Engineering in Urban Ecosystems

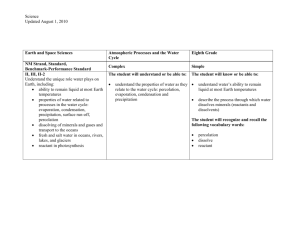

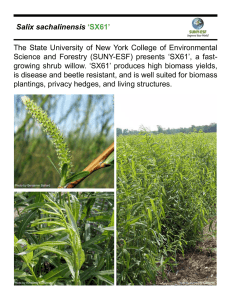

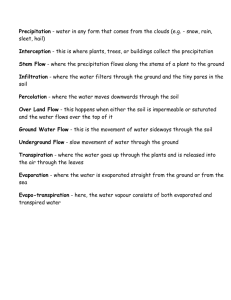

advertisement

Engineering in Urban Ecosystems Perspectives on Engineering using Natural Systems Douglas Daley, P.E. Environmental Resources and Forest Engineering SUNY College Environmental Science and Forestry Objectives Describe natural resource / ecological engineering Relate cases of integrating natural processes within urban context What’s an Engineer? Engineer : Design: a creator, a problem solver, more than applied science a creative, intuitive, iterative, innovative, unpredictable process of developing a solution Ecological Engineering: design of sustainable systems that integrate human society with its natural environment. Themes Ecological Engineering and Sustainable Development share a common philosophy Use development practices that support a sustainable world with high quality of life. Implement engineering practices that protect and enhance the ability of ecosystems to perpetuate themselves while continuing to support humanity. Ecological Engineering Harnesses the self-organizational properties (complexity, diversity) of natural systems. Adds the element of societal interaction with existing ecosystems (beyond created or restored ecosystems) in built environments. Derives benefit from ecosystem. Principles of Ecological Engineering Energy Signature Self-organization Eenrgy sources that determine ecosystem structure Selection processes by which ecosystems emerge (seed dispersal, animal migration, etc) to determine species composition, abundance and network connections Preadaptation Fortuitous adaptation by an organism to an entirely different set of environmental conditions Engineers Can use Nature in Urban Environments Energy Management Water Quality and Quantity • Stormwater pollution Land Resource Abandoned or contaminated sites • Landfills • Brownfields Bioremediation and phytoremediation Context of a Type II Ecosystem Energy and limited resources Type 2 systems evolve to reduce waste generation, improve energy utilization Semi-cyclic Resource limitations exist Greater efficiency than Type I Unsustainable in long term Increasingly representative of industrial models in late 20th century Limited Waste Project Case Study: Solvay Waste Beds History Local Industrial Legacy Soda ash manufacturing using the Solvay process (1887 – 1986) Raw materials locally available Solvay Process Company Facility and Erie Canal, early 1900s limestone, brine (NaCl) and water 1907 – Solvay began operation of settling basins along Onondaga Lake Process residues discharged as a slurry (5% solids) Solvay Process Residues Solvay process to produce soda ash 1887 -1986 Primarily a non-hazardous mixture of calcium, magnesium and sodium compounds Waste Beds 9 to 15 15 to 21 m deep 270 ha (662 acres) Elevated chloride levels in leachate and stormwater Stressful growing conditions pH (8.0 – 12.3) Electrical conductivity (0.5 – 9.2 dS/m) Organic matter (0 - 3.9%) Project Site Location Syracuse, NY N 43o 04’ 26” W 076o 14’ 58” Water Movement in Wastebeds PPT = (E + T) + RO + DS + D Provided by Honeywell and O’Brien & Gere Engineering Issues Mandate: Protect Public Health and Environment Management Choices: Treat residuals and byproducts (end-of-pipe) Prevent generation Existing Problem Transport mechanisms • Leachate, erosion (wind and water), contact Solutions? • Barriers, diversions, capture and treat Concept Develop end use options that substantially reduce percolation Develop end use options that result in environmental and community benefits and economic development Integrate engineering, forestry, landscape architecture to increase public awareness of environmental