:·JPL ' ';:.�:i�" '.

advertisement

�

,

':/

';:.�:i �" '.

.'

�i;" '(�_: -?

I'

.-

-:

;

j

'

,

,

,

',;

"Camera

.

",

,

.

.?

.

. .

'

.

..

.'

'

..

.:

'1 'I .

'.

.

,

.

.,

'

". '

, ,': '

:,

-I.,

,

'. .

."

'

1

,. ,

"

,'1"-': ;'

"

:;.;

� ,:

:'

.-.

.'I '

,

.'

'.

i

"

�'�;\J�j;jj:,w,X:;�>;'::,'J!·.'

.

,

'>

}\

�: ,

'"

�} ;

. ,�.

.. '

'.:

; .t.

.

�

';

'

'

1,'

,' ,

, .\;

:�

'

.. "

. '�

"

,I

•

.

;�

'-: .

t,

,

.;

.

.

.,

..

..' , .

"

.�

,

r."

,, :

.

.

"

r

•

;

.

-

.

...

.

.

"

. . ;" ;1'

.

. :'

.

)

"

';"

{:

;

'

,

"

'

.�.

:

. -",

( :.

.. '

.

"

.

. ' . ;.�

.

.

·r'·

.

/.

:

',' ; :

"

,. '

'

'

::

.

.')\" ",

"i

I. ,

'''

.

..

.

:;;

'.

j

. Jet Propulsion Laboratory . , ,;" .

Calilornia Inst�ute ofTechnoiogy.

-,'

:

.

);- .

,

'

.

..

:,.

'

"

.

, ,:

:·JPL

";

,.

.'

"

";\

�}

!'

,

"

' ,

.

, 'I,

,

� ; ;; .

.

"

.

.

"

(, .

, ,'

"i

,1

.,

" '\ :

",. ,

.

.

.: �

'. :

TJl

'.

.:. .:

,

,

:�

,.

':<: '

, "

10

Iii

=J

J>

5/ 21/9 3

AGENDA

WFPC-II PRE-SHIP REVIEW

27-28 May 1993

JPL 180-101

presenter

8:30AM

Welcome & Introduction

Simmons

8:40AM

Review Purpose and Structure

Devirian

8:50AM

Review Board Chairmen Comments

JPUGSFC

9:00AM

Science Objectives

Trauger

9:15AM

Instrument Description & Status Overview

Beckert

9:30AM

System Design Change Summary

Rockey

9:45AM

EMI/EMC Test Resutts

Whittlesey

10:05AM

Dynamics Test Resutts, Weight and C.G.

BrenV O'Connell

10:35AM

Thermal Vac Test Summary and Resutts

Gallagher/Garcia

11 :35AM

Lunch

12:25PM

Optical Alignment Results

Macenka

12:55PM

Science Calibration and Characterization

Trauger

1:40PM

Contamination Control Status

Scon-MonckITaylor

2:10PM

Open Items/Plans for future work/test

Gallagher

2:20PM

Performance Verification Status Overview (CM-02)

Rockey

2:55PM

Compliance wijh Environmental Test Requirements

Gibbel

3:10PM

ECR, Waiver, DAR and Limited Life Items

Thomas

3:25PM

Mechanical Envelope Verification Measurements

Herrell

3:40PM

Acceptance Data Package Description & Status

Martin

3:55PM

Safety Data Package and Compliance Verification

Ross

4:15PM

Reliabilijy and QA Summary/PFR History & Status/Risk Assessment

Schneider

5:00PM

Adjourn

28-May

8:30AM

Post-Shipment Preparations Overview

Collins

8:45AM

Transportation & Handling Plans

Argoud

9:05AM

GSFC I&T Plan

Collins

9:20AM

KSC Launch Processing Flow

Collins

9:35AM

GSFC/KSC Facility Evaluation

•

Schneider

9:45AM

Summary

Devirian

9:55AM

Review Board Meeting/Consent to Ship

JPUGSFC

I

�

w

:E

«

0

�

�

W

Z

«

...I

Q.

C

...I

W

LL

W

C

-

-

�

.J

Il.

.,

�

w

-

>

W

0::

Q.

J:

en

W

0::

Q.

-

I

(II)

en

en

..

�

co

N

I

......

N

�:E

Q)

•

:l

...

as.

..CD

•

==

E

(I)

.>

(I) .

as

0

..

as

CD

>-

a:

c:

as

Ii:

C.

.-

CD

'C

(I)

J:

'C

.u..

en

3:

0..

Gi

•

.-

�

(.)

:l

•

...

en

-C

C

as

Q)

en

0

C.

•

:l

a..

.J

D.

.,

Wide Field Planetary Camera

JPL

Pre-Ship Review Purpose & Structure

Purpose

•

Verify that testing has been completed with no unacceptable problems or

anomalies

•

Assess the extent to which flight qualification criteria were attained

•

Evaluate readiness of hardware and software for delivery

5120193

MO-2

Wide Field Planetary Camera

.JPL CRITERIA FOR INSTRUMENT SHI PMENT

•

WFPC must have completed all planned testing and verifications, as

documented in the Performance Verification Plan, except for:

a. those compatibility items which can only be verified at GSFC; or

b. those requirements for which waivers have been approved.

•

•

•

Transportation vehicles and equipment must have been successfully tested,

using approved procedures, and ready for shipment.

Facilities at GSFC (Bldg. 29 cleanroom) must be confirmed to be ready to

receive WFPC-II and associated GSE.

WFPC ground operations team, along with all required GSE, must be ready

to deploy to support GSFC and KSC pre-launch operations.

5/20/93

MO-3

Wide Field Planetary Camera

AGENDA

.JPL

27-28 May 1993

180-101

Ti m e

Topic

Presenter

8:30 AM

Welcome & Introduction

Simmons

8:40 AM

Review Purpose and Structure

Devirian

8:50 AM

Review Board Chairmen Comments

JPUGSFC

9:00 AM

Science Objectives

Trauger

9:15 AM

Instrument Description & Status Overview

Beckert

9:30 AM

System Design Change Summary

Rockey

9:45 AM

EMIIEMC Test Results

Whittlesey

10:05 AM

Dynamics Test Results, Weight and C.G.

BrenV O'Connell

10:35 AM

Thermal Vac Test Summary and Results

Gallagher/Garcia

11:35 AM

5121/93

JPL

Lunch

12:25 PM

Optical Alignment Results

Macenka

12:55 PM

Science Calibration and Characterization

Trauger

1:40 PM

Contamination Control Status

Scott-MoncklTaylor

2:10 PM

Open Items/Plans for future work/test

Gallagher

2:20 PM

Performance Verification Status Overview (CM-02)

Rockey

2:55 PM

Compliance with Environmental Test Requirements

Gibbel

3:10 PM

ECR, Waiver, DAR and Limited Life Items

Thomas

3:25 PM

Mechanical Envelope Verification Measurements

Herrell

3:40 PM

Acceptance Data Package Description & Status

Martin

3:55 PM

Safety Data Package and Compliance Verification

Ross

4:15 PM

Reliability and QA Summary/PFR H istory & Status/Risk Assessment

Schneider

5:00 PM

Adjourn

MD·4

Wide Field Planetary Camera

AGENDA, continued

JPL

Time

Topic

P resente r

28-May

8:30 AM·

Post-Shipment Preparations Overview

Collins

Transportation & Handling Plans

Argoud

9:05 AM

GSFC 1&T Plan

9:20 AM

KSC Launch Processing Flow

Collins

8:45 AM

9:35 AM

GSFC/KSC Facility Evaluation

Collins

Schneider

9:45 AM

Summary

Devirian

9:55 AM

Review Board Meeting/Consent to Ship

JPUGSFC

5/20/93

MO-5

"'i'

<[

a:

w

:E

<[

(,)

>

a:

<[

Iw

2

<[

...I

a.

-

C

...I

W

u:::

w

c

i

en

w

>

-

I0

W

�

0

W

0

2

w

-

0

en

�

CD

(W)

en

en

....

.c

N

-

CD

>

a:

Q.

-

-

en

I

CD

...

a.

..

....

>

m

==

...

CD

0)

::::J

m

...

I-

..,

JPL

WF/PC-II PRE-SHIP REVIEW

INSTRUMENT DESCRIPTION &

STATUS OVERVIEW

MAY 27-28,1993

JEWEL BECKERT

,

HST:, WFPC-2

,

,

arA IrnAgd:

- ,,

,

,

I

,

,

5DFeu.,,:

,--I-

�

,

5

F124

Pickoff

Mlm>r

Mech.lln16m

,

Ooclo"

;

(6.y3)

SOF

5o,",ct.

1

r-

s;t:t

RJUe �

�

RJU6

I-

�,uo .....

�UA� I-t

,

,

,

,

,

...... !)USA:

...... �USOI

,

I

RfU

A

I-

DI".".

TlI.I

S....I

I

r-

CH Elee.

(CH I)

CH Elee.

(CH 2·4)

I

r

CMD& �

TlI.I

5�

r ���

M

I

Engr.

Oat.o

Meeh.

Driver"

CCD.

TEC

1--4)

(eH

TEeps

I+-

.y

M.scJunlsms

&umpt

EMf

Fltte.6o>c

Select

_

h

Pow..ON/OFF

B@,

SOFA

CCD

I'.1ndowo

(CH 2-4)

1-

1-

�

0

ElcctrI",,1

UlrTOr

t.i:

PC Relay

0 '"

( 130)

Optlc.

(FI12.9)

LVPS

•

0.,1-5

&o-U .....

OfF

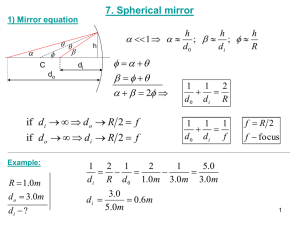

WFPC-II Functional Block Diagram

..

