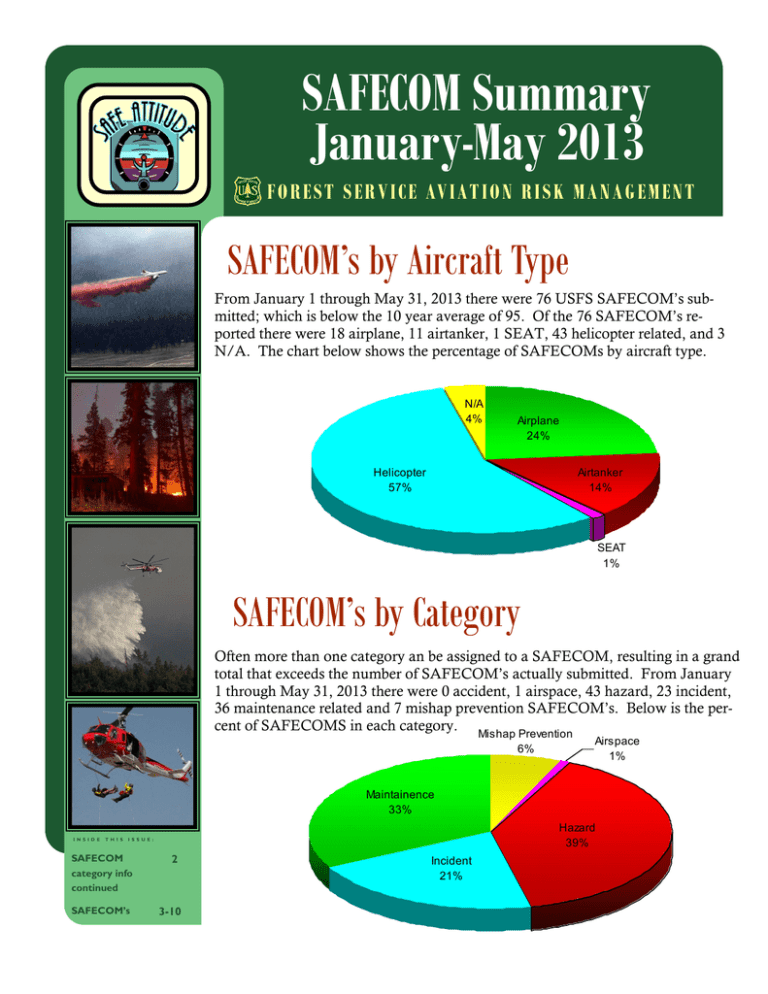

SAFECOM Summary January-May 2013 SAFECOM’s by Aircraft Type

advertisement

SAFECOM Summary

January-May 2013

F O R E S T S E R V I C E AV I AT I O N R I S K M A N A G E M E N T

SAFECOM’s by Aircraft Type

From January 1 through May 31, 2013 there were 76 USFS SAFECOM’s submitted; which is below the 10 year average of 95. Of the 76 SAFECOM’s reported there were 18 airplane, 11 airtanker, 1 SEAT, 43 helicopter related, and 3

N/A. The chart below shows the percentage of SAFECOMs by aircraft type.

N/A

4%

Airplane

24%

Helicopter

57%

Airtanker

14%

SEAT

1%

SAFECOM’s by Category

Often more than one category an be assigned to a SAFECOM, resulting in a grand

total that exceeds the number of SAFECOM’s actually submitted. From January

1 through May 31, 2013 there were 0 accident, 1 airspace, 43 hazard, 23 incident,

36 maintenance related and 7 mishap prevention SAFECOM’s. Below is the percent of SAFECOMS in each category. Mishap Prevention

6%

Airspace

1%

Maintainence

33%

I N SID E

TH I S

Hazard

39%

I SSUE:

SAFECOM

category info

continued

SAFECOM’s

2

3-10

Incident

21%

PAGE

2

SAFECOM’s by Category continued

AIRSPACE - There was only one airspace event reported, SAFECOM 13-177 describes two Blackhawks that encroached on Helitack operations. Helicopter crew

members advised the pilot of the Blackhawks and the pilot was able to make radio

communication with them. The area was de-conflicted with the AFB prior to the

helicopter launching; however, there’s no guarantee that all non-incident pilots will

avoid smoke. See and avoid must be a focus for individuals flying in aircraft. Kudos to all involved for their actions to reduce the risk of a mid-air collision.

HAZARD - There were 44 hazard SAFECOM’s reported. Communication issues

were the most reported ranging from aircraft and base radios, repeaters, frequencies, flight following and verbal/instructional communications between the ground

and aircraft and pilot and spotter. Mission equipment accounted for a significant

number as well, most being issues with PSD equipment/spheres and rappel equipment. There were also several pilot actions which included dragged & dropped

loads, checklists, drop height, dealing with maintenance issues and inadvertent aircraft movement on the ground.

INCIDENT - There were 23 incident SAFECOM’s filed. The most reported in

this category were mission equipment related mostly to PSD equipment/spheres

and a couple bucket issues. There were 2 dropped loads, 2 dragged loads, 2 precautionary landings and 1 bird strike. The line was not cleared and a dozer was hit

with retardant and a cockpit door came open in flight.

