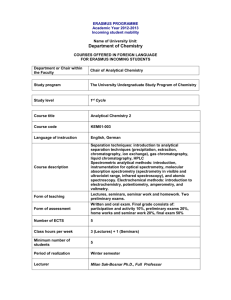

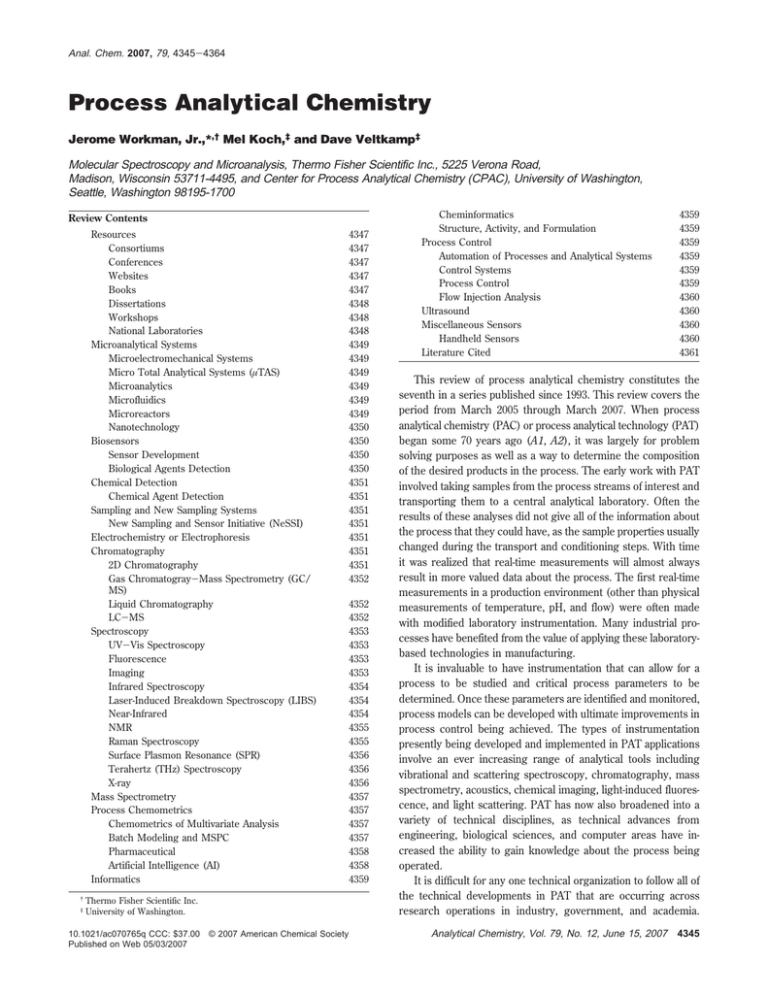

Process Analytical Chemistry

advertisement