Formation of smart nanocapsules for defined slow or sudden release

advertisement

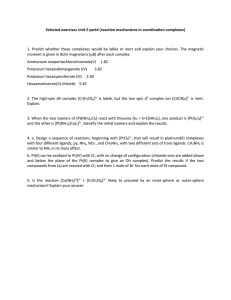

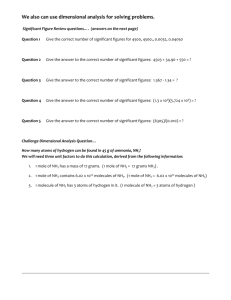

Formation of smart nanocapsules for defined slow or sudden release Anna Musyanovych and Katharina Landfester Max Planck Institute for Polymer Research, Mainz, Germany CO O COO CO O CO O Functionalized nanoparticles from degradable and nondegradable materials PCR Capsules for hydrophilic compounds Bio-reactions with a single molecule inside a droplet Criteria for “perfect” nanocarrier Inert polymer, e.g. polystyrene Hydrophilic surface Other receptors, e.g. cell death receptor or Contrast agent, e.g. MRI Biodegradable polymer, e.g. polylactide “Stealthness”, e.g. PEG-chains Fluorescent marker Release receptor, e.g. pH-, T-, UVsensitive Drug Cell receptor Principle of the miniemulsion process Formulation Formulationof ofsmall smalland andstable stabledroplets dropletsby byusing usinghigh highshear shear(e.g. (e.g.ultrasound) ultrasound) Reactions in confined geometries Phase I high speed stirring, ultrasound reaction Phase II Narrowly Narrowlydistributed distributednanodroplets nanodroplets Size Sizerange: range:50-500 50-500nm nm 1:1 1:1copy copy (nanoreactor) (nanoreactor) Growth of droplets Ostwald ripening: + Coalescence: diffusion of oil through the water phase Suppression of Ostwald ripening: Addition of a co-stabilizer with low solubility in a continuous phase collision and fusion of oil droplets Suppression of coalescence: Effective surfactants CH3 (CH2)11 SO4- Na+ Sodium dodecylsulfate (SDS) C 16H35 OCH2CH2 OH 50 Lutensol AT50 Force: Force:Same Samechemical chemicalpotential potentialin ineach eachdroplet droplet K. Landfester, Macromol. Symp. 2000, 150, 171-178. Direct and Inverse miniemulsions non-polar phase and hydrophobe H2O surfactant e.g. sodium dodecylsulfate (SDS) cetyltrimethylammonium chloride (CTMA-Cl) polar phase and lipophobe (e.g. salt) cyclohexane surfactant block copolymer e.g. poly[(ethylene-co-butylene)-b-(ethylene oxide)] Polystyrene functionalized nanoparticles Oil phase Aqueous phase Styrene Oil-soluble initiator Oil-soluble fluorescent dye Water Surfactant Water-soluble comonomer: e.g. PEG-acrylate, vinyl phosphonic acid, aminoethyl methacrylate, etc. COO COO COO + NH3 + O CO OH O CO O 2 PO 3 O CO PO 3 2 PO O 2 3 PO3 2 Langmuir, 2007, 23(10), 5367-5376. 2 O 3 NH3 + OH H3N OH + NH3 + NH3 OH OH O PO NH3 + PO3 2 O CO O + NH3 + NH3 O CO O Oil-soluble comonomer: e.g. acrylic acid, glycidyl methacrylate, etc. OH OH Colloid Polym. Sci., 2009, (in press). Polystyrene functionalized nanoparticles Oil phase Aqueous phase Styrene Oil-soluble initiator Oil-soluble fluorescent dye Water Surfactant Dispersion of magnetite Water-soluble comonomer: e.g. PEG-acrylate, vinyl phosphonic acid, aminoethyl methacrylate, etc. COO COO COO + NH3 + O CO O OH PO 3 2 PO 2 3 O PO3 2 3 2 O PO NH3 + OH H3N OH + NH3 + NH3 OH OH O CO O 2 PO 3 O CO NH3 + PO3 2 O CO O + NH3 + NH3 O CO O Oil-soluble comonomer: e.g. acrylic acid, glycidyl methacrylate, etc. OH OH J. Phys.Condens. Mat. 2003, 15, S1345-1362. Encapsulation of materials in nanoparticles One colloid particle per polymer particle: CaCO3 in PS Many colloid particles per polymer particle: Fe3O4 in PS 100nm 250 nm Macromol. Symp. 2000, 151, 549. Macromol. Chem. Phys. 2003, 204, 22. One aggregate per polymer particle: Carbon black in PS 50 nm Macromol. Chem. Phys. 2001, 202, 51-60. Characterization of functionalized nanoparticles Particle Particlesize sizeand andsurface surfacegroups groupsdensity densitycan canbe beadjusted adjustedby byvarying varyingthe thetype typeand and amount amountof ofsurfactant/functional surfactant/functionalmonomer monomer Poly(styrene-co-acrylic acid) 0.5 wt%, Dz=220 nm, 200 mg Lutensol AT50 2 wt%, Dz=165 nm 1 µm 1 µm 1 µm 0.5 wt%, Dz=170 nm 400 mg Lutensol AT50 