MAINTENANCE - There were 36 SAFECOM’s submitted in this category.

There were 9 categorized as “Engine” however; none were engine failures or engine shutdown. Some of the other most reported issues were 5 avionics (radios), 5

mission equipment, 4 instrument, and 3 main rotors.

MISHAP PREVENTION - There were seven mishap prevention reports ranging

from correcting weight and balance data; reporting and following up on PSD problems; good risk management decisions and last but not least: Airtanker base personnel preventing a gear up landing by noticing and notifying an airtanker that his gear

was up as he was coming in to land. Great job folks, keep up the good work!

SAFECOM Working Group

(SWG) Update

Unfortunately we had an issue with the development of the APP for SAFECOM

and it did not get completed. We are looking at contracting it out as well as updating all the SAFECOM web pages so they are accessible for all mobile devices.

We will have a fillable form available in the next couple of weeks. Please accept

our apologies, we had hoped to have it available by now.

SAFECOM’s

PAGE

3

These are samplings from the SAFECOM’s submitted for the months of January-May. We hope you

will select a couple of them a day to discuss and use the lessons learned in your daily briefing. Some

of the SAFECOM’s have been edited due to length. To read the SAFECOM in it’s entirety, please

click on the link.

SAFECOM 13-13-286: Received sphere order in April and in May conducted a bench test on the new shipment of

spheres. We quickly saw a major difference between the old spheres and the new spheres. The new spheres were

igniting in eight seconds whereas the old spheres ignited at 18 seconds {at an 80 degree temperature}. The new

spheres also are more explosive and some also fragmented upon ignition. One sphere blew the screen from the top

of a two gallon bucket three feet into the air. Also, ignition of the spheres is very erratic and some flew up to 40

feet away after combustion. Contacted manufacturer and we described the problem as stated above to them. The

sphere representatives told us they have changed from a clay based to a pharmaceutical grade potassium permanganate-they also stated they knew this was a hotter material. We have tried to adjust both of the PSD machines on

RD and have not achieved a 20 second ignition, only 8 to 10 seconds. CORRECTIVE ACTION: Submitter: Until this issue of early igniting, explosive and fragmenting of the spheres is resolved the RD will not use these

spheres. RASM: good risk management. This issue is being worked on several fronts and I`m confident we will

have a solution very shortly. Unfortunately we will have some logistical interruptions to return the unsatisfactory

products and obtain replacements. NASS: The sphere manufacturer has issued a Tech Bulletin regarding the issue

with recommendations for resolution. The Tech Bulletin Recommendations are: To delay the ignition times of the

Premo balls to no less than 20 seconds please note the following:

At high ambient temperatures use a commercial grade automotive 50/50 mix of ethylene glycol and water in

the PSD to delay ignition times. Refer to manual Sec. 1: Premo MKIII Overview p.2.

Use of empty spheres allows operator to confirm that ethylene glycol is dispensed adequately and there are not

issues with pump, feed line or needle assembly. Sphere should be approximately 1/8 full after injection. Bench

test procedure can be found in the manual (Section 2: Operations, p.9).

Initial calibration of the PSD @ 1 cc of ethylene glycol into the sphere while operating at the slow setting and

evaluate volume dispensed after turning to fast setting OR; initial calibration of the PSD @ 0.6cc of ethylene

glycol into the sphere while operating at the fast setting and evaluate volume dispensed after turning to slow

setting.

Please note that the temperature of the potassium permanganate and ethylene glycol has a significant impact

on chemical reactions times and therefore it is recommended to avoid prolonged exposure to extreme heat.

Also, if these materials have been exposed to prolonged high temperatures, additional calibration procedures

should be carried out. Calibration instructions can be found in the manual (Section 2: Operations, p.11).

SAFECOM 13-264: Three maintenance IR calibration flights were executed without a current weight and balance

onboard. The experimental AMS IR sensor equipment {that did have a current W&B} was removed and replaced

with the legacy Phoenix IR sensor. Discussion among the crew members and maintenance led to the belief the

W&B documentation from past installations with the Phoenix sensor was sufficient. No further documentation

was reviewed to ensure the PIC had the most accurate W&B calculated. Later it was learned that the calculated

W&B with a Phoenix system had been `superseded` and lined through as null/void when the AMS was installed.

It was late at night and the external pressures of crew duty day may have been a factor. This administrative error

in weight & balance calculations and paperwork highlighted the lack of standardization amongst the various fixed

wing aircraft operated within the region. Some fleets utilize a single Basic Empty Weight baseline document calculated by an A&P mechanic from which to build boiler plates for different configurations. Other fleets utilized two

Basic Empty Weight baseline documents calculated specifically by typical configurations. CORRECTIVE ACTION: The region has taken steps to standardize the fixed wing fleets to all have only a single Weight & Balance

baseline calculated by an A&P mechanic. Some fleets will be physically reweighed to a single baseline in the fall.