quality issues, improve wildlife habitat, provide recreational opportunity Proposal Design and cosntruct an enhanced evapotranspiration landfill cover system Reduce percolation into settling basin Provide biomass resource for energy conversion Provide wildlife habitat Restore damaged salt marshes Add recreational activities Capture nutrient and carbon resources from biosolids and woody residuals generated in urban environment Benefits Improvement of soil and water quality • Willow promotes evapotranspiration, which reduces percolation and minimizes leachate generation and chloride loading • Willow is a perennial crop with low erosion potential and the ability to increase soil C levels Improvement of biological and landscape diversity • Bird diversity in willow crops is the same as in natural shrub lands Maintenance of productive capacity • Willow yield has been shown to increase from the first to second rotation and is maintained in subsequent rotations Enhancement of regions contribution to global C cycles • No net addition of CO2 to the atmosphere Economic development • Willow has a short supply chain so it is produced and used in a community, circulating dollars through the local economy • Enhances momentum in local renewable energy initiatives Key Design Considerations Optimizing soil conditions to maximize rooting depth and soil moisture storage capacity Site grading and storm water management Seasonal storage within wetlands and settling basins Willow crop rotation and management procedures WATER Engineering Design Criteria What makes a design “good?” Works all the time Meets all technical requirements Meets Code requirements Requires little or no maintenance Is safe Creates no ethical dilemma Recall “preadaptation” Salix and Populus the first woody species to establish naturally Tolerant of harsh site conditions on site (elevated chloride and pH) Recall the Naturally established willow and poplar on the Solvay waste beds. Landfill Cover Systems: Conventional vs. Evapotranspiration Reduce percolation (leachate) Conventional systems rely on low permeability soil and geomembrane Alternative systems enhance evapotranspiration Issue: Long-term reliability, flexibility, sustainability Amended waste material A conceptual model of the water balance and hydrology of energy crops (Mirck 2008; Stevens 2001) Field Performance – Soil Barriers Climate Construction materials and quality Design: Growth and Yield Field Trials Two 2-acre fields (2004) Multiple Salix varieties selected from greenhouse trials (2003) Two cutting lengths to test rooting depth and survival (25 and 50 cm) High planting density First-season’s growth of willow on biosolids-amended Solvay waste (Fall 2004) biosolids-amended (1986) unamended Solvay waste 15,000 stems/ha (6,000 stems/ac) Willow Variety SX64. SX61. SV1. S365. 9882-34. 9871-31. 9871-26. 9870-23. 9837-77. 98101-66. SX64 SX61 SV1 S365 9882-34 9871-31 9871-26 9870-23 9837-77 98101-66 Biomass (odt ha-1 3-yr-1) 50 25 cm cuttings 50 cm cuttings 40 30 20 10 0 Today’s view Simultaneous Heat and Water (SHAW) Model Humid climate 30-yr Average Annual PPT = 978 mm PET:P = 1.3 Model simulates heat and water transfer through soil-plant-air continuum Management • Salix as short-rotation woody crop (SRWC) • Part 360 Conventional Cover (Figure supplied by USDA) Year 1 New Planting Percolation & Precipitation (2008) 10.0 0 9.0 5 10 7.0 15 6.0 5.0 20 4.0 25 3.0 30 2.0 35 1.0 0.0 8210 8230 8250 8270 8290 8310 Julian Date yddd (beginning 7/29/08, ending 12/16/08) 8330 40 8350 Precipitation (mm/day) Average Evacuation (mm/day) 8.0 PLOT A1 PLOT A2 PLOT B1 PLOT B2 Preci pi tatio n Year 2 (2009) after coppice Percolation & Precipitation (2009) 10.0 0 9.0 10 20 7.0 30 6.0 5.0 40 4.0 50 3.0 60 2.0 70 1.0 0.0 