Langmuir, 2007, 23(10), 5367-5376. Particle - Cell interaction HeLa HeLacells cells 30 a 3 wt% NH3+ 25 b nFL1 20 20 μm 20 μm c d - COO 0 wt% NH3 + COO + NH3 CO O Surface Surfacefunctional functionalgroups groupsdensity densityinfluence influencethe thecellular cellularuptake uptake CO O + COOCOO CO O O CO O CO + NH3 NH3 + + H3N NH3 + NH3 15 10 5 0 20 μm 50 μm 15 wt% NH3+ 20 wt% NH3+ Increase Increaseof ofsurface surfacefunctional functionalgroups groupsamount amount Musyanovych A., et al. In „Clinical Chemistry Research“, Mitchem, B. H. and Sharnham, C. L. (ed.); Nova Science Publishers, Inc., 2009, Chapter VI. Biomaterials, 2006, 27(14), 2820-2828. Bioactive multifunctional composite particles Induced Induceddrug drugrelease releaseof ofthe thetumor tumornecrosis necrosisfactor factorTNF TNF Functional building block 1 (TNF nanocyte) Functional building block 2 (Lipid layer) Fluorescent amine functionalized particle Funktional building block 3 (PEG-scFv = Ligand) Funktional building block 4 (cleavable PEG chain) J. Control. Release 2009, 137, 69-77. Bioactive multifunctional composite particles FACS + NH3 + NH3 + NH3 + H3 N free lipids/liposomes lipid-encapsulated particles non-encapsulated particles Cryo-TEM - specific 100 nm J. Control. Release 2009, 137, 69-77. - non-specific + NH3 Bioactive multifunctional composite particles cleavage in cell by enzyme tumor necrosis factor becomes active Polymer precipitation within a nanodroplet Poly(L-lactide) Poly(ε-caprolactone) Water Solvent Water Solvent evaporation Poly(lactide-co-glycolide) Polymer Hydrophobic compound, e.g. marker, drug, etc. Particle Particlesize sizeand andsize sizedistribution distributionmainly mainlydepend depend on onthe theamount amountand andtype typeof of polymer polymerused used Macromol. Biosci., 2008, 23(10), 5367-5376. Biodegradable magnetite particles Water Water Solvent evaporation Solvent Polymer Magnetite Effect Effectof ofmagnetite magnetiteamount amount 6.7 wt% 20 wt% 50 wt% Macromol. Chem. Phys. 2009, 210, 961. Degradation of nanoparticles Release Releaseof offluorescent fluorescentdye dye from frompoly(L-lactide) poly(L-lactide) particles particles(HeLa (HeLacells) cells) CLSM Release Releaseof ofmagnetite magnetite from frompoly(L-lactide) poly(L-lactide) particles particles(MSC) (MSC) TEM The Therate rateof ofpolymer polymerdegradation degradationmainly mainlydepends dependson onthe thetype typeof ofsurfactant, surfactant, molecular molecularweight weightand andTTggof ofpolymer polymer Macromol. Biosci., 2008, 23(10), 5367-5376. Crystallization in Gelatin Microgels Transfer to H2O X-linking Gelatine in water droplets Particle size: 220 nm Cross linking with glutaraldehyde Loading with CaCl2+ crystallization by Na2HPO4 Apatite Ca10(PO4)6(OH)2 in gelatin microgels Biomacromolecules, 2008, 9(9), 2383. Adv. Funct. Mater., 2008. Encapsulation of liquids in miniemulsion Capsules via phase separation hydrophobic oil polymer Styrene/ Hexadecane PMMA/Parfume Demixing Polymerization and phase separation 500 nm Final morphology depends on: • the interfacial tension between three different phases (polymer, continuous phase, dispersed nanodroplet) • kinetics of the polymerization vs phase separation • miscibility of the phases Macromol. Chem. Phys. 2009, 210. Langmuir 2001, 17, 908-917. Capsules via polymer nanoprecipitation in inverse miniemulsion Solvent/Non-solvent Non-solvent Solvent evaporation Water Water Polymer poly(L-lactide) poly(L-lactide)capsules capsules 200 nm poly(ε-caprolactone) poly(ε-caprolactone)capsules capsules 200 nm Macromol. Biosci. 