From that baseline template, the pilots will develop calculated boilerplate Excel spreadsheets to represent the various configurations they may encounter. To ensure the information is disseminated immediately, interim guidance

in the form of a `Read File` will be signed off by all pilots advising them which aircraft still have multiple baselines

still included in their forms binder. RASM: There was no real physical risk as a result of this particular paperwork

error. This event does however serve to sharpen the program through identification of a process glitch that will result in a higher level of fleet standardization. No further action required.

PAGE

4

SAFECOM’s continued…...

SAFECOM 13-233: While conducting prescribed burn activities on 6 different days the Premo PSD machine experienced a blockage of at least one of the chutes on each of the dates. The blockage was from separated spheres

that had become attached to another sphere {see photo}. On the first occasion the PSD operator noted that the bag

of spheres seemed to have some residue on the outside of the sphere, seemingly from the potassium permanganate

of the broken sphere. The other dates this did not seem to be the issue, as the spheres

were clean on the outside. Noted when cleaning the machine on these dates the PSD

machine had a fine covering of potassium permanganate on the slipper blocks, cams,

and needle area. The broken sphere becomes attached to a viable sphere and this larger

shape allows the unit to enter into the chute but then becomes lodged in the chute. The

only way to vacate the chute is to remove the hopper and to push the sphere unit from

below. CORRECTIVE ACTION: Due to the nature of the blockage, the helicopter

landed and the hopper was removed and the sphere unit was discharged from the hopper {by pushing on the sphere unit from below}. The occurrences from May 9th to

May 29th were from a pallet of PSDS spheres that had 1084C marked on the boxes.

Unknown if there is an issue with this lot. This is only noted as this has occurred 5 of

the last 12 times we have used the machine. Care is used in watching the spheres as

they are being loaded into the hopper but the unit is difficult to catch prior to the blockage. The blockage is removed and the mission completed without any further issues.

The manufacturer is aware of problem and working on a solution.

SAFECOM 13-207: Was preparing to drop a SEAT on the left flank of the fire. Was in communications with the

IC to assure the line was clear. After the drop I checked with the IC on his load and return preference, and he informed me that a dozer had been on that portion of the line. No damage other than a red roof. CORRECTIVE

ACTION: I did not see the dozer prior to the drop. Good reminders to double check visually and to be sure that

the ATGS and IC are on the same page from a target description standpoint. My responsibility. RASM comments: There were a few factors that set up this event. The ATGS and IC had positive communication that the line

was clear, but there was a difference of understanding as to where the line would be. The dozer operator was farther down the line than the IC knew, and the retardant line extended beyond where the ATGS had intended. As

the ATGS states visually confirming is a second check, but not always possible depending on the fuel type. This

could have been serious. Accurate communication by all to ensure the line is understood and clear of personnel

along with a visual check to confirm if possible should be in place for aerial delivery of water, retardant or foam.

The key lessons here are to ensure everyone has the same understanding and is well clear of a potential drop.

SAFECOM 13-199: During a typical terrain training rappel the ropes became twisted and wrapped in some trees.

The 2nd stick of rappellers were trying to get to the ground and the situation worsened. This was compounded by

the aircraft drifting forward during the rappel sequence. At one point the spotter mentioned that the pilot was drifting forward and the pilot thought the spotter was asking him to move forward. The spotter and pilot determined

the best course of action was to lower the rappellers to the ground. The rappel site was directly adjacent to a road

running through a meadow allowing for adequate rotor clearance while lowering the rappellers. On the ground the

first stick of rappellers, which included a check spotter, were assisting and giving guidance to the rappellers still on

the rope. The first rappeller got to the ground and was able to unhook from the descent device. The second rappeller upon reaching the ground determined the best course of action was to deploy his raptor knife and cut the

rope above the descent device instead of unhooking. He stated he was concerned about sufficient rotor clearance

and felt he should remove himself from the rope immediately. Once all four rappellers were clear the spotter threw

the ropes and departed the area. CORRECTIVE ACTION: Once on the ground, the rappellers de-briefed with

the check spotter on possible actions to be taken in a similar situation. Upon returning to the Airbase the spotter de

-briefed with the check spotter and conducted an After Action Review with the rappellers. The spotter had determined that the rappellers could get to the ground even with the ropes in the trees. In hindsight, it may have been

more prudent to re-position the aircraft while the rappellers were still on the skids prior to sending the rappellers. A

better assessment of the problem by the spotter is critical. In addition, the spotter and pilot miscommunication

could have been prevented by telling the pilot what the spotter wanted instead of informing him of what he was

doing. Clearer communication by being Directive and then Descriptive “HOLD, HOLD, HOLD... you`re drifting” could have prevented the forward movement of the aircraft during the rappel sequence.

SAFECOM’s continued…...

PAGE

5

SAFECOM 13-196: During rappel recertification training, it was discovered that the

Snap Hook detent pin was moving independently from the other side. Another Snap

Hook was discovered during Buddy Checks to have a deformed/bent pin that holds the

movable Snap Hook gate. The deformed/bent pin didn`t seem to restrict the gate from

closing or opening and seemed to function properly. A picture of the deformed/bent

pin is attached. CORRECTIVE ACTION: Both Snap Hooks were taken out of service

and replaced with new ones. RASM Comments: no further action required. Good attention to detail. NRS: The rappel community continues to have issues with the

Bourden BE snap hook, when there is an issue remove equipment from service.

