<{

a

UJ

~

o

Z

0

J=

::>

-lC

aUJ

~a.

-00.

>~

r-~

Uu..

00

..J

UJO

)2

uJ

~t:r

<3:

ct.

UJ

~

f/)

.J

(0

0

>-

~

CIl

~

Z

Q

..

tz

0

-

t1

~

~

~

II

Z

0

\)

o 000

<'

00000\.0

CO,....d)lt}~(1)

..

0

.' " .' "

<!L~C!l..ec...~\!L

I'--COIDO-N

___

NNN

:J:::>::>::>::>:J

2ZZZZ2

ct.etCf.Cf.Cf.et.

0<30[><>0

.

(0

,'VN\.

o

(\J

0

o

FIG.4

lU

en

I

(j

,

2

et)

0

:>

<:!

Cf.

Z

0

-

::>

I-

oJ

Cf.

t-W

(/)(1

On

>-~

r-~

.J

cf)

u:

u.J

Ci.

Ioooooo

•

.. "

II

"

..,°0000000

ZO)CO,,~lOv(t')

iu

() <!l.c..e..\C..~~

rtlrr)rOct)

O<lO(><>oOA

II

"~N\

:J:J:>:::>:>:>:>:>

dCf.dCf.arta.et.

ZZ2ZZZZZ

NN~

~tOl'~O-NtO

O tto

~

>-

(f)

I'll

LC

2

2

Q

t-

z

0

-~IL

Z

0

u

-

N

0

co

FIG.5

en

~

0

:>

f/)

,

u

J:

UJ

UJ

::>

UlL

~~

<{

>

UJ

«

a.

>Z

z

o

°0

-.J

WQ ~d

o

o

o

o

FIG.G

U')

I

lU

u

I

2

(()

Q

:>

~

IU

.J

~

Z

<t

uJ

a

~

.J

dl

Ul

>1

&

uJ

a.

J

a:

~

LL

0

0

2

UJ

I-

~

':I.t~

lJJ

,., r4

-iLlafZ2_.2,..

2z-i"izZ2-

>

0

o<JOl><>oOA

U oooo~aDO

ill I-t-t-t- t-rt-

a

a

uJ

:J

(/)

en

lU

CJ.

a.

d.

llJ

tf)

:>

u..

lL

a

u.

0

0

2

IJJ

~

"Lb<

~~~

iz"i

222

Illl

... r4 ,..

n

Q

&-0----0-\0

-0---..co

~

o

Ql..

J

0

l1J

t1

~

lU

ILl

Ul

FIG. ?

o

~

~

0

tn

0

\P

,...0

0

co

o

m

(/)

:J

-

lJ

<{

CY

(()

>

uJ

..J

l!)

z

«

uJ

0

<l

..J

..J

..J

~

0

Z

~

l3

uJ

rJ.

~

£:)

I

OOH.9't~

,

......

OCO('lO<O\n(Q

Od1I'-Nr-~N

CJ\CX)r-,....<..9

It)

CO--dl

'-D

~cri~lti~"":'cri<riQ

/

o

(,()

III

It'

:J

~

N

~

2

0

ll..

a

~

~

'P

en

u.: o~lOm~m\SicOci

mcol"\O

lI)lnltlltl

~

jf

//

:> N

-oooooooq

(f)

C!l..l[

lftrll

II

II

JI

o

co

I

/

I

I

>tNb'HS

o

~

0

o

FIG.8

g]

u

I

z

J

I

(/)

0

<{

et

UJ

(!)

...J

2

<1:

W

0

~

..J

t-

<J 0 [>

I- J-

Q 0 £)00

r

0

I-

<>

0

(0

0

~

It')

0

0

I'

0

\D

FIG.9

(fl

lU

C!l...

J

d.

£!)

z

3

a

_ ~

~

r4

~

ll.

Z 2

Cl iiz-z-z-

~

UJ

o

V)

'~'d''tj

>

-

~

UJ

0

iClJ!

0001

en

r-

Z

uJ

~

lL

-

Z

0

o.

cJ. r

0

Z

~ 0

U

z

II

(!)

to

.J

en

0

10

~

~

_ N rn - ~

(t\

-

~~~~~~K~~

~u.-lCa

~iiZ[t~~oo

~g~r-rto<J[Ju~'tJ.o..<J)J

.ijJ

rJ tn

~t0

~

0

et)

I1J

uJ

Cl

l!)