PC fold

MlrrO(

(FI3O )

11 AFJ..f

WFCReloy

l+�

----+

Pyramid

H..t

. 1.Iochr;�;j

_

I

PATHS

- --"--

1 1 f'YR ump. 1

� ,[.r;:"4) �I

Mcch.PS

Hoa...-.

CAL L.mpo

CCO

I'.IM<Iow

(CH I)

�-

ON/OFF

5..!...

f'ower

1

f+-

(CH 2-4)

romp.

Co_oI

1

.�

�

Logic

1

�

CCO

(CH I)

�

I.

I

AFM

E1ect.ron1c.

"'"""'"

"-

(6oy 4)

Clode IIF

CI�1t

WCALLsmp

_____

�

OSP/ADC

-I

.... - VIS CAL ump.

OSP/ADC

Clade I/F

S.1ect

Ooclo 0

;"p';t

ou.

I

5DF 6

,

....

�-

SOF A

,

,

,

-0

C.IFUp

MlrTOr"

MW1..nr�

�

Y.JFC Fold

MlrTonlo

(FI12.9)

__

,

n Fbc6<l

�

1:3,+. "h"'�

Radiator

r1RcPf.

Her•.

ON/OFF

f-.

L

HP Her..

ON/OFF

Ho.ot

0.,

0.,.

&Oi

Hoat

f-- .HrI

Hut

R.a.::!l.ItMh4..t

to -V'GO

J

Wide-Field!._ �letary Camera

Cutaway View

Showing Interior

RADIATORIBAY 5

SUPPORT STRUTS

. MULTILAYER

INSULATION

RADIATOR

LIGHT SEAL

RADIATOR

SUPPORT STRUTS

-V

3

�

MULTILAYER

INSULATION

'-.

LIGHT BAFFLE

HEAT

PIPES

PVRAMln (FIXED)

OPTICAL BENCH

(GRAPHITE EPOXY)

FILTER SELECTOR

(48 FILTERS)

UV FOLD MIRROR

1124 PICK-OFF

MIRROR

-V2

ELECTRONICS

COMPARTMENT

�I

REGISTRATION

FiniNG· POINT B

OPTICAL BENCH

SUPPORT STRUTS

......�+

V3

-v

,

REGISTRATION

FiniNG

POINT A

PICK·OFF MIRROR

MECHANISM

ENTRANCE

APERTURE

PURG,,-... AS LINE

HEAT PIPES

CONNECTOR

RADIATOR/BAY 5

SUPPORT STRUTS

3-V

MULTILAYER INSULATION

RELAY OPTICS ASSEMBLY

-

111II1�32§'&"'Jf\J@:���

LIGHT BAFFLE

MULTILAYER INSULATION

OPTICAL BENCH (GRAPHITE EPOXY)

ENTRANCE APERTURE

1/24 PICK-OFF

MIRROR

JACKING ROD AND

CONNECTOR LOCK,CONNECTOR

BRACKET

+V3

PICK-OFF MIRROR

MECHANISM

I

�

-v,

REGISTRATION

FiniNG

POINT A

�+V

REGISTRATION FiniNG

OPTICAL

POINT C

BENCH

SUPPORT STRUTS

INVAR BULKHEAD

2

OPTICAL BENCH

SUPPORT STRUTS

PYRAMID (FIXED)

FOLD MIRRORS (3 ARTICULATING,

FILTER SELECTOR (48 FILTERS)

1

FIXED)

MULTILAYER

INSULATION

EVA HANDRAIL

TRIPOD

ASSEMBLY

I���

WIDE FIELD/PLANETARY CAMERA - II

JET PROPULSION LABORATORY

PROJECT SCHEDULE

APPROVAL:

1991

ACTIVITY

I

�

STATUS AS OF:

May 27, 1993

REV G, DATE:

Dec 14, 1992

CREATION DATE:

Oct 31, 1991

FY91

J

1993

1992

FY92

FY93

1994

FY94

REVIEWS

2

3

4

REL OPT PNULSFLe,'Y STIM

"

5

6

7

m�

II

"

16

e"'�-:'S/GFE/IVT ABA

[9) [SAF)

'LATING FOLD MIRRORS

[IIIJ [SAF)

, HEADS

(I-5J

_._

-

__

_______ 0 . 0

OPTICAL BENCH

HOUSING

[29) [SAFJ

[27) [SAF)

19

MECHANISM COVER

20

RADIATOR & TRUSS

CABLING

(FLT,

[4BJ [SAF)

[110) [SAF)

GSE & Ttvl [34J [SAFJ

22

THRML SYS-HEAT PIPES. MLI [21} (SAF)

23

FLIP MIRROR MECHANISM

24

PICKOFF MECH,

25

FIXED PYRAMID ASSEMBLY

[99] [SAF]

ARM & COVER [I] [SAF)

[I] [SAF)

26 BAKEOUTS & ADSORBER DEVICE [lOJ [SAF)

27 INTEGRATION AND TEST

2B

OPT BENCH INTEG & ALIGN

[0)

H

30

EMI/EMC & DYNAMICS TESTS

[0)

WT.

H

H

[0] (9)

31

32

33

..................

.........r-"".... ............

SYST VERIF,

� _GSFC

CG,

T/V & SCI CAL

FNL CLOSEOUT,

SERVICING

& KSC OPERATIONS

SHIP

r....' ,-_,

[0)

-'--'--'

I

i

i

i

"

i

t-++-t....t-t--l

.J

,It-t-+-t-lt-t-+-+-II-t--t

."IIUVC.

4 ,,0:;. '.

·_-._=

FAB CERT DELIVER

CERT T

lolL!

_De lolL

�

i;����S

__

;�

�

/

�

F

L

V

.CCVER

e'M

S

����::�ii����!:���������� �' f'� :t"";;Mt:L' :J::J::J::t::J::t::J::t::J::t::J::l

PVRAMIO -FOLOS

SM REV SIPE CO� CMO/TLM :"OV:R"': SM PLAN OPS PLAN P FLT READINESS REV

u � [OSFC IST"':SlP' INHl\7"UNCH&FLT SUP;>

"if......

••

HSG

_•

1

11

.1 .1 .1 .1

.1 .1

I I

1

SVS

1

1

...

NOTES:

4-CAMERA BASELINE WITH AFMs

FOR [XX) [YYJ: XX DENOTES' OF WORKING DAYS FLOAT ON 31 OCTOBER 1991

YY DENOTES. OF WORKING DAYS FLOAT AS OF STATUS OATE

Rev. A:

Rev. B:

..

•

0_._0

STRUCTURES AND MECHANISMS

.. I<IO O"S .EW SUI MONITOR CAM

_

[5) [SAF)

LUHAL l,;l,;US. t A�. t"KI.i. !)I,;Ht.t.N l4J I::iAt J

fER, SOFA & FILTERS [69J [SAFf

18

RI�.BAFiT. EVA

NULL.

[l2J [SAF)

IONIC BAYS

17

21

[20J [SAF)

_

IONICS

_CAl,IBRATION SUBSYSTEM

12

�

•

.1

1

_

J

I

1

1

.1.1

...

AODED MILESTONES, SCIENCE DELIVERABLES, CRITICAL PATH INFO 11/30/91

FACILITY IMPACT,OPTICS RELOCATIONS FOR AFMs,PC CAMERA RELOCATION 1/20/92

1_'"

_

...

I I I I I I I I

1

�

�::,

1

1

1

I

I

I

I

'I;iI

1

,

Rev, C:

Rev, 0:

MID-FY92 REPLAN (4/20/921

RETROFIT FIXED PYR ASSEMBLY,

Rev, E:

Rev. F:

Rev. G:

FY93 REPLAN, DELIVER 5-31-93 (9-21-921

EXTEND T/V TEST, DELIVER 6-7-93 (11-30-921

INCLUDE CCD TILT PC CAM, DELIVER 6-11-92 (12-14-921

DELIVER 5-31-93

(6-1-921

, .PL3/May 25. 199�

WF/PC-II PRE-SHIP REVIEW

SUMMARY OF

SYSTEM DESIGN CHANGES

MAY 27-28,

1992

DON ROCKEY

WFPC-II SYSTEM ENGINEER

HEAT PIPES

CAMERA HEAD

RADIATOR/BAY 5

SUPPORT STRUTS

MULTILAYER INSULATION

-

/'

�IIIW� W-&4\�

EVA HANDRAIL

TRIPOD

ASSEMBLY

LIGHT BAFFLE

MULTILAYER INSULATION

OPTICAL BENCH (GRAPHITE EPOXY)

ENTRANCE APERTURE

1124

PICK-OFF

MIRROR

-V2

PICK-OFF MIRROR

MECHANISM

CONNECTOR

BRACKET

-v

,

'JACKING ROD AND

LOCK,CONNECTOR

REGISTRATION FITTING

OPTICAL

POINT C

BENCH

SUPPORT STRUTS

I

�

REGISTRATION

FITTING

POINT A

MULTILAYER

INSULATION

..

RELAY OPTICS ASSEMBLY

/

+V3 £1'

V

t!73-

+V2

OPTICAL BENCH

SUPPORT STRUTS

INVAR BULKHEAD

PYRAMID (FIXED)

.

