Based on Micro-Algae New and Emerging Biofuels Technologies in Upstate New York

advertisement

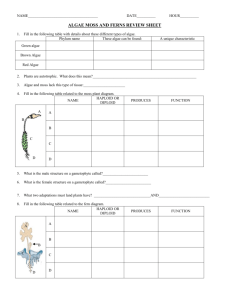

New and Emerging Biofuels Technologies in Upstate New York Based on Micro-Algae Joseph Holroyd LakeMaster Corporation LAKEMASTER Corporation Algae to Biofuel What About Algae? • Algae has a high productivity rate (doubling its mass every 24 – 36 hours) • The oil yield from algae can be thousands of times that of corn, soy, or other crop based feedstocks • Harvested daily, reducing inventory and logistics • No need for arable land • No need for potable water • De-links food/fuel competition Algae consumes CO2 at the rate of 1.8 tons per ton of algae biomass • Many bi-products from the bio-mass 3 Algae’s Potential • Feedstock to produce biofuels • Food supplements (Spirulina) • Nutritional supplements • Livestock feed and supplements • Fish food • Fertilizer • Pharmaceuticals • Cosmetics • Wastewater treatment LakeMaster™ Corporation A bio-technology company developing technologies to enhance the growth of algae for biofuels. LakeMaster has applied for patents to provide an integrated lighting system that captures solar energy and separates out the optimum wavelengths of light for growing algae. The remaining solar energy is captured by photo-voltaic cells to produce electrical energy to light LEDs in the specific wavelengths to grow algae. Solar Energy Collection 1 2 22 21 17 PV-cell 18X 7 Spectral Splitting Mirror 8 Power Control Unit 6 4 18A 5 9 Direct Solar Energy 2 2 20A 19A 10 11 12 13 Mirror 14 20X 23 15 16 Photo-bioreactor 19X LakeMaster™ Photo-bioreactor Technology Patent Pending Algae Out to Harvesting & Lipid Extraction Algae Starting Reservoir Light Bars Supply Natural and Artificial Light Impeller Algae In Nutrient Input CO2 Bubbles CO2 Input 7 LakeMaster™ Corporation LakeMaster has filed three provisional patent applications to protect its intellectual property around effective use of light to grow algae. The biggest hurdle for the company has been the inability to raise sufficient capital to go beyond the prototype stage and scale the system to production levels. Currently assessing Spirulina potential for health food market. Northern Biodiesel, Inc. (NBI) is an innovative energy company specializing in the production of alternative fuels. NBI is an ASTM 6751 certified biofuels producer concentrating on home heating oil and biodiesel fuel. The company currently produces at 4.5 million gallons annually and has capacity on site to produce 20 million gallons. NBI has produced several proprietary pieces of processing equipment and continues to refine their process capability. Initial Bio-refinery System • 20 mil gallon capacity • multiple feedstocks • space for expansion • LakeMaster co-location Sustainability: The Northern Biodiesel bulk loading terminal can accommodate any size tuck up through the NYS max 12,500 gallon tankers. At Northern Biodiesel, we proudly embrace the sustainability principles put forth by the National Biodiesel Board. We consistently implement practices of sustainability in our daily operation. We continuously work toward becoming a “zero footprint” company. Environmental Energy Technologies, Inc. - Wastewater Systems is a university spinout from Rochester Institute of Technology which has embarked on a path to remediate municipal wastewater using the rapid growth of algae and a proprietary monitoring and control system. Algae Based System No toxic chemicals Algae is biodegradable Capital costs are low Reduces solids by 95% Reduces greenhouse gas (GHG) emissions • Algae converts organic matter to live plant life • Algae produces oxygen for biodegradation • • • • • Typical Small Community Waste Water Treatment Facility • Algae biomass can be used as biofuel feedstock or • Used in digester to produce methane 13 Initial Test Sites 2011 EET Algae System Implementation EET Wastewater Solution 1,000 gallon pond for proof of concept 10,000 gallon pond for commercial scale-up Integrate to System-wide Water Treatment System 15 Nutrient Removal and Coliform Count Using EET Algae System Laboratory Test Results Chemical in Effluent % Reduction 4 days % Reduction 7 days Ammonia 99.8 99.9 Nitrate 66.7 88.9 Phosphate 96.7 99.9 Coliform Count Fecal Coliforms Total Coliforms Day 0 350 MPN/100ml >1600 MPN/100ml Day 2 0 MPN/100ml 6.5 MPN/100ml Day 4 3 MPN/100ml 0 MPN/100ml Regional Resources The RIT Clean Energy Incubator • Help commercialize products • Networking opportunities • Access to technical resources (CIMS) The Saunders School of Business • Economic Modeling New Venture Development Manufacturing Extension Partnership Funding Opportunities 17 LAKEMASTER Corporation Joseph Holroyd, COO jholroyd@lakemastercorp.com 585-309=7009 John Valvalo, V.P. john@northerbiodiesel.com 315-415-2005 Dr. Ali Ogut, President aogut@eetds.com 585-503-6602