~o.

o

0

0)

~

~

In

0

ca..

J

uJ

(!)

~ en

uJ

..J

~

Z

<!

>

uJ

a:

q

t-'

lLJ

«

Z

(!)

..J

:J

«

Cl

0

llJ

uJ

.J

U.

(,)

l-

0

£il

.J

«

0

uJ

z

~

lu

.~

... f\

o

...J

~.

~

D

l:l

,f:)J3A)

C'I

--~--- o

o~

«

vd

a -~"OUle'\l

'0

""'0-

~.

o

~~

-j(\

~

.a.oco

s '3 =n:j~da - e..Y

z

<r

a

uJ

<{

-.J

en

~

z

0

F

u

l1J

J

11.

uJ

0

a:

2

~

:J

~

«

\!)

<{

:J .J

c:J. :J

- F« 2

'0

a

-2 :>

2

0

0

V

<(

x

a

~

CJ

ILl

0

o

\0

-&.3 3l:1~~

o

6

N

0

(t)

~

0

0

It')

0

U)

0

"

0

co

o

m

FIG.IO

rn

UJ

111

d

t!)

tU

0

I

~

lJ..tIl

z-

0

Z

..

c:J. t-

0

~

l1J

J

l?

z

<t

uJ

a

j

CO

~

Z

0

t-

o

W

J

en u.

0

r" uJ

oJ

~

_ rl

r{\

tr

Q

-

..uJ

N

d\

.JJI

-NIfl

Q. ~

(fl.

.

ell.

en..

tl' ~ u.=

D

d)

D 0 000

d)

~~~t ~~ ~.-:

0.

~ ~ If»

0

~i2-2-iiZZ2Z

t

If'

