“La deposition couche-par-couche : Les millefeuilles moléculaires ” à tout faire

advertisement

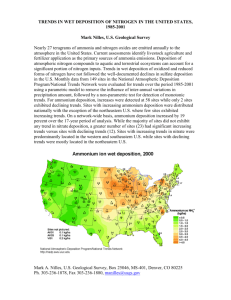

“La deposition couche-par-couche : Les millefeuilles moléculaires à tout faire” Traitements de surfaces des matériaux souples : Quels procédés pour quelles applications ? Journée ECRIN-Traitements de Surfaces et ECRIN-Agroalimentaire, Grenoble, le 13 octobre, 2005 Layer-by-Layer Assembly (LbL): An Enabling Technology for the Nanofabrication of Multicomposite Films on Solvent Accessible Surfaces. Gero Decher / Institut Charles Sadron Pierre Schaaf, Gero Decher, Jean-Claude Voegel La Recherche, No. 389, SEPT. 2005, 56-58 Institut Charles Sadron New Laboratory 2006 Integration into the Materials Science Campus / Cronenbourg The Strasbourg Multilayer Team : Chemistry (CNRS, UPR22) Physics (CNRS, UPR22) Biomedicine (INSERM, U595) G. Decher P. Schaaf J.-C. Voegel Ph. Mesini O. Felix V. Vivet A. Izquierdo S. Ono B. Saulnier M. Eckle D. Pointu G. Schneider B. Struth V. Ball G. Ladam P. Nagankam F. Boulmedais E. Hübsch N. Laugel M. Michel C. Porcell P. Schwinte ... C. Picart N. Jessel Ph. Lavalle F. Cuisinier J. Ogier A. Klucsar J. Chluba B. Senger L. Richert ... Differences between chemistry in bulk and at interfaces Some trivia: • Surface functional groups accessible only from the solution side. ( SN1 might be favored over SN2 ; reactivities different from bulk) • Typical monolayer thicknesses of 0.5 nm to 5 nm. • Typical surface areas of 0.20 nm2 per molecule, 5 1014 molecules per cm2. • At a mass of 400 g/mol, 1 cm2 of a densely packed monolayer corresponds to 0.33 μg of material. • 5g (semi-preparative scale), would cover an area of 1500 m2. • Monomolecular layers of polymer may be thinner and less dense and typically consist of 0.1 to 1.5 mg of material per 1 m2. • Less than 0.02 mg for chemical analysis and physical characterization Advantage: We only need tiny amounts from colleagues doing synthesis For years, surface modification has been difficult. Now, functional surfaces and objects can be built to order using Layer-by-Layer deposition Build-to-Order Assembled Films Build-to-Order (BTO) is the capability to quickly build standard or mass-customized products upon receipt of spontaneous orders without forecasts. Layer-by-Layer assembly allows to design functional surfaces and surface-based nano-devices in a "build-toorder" fashion. It exceeds simple self-organization under equilibrium conditions by making it possible to arrange many different materials at will with nanoscale precision. Ready for a paradigm change in surface functionalization ? Can we dream to functionalize any surface with any ligand, independent of the substrate material, its shape or its size, by adsorption from aqueous solutions ? Toward a paradigm change in surface functionalization Drawbacks of direct covalent coupling (grafting): • • • • • optimisation of conditions for each ligand/surface combination side-products of the reaction cannot be removed very difficult to get a detailed chemical composition of the surface sometimes difficult to vary the density of functional groups organic solvents or harsh conditions are frequently required A modular approach: 1. Coupling, 2. Adsorption F F F F + + + + - - - - - - - - - Advantages of a two step (modular) approach: 1) • • • • classical chemical coupling of a ligand to a polymer in solution routine analysis of reaction products option to separate reaction products degree of substitution can be controlled quality control before deposition 2) • • • deposition of the polymer on the surface similar to identical deposition conditions for different ligand/surface combinations mild deposition conditions