IF IT AIN’T BROKE, FIX IT By Douglas H. Sandberg

advertisement

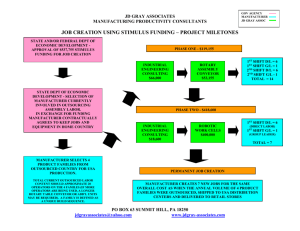

IF IT AIN’T BROKE, FIX IT Factors Effecting the Life Cycle of Mission Critical Systems By Douglas H. Sandberg Director of Operations ASCO Services Inc. I’m quite certain that anyone reading this recognizes the title play on an old axiom. With the tremendous financial impact and the risk of personal liability, many of those responsible for mission critical operations are rethinking their approach to systems. This paper focuses on the factors, which effect the useable life of these systems. For illustration, we’ll focus on the engine generator / turbine and switching elements however, the rational applies to all electrical systems. What is the life cycle of a given piece of gear? It could be simply expressed as the period of time beginning at installation and ending when it is no longer usable. The expected usable life of equipment may be dependent on number of operations, characteristics, model etc. Figure 1 illustrates the factors, which make up the continuing cycle of maintenance and determine product life. The equipment / system life cycle depends on all of these factors beginning with the engineering concept. Proper Design & Application The length of the usable life of any piece of gear begins long before installation. All too often we find some aspect of system design or application lacking. It may be physical restrictions, which prevent proper maintenance. It may also be improper application of a product type. Most manufacturers provide equipment models that satisfy various requirements of the facility. Automatic Transfer Switch manufacturers, for example offer specific technologies for specific applications. The major types supplied by most manufactures are as follow. • Standard break before make with no service bypass. • • • • Standard break before make with service bypass. This is basically 2 switches (one automatic, one manual) in parallel. The manual switch is used to bypass the automatic for maintenance or replacement of the automatic unit without impact to the critical load. Make before break or closed transition with or without service bypass. Delayed transition is designed to pause in mid position thereby allowing electrical fields to collapse, which in turn limits current inrush. Softload is basically a closed transition ATS with a synchronizer and power controller. This type of unit is employed to “walk” the load from one source to the other. This design is especially useful where the standby source size is marginal or soft like natural gas or methane plants. These basic types of automatic transfer switches are employed today in mission critical systems. While individual components are important, how they are configured in a system is equally important. For example, a closed transition switch is ideal for feeding a UPS. While the initial power outage transition to the emergency source of power operates the same as if a basic break before make ATS was installed, that’s where the similarity ends. • After the event, a seamless transfer back to the normal source prevents the UPS from loading the battery again. • Should the owner decide to place the facility on standby power in the event of impending bad weather or for other reasons, a seamless transfer can be made in both directions and battery depletion is minimized. • Should the UPS module or system be in the bypass mode, a no break transition prevents loss of load. 1 • If the ATS is equipped with an isolation / bypass feature, the ATS mechanism and controls may be serviced without effect to critical loads. Maintenance access means this essential element will be in top condition when called upon to operate. Having decided what type is best suited for the system demands; one must consider how the individual ATS will interface with other system components. • How will loads be managed? It’s paramount to protect the highest priority loads while preventing the standby engine system from being subjected to an overload. Are the ATSs associated with the system equipped with the proper controls and features? • Are the governors, voltage regulators and controls of the proper type to interact with the UPS? • What about communications and monitoring? It is essential in today’s critical environment that operators know instantly the status of or changes in the system they depend upon. • Are time delays and voltage sensing setpoints properly coordinated between all critical members of the system? Careful Handling & Installation Here again events occur which can severely effect the useful life of a piece of equipment even before it’s installed. • Did it ship well? Only incoming inspection can tell. Inspection should take place obviously before you accept the gear. The presence of the manufacturer’s representative is recommended. Waiting until the gear is installed to discover a problem creates many problems and may impact commissioning schedules. • Store the gear in a dry, safe environment. Moisture or condensation can and will degrade insulators or stand-offs. Moisture also attracts dust and dirt, which may become conductive. • Those charged with installing the gear should be thoroughly familiar with the manufacturer's recommendations. Extreme caution must be observed not to let metal shavings or other debris contaminate the unit or controls. • Personnel should read the installation and operations manual. Do not force controls or • the mechanisms. If you’re not sure what to do, call the manufacturer for guidance. Remove all shipping blocks, bolts etc. Benchmark Testing This aspect of commissioning cannot be emphasized enough. The manufacturer should be contacted to participate in the planning of the benchmark or initial commissioning test. This may well be part of the purchase package, however if it is not, a few dollars invested at this point may save a few thousand later. • A team should include the owner, design engineer, consultant and all manufacturers’ representatives. Usually, these benchmark / acceptance tests include functional testing of each component, functional testing of the system and specific performance criteria. For example, measure and record cold start time from initiation of the start signal until each generator closes to the bus. • You must insure that all programmable set points and time delays are understood, properly set and indeed function. For example, are the low voltage set points for the ATS, UPS and engine control system properly