~~~~~r r r r

> 0

~

o<lCJo~bcf<fc(

~~~

Yo-

0

)(

<t

~

0

~

a

",

~

III

0

0

U)

0

,.....

g

en

IlJ

l1J

a

1LI

~

I

a

~

UJ

..J

2

~

cq:

CJ

W

~

J

£0

~

2

(J

0

t-

IlJ

..J

lL

UJ

Q

d

..J

<t

:>

Z

"

<{

UJ

<{

<i

C1

g-

~

f:f-<f

N

X))UI

ev

:>

V

a-

a.

uI

>

I

<t

~

2

:J

U 0 2 a

:J <i

0 ~ d. .J

~

j

Z a

Z

0

u

0 II

z

t-

(J

UJ

a

0

------000

'"

S 3"3 ~~"3

Yo-Y'a.

~ '.

c:a..

I

0

W

~

rt.

uJ

w

CI)

FIG. It

~

1"\

0

0

~

0

In

0

\SI

0

,.....

0

()

(/)

J-

z

I~

~ 2

W Z

J

ILl

0.

2

<[

~

«

~

t-

0

z

./

a ~ ci5

::> ...,.

~ z

Z

<3: ~

UJ ~

~

uJ

u

o

a. t~

rf)

0..

0

t; z v ~

~

5

cJ - Z ,.,

:> ~

Q ~

r:t.

~

z

~

l!)

Z et.

-:l

u.

Z

o

::>

~

u

~

....

o

)(

~

C!.

uJ

~

«

o

o

<0

o

o

v

I/)

u.J

lLJ

Cl.

t!)

Co.

0

,

o w

lI)

o

'-D

Q

I()

o

(J)

IlJ

.J

~

2

<:{

u.J

o

«

..J

co

~

z

o

F

(J

uJ

.J

1L

IlJ

o

r:i.

<

..J

::>

C)

Z

«

«

uJ

~

C!.

ILl

>

<t

o

N

o

o

o

m

I()

o

'"

o

\D

tn

~

o

et)

o

N

o

F(G

o

. 12.

fI)

1LJ

W

Ci

C)

UJ

J

o

ca..

'"

Z

lU

2

(t

lJ.J

:J

Cfl

<l

lL"

c4

IU 2

Z

2

0

0: t-

0

IU

..J

l!)

2

IL.I

~

£)

..J

<t

lO

~

Z

0

F

w

U

.J

lL

Ul

z ~o

CJ

i[

~

:J

<!

Z

~

U 0 "4' d

2 <l

Q

:) .J

Z ~C! d ::>

~

::>

Z

0

z

0

u

<t

b

l1J

CJ.

~

~

><

0

o

U>

~~

(f)

A-

~

r:

[j

Q.

N d\

t-=

II

o <J

~~

o

N

"""'",

t~

GJ

o

0

N

0

ct)

0

V

(I)

d

UJ

I1J

<!l...

I

~

0 0

10

0

\D

0

"

o

(1)

UJ

..J

C)

z

IlJ

«

«

a

.J

CO

~

Z

0

u

~

uJ

.J

lL

lU

Q

tJ.

..J

4

:l

u

z

<{

III

~

\J

rJ.

IlJ

>

<{

o

_.... rfI

~[t

o

~

£)

,

UJ

C)

uJ

W

d

en

FIG.I'3

0

N

0

ct)

0

V

~

0

\0

0

""

0

CO

(J)

o

Explanation

The diagrams

observer

would

The

the tailpipe

inside

area between

circles

represented

on the following

see looking

wall,

of Tuft Study

upstream

the diffuser

flow, unseparated

represent

the tailpipe

and middle

between

wall.

as follows,

flow

Separated

into

the outside

by cross hatching

Rough

pages

and the area enclosed

represents

Smooth

Diagram

The

what

the

thus,

circle

represents

the middle

and

type of flow is

FfC.14

TUFT

STUDIES

CONFIGURATION:

NOTED

FIG.IS

TUFT

STUDIES

CONFIGURATION:

TDN,F.

~"400

FIC.,..lt;

TUFT

STUDIE.S

CONFIGURATION:

TDN.Fs

~-700

~esoO

Fl Coy.l1

TUFT

STU DIES

CONFIGURATION:

TDN,N2F2.

FIC.. lB

o

TUFT

STUDIES

FIG. 19

TUFT

STUDIES

(3 = 60°

(3

~

I:

30°

~c

I:

40°

2.0°

VII CONCLUSIONS

A.

General Remarks

Detailed

conclusions

to be drawn from this investiga-

tion are as follows,

(1) The presence

of a large nacelle

inlet increases

turbulence

induces

flow separation

earlier

near the diffuser

and energy losses greatly,

on the diffuser

and

wall.

(2) The velocity

distribution

at the tailpipe

poor both with and without

the upstream

nacelle

(3) The use of a windmill

upstream

nacelle

does not greatly

tion at the tailpipe

energy

improve

losses, and decreases

turbulence

mounted

reduces energy

appreciably

at the tailpipe

blade stalling

if tip stalling

only

but reduces

a good velocity

distribution

Recommendations

at either

root or tip, although

wili normally

occur.

reduced

turbulence

tested.

for Further Study