from aqueous solutions characterisation can be carried out on separate samples, even on different substrates Schematic of the Layer-by-Layer Deposition Process Simplified “molecular” molecular” picture of the first two adsorption steps depicting film deposition as starting with a positively charged substrate. Counterions are omitted for clarity. Polyion conformation is highly idealized and layer interpenetration is not shown in order to better represent the surface charge reversal with each adsorption step. G. Decher, Science 277, 1232-1237 (1997) Automatic Layer Deposition Using a “Dipping” Robot Automated deposition device, R&K Ultrathin Organic Film Technology, Berlin, Germany The process is (in general) very reliable, the film thickness being precisely controlled by the ionic strength PEI/(PSS/PAH)5 on quartz from x M NaCl automated device; no intermediate drying 300 0.15 300 0.14 280 0.14 280 260 0.13 220 0.11 200 0.10 180 160 0.09 260 0.13 240 0.12 220 0.11 200 0.10 180 160 0.09 140 0.08 140 0.08 0.4 0.6 0.8 1.0 1.2 1.4 1.6 0.4 0.6 0.8 cNaCl D [Å] A @ 226 nm y = m1 + m2*m0 m1 m2 Chisq R Value 0.054 0.061 6.8405e-06 0.99822 1.2 1.4 1.6 m1 m2 Chisq R Value 67 146 243.12 0.98912 D [Å] A @ 226 nm y = m1 + m2*m0 Error 0.002 0.003 NA NA 1.0 cNaCl y = m1+m2*m0 Error 15 15 NA NA y = m1+m2*m0 m1 m2 Value 0.059 0.063 Error 0.006 0.006 m1 m2 Value 74 150 Error 1 1 Chisq 4.3167e-05 NA R 0.98951 NA Chisq 1.151 NA R 0.99995 NA D [Å] 240 0.12 A @ 226 nm 0.15 D [Å] A @ 226 nm PEI/(PSS/PAH)5 on quartz from x M NaCl manual dipping; dried after every layer Some polyions already “multilayered”, here we use PSS and PAH SO3OSO3- Na+ N NH SO2 SO3- Na+ O- Na+ NH+ • O O S HO3S NH HO3S HN N N CO2Na+ OH NaPSS PVS NH3+ Cl- PAZO S+ Cl - PAPSA SPAN PTAA PAMPSA + H + N Cl - NH2 N + N N R H2N HN N+ N I- N S+ Cl HN NH2 PSMDEMA PAH Pre-PPV PDDA PMPyA R-PHPyV PEI Inversion of surface charge with deposition of each layer 40 PAH Zeta Potential [mV] Adsorption of polycations poly(ethylene imine) imine) (PEI) and poly(allyl poly(allyl amine) (PAH) renders the surface positively charged. The deposition of poly(styrene sulfonate) sulfonate) (PSS) yields a negative surface charge. Similar measurements were also obtained from other groups. PEI PAH PAH PAH PAH 20 0 -20 PSS PSS PSS PSS PSS -40 bare SiO surface 2 0 5 10 15 20 25 30 35 40 For a theory of surface charge inversion see M. Castelnovo and J. F. Joanny, Langmuir 16(19), 7524-7532 (2000) and for a mechanism of multilayer formation see J. B. Schlenoff and S. T. Dubas, Macromolecules 34(3), 592-598 (2001). Number of Measurement G. Ladam, P. Schaad, J. C. Voegel, P. Schaaf, G. Decher, and F. Cuisinier, Langmuir 16(3), 1249-1255 (2000). QCM-D (Q-Sense D300), Q-Sense AB, Gothenburg, Sweden, unpublished data Creating New Film Architectures is: SIMPLE ! At least 2 oppositely charged (or otherwise interacting) molecular species are required. If the 2 solutions yield a precipitate upon mixing, chances for “multilayering” multilayering” are excellent. Adding more “beakers” beakers” leads to periodic or non-periodic multilayer architectures as defined by the deposition sequence. Typical concentrations: 0.1 to 20 mg/ml Typical adsorption times: 20 seconds to 1 hour 10 7 10 5 8.0 10-6 7.0 10 -6 6.0 10 -6 5.0 10 -6 n Scattering Length Density [Å-2] Reflected Intensity (Neutron) From Neutron Reflectivity Curves: Number of Deuterated Layers, Layer Positions and Layer Profiles 10 10 3 1 10-1 10-3 10-5 0 0.02 0.04 0.06 Qz [Å-1 ] 0.08 0.1 4.0 10-6 3.0 10 -6 2.0 10 -6 1.0 10 -6 0.0 10 0 0 500 1000 1500 2000 2500 Z [Å] M. Lösche, J. Schmitt, G. Decher, W. G. Bouwman, and K. Kjær, Macromolecules 31, 8893-8906 (1998). Large surfaces are coated by spraying Albert Izquierdo and Claudine Porcell High-Speed Layer-by-Layer Deposition A. Izquierdo 15 min. / layer 6 sec. / layer 50 -150 times faster A. Izquierdo, S. S. Ono, J.