FOLD MIRRORS (3 ARTICULATING,

FILTER SELECTOR (48 FILTERS)

1

FIXED)

TEST

CONNECTOR

RADIATORIBAY 5

SUPPORT STRUTS

MULTILAYER

RADIATOR

INS!)LATION

LIGHT SEAL

PURGE

GAS LINE

RADIATOR

SUPPORT STRUTS

-V

3

�

MULTILAYER

INSULATION

LIGHT BAFFLE

HEAT

PIPES

PYRAMID IFIXED)

F1L TER SELECTOR

(48 Fil TEAS)

CAl FLIP

MIRnOR

f/24 PICK-OFF

MIRADA

.v

ELECTRONICS

COMPARTMENT

CAMERA

HEAD

ARTICULATING

FOLD MIRRORS

CALIBRATION

MODULE

REGISTRATION

FITTING - POINT B

OPTICAL BENCH

SUPPORT STRUTS

+V

,

...0

d'.

PICK-OFF MIRROR

COVER

HINGE LUG

�I -v,

,

' � +V

REGISTRAnON

FITTING

POINT A

PICK-OFF MIRROR

MECHANISM

ENTRANCE

APERTURE

3

WF/PC-II PRE-SHIP REVIEW

MAJOR WF/PC-II CONFIGURATION CHANGES

WF/PC-I

WF/PC-II

CONFIGURATION

8 CAMERAS (4 WFs, 4 PCs)

4 CAMERAS (3 WFs, PC)

PYRAMID MIRROR

ROTATE/FOCUS

FIXED

PICK-OFF MIRROR

FIXED

ARTICULATING (pupil alignment)

FOLD MIRRORS

FIXED

AFMs IN PC, WF-3, WF-4

12 C +2 C FOR AFMs

THERMAL CONTROL

APERTURE

,

MgF WINDOW

OPEN

CORRECTIVE SECONDARIES

RELAY OPTICS

CCDs (15 micron pixels)

TI (800 X 800 pixels)

CORONENE COATING

-90 C OPERATION

LORAL (800X800 pixels)

LUMOGEN COATING

-78 C OPERATION

ELECTRONICS·

NON-REDUNDANT

REDUNDANT (7.5 & 15 e/DN)

STRUCTURAL DELTAS

PICK-OFF MIRROR COVER,

EVA HAND RAILS, PC HEAT PIPE,

SIPE I/F, T-O PURGE

CONTAMINATION CONTROL

BAKEOUTS, ADSORBER,

CCD DECONTAMINATE SEQ.

LIGHT PIPE

CCD UV FLOOD

CAL SIS (UV + INCANDESCENT)

WF/PC-II PRE-SHIP REVIEW

SUMMARY OF SYSTEM CONFIGURATION CHANGES

ECR#

TITLE

19215

RAM PATCH INCREASED WAIT TIME: SOFA PHOTODIODE TURN-ON TO POSITION SAMPLE

19214

SHORTENED POMC RELEASE BAR V3 DIMENSION TO AVOID POSSIBLE SIPE INTERFERENCE

19213

TILTED PC TO AVOID GHOST IMAGES OFF SOFA

19212

MODIFIED CAL SIS WINDOWS TO OBTAIN MORE UNIFORM RADIOMETRIC OUTPUT

19211

REMOVED PYRAMID ROTATION FIRMWARE PATH FROM RAM LOAD

19210

REVISED THERMAL ANALYSIS TO REFLECT FEWER CAMERA HEADS, INCREASED ALLOWED

HEAT PIPE NON-CONDENSIBLE SLUG GROWTH

19209

REVISED AFM POWER BUS FUSING TO AVOID INADVERTENT TRIPS

19208

CHANGED GAIN OF REDUNDANT ADCs FROM 7.5 TO 15 ELECTRONS/DN

19207

DELETED ECR 19204 TO PAINT EDGE OF PICK-OFF MIRROR

19206

MODIFIED BAYS 1-4 HEATERS TO MAINTAIN OPTICAL BENCH WITHIN 10 C TO 14 C RANGE

19205

REPLACED MOVEABLE PYRAMID WITH FIXED MOUNT PYRAMID,

REVISED SPECIFIED OTA CONIC CONSTANT TO REFLECT CORRECT FOCUS

I JANUARY 1993 PRE-ENVIRONMENTAL TEST REVIEW I

MAY 1992 DELTA CRITICAL DESIGN REVIEW

WF/PC-II PRE-SHIP REVIEW

SUMMARY OF SYSTEM CONFIGURATION CHANGES

ECR#

TITLE

19199

ADDED EVA HANDRAILS

19198

MODIFIED HST APPLICATION PROCESSOR PROGRAM TO MAINTAIN TEMPERATURE OF

AFMs WITHIN OPERATIONAL LIMITS

19197

ADDED ZEOLITE MOLECULAR ADSORBER

19196

ADDED AFMs (TO MAINTAIN PUPIL SHEAR CORRECTION)

ROUTE CABLE THROUGH PC FOLD MIRROR BULKHEAD OPENINGS

POWER & TELEMETRY INTERFACES THROUGH RIU-C

19195

CONFIGURATION CHANGE TO THREE WFCs + ONE PC

REBEND PC HEAT PIPE

ELIMINATED SCABBED WFC TEC POWER SUPPLY

TERMINATED UNUSED TEMPERATURE CHANNELS

ADDED SOFA PARTIAL STEPPING CAPABILITY

MODIFIED MEGA-BRACKET, DELETED/TERMINATED CABLING

19194

ADDED BAY 3/4 ELECTRONICS "CROSS-STRAPPING"

19193

ADDED TEMPERATURE SENSOR TO THE PICK-OFF MIRROR

19192

INCREASED BOLT HOLE SIZE OF RELAY OPTICS FLEXURE TO ALLOW PUPIL& BORESIGHT

ALIGNMENTS (EXTRA DEGREES OF FREEDOM)

WF/PC-II PRE-SHIP REVIEW

SUMMARY OF SYSTEM CONFIGURATION CHANGES

ECR#

TITLE

19191

CANCELED ECRs 19126 & 19138-A, MAINTAINED WFPC-I RAM LOAD & PROM

19190

SHIMMED WF/PC FOLD MIRRORS & PYRAMID TO PRESERVE OPTICAL PATH LENGTH &

PROVIDE AFM CLEARANCE

19189

MODIFIED TEC COLD JUNCTION SET POINTS FOR LORAL CCDs

19188

MODIFIED CCD FRAME OVERLAP REQUIREMENT (FROM 50 TO 40 PIXELS)

19187

INCORPORATED LORAL CCDs

19186

UPDATED ASSEMBLY DRAWING TO SHOW EXTENDED GUIDERAIL

19185

PROVIDED FLIGHT COVER FOR PICK-OFF MIRROR

19184

ADDED CONTAMINATION CONTROL BAFFLES NEAR CCDs

19183

IMPROVED TELEMETRY RESOLUTION ay ADDING FOUR TEMPERATURE TRANSDUCERS

TO THE RADIATOR

19182

MODIFIED PICK-OFF MIRROR MOUNT (FROM 4 TO 3 POINT MOUNT)

19180

MODIFIED BAY 5 REPLACEMNT HEATER TO MAINTAIN A TEMPERATURE >-20C (REVERT

TO WFPC-I CONFIGURATION & CONFORMAL COATING)

Wide. Field/Planetary Camera II

ELECTROMAGNETIC COMPATIBILITY AND

MAGNETICS TEST REQUIREMENTS

COMPLIANCE

MAY 27,1993

A. WHITTLESEY

Wide Field/Planetary Camera II

EMC/MAG TEST OBJECTIVES

TO VERIFY COMPLIANCE TO EMC/MAG REQUIREMENTS OF

ST-ICD-03F AND JPL TS512406.

Wide FieldlPla•. �tary Camera II

EMC & MAGNETIC TEST RESULTS

TEST

RADIATED EMISSIONS

14 KHz TO 18 GHz

PASS/FAIL

COMMENTS

FAIL

EVALUATION

HIGH AMBIENT. BUT WITH

USE AS IS DAR

#20 SUBMmED

NARROWBANWBROADBAND

RADIATED SUSCEPTIBILITY

14 KHz TO 3 GHz

14.8 TO 15.3 GHz

CONDUCTED EMISSIONS RIPPLE

AND NOISE

30 Hz TO 50 MHz

PASS

PASS

USE AS IS DAR #18 SUBMmED

SIMILAR TO WFJPC I

FAIL

NARROWBAND/BROADBAND

IN-RUSH CURRENTS

PASS

CONDUCTED SUSCEPTIBILITY

RIPPLE AND NOISE

30Hz TO 50 MHz

PASS

TRANSIENTS

PASS

MAGNETICS, DC

FAIL

MAGNETICS, AC

PASS

I

I

I

TRANSIENT AMPLITUDE LIMITED

BY 2A SPEC LIMIT; NOT VOLTAGE

LIMIT

AT A,B,C, LATCHES (GFE'D BY

GODDARD) OK AT 3 CM.

I

USE AS IS DAR

#19 SUBMITTED

WIDE FIELD/PLANETARY CAMERA II

DYNAMIC TEST RESULTS

David Brent/Mike O'Connell

Sections 354/521

May 28, 1993

AGENDA

Test Objectives

David Brent

Test Appproach

Mike 0' Connell

Test Results:

Mike O'Connell

Sine Vibration Test

Random Vibration Test

Acoustic Test

Verification of Test Objectives

David Brent

Structural Integrity

Optical Alignment

Contamination

Development of FEM

David Brent

Conclusion

David Brent

TEST OBJECTIVES

1) Verify system structural integrity.

2) Verify optical alignment stability.

3) Verify contamination requirements met.

4) Enable development of a test verified finite element

model.

5) Verify adequacy of subassembly vibration tests.

