Natural Biodegradation vs. Bioremediation of Crude Oil

advertisement

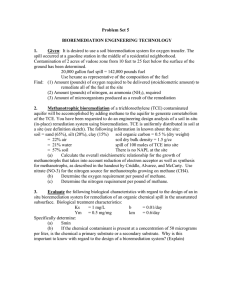

Natural Biodegradation vs. Bioremediation of Crude Oil Dr. David Tsao, Americas Technology Manager, BP Remediation Management ABSTRACT Natural biodegradation of crude oil requires five components: 1) the hydrocarbons, 2) a microbial consortia able to metabolize the oil as a food or energy source, 3) oxygen or other alternative electron acceptor for the energetic metabolism, 4) micronutrients (e.g. N, P, Fe) to support the metabolism, and 4) contact area between the oil, microbes, electron acceptor, and micronutrients. If any one of these components is found to be limited or lacking, then the rate of natural biodegradation will be limited or lacking. However, many strategies to address one or more of the limiting or lacking components are commercially available. The supplement or supply of the component is known as bioremediation. Several commercially available bioremediation products are listed on the U.S. EPA’s National Oil and Hazardous Substances Pollution Contingency Plan (NCP) Product Schedule (PS). The NCP PS is a list of oil spill response and countermeasure products available to an oil spill response incident coordinator should bioremediation be deemed a reasonable response strategy. In order to evaluate these products, comparisons to natural biodegradation conditions predominant at the spill-impacted location can be conducted to support the determination of whether bioremediation is a reasonable strategy. This presentation summarizes a study conducted to evaluate 10 commercially available bioremediation products to enhance the rate of natural biodegradation of crude oil from a spill incident. BIOGRAPHY Dr. David Tsao is the Americas Technology Manager for the Remediation Engineering & Technology group in BP’s Remediation Management function at their Naperville, IL office. He is a three-time chemical engineering graduate of Purdue University (B.S., M.S., Ph.D) where his areas of research included plant biotechnology, pharmaceutical production, plant nutrition, and plant biomass production for space (NASA) applications. Upon graduation, David came to work for Amoco in the Environmental Technology Assessment and Development group where he specialized in the areas of phytotechnologies and the remediation of gasoline oxygenates. Currently, David is responsible for a team of technical specialists coordinating, developing, and implementing the technical aspects of clean up strategies for a broad range of sites around the globe. He is personally active in bioremediation, phytotechnologies, wetland technologies, native prairie restorations, ecosystem developments, biodiversity, and greenhouse gas emissions reduction. David is also responsible for evaluating the potential environmental impacts of new BP biofuel products. Furthermore, David actively participates in the development of these naturalbased technologies, establishes regulatory guidance on their use, and teaches these technologies through the Interstate Technology and Regulatory Council. Most recently, David was stood up by the Deepwater Horizon Unified Area Command as the Strike Team Leader for evaluating biological and chemical agents for the long term remediation and restoration of Gulf Coast shorelines and wetlands. He leads a multi-organizational team engaged in testing natural and enhanced bioremediation approaches.