The windmill

mounted

results.

velocity

should have sufficient

screen appreciably

for the few conditions

uniform

outlet

in the diffuser

losses only slightly,

and promotes

(6) A damping

most promising

reduces

exit.

twist to prevent

B.

distribu-

turbulence,

near the diffuser

(5) The blade of the windmill

it is doubtful

the velocity

the area of flow separation.

the amount of flow separation

slightly,

installed.

on the re~. of the

exit, but does decrease

(4) A windmill

reduces

mounted

exit is

at the diffuser

It is capable

distribution,

exit showed the

of giving a fairly

while at the same time reducing

the level of turbulence.

To reduce the turbulence

damping

screens

is suggested.

screen is considerable,

still further the use of

Since the pressure

any reduction

of energy

- 14 -

drop across a

losses elsewhere

1S

desireable.

The best way to do thi~

nacelle, but since considerations

into this decision

is merited here.

1S

to remove the forw~d

other than aerodynamic

enter

WB~T no further discussion

in the case of the

A windmill mounted on the forw~d

nacelle

could be used, since its favorable effect on energy

losses has

been demonstrated.

The next step should be to design. and test an improved

wind direction

incorporate

indicator.

The indicator

should preferably

the following characteristics,

1.

Single vane type

2.

Damping

ratio approximately

0.7, independent

of

air velocity

3.

High natural frequency

4.

Responsive

at all ai~ velocities

only to change in direction

of air

velocity.

The single vane type will have no undesireable

large deflections

accurate

and a high natural frequency

response characteristics.

these requirements

aerodynamic

are needed for good frequency

For the instrument

should be independent

the damping

ratio and

of air velocity.

All

non-

springs and dampers, but by doing this the instrument

to changes in air speed, an undesireable

Some compromise

will have to be made, but further

study of this problem is needed.

A method of recording

indicator movement which has no influence

instrument,

to have the same

can be achieved by incorporating

becomes more sensitive

feature.

A damping ratio of 0.7

'under all flow conditions

natural frequency

at

and can be made small enough to give an

local value of wind direction.

characteristics

instability

the

on the behavior

such as a type of optical measurement,

of the

would be most

satisfactory.

With an accurate wind direction

of turbulence with such combinations

screens as has been suggested

indicator

of windmills

the reduction

and damping

above should be investigated.

- 15 -

VIII

1.

P£FERENCES

Peters, He: Conversion of Energy in Cross-Sectional Diffusers

under Different Conditions of Inflow. T.M. No. 737, N.A.C.A.,

1934.

2. Patterson, G.N.: Modern Diffuser Design.

Aircraft Engineering, vol. X, No. 115, Sept. 1938, pp. 267-273.

3.

Collar, A.R.: The Use of a Freely Rotating Windmill to Improve

the Flow in a Wind Tunnel. R. & M. No. 1866 British A.R.C. ,

1939.

4.

Den Hartog, J.P.: Mechanical Vibrations. Me Graw-Hill Book Co.,

Inc., 1940, pp. 221-228.

5.

Summers, R.A.: An Investigation'of the Effect of Honeycomb on

Large-Scale Disturbances in Wind Tunnels. Massachusetts

Institute of Technology. Thesis for masters degree in aero.

engr., 1946.