..JPL

WIDE FIELD/PLANETARY CAMERA

VIB RATION TEST A PPROACH

o

V1 AXI S WF/PC II SI NE SURVEY, NO FORCE LIMITING

-

.1 gpk, 5-2000 Hz, 2 OCTAVES

I

MINUTE

- EXTREMAL CONTROL OF 3 ACCELE ROM ETERS, ONE AT EACH LATCH

- PERFORM BE FORE AND AFTER RANDOM VIB RATION

o

WF/PC II TENTED WITH FLIGHT LIKE PURGE FOR ALL DYNAM IC TESTS

o

FUNCTIONAL TESTS PERFORMED B E FORE AND AFTER EACH VIBRATION TEST R UN

.lPL

WIDE FIELD/PLANETARY CAMERA

( VIB RATION TEST APPROACH CONT'D )

o

SINGLE AXIS TEST APPROACH, V1 AXIS

o

WFIPC II FO RCE LIMITE D PROTOFLIGHT ( PF ) RANDOM VIB RATION TEST, .02 g2/Hz,

2.9 grms

- FORCE LIMITS FINALIZED FROM SINE SU RVEY DATA

&

PF-1 2 d B RANDOM

o

EXTREMAL CONTROL OF 3 ACCELEROMETERS, ONE AT EACH LATCH IN V1 AXIS,

AND FORCE TRANSDUCER AT LATCH A, V1 AXIS

o

R ESPONSE PEAK LIMITED AT 1 0 CHANN ELS ( OPTICAL BENCH, POM M ECH.,

RADIATOR)

o

STEP THROUGH LOW LEVEL RUNS TO PF LEVEL; P F-1 2dB, PF-4dB, PF

o

FUNCTIONAL TESTS PERFORMED B EFORE AND AFTER EACH VIB RATION TEST RUN

..IPL

WIDE FIELD/PLANETARY CAMERA

ACO USTIC TEST APPROACH

o

WF/PC II ACOUSTIC TEST TO WF/PC I RADIATOR PF LEVELS, 1 47.0 dB OVERALL

- AVERAGE CONTROL OF 4 MICROPHONES

o

STEP THROUGH LOW LEVEL RUNS TO PF, PF-1 2, P F-4, PF

- MOLECULAR ABSOR B E R V1 AXIS TEST PERFORMED PRIOR TO PF LEVEL RUN

o

WF/PC II TENTED WITH FLIGHT LIKE PURGE FOR ALL DYNAMIC TESTS

o

FUNCTIONAL TESTS PERFORMED BEFORE AND AFTER EACH VI BRATION TEST

RUN

.JPL

WIDE FIELD/PLANETARY CAMERA

TEST RESULTS SUM MARY

ALL

o

WF/PC II RANDOM VIB RATION RESPONSE GENERALLY LESS THAN WF/PC I

•

•

•

•

WF/PC II VIB RATION

&

o

ACOUSTIC INPUTS WERE WITHIN SPECIFICATIONS

D U E TO FORCE LIMITING WITH EXTREMAL CONTROL, USE OF FLIGHT LATCHES,

AND USE OF SMALLER MORE RIGID VIBRATION FIXTU R E

1 .8 Qrms vs. 2.6 Qrms O N PYRAMID BULKH EAD/OPTICAL B ENCH

ASSEM B LY/SUBSYSTEM VIB RATI ON SPECI FICATIONS BOUNDED SYSTEM

VIB RATION TEST RESPONSES EXCEPT SLIGHT EXCEEDENCE, 3dB AT 55 Hz

H z, OF AFM SPECI FICATION

&

ACCELE RATION SPECTRUM NOTCHING DUE TO FORCE LIMITING WAS 4·8 dB,

WITHI N RECOMM ENDED RANGE

85

..IPL

WIDE FIELD/PLANETARY CAMERA

( TEST R ESU LTS SUMMARY CONT'D )

o

WF/PC II ACOUSTIC TEST R ESPONSES G EN E RALLY EXCEEDED VIBRATION TEST

RESPONSES (EXCEPT AT 32 Hz) & WF/PC I ACOUSTIC TEST R ESPONSES

(ESPECIALL Y 40-200 Hz)

o

ASSEMB LY/SU BSYSTEM VIB RATION SPECI FICATIONS BOUNDED SYSTEM

ACOUSTIC TEST R ES PONSES EXCE PT:

- AFM SPECI FICATION EXCEEDED BY 4 d B @ 85 Hz

- MOLECULAR ABSORBER V1 SPECI FICATION EXCEEDED BY 2X IN TERMS OF grms

o

AFM EXCEEDENCES NOT A CONCERN; Fn » 80 Hz, AFM SPEC. WAS 5.0 grms VS. 2.1

grms WF/PC II SYSTEM R ESPONSE AND SYSTEM ALIGNM ENT NOT EFFECTED BY

DYNAMIC TESTS

o

2 MOLECULAR ABSOR BERS WERE SUCCESSFU L LY PF VIBRATION TESTED IN TH E

V1 AXIS TO 30.4 Qrms PRIOR TO PF LEVEL ACOUSTICS RUN

..IPL

WIDE FIELD/PLANETARY CAMERA

TEST RESULT CONCLUSIONS

o

WF/PC II DYNAMICS TESTS VERIFIED COMPLIANCE WITH PF TEST

ENVIRONM ENTS DEFINED BY GSFC

- ASSUMES VIB RATION SPECIFI CATION PROVI DED BY GSFC HAS MARGIN OV ER

FLIGHT (NOT VERIFI E D)

o

SOM E RISK ACCEPTED BY PERFORMING 1 AXIS VIBRATION TEST

- RISK M ITIGATED BY CONSERVATIVE ACOUSTIC TEST

FIGURE 11. WFPC PF VIBRATION TEST, CONTROL ACCEL SUMMARY

. .

,

iii .[

..

ii

•

0.1

_.i: 1,.

,

"

.

! 1 1�!

.'

ii

�" "

."I""

Ii,

i i.l.

2

g 1Hz

0.001

1 i III1 1

+ ++

·

·· ··· ·············

,

+..,..

•

,

11

IIII!

10

•

•

•

.

. ... ......

_

.. . .. ... .. _._. .

,

-

.S!«,2]gnns

- Control Aceell, 2.2 grrns

·

··········

Control Aceel 2, 2.3 grrns

Control Aceel 3,2.3 grrns

III

r r

············

······

···

,

.

. . .-.. .;. .--..L

�

.....-.

'Iit t111t

T T

···

···

'

· ··

1 1 1 1 i

. . L!. L,

j

.t................

1\11 '1111

100

Frequency, Hz

... ..

..

�...!

·····.........

1000

.

FIGURE 12. WFPC PF VIBRATION TEST, FORCE V1 SUMMARY

!

1000

,

i

!'

I

,l

,

'J

,

,

,

,

I

.... .

10

"

:r

I,

,

!

t

I

,

I,

;.

,

•

, , _\

,

'

•

/

,

,

�!

"

,,

,

,

.,

'

,

• �...

,', :

i

,'J I,

•

i

'

,

i

�I� I

1

", \ ,,\

'\'

,

•

,

"

"'

l

i

.,

. .

, ,� "

", "I

l

i"

r:\.; ! �,

1\:' :/r

I

,I',, '

•

I

0.1

- - Force A Vl, 219.8 lbs rms

. . .

•

Force B Vl, 187.8 Lbs rms

....... Force C Vl, 98.1 lbs rms

,

,

I

•

-

'-" ,

!

,

,

,

•

Force Specification, A Vl

,

�

!

.,

'

,

:

,

!-

-.�--

I

'

:

,I

I,

'

'.

"

,

.'

f,

7 !��f

l

��

�,

ll:

, I.

,�

,

�

,

!

0.001

10

100

Frequency, Hz

f

I� 13�

),

,

1000

FIGURE 13. WFPC PF VIBRATION TEST, FORCE V2 &V3 SUMMARY

1000

j. 4 i i i

: 1 j j j

l il l

·· ···· ···· ··· ··· ·········.........•....

�.............

.

. .

:

:

.l .... l . L

j j r f �1:

�....

...•.......

.

...

.

.

.

.

.

.

.

. l.

.. .....l..... .. ..

.... ..... .

..

.

,r",! !'! ! iii!

,

.

..

i.

.

.. ...

j. .

.

l

.

. .. . .. ..

�

i ...i..••�•..i.••••• •••••.•.••.••••

.... .

. l . j j �

1'1

,I

!

10

0.1

IIII Iii! ! 1,1 II

j .t .

Force Spec., A V3

. .

i

,

•

,

•

•

•

i,

:

, .

Force A V3 1917 Lbsrms

ir t

Force C V2, 99.2 Lbsrms

I: ::--111111!111 ........

·· ··..

0.001

·

·······

II

,

10

. . . .... ..+ ...

. .... .. .. .

-Force A V2, n.2 Lbsrms

:

�/JJ.l.I"'LrJt\�IIll�l .jJIII l :

!.

,i

..

i

:

"

!"

i

, .

100

Frequency, Hz

.,fi

' i '" i :

I

"

. ..

. .

J

1"

1\',1;' "" """ 1\

'

I.:

.

!\\'� ,! ." " "! l'l 1, � !'1\, I�'

i i . ! i\.

'I'�I

..

'

..

1

..

"

t"�

' lII\ ' i, i \, ,.

�"l

.

. ..

q:

�

,"

..

C i'

" ,

.............

,

.

1000

I

FIGURE 25. WFPC 2 AVERAGE PF ACOUSTIC INPUT, 4 MICROPHONES

STOP BND

43 BAND

B:STORED

._--

_••

d

���� [I

.

---

_

120

10

dB

100

90

P2470 26 Mar

_--_.

_.__

.-._--

_•.__

._-_

--�.

r--t

•

•

•

•

•

•

" rJ'

I

1"

"

.

•

"

.

•

"

.

"

.

.

"

"

.

.

.

"

•

"

�.

