Glider Design Project Information MATERIALS DESIGN CONSTRAINTS

advertisement

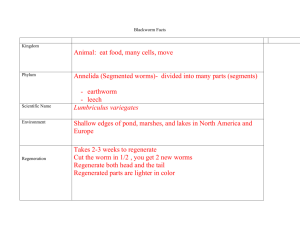

Glider Design Project Information MATERIALS: Each student will be issued the following materials: 1/16” x 4” x 18” balsa sheet, 3/16” x 1/2” x 18 balsa stick, clay ballast DESIGN CONSTRAINTS Your glider must be constructed only from your issued balsa (one sheet and one stick) Wing span 18 in, ballasted gross weight 1 oz, Vtrim 25 ft/s The spreadsheet does not account for control surface stall. Therefore, it is very important to avoid lift coefficients above stall. As a rule of thumb, keep CL for the wing and horizontal stabilizer below 0.5. Other design constraints are contained in the spreadsheet, beginning with cell Q32. These constraints are meant to ensure your design is reasonable and has a chance of performing well. No cells on the left side of the design worksheet (columns A through L) may be red (indicating you have violated a design constraint) at your design’s maximum range velocity. Cells may be red at your design’s maximum endurance velocity. Exceptions may be approved by your instructor once he/she has determined your design is reasonable. GLIDER HINTS AND GUIDANCE 1. You could have the best design in the world, but if you don’t build it right, it won’t fly well. 2. You can design a conventional (rear tail) or canard glider (rear wing). The canard design seems to have fewer problems with spiraling. Regardless, the wing span and the fuselage should each be around 15 inches. Adjust wing and tail location forward and aft as appropriate. Wing root chord should be at least 2.5 inches to prevent stalling due to low Reynolds number. 3. Wing dihedral (less than 6 degrees) helps roll stability and wing sweep (less than 20 degrees) helps yaw (directional) stability. Directional stability is also function of tail size and distance from center of gravity. A larger horizontal tail size has a significant impact on pitch stability. Tail dihedral is not very useful and is difficult to implement. 4. |CN/CL| ratio needs to be between 1/3 and 2/3. If it’s too high, increase CL by increasing the wing dihedral (). Increasing wing sweep (LE) should also help. If the ratio is too low, increase CN by increasing the size of the vertical tail or moving it farther away from the nose of the aircraft. You want the value to be closer to 1/3 to avoid the spiral mode. 5. Make sure the Vtrim you input in cell K21 is the same value the spreadsheet calculates in cell E39. This value changes every time an adjustment to the glider design is made. 6. The L/D ratio should be as high as possible, but if it’s too high (more than about 12), they could be designing a glider that’s unrealistic. Just look at the design, and something may jump out at you. 7. Be sure the angle of attack () isn’t too high… anything more than about 10 degrees or so. They may have to redesign the entire glider to make this one work. This could also be the result of a too small a horizontal tail. If the tail is small, the incidence angle must be high, which causes the trim angle of attack to increase. 8. Be sure the tail incidence angle (it) isn’t too high... anything more that about 10 degrees or so. If it is, they need a bigger horizontal tail. Their L/D ratio may decrease, but the glider won’t be stable without a decent tail! 9. When you are satisfied with your glider’s layout, evaluate its stability and glide performance. Investigate different combinations of parameters to optimize L/D while satisfying stability constraints. Refer to the following table for stability guidelines: STABILITY TYPE PRIMARY CONTRIBUTOR DESIGN PARAMETER SUGGESTED RANGE TO INCREASE DESIGN PARAMETER Longitudinal (pitch) Wing & Horizontal Tail 0.01 < SM < 0.20 add ballast to nose move wing or tail aft make horizontal tail larger Directional (yaw) Vertical Tail 0.001/° < CN < 0.003/° make vertical tail larger move tail aft sweep wings aft Dir/Lat ratio (yaw/roll) Wing / Vertical Tail 1/3 < |CN / CL| < 2/3 decrease wing dihedral make vertical tail larger 10. You must be able to cut your glider from the 4”-x-18” sheet of balsa wood. Before you cut, sketch each component (scale: each block is one inch square) on the diagram below: 11. Do not glue the horizontal tail to the fuselage but to use rubber bands and wooden wedges to attach the tail so that you can adjust the tail incidence angle on fly-off day. However, it may be beneficial to glue the horizontal tail to the fuselage at an incidence angle at which the glider seems to fly well, and then adjust the speed by adding/subtracting ballast.