6 .. Dryden, H.L. and Schubauer, G.B.: The Use of Damping Screens

for the Reduction of Wind Tunnel Turbulence. Jour. Aero. Sc.,

vol. 14, No.4, April 1947, pp. 221-228.

7.

Schwartz, I.A.: Investigation of an Annular Diffuser-Fan

Combination Handling Rotating Flow. R.M. No. L9B28, N.A.C.A.

25 Apri I 1949.

- 16 -

IX APPENDIX

A.

Nomenclature

A

cross sectional

CL

lift coefficient

c

damping constant

D

duct diameter

h

total pressure

I

moment of inertia

k

spring constant

1

centerline

area of duct

1

ft lb sec radft

head

inches of water

2

slug ft

ft lb rad-1

distance

rotation

to quarter

undamped

natural

from aX1S of

cho~d of surface

static pressure

q

local dynamic pressure

weighted

cycles sec.1

frequency

p

head

dynamic

inches of water

head (Y~U2)

pressure

inches of water

mean dynamic pressure. head at any

particular

r

inches of water

head at

any given radius

q

ft

station

radial distance

inches of water

from duct center-

line

S

projected

T

torque

u

local free stream velocity

surface

area

ft lb

angle of attack

damping

ratio

angular

POSt

ft sec.1

rad

ition

rad

time mean angular deflection

rad

maximum

rad

angular deflection

coefficient

of viscosity

2

Ib sec ft-

slug ft -3

density

- 17 -

Subscripts

1,2,3

i

Configuration

T

station

(see fig. 66)

location

uncorrected

for instrument

error

Hef. Fig.

symbols

Tunnel

only, up to but not including

66

diffuser

D

diffuser

N1

nacelle

66

and tailpipe

(mock up of WBWT

prop. and motor

67

fairing)

N2

aft windmill

F1

small windmill,

untwisted

blades

8,

small windmill,

linearly

twisted

8,

small windmill,

variably

twisted

large windmill,

untwisted

blades

F4

large windmill,

constant

H

windmill

S

damping

lR mesh,

nacelle

68

pitch

69, 71

8, 69, 71

8,

70, 71

8,

70, 71

71

hub only

screen

blades

69, 71

at end of tailpipe

.010. inch dia.

- 18 -

B.

Pitot Tube Calibration

The pitot tube used in Runs 1-3'was calibrated in

Run 43 in the M.l.T. Student Wind Tunnel ag~mst the 'standard'

pitot tube used by the Wright Brothers Wind Tunnel. The procedure was to make two runs over the same speed range; first with

the standard pitot tube mounted in the test section, then with

the uncalibrated pitot tube and mount in the test section with

the static pressure orifices in the same location as .for the

standard pitot tube. Total and static pressure heads were read

from a vertical manometer when the tunnel speed had been

stabilized at the correct value. The correction is computed as

(g-qi) and plotted vs qi in fig. 20.

below.

RUN 43

The data is tabulated

7/1/49

heads - inches H2O

PlTOT TUBE RIG

STt~~ARD PITOT TUBE

E.A.S.

M.P.H.

20

30

40

50

60

70

80

90

100

h

.16

.46

.82

1.28

1.81

2.48

3.21

4.09

4.98

p

q

h.

1

Pi

qi

(q-qi)

.00

.00

.00

.00

.00

.00

.00

.02

.02

.16

.46

.49

.02

.83

1.28

1.81

2.48

3.21

4.08

.04

.05

.06

.09

.12

.16

.47

.79

1.23

1.76

2.39

'3.09

4. g;

.19

-.01

.03

.05

.05

.09

.12

.15

.16

.82

1.28

1.81

2.48

3.21

4.07

4.96

_ 19 -

3.92

4.80

FtG.20

Z

J

o- ~

Z

C1.

~~

In

ct. ~

Q

lO z

-Uj

..J 0

~

~

«F

rn

U rn

'V

UJ. r

UJ

I

0

2

41-=

F~

I

etl

f- ~

gz

-

to

j

Q.a.

E)

0

~

\0

l:J'3.J.. '9/\/\

N

S3H:::>NI

CO

q

~t- t)

~

0

0

0

~

."

c.

Direction