SAFECOM 13-193: Upon landing at the tanker base T-XX was required to abort a landing because of an aircraft

still on the runway. It was noticed on his second attempt, his landing gear was not in the down position. Calls by

the RAMP mgr, and base radio were made to notify T-XX his gear was not down. A last attempt call to T-XX to

``abort, abort, abort gear is up`` call was made. The tanker responded and a gear up landing was adverted. The aircraft was reported to have been 10 feet or less over the runway. CORRECTIVE ACTION: RASM: The pilot stated that he already went through the checklist the first time and his gear was down, when asked to do a go-around

by the tower in the opposite pattern that he had been doing all day, and this final was shorted, he was going

through his checklist and did just got to ``Gear down`` when he heard the ATBM say ``abort, abort, abort`` over

the radio. Pilot stated ``Lesson Learned`` is when something changes, don’t get rushed and operate like you train.

The ATB was extremely busy with 8 airtankers and the fire was straight off the runaway, so turn around times

were no more than 15 minutes. The situational awareness of the staff on the tanker base was excellent. Their

quick response to this event prevented an accident.

SAFECOM 13-189: During the DOJ/CAMP annual Short Haul certifications one of the vendors, had three pilots

(The Lead Pilot, and two additional pilots) present with the one aircraft. Of the three, only the Lead Pilot and one

of the other pilots were “carded” pilots. During the re-certification process, the Lead Pilot inserted a second pilot

into the aircraft with him for pilot training purposes. The second pilot flew an undetermined number of short haul

evolutions while on dual controls with the Lead Pilot. The second pilot was not carded for any flight operations.

While on-scene management/inspector personnel had observed that a second pilot had gotten into the aircraft following a refueling cycle, it was assumed that it was the second “carded” pilot. The identity of the second pilot was

unrecognizable due to PPE (helmet/visor). At the end of the day it was determined that the second pilot in the aircraft was actually the un-carded pilot flying on dual controls with the Lead Pilot. In talking with the Lead Pilot, he

advised that he had assumed it was permissible as a Load Calculation reflecting the second pilot had been completed, all pilots had attended the pilot briefing and they were flying on dual controls. He had not discussed placing the

“un-carded” pilot or received authorization from the manager, management or the inspector prior to taking such

action. CORRECTIVE ACTION: Immediate corrective discussions were conducted with the Lead Pilot and other company pilots explaining the requirements for “carded” pilots at all times. Additionally, such actions are not

permissible without direct approval of the manager, and in this case on-scene management personnel. In this case,

had the second pilot been a “carded” pilot, the actions may have been permissible for training purposes. In discussion with the manager, he realized his mistake in not questioning the presence of the second pilot, but had assumed that the actions were permissible in that management and inspector personnel were on scene and did not

question the second pilot in the aircraft. All involved were reminded of applicable policy and procedures that need

to be followed. Additional discussions were conducted with the company owner. Policy & procedures were reinforced and the company owner assured that such events would not occur in the future. All acknowledged assumptions lead to this breach in policy that had potential for a more serious outcome.

SAFECOM 13-187: During a post flight inspection, while prepositioned at San Bernardino Helitanker Base, mechanic noticed a crack in the free turbine. It was within limits, but company decided to take a proactive approach

and change it before it became an issue. CORRECTIVE ACTION: The manager was notified about the crack in

the free turbine 5/6/13. On 5/8/13, after parts arrived and aircraft was released for the day, mechanics started

changing the free turbine. The free turbine and exhaust duct replacement was completed on 5/9/13. A test flight

was performed, R5 AMI was contacted, and aircraft was put back into contract availability. RASM: This company’s pro-active measures are appreciated and an example of how SMS is evolving into the field and contractors.

PAGE

6

SAFECOM’s continued…...

SAFECOM 13-186: Detection flight over the Forest. Communications from dispatch to the aircraft was interrupted several times by Scratching and Alert Tones coming over the South Frequency. This problem has been on-going

for 3-4 weeks now with ground resources, but is now making communications with aircraft difficult and at time

impossible. Work around is National Flight following, but was NOT the frequency utilized for with local missions.

Local radio Tech has been working on this issue, but there seems to be no solution developing. This interruption

with radio traffic is affecting essential mission transfer of operational communications. CORRECTIVE ACTION:

RASM comment: The issue centered around a repeater which was subsequently taken out of service. The dispatch

office is able to maintain communications in that area through another frequency, and aviation flight following is

not affected. We have experienced hardware issues for several years now. The unit here is pursuing remedy

through the CIO organization. While CIO tries to find resolution, the dispatch office also has developed a way to

ensure continuing operations with aircraft to provide for emergency response. Kudos. Solid communication is a

key to reducing risk, if it cannot be established or maintained, consider shutting operations down.

SAFECOM 13-185: At 1010 H-XXX lifted off from helibase with 5 Helitack Crewmembers to do a recon of the

Fire. At 1020, while enroute to the incident, the aircraft had contact with a small bird. The Pilot notified the crew

and he decided that a precautionary landing was needed to ensure that there wasn`t any damage to the aircraft.