-C. Voegel, P. Schaaf, and G. Decher, Langmuir 2005, 21, 7558-7567 New Applications require Substrate-Free Membranes Dr. Shoko Ono Functional layer Multilayer formed via electrostaticinteraction pH 2 => 7 pH responsive layer Multilayer formed via hydrogen-bonding 5 mm 4 mm Self-Standing Polyelectrolyte Multilayer Film Release of the Membrane from the Substrate n = 20 n = 80 PEI/(PAA/PEG)9/PAA/(PAH/PSS)n Which Factors Control Release ? 2) Chemical Composition of the Upper Layer PEI (PAA/PEG)9PAA (PAH/PSS)12 (PAH/Clay)20 Clay Platelets pH 2 stiff 24 mm Neutral pH Photo in Milli-Q water Mechanical Reinforcement Barrier Layer (B. Struth, M. Eckle, G. Decher, R. Oeser, P. Simon, D. W. Schubert, and J. Schmitt Europ. Phys. J. E 6 (5), 351-358 (2001). Can be made on ANY surface Control of composition Dierent colors represent dierent functionalities Examples: proteins, factors, nanoparticles, … nanoscale 50 nm to Components can be fixed or mobile Porosity control, … macroscale 5 mm Molecular scale (0.5 to 10 nm) "The nature of a biomaterial surface governs the processes involved in biological response." B. D. Ratner, A. B. Johnston and T. J. Lenk, J. Biomed. Mater. Res., Vol. 21, (1987), 59-89. Motivation for Research • Human benefit Making available medical treatments and devices for improving the quality of life • Economic reasons The medical device industry has yearly sales of at least US $ 100 billion, worldwide (1999). A modular approach: 1. Coupling, 2. Adsorption F F F F + + + + - - - - - - - - - Advantages of a two step (modular) approach: 1) • • • • classical chemical coupling of a ligand to a polymer in solution routine analysis of reaction products option to separate reaction products degree of substitution can be controlled quality control before deposition 2) • • • deposition of the polymer on the surface similar to identical deposition conditions for different ligand/surface combinations mild deposition conditions from aqueous solutions characterisation can be carried out on separate samples, even on different substrates The Advantage of Synthesis Followed by Standardized Deposition: Quality Control and Independence of Substrate H N O O H H N O H N NH H N O O H O S N O NH+3 Br- O n = 220 NH O NH2 y=3 x=1 N-methyl-morpholine, H20 / CH3CN 4h, room temperature H H N S O N H H Rather than optimizing the coupling chemistry for each ligand and each substrate individually, the combination of solution coupling with a standardized deposition procedure represents an important competitive advantage. A Photopatterned Multilayer with Biotinylated Polymer and Fluorescently Labeled Streptavidin A “me too” experiment underlining that LbL is capable of adressing problems similar to the ones treated by e.g. classic coupling methods. Decher, G.; Lehr, B.; Lowack, K.; Lvov, Y.; Schmitt, J., Biosensors and Bioelectronics 1994, 9, 677-684. RGD - induced promotion of osteoblast binding to cationic surfaces V. Vivet, Ph. Mesini with F. Cusinier, J.-C. Voegel cell RGD Last layer PLL (poly-l-lysine) NH H3N C O O HN O C N H C C O H N O C N H C O H N C OH O C HO O HN C PLL Spacer H2N NH RGD Last layer PLL-RGD Film Architectures Allowing to Control the Access of Cells to Neighboring Functional Layers: Tailored Bio-Interfaces Monocytes accessing an embedded layer of Protein A, probably by developing extensions called pseudopods. This behavior is controlled/suppressed by choosing the chemical composition of the individual layers within the film architecture. N. Jessel, F. Atalar, Ph. Lavalle, J. Mutterer, G. Decher, P. Schaaf, J.