Indicator Characteristics

The dynamic response

characteristics

tion indicator can be best described

1. Damping

of the wind direc-

by the parameters

ratio, ,

2. Undamped natural frequency, nn

Considering

the indicator

degree of freedom the equation

to be a body with a single

of motion

for the condition

of a

uniform air stream is,

Ie

where

e

+

cB

0

(2)

the angular deflection

1S

and all derivatives

ref. 4,

=

+ ke

from the equilibrium

are taken with respect

the expressions

for'

to time.

position,

As shown in

and nn are,

, = 2JkI

c

and

1

=

nn

(4)

21TJ~

the coefficient

c is calculated

for each component

from the

expression

(5)

and the coefficient

k

=

dT

de

=

k

1S

given by

qS dCt..1

da

(6)

where T is torque in ft. lb. and I is the distance

the centerline

of the indicator

measured

along

from the axis a-a to the quarter

chord line of the surface considered.

- 20 -

The moment of inertia I is

based on a density

of .310 lb/cu-inch

giving some allowance

for all components,

for the soldered

connections.

sions are taken from fig. 73 and the computed

coefficients

are listed in the following

thus

The dimen-

values of all

table for an air speed

of 100 M.P.H.

I

1

2.208 x 10 -8

2

2.360

X

10-8

3

.566

X

10-8

8

1.595 x 10-

4

I

c

k

=

=

=

,=

1.084

X

10-6

4.045

X

10-3

1.156

X

10-6

-2.961

X

10-3

10-3

ft lb ra d -1

cycles per second

forces on components

effects between

in this simple analysis.

2 and 3, as well

all components

The low damping

of the input signal near the natural

that quantitative

However

results obtained

the variation

is altered allows a qualitative

intensity

X

0.15

as mutual interference

accurate.

1.448

1

2.604 x 10 -6 ft 1b see ra d-

The aerodynamic

amplification

k

c

2

6.729 x 10-8 slug ft.

nn .= 20

neglected

1C4

,a,

Component

has been

ratio causes

frequency

from the indicator

so

are not

of output as the configuration

estimate

of turbulence.

-- 21 -

of the change in

D.

Pressure Recovery

H. Peters,

efficiency

ref. 1, gives an analysis of diffuser

in which it is shown that the commonly

used expression

(7)

1S

in error when the velocity distribution

are not uniform.

The correct equation

P2

T/TOT

where subscripts

-

a~ the inlet and exit

is shown to be,

Pi

(8)

1 and 2 refer respectively

to the diffuser

inlet

and outlet, and

The constants X and Yare

the deviation

equation

necessarily

qreater than 1 and reflect

from a uniform distribution.

By applying

to the diffuser - tailpipe combination

efficiency

of energy conversion

=

P4

-

this

to find the

between station 2 and 4 we have

P2

From an inspection

(9)

of fig. 1 it appears

that the constant

X will not differ greatly from 1.00 due to the nearly uniform

velocity

distribution.

introduced

by taking y=

investigation

Since (A2)2

A4

is approximately

1.00 will not be ~eat.

the assumption

that X = Y.=

- 22 -

~ , the error

For a preliminary

1.00 is considered

justifiable

in V1ew of the simplification

lengthy computation.

modified

efficiency

Pressure Recovery

To avoid misinterpretation

we define this

as,

= __

P-:=4=-_-_P_2_ ::: P4-

- ~

A2

q2 ~-(A4)

/

of an otherwise

P2

(10)

~

J

I~

)

-

-

V

STA.I

STA.2

To calculate

q2 and q4.

5TA.3

pressure

recovery

Since we have assumed X=