The manager trainee notified the forest FAO of the strike and plan of precautionary landing. CORRECTIVE ACTION: A precautionary landing was conducted to have the mechanic inspect for damage. Mechanic inspected the

aircraft and found no damage. The manager trainee and the mechanic spoke to the Maintenance Inspector and the

Helicopter was put back into service. RASM: The decision to land off-site as a precautionary was good CRM and

risk management, that is how the region wants all emergencies handled. Its better to be safe then sorry. Good job!

FAO: good job by all following established procedures for reporting and returning aircraft to availability after precautionary landing.

SAFECOM 13-184: While flying the final leg of a crew shuttle back to the Wrangell airport, the pilot identified an

engine chip light and immediately searched for a landing spot on the Stikine River, which is part of the Stikine LeConte Wilderness Area. During this time, the manager notified Dispatch of the problem and asked them to notify

the appropriate personnel, including the District Ranger about landing in the wilderness area. CORRECTIVE

ACTION: HMGB Comments: Upon safely landing, the chip light went out for a second prior to shut down. The

pilot, who is also an A&P, performed the appropriate check and found a tiny fleck of carbon in the fluid and surmised that caused the light to appear. Permission was obtained from the RAMI to do a run up and make sure that

the chip light did not re-appear and clearance was given to fly back to WRG if no light came back on. The pilot

performed the run up and the light did not come on. The Helicopter departed for WRG without further event. In

the meantime, Dispatch performed the appropriate approvals and also had arranged with the company for an Astar to be available to pick up the crew if necessary and had obtained permission from the Forest Supervisor for it

to land in the Wilderness. RAMI Comments: Spoke with DOM to discuss size of chip, history of this aircraft and

determined pilot should clean, test fly then continue operations if no issues. RASL Comments: No further actions

at this time, continuing to monitor.

SAFECOM 13-174: Porterville Airbase received pre alert tones for a fire in Tulare Unit toward the Reservation,

and at the same time Kern County was requesting aircraft, AA and 2 AT. The decision was made by ATBM to

send AA-YYY with a trainee to KRN and one tanker and send AA-XXX to the other fire with other tanker. The

frequencies were given to AA-XXX over the radio and T-ZZZ was given Air Tactics 45 and T-AAA was given the

KRN frequencies. After the fire AC return from the TIA Fire, AA officer asked what air tactics frequency was given to T-ZZZ and I told him air tactics 45, 168.9625. He stated that the air tanker was on the wrong air tactics frequency and T-ZZZ flew under the AA approximately 1500 feet separation. I spoke with the pilot of T-ZZZ and

stated he wrote air tactics 35 and was unaware that AA-XXX was going to same fire, he thought that AA-YYY

was going to the reservation and AA-XXX to KRN. CORRECTIVE ACTION: ATBM Comments: Take extra

time and ensure all aircraft have the proper frequencies, what aircraft are to going to which fire and not assume

they know. RASM Comments: Spoke with ATBM and this was a good lesson learned for all the pilots and ATB.

When multiple aircraft dispatched at the same time it is imperative that ``instructions are clear and understood``.

SAFECOM’s continued…...

PAGE

7

SAFECOM 13-177: During the IA of the fire, a near miss was encountered by an agency helicopter and two Military Blackhawks. The helicopter had just inserted two helitack on the southern flank of the fire, and was departing

to the west to find a water source for bucket work. The HMGB, onboard aircraft, was talking with dispatch when

one of the helitack called to notify of approaching Blackhawks from the east. The pilot of the agency helicopter

turned to the east for a visual, visual contact was made with the approaching aircraft, as H-XXX come to a hover.

The Blackhawks were at the same altitude as H-XXX, with only the northern Blackhawk veering wide as the

southern Blackhawk remained on course straight towards the agency helicopter. The southern ship flew within an

estimated 200’ of H-XXX as we moved away to create more separation. The pilot of H-XXX was able to hail the

Blackhawk on 123.025 to inform them to stay clear of the fire area, with the response from the Blackhawk pilot

being one of indifference. Note: The airspace over the fire was de-conflicted prior to the agency helicopter arriving.

There was no TFR ordered for the fire at the time of the incident. H-XXX was monitoring 123.025/ National Helicopter Freq at all times. The close call was relayed to Dispatch who is following up with the FAA Tower, and Davis Monththan AFB. It was determined the Blackhawks were not flying within an established military route. CORRECTIVE ACTION: Notification was made to Dispatch, so the issue could be followed up on Once an aircraft is

assigned to a fire, order a TFR immediately if appropriate. When visual contact is made with other aircraft make a

call out on 123.025 for notification. An AAR was conducted with all crew members and the pilot. FAO comments: Contacted Davis Monthan AFB. They stated that aircraft were an AF reserve unit and that they do have a

standing policy to stay above 2500` AGL and 5 miles from any smoke. They will advise all air crews again on fire

operations in the zone and to follow established policy on avoidance. RASM comments: Here is a good example

where the Agency did what we should to reduce risk and the unexpected still occurred. The dispatch had deconflicted the airspace, ground crews contacted the helicopter once the Blackhawks were observed in the area, and the

pilot faced the oncoming risk and took action. We cannot guarantee that all non-incident pilots will avoid smoke.