-C. Voegel and J. Ogier Adv. Mater. 15(9) (2003), 692-695 TNF- secretion as a function of layer composition Poly-L-Lysine A Poly-D-Lysine B N. Jessel, F. Atalar, Ph. Lavalle, J. Mutterer, G. Decher, P. Schaaf, J.-C. Voegel and J. Ogier Adv. Mater. 15(9) (2003), 692-695 A single technology for coating surfaces of any size and any shape ? Surfaces of Any Kind and Any Shape? Here is an example of hollow multilayer capsules made by templating on colloidal particles First, deposit polyelectrolytes on a micron-sized colloid Then dissolve the colloid core E. Donath, G. B. Sukhorukov, F. Caruso, S. A. Davis, and H. Möhwald, Angew Chem Int Ed 37, 2202-2205 (1998). Polyelectrolyte - Charged Sphere Interaction in Theory Rene Messina, Christian Holm and Kurt Kremer, Langmuir 2003, 19, 4473-4482 Equilibrium conformations of polyelectrolyte chains on small spheres as a function of the strength of the specific van der Waals attraction 1) a single polyelectrolyte chain on an oppositely charged sphere 2) two oppositely charged polyelectrolyte chains 3) many polyelectrolyte chains ( (a) to (c) = increasing number of chains) Powerfull Templates: Gold Nanoparticles (13.5 nm) 1.6 eff Absorbance Absorption 1.4 1.2 1.0 0.8 0.6 0.4 m 0.2 0.0 300 400 500 600 Wavelength (nm) Longueur d'onde (nm) Advantages: dispersion in water plasmon band reports of the surrounding medium 700 800 Spectroscopy vs. Electron Microscopy 0,30 520 nm Absorbance 0,25 0,20 650 nm 0,15 0,10 0,05 0,00 300 400 500 600 Wavelength (nm) 700 800 Colorful Colloids Excess of polycation 1:1 stoichiometry Excess of colloids Excess of polymer must be removed Flocculation (worst case) Incomplete surface coverage So, evaluation by the naked eye allows to quickly screen a whole matrix of parameters or the ageing of samples Multilayer deposition as observed by TEM Redispersion of coated nanoparticles in the absence of agitation Taken after deposition of layer #14 (corresponding to 27 centrifugation cycles) Dilution factor 50-60 per cycle Average recovery 95% per layer over 20 layers A single aspiration/release in the tube at the very right Reproducibility Dissolution of the gold core with KCN: Empty Nanospheres 2 Au + 1 /2 O2 + H2O + 4 KCN 2 K[Au(CN)2] + 2 KOH LbL is (analogous to) a chemical reaction ! Classic Synthesis Reagent(s) (atoms, synthons) series of reaction steps LbL - Deposition Surface (template) series of deposition steps Product(s) (typically single species) Multilayer Film (defined layer sequence) Molecular scale Nano (meso) scale Multilayer Thin Films: Sequential Assembly of Nanocomposite Materials; Decher, G. and Schlenoff, J. B., eds., Wiley-VCH: Weinheim, 2003; 524 pages. „Reagents“ for LbL Deposition Reagents: polymers colloids biomacromolecules small molecules small & complex ions linear branched (starshaped) copolymers tacticity degree of polymerization composition monomer sequence polymeric metallic oxidic size polydispersity composition surface functionality proteins polynucleotides bioaggregates ... ... ... Multilayer Thin Films: Sequential Assembly of Nanocomposite Materials; Decher, G. and Schlenoff, J. B., eds., Wiley-VCH: Weinheim, 2003; 524 pages. LbL - the ONE does it ALL nano-coating solution Technological advantages over competitive techniques: (Langmuir-Blodgett, self-assembled monolayers, covalent coupling, grafting from, grafting to, spin coating, ...) • • • • • • • Broadness, Integrateability, Adaptability, ... Choice of components (bio/macro)molecules, colloids, ... Choice of surfaces (any size, any shape) Choice of solvent (water, others are possible) Patternability Quality control (chemical purity, homogeneity, reproducibility) Overall