2006, 6(1), 33-40 Capsules via reaction at the interface Oil Addition of M2 Crosslinking reaction at the interface M1 Water, hydrophilic compounds, e.g. salt, contrast agent, DNA, etc. Hydrophilic monomer O=C=N HO OH O R R' N=C=O Polymeric shell M1: Crosslinking: M2: Redispersion in Water aqueous phase Oil + C or H2N O NH2 R R O H N C O R' H N H N or C O Polyurethane n C O R H N H N C R' O Polyurea H N C O n Capsules via reaction at interface Polyurethane Polyurea Crosslinked starch 200 nm M1: Crosslinking: M2: R' O=C=N N=C=O HO C O R' + N=C=O n O R Hydrolysis: H N OH C or H2N R O O C O NH2 R' H N H N C or C O R O n H N C O R' H N C R' H N C O n Polyurea H N NH-COOH C n H N O Polyurethane R + H2O H N O R' NH2 + CO2 Macromolecules 2007, 40, 3122. n Langmuir, 2009, (in press). Capsules via reaction at interface Anionic Anionicpolymerization polymerizationof ofn-butylcyanoacrylate n-butylcyanoacrylate(BCA) (BCA) CN n CH2 C OH CN - HO CH2 CN C CH2 C- CN H+ HO CH2 C CN CH2 CH O=C O=C O=C O=C O=C O O O O O C4H9 C4H9 C4H9 C4H9 n -1 DNA- Marker Oil PBCA shell 400 200 100 Progr. Colloid Polym. Sci., 2008, 134, 120. C4H9 Amount of dsDNA inside the droplets 1000 600 dsDNA (790 bp) n -1 Amount of dsDNA inside the PBCA capsules About 15% of encapsulated DNA is in a form of free chains Capsules via reaction at interface Increase Increaseof ofn-butylcyanoacrylate n-butylcyanoacrylateconcentration concentration Progr. Colloid Polym. Sci., 2008, 134, 120. Capsules as nanocontainers Reaction in the nanocapsule, e.g. reduction of Ag+ to Ag Hydrophilic Gd complexes for magnetic resonance imaging (MRI) Biomedical application H H O O H H H O H Gd3+ 3+ Gd3+ Gd H O H H O H Macromol. Chem. Phys. 2007, 208, 2229-2241. Gd3+ O H O H H O 200 nm H H H O H H Multiplication of dsDNA inside the drolpets PCR 50 nm Macromolecules 2007, 40, 3122-3135. Biomacromolecules 2005, 6(4), 1824-1828 Droplets as “Bioreactors” Polymerase PolymeraseChain ChainReaction Reaction DNA DNAtemplate: template:286 286bp bp PCR PCR––product: product:135 135bp bp DNA- Marker dsDNA Oil + Surfactant Primers dNTPs Taq DNA Polymerase Taq 10x Buffer Mechanical stirring 1500 bp 600 bp 400 bp 200 bp PCR, several cycles Ultrasonication 100 bp Biomacromolecules 2005, 6(4), 1824-1828 Cellular uptake Polyurea Polyureacapsules capsuleswith with fluorescein fluorescein taken takenup upby byHeLa HeLacells cells Crosslinked Crosslinkedstarch starch capsules capsuleswith withrhodamine rhodamine taken takenup upby byHeLa HeLacells cells CLSM CLSM Langmuir, 2009, (in press). Release Releaseof ofmagnetite magnetite from frompoly(L-lactide) poly(L-lactide) particles particlesin inMSC MSC TEM Release mechanisms 1. Slow release • Diffusion from the nanocapsules: release depends on the shell thickness and type of polymer 2. Fast release •„switch“ e.g. by temperature, pH change, enzyme… • Degradation of the nanocapsules: release depends on (bio)degradibility without azo compound Incorporation of blasting agent inside the capsule with azo compound Macromol. Mater. Eng. 2007, 292, 1237-1244. Summary uptake by cells Inert polymer, e.g. polystyrene Hydrophilic surface specifity to certain cells Other receptors, e.g. TNF or Contrast agent, e.g. MRI Biodegradable polymer, e.g. polylactide D marker included “Stealthness”, e.g. PEG-chains Fluorescent marker defined release Release receptor, e.g. pH, T, UV-sensitive, enzyme… stable in blood stream Drug Cell receptor encapsulation of drugs Acknowledgments Grit Baier (Cross-linked starch and PBCA capsules, PCR) Eva Rosenbauer (Polyurea capsules) Dr. Umaporn Paiphansiri (Polyurethane capsules) Markus Urban University of Ulm Prof. Paul Walther Dr. Oliver Zimmermann Dr. Juliane Weich Institute of Cell biology and Immunology, University of Stuttgart Prof. Roland Kontermann Sylvia Messerschmidt (Polylactide composite particles) MPI for Polymer Research Anika Hamberger Dr. Anitha Ethirajan Dr. Daniel Crespy Dr. Ingo Lieberwirth (PMMA capsules with blasting agents) Financial support: DFG (SPP1259, 1166, SFB); Max Planck Society; EU VW-Stiftung; Fonds der Chemischen Industrie; Degussa/Evonik Landesstiftung BW; BASF; Bayer Materials; Clariant