See and avoid must be a focus for individuals flying in aircraft. The local unit is developing learning points to share

from this event. Kudos to all involved for their actions to reduce the risk of a mid-air collision.

SAFECOM 13-160: During MAFFS training prior to engine start, Pilot set parking brake and had the Line person

remove chalks. Several minutes after start while the pilot was inputting info into the GPS, the instructor pilot noted

that the airplane was creeping forward. Pilot immediately jumped on the breaks and stopped the airplane, the line

person was backing out of the way and giving the taxi signal thinking we were ready to move. The total movement

on the airplane was probably less than 5 ft. Pilot confirmed with the instructor pilot that the parking break handle

was pulled out correctly and put it in and reset the break. No further issue was noted. Upon landing a discussion

was had with the lineman explaining what happened. CORRECTIVE ACTION: This is an example of how the

systems we have in placed worked. No one was hurt, no damage was done etc. Kudos to the IP and the lineman

for being heads up and noticing the unexpected movement. RASM: Tasks in the cockpit can lead to tunnel vision.

Good early season reminder to all of us to maintain our situational awareness. Thanks for the timely reporting.

SAFECOM 13-122: We started the RX burn, Everything was going fine with no problems. After about 1 1/2

hours of firing we went back to the helispot to refuel, eat, and warm up for approximately 30 minutes. We left the

helispot around to finish the RX burn. We had been firing about 20 minutes when all of a sudden the machine lost

power. I immediately told the ignition boss and the pilot that the machine had lost power and I was accessing the

problem. I closed the feed control and turned the control panel to the off mode. I looked to make sure the power

cable hadn`t come loose. Everything was connected. I started turning the manual assist to get any balls out of the

exit chute. A couple of balls exited but I was having problems turning the manual assist. At that time I noticed a

glow around the feed control and exit chute. I immediately pushed the water button on the control panel extinguishing the fire. At that point I told the pilot and ignition boss that I had to use water to extinguish the fire, we

still had no power and we needed to go back to the helispot. We landed at the helispot at 15:25. Once we took the

hopper off we saw that the third needle had been bent up and to the right and there were two balls jammed in the

block. Where the needle was bent this was not allowing me to use the manual assist which caused the fire. We replaced the needle and once that was done then the plunger/guide would not move. CORRECTIVE ACTION:

We decided this machine was not usable and replaced with another machine. We were able to finish the burn

FFMO ~ machine has been taken out of service until vendor rep can assess and work on a retro-fit (bar). Local

fire and aviation personnel are working with vendor. RASM-good work-good procedural approach. Field rep is

contacting each premo operator and will install a factory fix for each machine in the field.

PAGE

8

SAFECOM’s continued…...

SAFECOM 13-114: During preparation for helicopter prescribed fire operations with the PSD aerial ignition machine, the operators noticed that some of the aerial ignition spheres had a `leopard print` pattern noticeable on the

inside of the spheres. It looked as if the potassium permanganate had been caked together forming clumps inside

and on the walls of the spheres. This contrasts with the normal `loose powder` that can be seen on the insides of

the spheres. The operators tested the spheres in the PSD machine and found that they began to prematurely smoke

at 10 seconds after injection. They would then stop smoking and eventually ignite at the normal range of 20-30 seconds after injection. The crew was able to confirm that the spheres had been rotated as suggested for storage practices. During the same RX fire operation the crew also used other spheres with older manufacture dates which did

not show this issue. Upon opening a number of boxes that were received in the same shipment, it was confirmed

that all of these boxes showed the same leopard print and caking issues. These boxes showed stamped dates between May 28 and May 30 2012. The boxes were from Premofire and `Made in Canada. The spheres were cut

open to examine them more in depth and view the clumping more clearly. CORRECTIVE ACTION: For the

time being the crew has been able to use the spheres as normal without seeing any adverse affects. The ignition

times are still within range and the aerial operations have been successful. The SAFECOM is being submitted to

document the issues with the balls, and to create awareness and confirm that no one

else has had issues with keeping the balls in service. The crew has made contact with

Premo fire (now SEI Industries) to make them aware of the issues. HOS comments: I

ran this by MTDC POC and SME with aerial ignition devices, just to see if it seemed

to him to be significantly different than past issues. His comments: “I don’t think there

is any concern.” The premature smoke would be the fine powder reacting quickly...SEI did confirm that their clumping additive would have been in the Premo spheres

from May 2012. The additive was just to help keep the machine cleaner, and the potassium permanganate probably looked a little moist. In this case, it is not necessarily a

problem... The clumping additive is no longer being included ... The ignition should be

consistent with these spheres. Thanks for the submittal, continue to monitor and report. RASM comments: Tech Tip 1151–2312P–MTDC, issued in May of 2011, identifies unintentional clumping of permanganate along with excess plastic protrusions

that may cause the PSD machine to jamb or malfunction. Because of these concerns,

spheres manufactured before the end of calendar year 2011 that have clumped permanganate, are misshaped, or have excess plastic, should not be used. Spheres produced in

early 2012 through late 2012 may have clumped permanganate due to the additive, as

in the case of these spheres, and are acceptable to use and should produce acceptable

ignition results. Any spheres, no matter the manufacture date, that are misshaped or

have excess plastic protruding from the seam or elsewhere should not be used. As of

now, spheres produced in 2013 should no longer have the clumping additive. No further action necessary. Thanks for the submittal and identifying an anomaly.