•

•

'I

•

t

- - -

'

•

I

.

lorv

_._.

10

1993

.

dBV

STATUS:

��....... .

.

.

.

---

-

_-,-_.•__

.

-:- -

-.

"'-".�.

... . . . .

.

.............................

•

.

.

"

.

.

.

"

.

.

.

"

•

.

.

"

"

.. .

.

"

.

"

"

"

"

.

.

"

.

.

"

.

.

"

.

.

.

"

.

"

.

.

.

"

"

.

"

"

.

"

"

.

"

"

.

"

"

.

"

"

.

.

"

.

"

"

.

"

"

.

•

"

. .

.

•

"

"

•

"

"

.

.

.

"

"

•

.

"

•

.

.

•

.

"

•

.

"

•

.

"

•

.

.

•

.

"

.

.

"

.

.

"

"

.

"

•

.

.

.

"

.

.

"

•

.

.

"

•

.

.

·

•

.

.

. ..

,,

.

.

•

.

.

.

.

.

•

.

•

.

.

.

,,

.

.

"

•

"

"

"

"

"

.

"

"

•

"

"

"

"

"

"

••_._

....

.

_.>' . •.

�.

.

•

•

.

•

-

'

'

--­

�

"

•

"

,,

.

"

·

•

"

,,

.

"

.

"

"

,,

"

"

"

"

•

,,

"

-

..

_

n

.

,.--..•

-,,-

"

.

.

.

.

.

-- �

. /__�

"

, .••.

.......

Sp8C1flcafIon

•

.

.-- .. -

___

.

--..

Lower Tolerance

.

.

____

\::._t:,

_

__

-

PAUSED

RMS: 12

.•-_

.••

.•.•. _•.

4 Mic Average...

130

RANGE:

"

·

•

..

,,

.

"

·

"

"

·

10

"

·

.

"

·

.

"

,,

.

"

·

.

.

,,

.

-,

.:..:...:.

"

.

.

"

,,

.

·

.

"

·

.

.

..

.

"

•

..

•

.

..

,

I

I

I

" .. \

I

"

I

•

.

,,

"

·

•

,,

•

,,

•

·

•

,,

•

•

•

•

"

•

•

!

... i

I

i

I

!

I

80

70

ST ART:

x:

i

. .. I

II

I

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

..

.

.

.

12-:5Hz ---- ,.-.--

RMS LEVEL

.

Y:

.

.

.

.

.

.

.

.

.

ANDS

B

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

."£ 1-43°··--------.. ·-·--'----·S"TOP: ····20-

147.73 dBSPL

.

.

.

600'

!,

Hz

i

WFPC 2 VS. WFPC 1 AVERAGE ACOUSTIC INPUT

150

I.I

.

140

m

'0

J

w

�.J

.

W

a:

�

Ul

Ul

w

a:

a.

o

z

�

�

130

120

--

110

WFPC 1 AVERAGE, 145.0 dB

- - WFPC 2 Average, 147.9 dB

100

90

1000

100

Freq, Hz

.

.

FIGURE 14. WFPC PF VIBRATION TEST, OPTICAL BENCH SUMMARY

,

i

,

/

I

�/!

.

l�

VI �;I

,

,

!

i

'\

i\

i,

�

,1.\'

I

_

.

!

!

\

,

I ..

,',�I

1

'�

"

1

�/'

n";

, �.

, [I

\' !

- -_

_

i

�:�i��":46:��S

1

i

I:

,

.�':

'

•

257V2, 1.0 grms

.•,

�: �

257V3, 1.5 grms

;' "

- - 258Vl, 1.8 grms

.'

!

� - 258V2, 1.0 grms

�+··r·+++-······-·---·+-······-+--·····'····�

t1:5 gnTIS ,.J

.r.'· "�,·+·····;-···+····!····f"-H··"'···············-:l

258V:t;

.

I�

•

•

•

•

•••• • • •

_

10

100

Frequency, Hz

1000

FIGURE 26. WFPC PF ACOUSTIC TEST, OPTICAL BENCH SUMMARY

f

,

0.1

,

. �:

1,'

i

)1,� �

�V

V

\.I

�

0.001

'-'-

F:i.

�

�

..... -

�'�f'J

.

. .

.

p.

i

�

:

" ' Y " \L .

'

!

i

,

'/, , "-

,

. !

i\

•

•

•

•

•••••••

1

.. � i \

i .'

·rI

257V2, 1.4 grms

,

,;

\.!

, ,

!

\

- -: 257Vl, 2.1 grms

Ii

i

:

,

M

:H

(

!

��

I

.

!

257V3, 1.5 grms

- - 258Vl, 1.8 grms

;

-6 - 258V2, 1.9 grms

-I- 258V3, 1.3 grms

, iii '1

10

�

,,'

/,

\

08 Spec., 6.3 grms

,

,

f

i;\

,

Nh

�", ��. "

V

2

g 1Hz

'\

II

i

100

Frequency, Hz

l,

,

,

1

1000

•

�

�

WFPC PF VIBRATION TEST, PYRAMID BULKHEAD & AFM SUMMARY

:

.

:

.

.

.

.

1

2

g 1Hz

0,01

0,0001

10

100

Frequency, Hz

1000

WFPC PF ACOUSTIC TEST, PYRAMID BULKHEAD AFM SUMMARY

0.1

V

2

'/

g 1Hz

i

i

,

,

�l';'

�

r'

,

•

.

1

·· ·

·····

" ""',,f'

,

;,

,

"

' '' ,

i

it".

" ,

'

,. "

" "

, ,

'}I

.

, �'

i'.

it"

+i. . .':... ... . . . +i.. .. . .. ii ... . . .. .

I

:

I:-+.++..!.

'

..

'\,

" 'l"• 'i

' '

',

'"

. . . ..

+.

. +...

H

,

"

, -

1,.

!i

--

"

,

•

•

.

"

. ': , .'

I'

.. 1

.

AFM, 5.0 gnns

- - 258Vl, 1.8 gnns

•

•

•

•

• • •• •

••

10

'

iIi' : : �/,��, :,,' :::

i

i �,I

:.

0.001

.

"i

258V2, 1.9 gnns

258V3, 1.3 gnns

100

Frequency, Hz

1000

I

1-:

FIGURE 32. WFPC PF ACOUSTIC TEST, MOLECULAR AD SORBER SUMMARY

10

IIII i

.

I ' II I

! .i ,

:

.

:

:

:

:

2

g 1Hz

0.1

,

0.001

'

j

i

�

'

i

!

II

i

iiii

i i

·.;·-·i-.··I·-l·-I·--_·.__·_.___;._··_··.··�··_·_..;···_·1-

11II1

10

I

-- Molecular Adsorber, 30.4 grms

- - 311Vl, 27.0 grms

\

.....

.

�.7 �s

ami,

100

Frequency, Hz

ii

...j...;

I!

....•..•..•.........

1000

VERIFICATION OF INSTRUMENT STRUCTURAL

INTEGRITY

1)

Visual inspection showed no failures.

2)

Pre and post low level sine vibration tests showed no change in the

3)

"frequency signature" of the instrument.

Short and long form functional tests indicate no problems with the

electronics or mechanisms.

>

I-

..J

-

m

<C

IC/)

Iz

w

�

z

(!)

-

..J

<C

..J

<C

0

I-

a..

0

LL

0

z

0

I<C

0

-

-

LL

-

a:

w

>

"t)

Q)

�

Q

..r::: .

(I) .....

�

� E:

� s:::

E:�

e (\l

:::Scs

�.�

Q) .....

E:§c:: Q)

.�

..... �

e.SE

:9(1)

:s

Q)

I t))

....

(I). c::

(\l

�-5

�cs

(\l. §

�.SE

ctE:

•

TEST VERIFIED FINITE ELEMENT MODEL

•

Sine vibration tests provided required data to produce a test verified

FEM.

I

First two modes of FEM must be within 10% of test results. (REF ICD-03F).

Mode

I

Frequency (Hz)

Description of Vibration Mode

Test

FEM

32.5

31.8

Instrument Yaw (V2)

2

33.0

35.3

Radiator/Housing Bounce (V1)

3

47.1

46.8

POM Arm Yaw

4

55.3

51.4

Optical Bench Bounce

5

64 0

63.0

Optical Bench Yaw

1

.

CONTAMINATION REQUIREMENTS

No Shedding of Radiator Zot Paint:

•

Witness plates were located both facing and beneath

the radiator during both the random vibration and

acoustic tests.

•

Inspection of the witness plates following the

vibration tests showed a negligible amount of

particles.

Housing Interior:

•

Inspection of the interior of the housing following all

dynamic testing showed an acceptable amount of

particulates.

CONCLUSIONS

All test objectives met.

1)

System structural integrity verified.

2)

Optical alignment stability verified.

3)

Test verified finite element model supplied to GSFC.

4)

Following revision of the molecular adsorber assembly test specification,

5)

all subassembly vibration tests envelope the system response.

Verified instrument meets contamination requirements.

WF/PC II Weight' And Center Of Gravity

Measurement Results

HST Coordinates

Center of Gravity

Weight (lbs)

V1 (in)

V2 (in)

V3 (in)

626.2.± 2.0

218.46.± 0.50

O.OO.± 0.02

-51 .06.± 0.04

WF/PC-2

Predicted

12/22/92

619.6.± 10.0

218.59.± 1.00

-0.92 .± 1 .00

-49.52.± 1 .00

WF/PC-2

Measured

5/13/93

6 18.4.± 0.8

Not Measured

- 1.21 .± 0.03

-49.48.± 0.04

WF/PC-I

•

•

•

•

--,

WF/PC II weight measured per JPl Procedure WF/PC II 140.

