Document 10558513

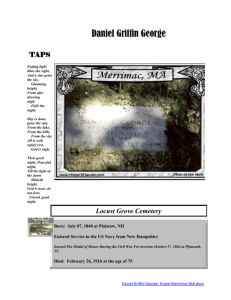

advertisement