SAFECOM 13-153: While hooking up the bucket on the Fire after doing the three checks, the clevis on the long

line was not put on the belly hook. The line was attached only by the electric connection. The Helicopter started

lifting and at approximately 50` the weight of the line pulled apart the pig tail attached to the belly hook. CORRECTIVE ACTION: The mechanic replaced the pigtail with the spare. The crew discussed the importance of

double checking the connections from the belly hook to the bucket as well as pulling tension on the line to ensure

that everything is attached correctly, prior to the helicopter lifting. FAO conducted AAR with crew on 4-18-13 discussing the need to double check all connections, especially when in a hurry to deploy the bucket during IA. Visually inspecting the belly hook during lift off by the marshaller should detect a loose connection that could be relayed to the pilot. RASM COMMENTS: After the off-season, it sometimes takes a bit to `get into the groove` of

working with helicopters. We must be focused and remember the basics, whether it is our first season or our twenty-first season. Brief your crews to keep sharp.

SAFECOM’s continued…...

PAGE

9

SAFECOM 13-113: Received order for State Assist to IA fire -Upon arrival, size-up , and scouting of dip-site/LZ,

aircraft was configured for bucket operations and advised to conduct bucket drops at the IC’s discretion. HLTK

remained at the dip-site to monitor operations. -On the first dip, Pilot advised that he was unable to pull up and out

of the site, the weight was too much for the A/C. Pilot lifted from the dip empty and landed in order for HLTK to

check the bucket. HLTK ensured the bucket was restricted to 80% capacity (168 Gal). Entire external load with

water would be 1469lbs. Pilot made another attempt at the dip and again advised that he could not lift out of the

dip. He advised that he was at 92% power and could not lift from dip-site. Landing, HTLK restricted the bucket to

70% (147 Gal), entire external load with water would be 1295lbs. Pilot advised it was still a struggle but was able to

lift from the dip and deliver it to the fire. HLTK observed bucket being fully submerged 2-3 feet below the rim of

bucket. Pilot continued bucket operations for 3 additional dips and each time HLTK observed what appeared to be

a struggling A/C and un-stable flight pattern when loaded. IC advised aircraft to land at the LZ and stand-by as

containment was established and only burn-out remained. Upon landing, both HEMG and Pilot inspected the

bucket and it appeared to be correctly restricted at 70%. HLTK replaced the 210gal bucket with the 120gal. Entire

external load with water would be 1071lbs. HEMG and Pilot reviewed the load calculation, found it to be correctly

calculated at 1612 lbs allowable. HEMG and Pilot completed another load calculation to exactly match the current

OAT and PA. It was found to be 1762 lbs allowable. HEMG discussed with pilot concerns on the A/C and Pilot

performance. Pilot advised he just did not want to over-torque the A/C and never went beyond 92%. Pilot advised

that he would me comfortable using the 120gal bucket for future operations. CORRECTIVE ACTION: In discussions with HEMG, Pilot, FAO, RAO, HOS, and Regional Pilot Inspector, it was determined that Pilot should pursue additional experience in Bucket Operations prior to serving as primary on contract. Though fully carded, this

was pilot`s first experience in live fire bucket ops. Power checks did not indicate any limitations with the A/C.

RASM - training and experience will address the issue, but anytime a difficulty is noted, or reported - it pays to be

cautious and conservative. If there had been a more serious outcome all parties would have had to respond to questions regarding the time delay between observed and reported difficulty and continued operations. This is a chance

for learning to occur -without a negative outcome. The actions taken were appropriate and effective, but think

about a review of actions taken after an over-torque, or worse situation. The pilot was very aware of his power

management, Good, but don`t be reluctant to take the next, indicated step-to stop and review what`s going on. The

HEMG performed this step, Good, but let`s not delay a review at the first indication of increased risk. There was

risk management at work in this situation and we`ll get better as we use risk management at every opportunity.