adjusted? Failure to coordinate these values may leave the UPS on battery while the ATS & engine system are unaware of a problem or it may be that voltage is sufficient and the UPS set point is simply set incorrectly. Either way, the critical load could be in jeopardy. • Unrealistic tests invalidate results and diminish the value of this important requirement. • Are the time delays adjusted properly? Overriding short outages is very important. Again, this feature should match the UPS settings to prevent unnecessary hits to the battery. • Insure that load priority blocks are properly assigned. For example, the ATSs feeding the most important loads should be of the highest priority and admitted to the generator bus first. Conversely, these should be the last to go in the event of generator failure. • Document and retain all setpoints and adjustments on each piece of gear. Test records should become a clearly defined package in the system master file. 2 Document Control Each piece of gear has documentation. The system also has documentation associated with it. This body of information includes operator’s manual, bills of material, one line schematic diagrams, detailed control and power schematics, mechanical details, maintenance records, software and test results. • • • • Maintaining this information is paramount. It is your only reference in an emergency. Benchmark control settings provide a default reference. A master one-line diagram on the wall under glass or plastic and adjacent to switchgear is a quick reference point in an emergency or when operating the system. Personnel should drill on system operational knowledge so that it becomes second nature in an emergency situation. Contact information for all key service providers and manufacturer’s representatives is critical and must be maintained and updated as changes occur. Routine Preventive (Scheduled) Maintenance The point to be made here is while routine maintenance according to the manufacturer’s recommendations is essential; it does not totally preclude a problem. Mission critical systems are complex. Many actions occur when they are called upon to change state. Regular scheduled maintenance does however increase the odds in your favor. This is one of the most neglected aspects of the critical power system. In this context, neglected can mean that maintenance is simply not done on a routine basis, may not be able to be done properly due to improper physical or electrical design, may be performed by a company, which is not qualified or simply because the owner does not understand the process. Recently I attended a conference and heard a presentation, which questioned the value of scheduled maintenance. The “expert” suggested that there is inherent risk associated with the performance of maintenance and tasks required to change the state of a critical system from “on line” to the maintenance mode, performance of the actual maintenance tasks and then returning the system or piece of equipment to it’s “on line” state. I cannot dispute the risk involved. However, the presenter inferred that a good portion of the risk was due to the probability that the maintenance provider would make some sort of error. The human factor is always of concern however, the owner or owner’s representative have a responsibility here as well. Successful maintenance requires a team effort. The team is the maintenance provider, the owner and the user. This joint approach provides for a wellplanned and coordinated event. In this environment, specific actions are planned and examined for risk. A master plan or method of procedure is essential. Contingencies are planned as well. The most important aspect is the verification of proper configuration and system performance following a maintenance routine. If you do feel that the risk of performing maintenance is too great, I would recommend you update your resume. The maintenance provider, the owner, operator and design engineer or consultant are part of an essential team. Failure of any team member may result in system malfunction. It is essential that all parties understand their unique responsibilities to the other team members. A manufacturer may hold the contract and responsibility to maintain a specific piece of system equipment however; they cannot be effective without the cooperation and understanding of the owner or operator. Too often the decision on the maintenance provider or type of program is made strictly on price. The problem is that all programs are not created equal. In order to understand exactly what you’ll be receiving for your maintenance dollar you have to ask some probing questions. Ask any prospective maintenance provider what kind of a job they do and they’ll tell you they are great. Before you run down to purchasing to cut the check, perhaps a little deeper analysis will reveal the true nature of a service company. If there’s a $2,500 dollar difference between service providers, they may be a reason. The following 10 questions will help you determine the value of the program, by comparing all perspective service providers on a level playing field. 3 • Q. How are your service technicians selected, trained and qualified to work on my critical equipment? This is important. Some maintenance companies have only a few specialists. While they may have many people, the person arriving at your site in an emergency may not be skilled or trained to effect the repair or worse, may cause a system level failure. Ensure that the folks who may respond are qualified on the equipment installed and understand how each piece relates to the system. • Q. How many folks do have on staff? Are there enough people to properly support your site in the event of a disaster or heavy schedule? • • • Q. Do you provide 24-hr. service? How? (Have them explain call handling, escalation and response procedures). The owner must understand how people will be contacted and directed when you need them. A good escalation plan provides for uniform steps and involvement of escalating levels of management. The critical system maintenance company should be ready, willing and able to commit all the necessary resources to solve a situation regardless of the date or time. Q. Is your company authorized and or trained by the manufacturer? Prove it. No big deal right? Wrong. Your emergency power system is the lifeblood of the facility. The people working on it must have the proper skill set and training. Your life may literally depend on it. And let’s not forget