The following flight hardware items were missing and were weighed separately:

1) pickoff mirror cover, 2) light shield, 3) non-flight top cover Mli.

The following non-flight hardware items were included in the measurements and were .

weighed at a later date:

1) optical bench TVT instrumentation, 2) lifting hardware, 3) flight top cover Mli.

Weight and C.G. calculations to be documented in an interoffice memorandum.

Wide Field Planetary Camera - 2 .

Pre-Ship Review

Thermal Vacuum Test

Summary and

Results

David Gallagher

JPL

May 27,1993

JPL

[ AGENDA]

•

TV TEST SUMMARY

•

AS-RU N TEST TIMELIN E

•

CONCLUSION

•

•

•

•

•

POWER PROFILE - D. ROCKEY

THERMAL PERFORMANCE - R. GARCIA

OPTICAL ALIGNMENT - S. MACENKA

SCIENCE CALIBRATION/CHARACTERIZATION - J.TRAUGER

CONTAMINATION - J. SCOTT-MONCK/D. TAYLOR

Dave Gallagher May 27, 1993 Pre-Ship Review

JPL

•

[-- SUMMARY ]

TEST COMPLETED IN 31 DAYS

- 5 DAYS HOT SOAK

- 6 DAYS HOT ORBIT

- 9 DAYS NOMINAL ORBIT

- 5 DAYS COLD ORBIT

•

12,800 FRAMES OF SCIENCE DATA

•

275,000 GALLONS OF LN2

•

CHAMBER/FACILITY SUPPORTED TEST

WITH NO SIG N I FICANT PROBLEMS

Dave Gallagher May 27. 1993 Pre-Ship Review

JPL

•

•

[

SU

IV!��RY

]

COMPLETED ALL PLANNED TESTS PLUS

SEVERAL ADDITIONAL TESTS DEFINED

DURI NG TV

1770 ANTICIPATED EXPOSU RES VS. 3200

EXPOSU RES RECORDED

Dave Gallagher May 27, 1993 Pre-Ship Review

JPL

•

•

•

[ . SU IV!��RY .)

DEMONSTRATED INSTRUMENT

PERFORMANCE AT 24,28, 32V I N

HOT,NOMINAL AND COLD ORBIT

CON DITIONS

VERIFIED ALL MECHANISMS INCLUDING

FAILSAFES

PERFORMED CCD DECONTAMINATION

Dave Gallagher

May 27, 1993 Pre-Ship Review

JPL

•

•

•

•

[

SU

���RY

]

PERFORMED POWER PROFILE TEST AT

EACH ORBITAL CONDITION

VERIFIED I NSTRUM ENT PERFORMANCE

FOLLOWING FA COLD EXPOSU RE

DEMONSTRATED I NSTRUMENT THERMAL

BALANCE

DEMONSTRATED INSTRUMENT M ET

OPTICAL BENCH STABILITY

REQU I REMENT

Dave Gallagher May 27, 1993 Pre-5hip Review

I

.J

11

I

-

I

-

w

z

..J

W

:!1

-

I-I-­

CIJ

W

I-Z

�

a:::I

CIJ

<C

,

TEMP

•

•

�

�

...

o

(J)

o

_I

.

Close Door

I

i

co

0>

'<

'"

en

:T

a

f

;u

0>

0en

:T

a

t

"

0>

<0

co

�

Jg

en

:T

a

I·

t

C'l

C'l

0

-i

POM Slep ,

lence

Power Profi

fortoqe Margin

fA Hoi

fun

3

t

I

Jg

�'"

" '"

""

,

CO

o

o

o

I\J

o

ification

In-Boy fun

,01

a

1

•

I\J

o

;*

Z

I

•

J.

Cl

<'l

Turn On T[,

Oecomlominotion 61

Heoler Mo

loltoge Uorqin

�

�

�2!

::!

0

z

Heater 1.40

Decontamination

?(

12

�

0

-

i3:

�

r

Imoge 510

Healer Mor

Power Pro:

I

:

""

•

•

•

•

n

lability

Shroud

C'l

0

(if "Qd)

i

g

�

----

�

-u-

I

I\J

'"

PI-

CCO 51, Iflity

I

Q'"

Z

<'l

'"

n

�

� :E

�::! ��

"

-n

o

Z

-i

�I

Linearity

O[H

>

r-

Reciprocily

AlIGNM[NT

Stim Slob

iii

s:

Col Repeal

f�ls

O[

i

c:

0

•

Sel

Shoding

Romp

Decontamination 63

Image

All

J

*

J.

J.

fAColdfu

Mol

CCO Sel PIceo

ifcl

I�

•

•

ep

Stim (xp

.",

0>

r:

Crude Aligr

0

..

�

Slimulus Te� s

•

•

I

•

I

•

I

J

3

L5:

:l

1

*

Z

I

SOfA Pori

I

+

t

J

�

Image 510

�wer Pro

11

•

I '

'"

•

I

'"

'"

Z

'"

'"

-.l

Vi

•

z

Cl

...

o

'"

a

o

.

,

"

Power Pro

;,.

•

(J)

o

I

-L

-',

(C)

.ns SOfA)

Aft Shroud

Break Vow

��

�

Desorb COC

co

"C

•

�

•

j-

iii

s:

"

m

;U

>

-i'

C

;U

m

;U

0

-n

r=

m

"

Woocs

NB fillers

Pholomeh)

�

�

a

W

'"

WING

�

��

c

c

�

K-Spols

Buyaff Images

-i

I

m

(J

CD

X

.C'l

40

20

0

-20

�

-

-40

11.

-60

w

�

-80

:;

WF/PC-II

HOT SOAK

� � ��v.

/,--,

,\

f-

�"\

AS RUN THERMAL-VAC TEST

�.�

�

,

j� . ..

HOT R IT

l• ••

25

�"". '1.

r if

..-

NOMINAL ORBIT

COL PRBIT

-----

-100

-120

�

-

;;;;.

z

z

i

�

lj;

,.

�

Q

-140

§

§

-160

3

35

I'

�

z

i

,.

8

DAY

•

Bay 5 Shrd

---0-- Rad Shrd

•

Hsg Shrd

--<>-- CCO Temp

•

Hgs

5121193

TVA::',-. .JNXLS

Test

No. Test Phase

1 Start

WF/PC-II As Run Test Sequence (5/21/93)

Test

Engineering Test Description

Bay Rad

Hrs

Hsg

CCD

Hrs Cum Day Shrd Shrd Shrd Temp

6.8

Start pump-down/back fill sequences

0

0

0

20

Hgs

20

20

20

20

Note and/or Science Test Description

20

2 Transition

Change Shroud Temperatures

9

0

0

25

25

3 Transition

Change Shroud Temperatures

11

0

0

30

30

30

25

4 Hot Soak

Start of Hot Soak +35 C (htrs, electronics on)

27

1

10

35

35

35

28 SOFA Open, Shutter Opened at 16:45, Bay 5 to +40

5 Hot Soak

POMM step sequencing (full range)

3.8

50

2

5

28

28

28

34 SOFA remaining below +35 C

6 Hot Soak

Long Func. both bays no SOFN AFMslTECs

3.1

58

2

2

28

28

28

35

V)

1 .2

72

3

2

30

30

30

35 Mod Funct. Test: No SOFA, AFM 0 V, Bay 5 at +44

0.4

106

4

2

28

28

33

35

28

28

33

35 AFM Electronics On, Stim Radiometry Various Filter.;

-30

-30

20

30

End Hot Soak - Start Transition to Hot Orbit

Aft Shroud Certification Complete

7 Hot Soak

Power ProfileNoltage margin (+32, 28, 24

8 Hot Soak

Verify RAM

9 Hot Soak

CaCM Data Verifies Ready to End Hot Soak

121

5

2

1 0 Transition

Lowered Housing Shrd Temps, End Hot Soak

151

6

-15

1 1 Transition

Aft Shrd (htrslelectrslAFM

1 2 Transition

1 3 Transition

1 4 Transition

(OV) On, TECs Off)

.

In-Bay Functional Test (SOFNAFMITEC Off)

End Transition from Hot Soak - Start Hot Orbit

1 5 Hot Orbit

7.0

151

6

-30

-30

-30

20

28

155

6

-50

-30

-30

20

23 Cal SIS On (Incandescents lamps only), HJ-2 failure

1 .7

159

7

-65

-30

-30

-20

20 Emulates On-orbit In-Bay Conditions

5.8

161

7

-65

-30

-30

-20

20

5.2

167

7

-65

-55

-5

-20

1 5 Stimulus Focus!Aberration Verification

End Transition from Hot Soak - Start Hot Orbit

1 6 Hot Orbit

3.6

1 72

7

-65

-55

-5

-20

20 Image Stability/Icing -32 C

1 7 Hot Orbit

3.1

1 79

7

-65

-55

-5

-20

1 4 Stimulus Characterization Test

1 8 Hot Orbit

1 9 Hot Orbit

20 Hot Orbit

CCD set point control (TECs off)

21 Hot Orbit

1.1

183

8

-65

-55

-5

-20

1 4 Crude Alignment (Test Abort: Stim Focus Problem)

7.5

184

8

-65

-55

-5

-20

14 Resume Stimulus Characterization Test

2.0

194

8

-65

-55

-5

-20

14 CCD Perf 1 st four set pts (-22 C, -32 C Obtained)

3.4

196

8

-65

-55

-5

-20

1 4 Vibration Environment Test

22 Hot Orbit

1.0 200

8

-65

-55

-5

-20

1 4 UV Calibration Channel Retest

23 Hot Orbit

1 .4 201

8

-65

-55

-5

-20

1 4 CCD Perf 1 st four set pts

24 Hot Orbit

0.5 202

8

-65

-55

-5

-20

1 4 Crude Alignment (Fine Focus)