SAFECOM 13-76: The aircraft was to be taxied in a non-movement area to a different FBO for refueling. As preflight was being accomplished I saw that the engine covers had been removed from the left engine and the mechanic was in the process of removing them from the right. I assumed everything would be removed properly and continued my walk around. After I had walked around the aircraft once the group climbed into the aircraft for the reposition. The aircraft had been sitting for a long period of time, so the battery indicated a little weaker than normal. I finished the pre-start checklist and began to start the right engine. The right engine spooled normally, with

the ITT reaching the normal range. I continued the start sequence then finished the after start checklist. At this

point the mechanic in the back said he had received a phone call from ground personnel and informed me there

was a plug in the right engine. I performed a precautionary shut down on both engines, got out of the aircraft and

removed the plug from the right engine, and verified no damage. Since no limits were exceeded on the start and

the plug showed no damage, we restarted and repositioned the aircraft. We repositioned the aircraft and discussed

what happened. We all agreed that we rushed the preflight since no flight was intended. I assumed that since the

engine covers were properly removed from the left engine that they would have been properly removed from the

right as well. As PIC I should have not assumed that everything was removed properly and verified myself. I

should have done a more thorough pre-flight, even if flight was not intended and should have not let the feeling of

being rushed affect the normal procedure that are expected of me as PIC. CORRECTIVE ACTION: The RAO

convened a meeting with all parties involved as well as all other personnel of the Maintenance Dept, the RASM

and available pilots. With inputs from all personnel, an in depth discussion identified contributing factors as mentioned above. Preventive actions were taken as described {attaching covers and ties} as well as emphasizing the

correct mindset of any operation and the discipline necessary to maintain personnel safety and prevent equipment

damage and or failure. Due to the group effort, a positive outcome was achieved from a potentially costly event.

RASM COMMENTS: Well done! No further action required.

PAGE

10

SAFECOM’s continued…...

SAFECOM 13-133: On Friday, March 22nd, upon completion of aerial ignition and support of the prescribed

burn on the Ranger District, helicopter returned to the helispot and shut-down for the day. The fuel truck driver

noticed one of the lower plugs on the main rotor blade retaining bolt had loosened and was coming out. He called

it to the attention of the pilot who proceeded to get a step-ladder to inspect it closer. The pilot pulled on the plug

and it came out and along with it four balance weights which were in the hollow bolt. One fell to the ground and

was retrieved by a HECM who was removing equipment used during the aerial ignition and saw where it landed.

The pilot spoke with his company’s director of maintenance and was told to clean the parts and re-glue the plug

with associated weights back into the bolt with two-part epoxy. The pilot (who is also a FS carded aircraft mechanic) completed this procedure before dark and the epoxy dried overnight. HMGB was informed by the HECM of

the loose plug and balance weights. When pilot was asked about the issue he informed the HMGB that he had spoken with his maintenance department and the repair was being done per their instructions. HMGB said that sounded good. Neither the Regional maintenance inspector or COR was called. They did not learn of the issue until

Monday March 25th. The next morning on March 23rd the helicopter flew from the helispot back to the helibase

with pilot, HMGB, HECM, and HECM-T onboard. Total flight time for return flight was 0.6 hours. Discussions

between the Regional maintenance inspector, pilot, and company were made on Monday March 25th. The company flew the helicopter to a Bell service center on Tuesday March 26th where it was repaired per Bell procedures

and was returned to contract availability on Wednesday March 27th at 0900 by the Regional maintenance inspector. CORRECTIVE ACTION: Field repair was determined to be unapproved and company flew the aircraft to

an authorized service center where an approved repair was completed. R8 RASM-any maintenance issue requires

the AMI be contacted and advised of all details. RASM-any maintenance issue requires the AMI be contacted and

advised of all details to return aircraft back to availability.

SAFECOM 13-141: The aircraft had been performing bucket operations on a 300+ acre wildfire for two fuel cycles. At the end of the second fuel cycle, while the aircraft was returning to the helispot for fuel, the pilot had an

amber governor warning light appear on the dash. The pilot knew this was a maintenance issue that did not pose a

flight safety risk but might cause a lengthy repair. He preferred to land the aircraft back at the helibase but did not

have enough fuel for the trip. The pilot proceeded to the helispot and landed for fuel. Before he shut the aircraft

down he spoke with the mechanic on duty about the warning light. The mechanic did not believe that if the aircraft

was shut down, it would be able to be re-started to return it to the helibase for maintenance so he informed the pilot they would need to hot-fuel. The pilot passed along that hot-fueling could only be done at the governments request and told the mechanic to check with the manager. The mechanic left the aircraft and explained the situation

to the manager. The manager asked if the aircraft was safe to fly and was informed that it was safe. The manager

then contacted the zone FMO to discuss the situation and it was decided to release the ship from contract to allow

the crew to hot-fuel and return the aircraft to the helibase. The mechanic and pilot were informed of the decision,

the aircraft was taken out of availability status and extra helitack stood by at a safe distance to monitor the fueling

operation. The aircraft then returned to the helibase without incident. After the aircraft left the helispot the manager called air support and the maintenance inspector to inform them of the issue. CORRETIVE ACTION: Once

the aircraft was safely on the ground at the helibase and the mechanic was able to return from the helispot the reason for the warning light was diagnosed and a TechRep was contacted. With the assistance of a second mechanic

and the TechRep the problem was diagnosed as a bad connection in the main cannon plug between the fuel governor and the aircraft computer. The connections were cleaned and tested which resolved the issue. The engine was

then spooled up for a test and after everything checked out a short test flight was flown. With the issue resolved the

maintenance inspector was informed and the aircraft was returned to availability. R8 HOS The aircraft was unavailable once it had the issue, non-revenue flights are common at that point. The vendor opted to do the hot fuel

during this period. R8 RASM-Should involve the AMI as soon as a problem is identified.