it is necessary

1.00, Bernoulli's

to find

equation

gives,

(11)

from continuity

(12)

from which we find

q2 =

P1

-

P2

(13)

~(A2)j

A1

But,

A2 =

177 sq in

A1 = 1910 sq 1n

A4 = 391 sq in

- 23 -

(14)

so that,

Pressure

Recovery

=

1.249 (P4 -P2 )

(Pi -P2)

- 24 -

(15)

Pressure

At Station

Pressure

25

29

38

39.

41

Recovery

-%

84.2

46.5

48.0

51. 9

54.5

55.0

54.8

52.2

55.0

56.8

57.6

48.4

52.1

53.1

54.8

4

6

7

8

9

10

11

12

14

15

16

17

18

19

20

Run

Data

4

Run

At Station

Recovery

Run

21

22

24

26

27

28

30

31

32

33

35

36

~7

38

39

40

3

Pressure

Recovery

37;4

39.4

40.8

43.1

43.3

- 25 -

- %

Pressure

Recovery

56.4

56.6

45.7

45.6

44.9

44.2

45.1

44.4

43.1

42.0

44.0

45.5

46.2

47.7

.48.5

49 ..

3

- %

E. Velocity

00

~

\0

M

~

~

~

~

Surveys

C'1

~

r-; ~ ~

~

M

0

C'J

0

N

C'tMooO~-.::r~

l.f')~~~MC'10

o

o

o

~

~

~

C'J

,....j

00

00

C'J

00

~

~

M

~

~

M

M

l.f')

M

M

M

M

r-r,

~

N

00

,....j

l.f') 0

C'J

0

C'1

N

C'J

\0

0

00

00

\0

,

~

~

N

0

0

~

I

M

C'1

~

0

l.f')

l.f')

M

~

\0

-.::r ~

,....j~

~

I

00

trJ

~

0

~

~

0

~

\0

~

l.f') N

l.f') \0

\0

~

~

~

l.f')

00

~

l.f')

00

00

~

0

0

M

~

N

l'-

M

0

00

0

0

V")

~

,....j

l.f') 0

J

C'1

000

\0 l.f') l.f') l.f') M

C'1C'1,....jM~O

,....j,....j,....jM

\0

0

~

C'1

l.f') ~

0

~

00

00

~

~

,....j~

~

~

00

~

0

,....j~

~

~

0

,....j~

~

~

0

\0

~

00

N

l.f') \0

,....j~

~

,....j,....j,....j~

0\

00

0

~

\0

~

00

,....jr-l

0

,....j~

\0 ~

00

~

~.

0

~

~.~

~

~

and Data

\0

~

~

00

l.f') 00

00

N

0 ~

~

M

~

C'1

~

C'J

<:0

C'1

00

0'1

~I

ro

00

~

~

l.f')

0

\..'") M

~

~

0\

0

l.f')

\0

~

0\

00

0

~

~

0

l.f')

0

l.f')

0

00

r-l

\0

~

l.f')

N

I

~

00

,....jM

I

M

I

r-l

O~O'\~Ol'-~oo

~

Moo~\OO

N ,....j,....j~

Lf') ~

M

C'l

C'J

~

0

l.f')

l.f')

~

0

0\

00

\0

0

l.f')

00

~

0

~

~

~

00

~

~

0

M

0

0

If')

~

0

M

0

M

C'J

~

0

l.f') \0

MOl'~

~

0

N

~

l.f') 0

~

~

\0 \0

~

,....j~

~MooO\oorol.f')OO\N

MMr-l~l.f')~~M~M

~

~

\0

~

l.f')

~

0

0

l.f')

0

M

0

0

~

l.f')

0\

C'1

C'1

0

~

o

l.f')

00

~

00

~

~

C'1

~

-26-

C"\I

O

~

0\

0\

0\

0

~

0\

0

~

M

Ln

~

0\

0

eo

\0

0

Ln

~

C"\I

~

~

~

0

C"\I

ro

~

t-

0

~

~

~

~

C"\I

C"\I

~

~

1.1")

~

~

0

~

0

~

~

~

0

~

~

1.1")

~

tM

0

t-

~

C"\I

0

~

~

\0

0

~

CO C"\I

0

1.1")

CO

0

t-

1.1")

C"\I

0\

0\

0

0

CO

0

0

~

0\

1.1")

t-

0

0

0\

~

~

0

t.r.l

0\

eo

~

t-

tt.r.l

~

0\

C"\I

M

CO

~

t.r.l

~

~,

CO ~

1.1")

0

~

0

0

~

0

0

~

~

0\

C"\I

I

I

M

0

....-j<

(Vi

0

M

0\

t-

CO

C"\I

0

M

0

I

~

C"J

~

0

M

0

~

0\

CO

\0

M

M

C"J

....-l

M

C'J

C"~

~

C"\I

CO

0

~

CO ~

0\

0\

eo

t.r.l

0\

0\

\0

~

0\

C'1

~

0\

CO

.'

~

Ln

0\

0

.-I

~

C"l

0

eo

~

U")

O\o\COMt-O

0

0\

0

.0

0\

0

~

t.r.l

~

CO

CO

0\

C"\I

eo

0

U")

0

o

0\

0

eo

t.r.l

teo

0\

~

1.1")

~

0

~

M

..

~

~

~

~t-

M

0

~

\0

0

~

0

Ln

~

0\

~

t-

LnoLnOtnOtr.>

tr.>

M

1.I")tr.>OC'lMLn

C"\ICClMM~O

OO~~~~

0

0\

~

~

o

tnLn~O\~..q.OOC'JO\OJ\OOttt0\

0

0"\

t....-l~~C"\I~~~~OOO\O\roroMMO

t-M\OCO\OO1.l")\O~COt-~~tt0

1.1")

tCO

~