25 Hot Orbit

1 .9 206

9

-65

-55

-5

-20

1 4 Image Stabilityllcing -32 C

26 Hot Orbit

27 Hot Orbit

CCD set point control (TECs on)

28 Hot Orbit

CCD Decontamination #1 (CCDs at 22 C)

16.4 208

9

-65

-55

-5

-20

1 4 Reverify CCD Perf set pts (-43 C , -52 C Not Obtaine

1 0.6 225

9

-65

-55

-5

-78

1 4 CCD Perf 2nd four set pts (-72 C, -78 C, -84 C , -90

14 CCD Calib Thermal Stability (includes 7 hr decontam

9.5 239

10

-65

-55

-5

22

3.1

248

10

-65

-55

-5

-78

1 4 Reverify CCD Perf set pts (-72 C , -78 C)

12.6 252

11

-65

-55

-5

-78

1 4 Short Term Monitor

1 .3 265

11

-65

-55

-5

-78

1 4 Shutter Shading Test

32 Hot Orbit

1 .9 266

11

-65

-55

-5

-78

1 4 Basic Function o f Both Bays

33 Hot Orbit

13.6 268

11

-65

-55

-5

-78

1 4 Light Transfer Test

34 Hot Orbit

3.8 282

12

-65

-55

-5

-78

1 4 Linearity Test

35 Hot Orbit

4.6

12

-65

-55

-5

-78

29 Hot Orbit

30 Hot Orbit

31 Hot Orbit

Heater duty cycle 25% (32

V)

285

Page 1

1 4 Short Term Monitor caE & contamination)

TVA� IN.xLS

.

.

Page 2

TVAb, .IN.xLS

•

WF/PC·" As Run Test Sequence (5/21/93)

Test

No. Test Phase

71 Nominal

Engineering Test Description

Problem with TQCM #2

Test

Hrs

Bay Rad

Hsg

CCD

Hrs Cum Day Shrd Shrd Shrd Temp Hgs

5.8 445

19

·95

·70

·17

·78

Note and/or Science Test Description

1 2 Long Term Monitor

72 Nominal

0.8 451

19

·95

·70

·17

·78

1 2 Crossed Ramp + Narrow Band Fitter

73 Nominal

0.7 452

19

·95

·70

·17

·78

1 2 Photometric Stability over FOV

74 Nominal

1 .1

453

19

·95

·70

·17

·78

1 2 Crossed Ramp + Narrow Band Filter

75 Nominal

7.2 454

19

·95

·70

·17

·78

12 Mission Simulation Photometry

9.0 462

19

·95

·70

·17

22

77 Nominal

2.0 471

20

·95

·70

·17

·78

78 Nominal

6.0 473

20

·95

·70

·17

·78

1 2 Far U V Diversity Test

79 Nominal

3.9 479

20

·95

·70

·17

·78

1 2 Verify CCD Perf set pts (-43 C , ·52 C Obtained)

80 Nominal

3.2 483

20

·95

·70

·17

·78

·78

76 Nominal

CCD Decontamination #2 (CCDs at 22 C)

81 Nominal

4.2 486

20

·95

·70

·17

82 Nominal

6.0 490

20

·95

·70

·17

·78

12

CCD Decontamination #2 (CCDs at 22 C)

1 2 Icing/Contamination Test

1 2 UV & Woods Filter Verification

12 Mission Simulation Photometry

1 2 U V Flat & Cal Channel Consistency

83 Nominal

4.4 496

21

·95

·70

·17

·78

1 2 Filter VerificationTest

84 Nominal

0.2 501

21

·95

·70

·17

·78

1 2 UV Flats/Cal ConSistency .

85 Nominal

3.4

501

21

·95

·70

·17

·78

12 2x2 Verification

86 Nominal

4.3 505

21

·95

·70

·17

·78

1 2 Filter Ghost Test

87 Nominal

2.2 509

21

·95

·70

·17

·78

1 2 Ramp Filter Calibration Test

·78

1 2 SOFA Clear Sensors Anomaly Test

88 Nominal

0.6

512

21

·95

·70

·17

89 Nominal

10.3

51 3

21

·95

·70

·17

·78

1 2 Ramp Filter Calibration Test

90 Nominal

0.4

523

22

·95

·70

·17

·78

1 2 Polarization Quad Flats

91 Nominal

6.2 524

22

·95

·70

·17

·78

12 NB Filter Thruput (subset of filters)

92 Nominal

1 .5 530

22

·95

·70

·17

·78

12 SOFA Clear Sensors Anomaly Test

532

22

·95

·70

·17

·78

12

Power Profile

532

22 ·150

·85

·22

·78

10

End Nominal Orbit - Start Cold Orbit

93 Nominal

94 Transition

Power Profile

1 .2

Shrouds for Cold Orbit (Switch to Primary Elect)

95 Cold Orbit

0.1

533

22 ·150

·85

·22

·78

1 0 Icing/Contamination Test

1 0 Short Term Monitor (contamination)

96 Cold Orbit

4.3

534

22 ·150

·85

·22

·78

97 Cold Orbit

7.6

538

22 ·150

·85

·22

·78

1 0 Cal Channel High Priority Flats

98 Cold Orbit

0.3 546

23 ·150

·85

·22

·78

1 0 Icing/Contamination Test

99 Cold Orbit

9.3 546

23 ·150

·85

·22

·78

1 0 Far UV Diversity Test

100 Cold Orbit

5.2 556

23 ·150

·85

·22

·78

1 0 Long Term Monitor

101 Cold Orbit

2.9 561

23 ·150

·85

·22

·78

1 0 AFM Grid Test/Alignment Test

·85

·22

·78

10 Photometric Stability over FOV

1 02 Cold Orbit

2.0

564

24 ·150

1 03 Cold Orbit

3.0 567

24 ·150

·85

·22

·78

1 0 Cal Channel High Priority Flats

1 04 Cold Orbit

2.9 570

24 ·150

·85

·22

·78

1 0 Quad Flats

105

3.5

573

24 ·150

·85

·22

·78

1 0 Peak TransmiSSion of Wide Band Flats

&old Orbit

Page 3

TVA::.. ,.JN.xlS

Page 4

TVAb"....N.xLS

WF/PC-II As Run Test Sequence (5/21/93)

Test

No. Test Phase

Engineering Test Description

Test

Bay Rad Hsg CCD

Hrs

Hrs Cum Day Shrd Shrd Shrd Temp Hgs

Note and/or Science Test Description

141 Warm-up

0.6 685

29 -100

-85

-35

2 SOFA Wheel 7 Homing Phase Characterization Test

142 Warm-up

685

29 -100

-56

-85

-35

-56

2

Set Voltage to +32 V

145 Warm-up

1 .4 690

29 -100

-85

-35

-56

-56

-56

146 Warm-up

9.0 692

29

-30 -100

-10

-56

147 Warm-up

704

29

-20 -100

-56

16

148 Warm-up

713

30

0

-56

22

149 Warm-up

2.2 713

30

o -105

o -105

-1 0

0

-56

20 Basic Functionality

1 50 Warm-up

715

30

0

-85

0

-56

19

Set Voltage to +28 V

151 Warm-up

71 5

30

0

-85

0

-56

19

Resume Warm-Up Sequence

143 Warm-up

1 .5 686

29 -100

-85

-35

144 Warm-up

2.1

688

29 -100

-85

-35

2 Schedule Test

2 SOFA Spin Wheel 6 Test

4 SOFA Ten Filter Shuffle Test

8 SOFA Homing Phase Characterization Test

1 52 Warm-up

716

30

0

-80

0

-70

21

1 53 Warm-up

716

30

0

-75

0

-65

21

1 54 Warm-up

716

30

0

-70

0

-60

155 Warm-up

717

30

0

-65

0

-55

1 56 Warm-up

717

30

0

-60

0

-50

1 57 Warm-up

717

30

0

-55

0

-45

158 Warm-up

718

30

0

-50

0

-40

23

22

22

22

22

718

30

0

-45

0

-35

23

160 Warm-up

719

30

0

-40

0

-30

24

161 Warm-up

720

30

0

-35

0

-25

24

162 Warm-up

721

30

0

-30

0

-20

25

163 Warm-up

723

30

0

-25

0

-15

26

164 Warm-up

724

30

0

-20

5

-10

28

165 Warm-up

726

30

0

-15

5

-5

29

166 Warm-up

727

30

0

-10

5

0

30

167 Warm-up

728

30

0

-5

5

5

31

168 Warm-up

728

30

0

0

5

10

31

169 Warm-up

729

30

0

5

5

15

27

10

26

20

159 Warm-up

.

170 Warm-up

730

30

0

5

26

171 Warm-up

730

30

20

20

26

26

172

732

30 OFF OFF OFF

26

26

End

Prepared 5118/1993

Page 5

Set Voltage to +24 V

End

JPL

•

•

•

[ CONCLUSION )

HOT JUNCTION 2 THERMISTOR PROVI DED

ANOMOlOUS DATA ( POSS.

DELAMI NATED)

U NABLE TO MAINTAIN BENCH > 10 deg C

@ COLD ORBIT/24V CONDITION

PASSED AFT SHROUD CONTAMI NATION

CERTIFICATION

Dave Gallagher May 27. 1993 Pre-Ship Review

JPL

[ CONCLUSION]

CONT.

•

SOFA· POSITION ANOMALY DIAGNOSED

AND RESOLVED VIA RAM PATCH

- RAM PATCH INCREASED

PHOTODIODE SAMPLE DELAY TIME

- TESTED AT BOTH COLD ORBIT,

NOM. ORBIT AND AM BIENT

•

WF/PC-2 QUALIFIED THERMALLY,

ELECTRICALLY, AND OPTICALLY

Dave Gallagher

May 27. 1993 Pre-Ship Review

JPL Integration and Test

WFPC-2 Test & Burn-in Hours

1 08.4 % . . . .