9070 9090 9110 9130 9150 9170 9190 9210 9230 Julian Date yddd (beginning 3/11/09, ending 9/27/09) 9250 80 9270 Precipitation (mm/day) Average Evacuation (mm/day) 8.0 PLOT A1 PLOT A2 PLOT B1 PLOT B2 Preci pi tation Cumulative Precipitation & Percolation (2008) 400 350 Precipitation & Percolation (mm) 300 250 Cumulative Precip Perc Plot A1 200 Perc Plot A2 Perc Plot B1 Perc Plot B2 150 100 50 0 8200 8220 8240 8260 8280 8300 Julian Date yddd (beginning 7/29/08, ending 12/16/08) 8320 8340 8360 Cumulative Precipitation & Percolation (2009) 600 500 Precipitation & Percolation (mm) 400 Cumulative Precip Perc Plot A1 300 Perc Plot A2 Perc Plot B1 Perc Plot B2 200 100 0 9060 9080 9100 9120 9140 9160 9180 9200 9220 Julian Date yddd (beginning 3/11/09, ending 9/27/09) 9240 9260 9280 Material and methods Total of 18 sensors used Five sensor sizes: 10mm, 16mm, 19mm, 25mm and 35mm Hourly sap flow data collected (g/h) Final output: sap flow liter per day Time Period Start Time Period End SHAW Predicted Transpiration Mean Daily (mm/d) Total (mm) Mean (mm/d) Mean Difference (PM) (mm) (-) indicates model under prediction Measured Sap Flow Day Date Day Date Mean Total (mm) 156 5-Jun 178 27-Jun 82.0 3.7 78.9 3.6 -3.1 195 14-Jul 200 19-Jul 19.7 3.9 29.3 5.9 9.6 205 24-Jul 212 31-Jul 31.9 4.6 26.5 3.8 -5.4 237 25-Aug 248 5-Sep 33.8 3.1 5.8 0.5 -28.0 270 27-Sep 281 8-Oct 32.1 2.9 12.3 1.1 -19.8 296 23-Oct 300 27-Oct 3.2 0.8 1.2 0.3 -1.9 Late Season Willow Transpiration (October-November 2004) Salix Variety Sap Flow (mm/month) Sap Flow (l/d/plant) S25 180 3.4 SV1 65 1.2 SX64 131 2.5 Equivalent transpiration 350,000 – 968,000 gal/acre/season Preliminary Model Projections Deep percolation 1500 1400 1300 1200 1100 1000 900 800 700 600 500 400 300 200 100 0 Mean: 978 mm SD: 165 mm Precipitation No vegetation 19 75 19 77 19 79 19 81 19 83 19 85 19 87 19 89 19 91 19 93 19 95 19 97 19 99 20 01 Water (mm) Different management regimes Year Uniform Stand 3-YR Harvest Rotation Deep Percolation (mm) PPT No vegetation CS (0.5m root) SRC (0.5m root) Three consecutive years of extreme annual precipitation coincide with stand establishment 1500 1400 1300 1200 1100 1000 900 800 700 600 500 400 300 200 100 0 Mean Precipitation +/- 1 Standard Deviation CS maintains constant percolation rate despite extreme annual precipitation 1975 1978 1981 1984 1987 1990 Year Percolation increases when harvesting coincides with greater total annual precipitation 1993 1996 1999 2002 ENERGY Biomass Produced for Energy and Products Captured Solar Energy Renewable Willow Biomass Production Select Species Plant Grow Harvest Coppice growthcycle.jpg Potential Uses for Willow Biomass Bender harvester cuts and chips willow biomass crops in one process. Chips can be used as a green energy source for on site heat and power generation Feedstock to produce biofuels or bioproducts LAND RESOURCE Brownfield site Abandoned, idle or under-utilized industrial or commercial facilities where expansion or redevelopment is complicated by real or perceived environmental contamination. Legacy of industrial boom/bust cycle Artifact of business lending practices, uncertainty and liability concerns Multiple Benefits of ET Cover A. A. Dhondt Energy independence CO2 neutral fuel source for heat and power generation Containment and remediation of soil and water contamination Visually stunning transformation of a wasteland into a green sustainable industrial site Creating Spatial Patterns with Willow Summary Ecologically- minded Engineers Creative Knowledgeable (science and math) Interdisciplinary Communicators (public, regulators, PRPs, scientists, etc.) Integration of natural sciences in a “controlled” environment to address today’s urban contamination problems and minimize creation of new problems