the personal liability you may have as an owner or operator. Civil actions and penalties are becoming the law of the land, protect your facility and yourself. Maintenance providers must have an official relationship with the manufacturer they claim to represent. Failure to do so may mean the maintainer is not aware of current procedures or service bulletins. Q. Can your company provide training for my staff? This is also important. Why? I’m not suggesting that your staff be trained to do the maintenance or repair on critical gear. I’m also not suggesting that they are incapable of learning how. I am suggesting that without constant exposure, they will not remain sharp. They should be taught how the equipment and system is expected to operate under normal and abnormal conditions. They should understand how to operate the system and what steps to take should the equipment not operate as expected. In the case of a transfer switch for example, one must understand how to operate the bypass if so equipped or manually operate the ATS safely. The engine control system is equally important. The ability to manually start and parallel engines may mean a lot to your data center or hospital in the middle of the night. • Q. How do you support the technicians who will be on my site? (Technical support, parts etc.) What happens when the technician can’t figure out the problem? Does the prospective service provider have help available 7 x 24? • Q. How does your company become aware of product changes, technical bulletins etc. from the manufacturer? This is normally limited to the manufacturer’s own Service Company or authorized agents. You will want your provider to be aware of anything effecting your system. How well they are connected makes a huge difference. • Q. What type of maintenance agreements do you offer? Take the time to understand what types of agreements are available and which one best fits the requirements of the system and facility. Some equipment is relatively simple and very dependable. So it is possible to little or nothing, call it maintenance and get by. This “dust off and test” philosophy is dangerous. You may feel comfortable in that your gear has been maintained when if fact, the system may be on the verge of failure. Trust but verify. • Q. What is the average experience of your field force on the equipment I have? There are many companies who have general knowledge or are not qualified. Make sure you understand these qualifications of your prospective maintenance company. For example, one major manufacturer advertises thousands of “feet on the street” to provide service to 4 critical gear. The truth is that only a few are experts while the rest are generalist. I guess the idea is the sooner someone shows up, the better regardless of weather they can fix the problem. This makes for great marketing but is shortsighted. • Q. What spare parts do you carry for my equipment? You will find that many companies do not invest in spares. They may bank on the manufacturer having spares available in an emergency. The bottom line is that if you’re in the maintenance business, spare parts are a cost of doing business. Will they have the parts you need in an emergency? If they are taking your money, they damn well better. Make sure they do. Maintenance is more important than ever. The dollars associated with critical operations are substantial, the maintenance window is shrinking or non-existent, in certain applications, life may literally depend on a properly operating system (should you find yourself in a hospital on life support you may want to think about that). In any case, the emphasis seems to be on the lowest possible dollar and very little is done to qualify the provider. Personal liability is becoming of concern. Some levels of staff are subject to civil or legal penalties should the system fail. Manufacturers strive to produce a better product for the market while reducing or containing cost. When a re-design takes place, the manufacturer must decide how long the prior model will be supported with parts and maintenance. Some manufacturers are better than others are and there is usually some quantity of new old or obsolete parts. The point is you need to understand the degree of support available for the systems your business depends upon. When it becomes clear that older equipment may lack support, it’s time to consider replacement or upgrade. Upgrading or modernization provides cost effective alternative to replacement. Testing Periodic testing is very important to the health and life expectancy of your mission critical system. It allows you to determine the system is fully operational following maintenance, track performance degradation and monitor performance set points. The benchmarks established during initial installation are the standard used for comparison. Results often tip you off to problems, which if left un-addressed will lead to unplanned failure. Normally as we said, testing is part and parcel of a well-designed maintenance program. If not, it should be. Modifications & Upgrades Summary Replace or upgrade? Upgrading systems is a viable alternative to replacement. Depending on the equipment or system, the manufacturer or service provider may be able to provide a range of services from a simple control replacement to a complete rebuild and modernization. The cost involved may be considerably lower than the total cost of replacement. This is especially true when you consider the collateral costs associated with de-installation, rigging and re-installation. Still not convinced? Take a long hard look at your equipment / systems. Ask the manufacturer if all components are readily available. Buildings are becoming increasingly complex, as are the systems they depend on. The evolution of technology coupled with the convergence of the truly connected environment indicates this trend will only continue. Mission critical systems must remain reliable. The concepts presented in this paper are really common sense but as with many other common sense issues, they must be dusted off and consciously examined. Weather it’s a data center, healthcare facility or a factory; electrical systems are the lifeblood of the facility. During the blackout of 04, many facilities were shocked to learn that systems they depended on failed. 5 EQUIPMENT / SYSTEMS LIFE CYCLE Design & Application Quality Testing Transport & Protection Modify & Upgrade Maintenance Proper Installation Training Benchmark Testing Documentation Figure 1 6