-

100%

-

. .

.

.

.

. - .-.,.-. - .-. - .- . . - . -. - .- . -.-- . -_ . . .

----

75%

----

50%

----

25% ---0%

----

Updated 5/21193

1 626 Hours

as of May 1 9 1 993

------l1 1500

hours

1125

---- 750

(GOAL)

I

Hours

Hours

375

Hours

306 Hours Bay 1 Rework

o Hours

WF/PC-2 PRE-S H I P REVIEW

WF/PC TEM P E RATUR E CONTROL

R. D. GARCIA

MAY 27, 1 993

WF/PC-2 PRE-SHIP REVIEW

A NALYTICAL APPROAC H

o

C O R R E LATE TH E R MAL A NALYTICAL MODEL WITH THERMAL BALA N C E T E S T R E S U LTS

A DJUST F O R TEST S ET U P

NOT P E R FECTLY BLACK S H ROU DS

CQ CM H EAT EX CH AN G ER ON S LANT PLATE

ISOTH ERMAL S H ROUDS COMPARED TO ICD D ISTRIBUTION

ADJUST FOR ADDITIONAL HEAT LEAKS

H O U S I N G BLANKET 1 5 LAYERS EMBOS S E D KAPTON

CAL SS S U P PORT BRACKET A N D CABLES EXPOS E D

BLiN DMATE C O N N ECTOR a n d CABLES N O T COVE R E D A S O N WFPC-1

o

U S E CORRE LATED MODEL TO MAKE FLIGHT P R E D ICTS

WFPC-2 P R E -S H I P REVIEW

"'OMPARISON OF S H RO U D TEMPERATU R E S WITH ICD S I N K TEMPERATURES

aST CCR 3364

PIRN 3 "195

P.age 6 ,,! 6

/

-Y2

-Y1

WF/PC

Shroud & Fixture

Thermocouples

1

l. 27

:/i········:··_-\

0:

33

.

.

o

<8> /

o ...-

.

32 ....

31

..:

:0

30

\"ig,:;\ .

\ <5> ;

\ 10'9:""

-:

••.•....

'\ '\o�

.

29

.

\\;/. ....

26

\'�P17 \'''25

.

• TC in View

r) TC out of View

.')

'

ContrOl Circuit

Designation

D.PERRY MAY29.1992

•• "

'-'

'''

'

' \_

WFPC -1 OBSER'

29

�

061 1

....,

.

.. _

_

. _

•

•

, VOLTAGE PROFILE

Month and Day,

0 61 1

061 1

30

_ 1 . 11

1 990

061 1

06 1 2

\.

-

1\

06 1 2

V

'\

I/)

:::J

'iii

�

,

06 1 2

\

28

f

.2

�

8.

E

�

27

26

•

�.-

25

1 62.0

MSID

M021

1 62.2

1 62.3

1 62 �5

Day of Year,

Name

VOLTSA

Subtract 1 .2 valls for losses to instrument.

1 62.7

1 99 0

j

1 62 .8

1 63 .0

WFPC-2 P R E S H I P REVIEW

T E MPE RATU R E CONTROL S U MMARY OF TEST R E S U LTS

o

O PTICAL B E N C H TE M P E RATU R E CONTROL

STABIL ITY ACCE PTABLE

H EATER D UTY CYCLE H I G H

27% I N H O T O R B I T 3 2 VOLTS

80% IN NOMINAL O RB IT 28 VOLTS

1 00% IN COLD O RBIT 28 VOLTS

, , , f!� ,

I :" @o�

041 2

40.0

041 4

041 6

, J:,:!�

35.0

,

041 8

"-

'

0420

"

,

0422

0424

,U

m- rurt .. !'

�

MONTH AND DAY

0426

0428

0430

32\1

NOM/N. L

I

OR

,

0502

I,

, ,

0504

0506

I

eo

0508

D oet, 1

r --j �

..

:i..

€.

�..

051 4

un Lll

TD II�&IE"r

-

I 2 11 �

z sv

I}

20.0

d

1 5.0

�

D-

E

�

0512

f-

t)

::J

�.

�

30.0

25.0

051 0

1 0.0

"

-......

I-

A

""

5.0

-

0.0

-

V

-5.0

-1 0.0

1 02

1 04

106

1 08

1 10

112

114

,

116

1 20

118

DAY Of YEAR

o BCH PYR

[] BCH CH

.Il.

BCH fM

1 22

1 24

1 26

1 28

-'-

1 30

-'--'-

1 32

1 34

93102 1 65400

0412

1 .00

0.90

0414

041 6

041 B

0420

, , ,

0422

, , ,

0424

, , ,

, ,

MONTH AND DAY

0426

042B

0430

,

0502

0504

0508

0506

051 0

"

0.60

V

0.50

.......

u

'"

.,

c

t

'"

f

.;:!

�

.,

Q.

E

.,

....

051 4

::

:

�

0.70

0

I

,

E

O.BO

..

:::J

051 2

E

0.40

�

I::

0.30

�

F

0.20

I::

0. 1 0

0.00

-0. 1 0

-0.20

-0.30

-0.40

-0.50

-0.60

-0.70

-O.BO

-0.90

I'

�

I::

-

"

r

r

-�

V

M.....

A. A

r- yv

nIlv vf> ..."

A

.-....

..

vv

.A

\."

'.

A

ftv V' �

_w

W1

:

/\

'"

�

�

�

:

I::

:

E

�

f

E

-1 .00

1 02

II

,

1 04

1 06

1 08

-

, ,

1 10

112

114

116

118

DAY OF YEAR

o DB FM

1 20

1 22

1 24

1 26

1 2B

1 30

1 32

1 34

93102 1 65.400

WF/PC-2 P R E-S H IP REVIEW

T E M P E RATU R E CONTROL S U MMARY OF TEST R E S U LTS

o

E LECTRONICS

INTERNAL (BAYS 1 -4)

C O NTROLLED BY H EATERS CYCLING

BA Y 3&4 LOCALIZED H EATING

BAY 5

TEST I N C L U D E D H A N D HOLD STUDS

SA F I N G TRAN S I E N T S IM ILAR TO WF/PC-1

D U R I N G HOLD MODE MARGINAL AS EXPECTED A N D S IMILAR TO WF/PC-1

o

CALIBRATION SYSTEM

A F F ECTS TEMPERATU R E OF OPTICAL BEN CH DURING LONG E R EXPOS U R E S . R EQ U IRES 24

H O U R O F F TIME TO F U LLY R ECOVER

041 2

40.0

0414

" '

35.0

fj

30.0

041 6

j�

041 8

..!seAl!..

'

0420

'L '

I

�

0422

t.40NTH AND DAY

0426

0428

0430

0424

.

uin-' t �/7: '

�,

,

.

.lz. V

0502

0504

�, "I. /SIT ·

NOH

0508

0506

OLD ('.

I

051 0

051 2

051 4

W 7f>

£&/7'+! I UTi

�H lENT"

I 2 !lV

•

-

:

I Z<,I

-

25.0

�

20.0

1 5.0

f

.2

I!

1 0.0

E

�

5.0

..

e

t>

�

..

D-

0.0

�l-

-5.0

e

:

.. �

..

.2

:

:

tr......

l

I ...

I

.

1

:

- 1 0.0

-1 5.0

/

:

:

�I-

-20.0 ,

1 02

:

-

,

,

,

1 04

,

,

,

1 06

,

,

,

1 08

,

,

,

1 10

,

.

,

1 12

,

,

,

1 14

,

,

,

1 16

,

,

,

118

,

,

,

1 20

DAY OF YEAR

o BAY 1

,

,

,

1 22

.

,

,

1 24

,

,

,

1 26

.

.

.

1 28

.

.

.

1 30

.

.

.

1 32

.

.

1 34

93102 1 65400

MONTH AND DAY

041 2

50.0

45.0

041 4

�r

40.0

35.0

30.0

co

.�

�

t

25.0

.i!

�

20.0

E

�

1 5.0

..

a.

041 6

1

0418

,

,

�

0420

0422

0424

0426

,

,

,

0428

,

,

,

0430

,

,

,

0502

,

,

,

0504

,

0506

,

,

0508

,

,

,

0510

,

,

,

051 2

,

,

,

051 4

,

'

\In

.

·

·

·

·

·

·

�r

·

·

·

·

·

r

-

�

-,-

I-

-

1

-

1-II

�

-

-

-

-

1 0.0

-

-

5.0

-

0.0

-

�

-5.0

- 1 0.0 ,

1 02

,

,

,

1 04

,

,

106

,

1 08

,

,

,

,

,

,

1 10

1 12

,

,

114

_1

"

1 16

,

,

1 18

,

,

,

1 20

DAY Of YEAR

o BAY 3

o BAY

4

,

,

1 22

,

1 24

,

1 26

-

,

1 28

1 30

1 32

1 34

93102 1 65040D

WF/PC-2 P R E -S H I P REVIEW

LOCATION OF BAY 3 A N D 4 TH E R M ISTOR A N D HEATER

THIER. M I 5 il'R

HEATER.

'9&

-. .

� ' ''.oo::.�

.......

� ,.t!�_&

til}

+

-.

•

- ..

•

'}

I • .-00£

� ..::\..... ...

.. &

� &.�t

...-

�.

!!:

r.:

•

'

�}

MI....

�.

,,)}.�

;7)

-

;

0

��

•

••

e

�&

0

--

s=

.. ' '-T-'

r ��

��1�-