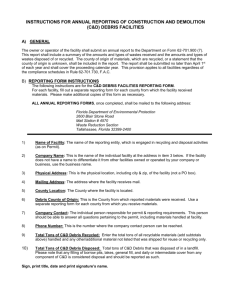

Disaster Debris Management and Recovery of Housing Stock in San...

advertisement