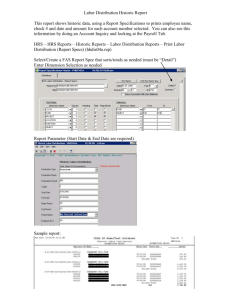

Document 10603067

advertisement