device yield All competitive techniques are limited (if not fail) with respect to several items of this list (in comparison with LbL) However, LbL can easily be integrated with most competitive techniques ! pseudo - inconvenience of LbL: • Number of proccessing steps - increases with number of components - increases with numbers of layers - BUT it just means adding a beaker (baths) to the deposition chain For years, surface modification has been difficult. Now, functional surfaces and objects can be built to order. Please ask us ! < decher@ics.u-strasbg.fr > Thank you for your attention ! A list of recent reviews, newsletters and books: (1) Decher, G., Layered Nanoarchitectures via Directed Assembly of Anionic and Cationic Molecules; in: Comprehensive Supramolecular Chemistry, Vol. 9, "Templating, Self-Assembly and Self-Organization" (Sauvage, J.-P. and Hosseini, M. W., Eds.), Pergamon Press: Oxford, 1996; 507-528. (2) Decher, G., Fuzzy Nanoassemblies: Toward Layered Polymeric Multicomposites, SCIENCE 1997, 277, 1232-1237. (3) Decher, G.; Eckle, M.; Schmitt, J.; Struth, B., Layer-by-Layer assembled multicomposite films. Curr. Opinion Coll. & Interf. Sci. 1998, 3, 32-39. (4) Bertrand, P.; Jonas, A.; Laschewsky, A. and Legras, R., Ultrathin polymer coatings by complexation of polyelectrolytes at interfaces: suitable materials, structure and properties. Macromol. Rapid. Commun. 2000, 21, 319348. (5) Paula T. Hammond, Recent explorations in electrostatic multilayer thin film assembly. Curr. Opinion Coll. & Interf. Sci. 2000, 4, 430-442. (6) Michael Freemantle, C&EN: Science & Technology - Polyelectrolyte Multilayers, Chemical & Engineering News, May 6 (2002), Vol. 80 (18), pp. 44-48 (7) Jessica Gorman, Layered Approach: A simple technique for making thin coatings is poised to shift from curiosity to commodity, Science News, Week of Aug. 9, 2003; Vol. 164, No. 6 (8) Multilayer Thin Films: Sequential Assembly of Nanocomposite Materials; Decher, G. and Schlenoff, J. B., eds., WileyVCH: Weinheim, 2003; 524 pages. A presentation is too short to tell the whole story Our book was the bestseller in the Wiley-VCH Materials Science series in 2003 Multilayer Thin Films - Sequential Assembly of Nanocomposite Materials Decher, G. / Schlenoff, J. B. (eds.) With a Foreword by Jean-Marie Lehn Wiley-VCH, Weinheim, Germany, 2002, 524 pages ISBN 3-527-30440-1 Chapters from: G. Decher (Institut Charles Sadron), V. Kabanov (Moscow State University), J. F. Joanny (Institut Curie), J. Schlenoff (Florida State University), M. Rubner (MIT), T. Kunitake and Y. Lvov (RIKEN and Louisiana State University), A. Jonas (University of Louvain-la-Neuve), N. Kotov (Oklahoma State University), J. Fendler (Potsdam, USA), P. Hammond (MIT), J. Shen and X. Zhang (Jilin University), F. Caruso and G. Sukhorukov (MPI-KG), H. Möhwald (MPI-KG), D. Kurth and R. v. Klitzing (MPI-KG and TU Berlin), B. Tieke (University of Cologne), R. Claus (Viginia State University), M. Brüning (Michigan State University) The Field is Rapidly Expanding The first symposium on 120 number of publications / year Polyelectrolyte Multilayers 500 total number of publications Was held on occasion of the 100 400 American Chemical Society National Meeting - Colloid Division San Francisco, Ca., March 26-31, 2000 80 Joseph B. Schlenoff, Gero Decher, organizers 300 60 More Symposia: 223rd ACS National Meeting Orlando, Florida, April 7-11, 2002 226th ACS National Meeting New York, Sept. 7-11, 2003 227th ACS National Meeting Anaheim, Ca. March 28-April 1, 2004 200 40 100 20 0 1990 0 1992 1994 1996 publication year 1998 2000 Source: P. Bertrand, A. Jonas, A. Laschewsky and R. Legras Macromol. Rapid. Commun. 21 (2000), 319-348