~~~~~~~~O~O\O\COCOM~O

~

CO

M

~

CO 0

0\

0

eo

M

eo

OJ

~

1.1")

~

~

0\

C"\I: \.f)

M

t.r.l

0

~

t-CO~O\~M~"'~~O\~O\~U")~t-~

ooeoO\O\O....-l~~~OOO\O\OOMt-O

("f)

~

t.r.l

CO

0\

~

0\

~

C"\I

M

o

~

\0

0

o ..q'

o ~

0\

o

~

0

~

o

o

o

M

If)

roM

~

M

~

~

ro

lO

M

M

~

~

M

ro

\00

~

~

~

0\

M

«:f'oo:::T'

C'1

I

C'J

I

C'1

C'J

0

ro

0

M

0

M

~

0

C'J

\.(')

ro C'1

ro '" lO

~

\0

C'J

"'.

.....

\0

I

M

C'1

~

0

M

~

0 M

~

ro

~

~

~

M

0

~

C'1 C'1 C'1 <:'1 C'1 M

~

~o

0

~

~

~

~

~

0

~

0

.-I

0\

~

'"

If)

ro

I

If)

~

00

0

~

~

~

~

M

M

M

C'1

0

M

~

~

0

~

.-I

M

M

lO

0

~

~

M

'"

M

M

ro

'"

ro

0

ro ~

000

0

0

0

M

\.(')

0

.-I

~

~

ro

~

~

~

M

0

.-I

M

M

0\

M

~

~

M

ro

0

MM

M

.-I

~

\.Olf)

0

M

ro

~

0

0

0

ro

C'1

0

~

\0

'"

~«:f'~lOM~MlOO\

0\

~

lO

ro ~

.-I C'1 .-I M

~

If)

0

M

0\

C'1 0

\00\

Mro~.-I\OO\

lO \0 ro

If)

ro

V

.-I .-I

C'1

~

~

C'1

C'1

~

C'1 ro

lO-O

If)

.-I

.-I

'"

M

M

0

lO \.(')

~

lO

M

lO .-I ~

OO\"'COrolOOO

0

0

~

0

lO

0

.-I

0

0

ro

C'1

0

.-I

~

~

0

ro

co

ro

.-I

M

C'1

M

ro ~

ro .-I C'J

CO CO \.(')

M

0\

ro

00- 0\

ro M

~

'"

~

~

'"

M

0

~

0

0

ro

0

'"

0

0\

If)

.-I

0

.-I

\0

0'\

~

~

C'1

«:f'M

.-100

~

0\

M

0

M

ro

M

M

~

.-I

.-I

~

~Olf)Olf)OlO

0\

<:'1 .-I

\0

0

0

M

ro

ro

lO

C'1

~

If)

~

\0

~

M

~

~

0

~

0

'" ~

«:f'M

00 '"

'"

M

~

0

.-I

~

~

0

C'1 ~

ro ~

C'1 M

'"

~

ro

M

~

C'1

\0

If)

.-I

-a)

MOOM\OroM

MM~OOO"l::f<

MMM~'MM

-.:T

~

ro

~

C'1

CO '"

~

0\

0\

0'\

0

~

CO

oo:::T'MMMMC'1

o

o

~

lO

ro

-28-

E-t

<:

<

Q

~

H

S

CO

H

f:S

I-f

en

Q

0"

c::"

I:IJ

0

...q<

Z

~

~

0\

M

~

~

eo

Z

('I")

~

0

0\

....-4

....-4

0

....-4

~

0

eo

0

,......j

0\

0\

~

...-i

...q<

If)

0

,......j

eo

....-4

....-4

('I")

eo

0\

0

CO

\0

\0

~

C'l

....-4

0\

0'

Ln

0\

0'\

Ln

M

0\

CO

0\

00