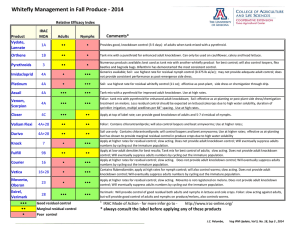

Carbon-Free, Site Independent Energy Storage for Grid Integration Boise State University Performance

advertisement

Carbon-Free, Site Independent Energy Storage for Grid Integration D. Shively, Dr. J. Gardner, T. Haynes, Dr. J. Ferguson Boise State University Performance Introduction The inherent intermittency of the two fastest growing renewable energy sources, wind and solar, presents a significant barrier to their widespread penetration and replacement of fossil-fuel sourced electricity generation. These intermittencies range from short term ramp events experienced by wind farms to the diurnal fluctuation of solar installations. The goal of this research is to develop an energy storage technology that is capable of meeting the challenges posed by renewable energy. This approach is similar to existing Compressed Air Energy Storage but with two key differences: it avoids the requirement of natural gas combustion that is mandatory in the traditional compressed air energy storage systems and is not site specific. The proposed approach incorporates the most attractive attributes from traditional CAES and pumped hydro energy storage systems and eliminates some of their shortcomings. This system is not site-specific, does not require natural gas, and has the potential to be very efficient. Water discharge reservoir Water Turbine/ Electric Generator Air/Water interface Energy in, Energy out, and Efficiency as functions of alpha (ratio of initial to final volume of air) Compressed air storage tanks (possibly tube trailers) Compressor One-Week Simulation Artistic rendition of how the system may look. Parameters: Cycle Four events are fundamental to the cycle • Wind Power Input – anemometer data taken from site in southern Idaho • Fourteen GE 1.5MW wind turbines = 21 MW • Target compression pressure = 3000 psi • Five 1MW pelton turbines for power output 20 Wind Power Energy Storage Power Output 18 Fill Existing Bulk Energy Storage 16 Power (MW) 14 Vent Compressed Pressurize 12 10 8 6 4 Air: 2 x Requires natural gas x Site specific 0 0 1 2 3 4 5 6 7 Time (days) Sinusoidal power output to approximate daily load curve Extract 20 Wind Power Energy Storage Power Output 18 16 Fill Pumped Hydro: x High capital cost x Site specific Power (MW) 14 The tank should be filled with water to an appropriate ratio of air to water: V Initialvolumeof air α= i = Vf Finalvolumeof air 12 10 8 6 4 2 0 0 1 2 3 4 5 6 7 Time (days) Constant power output 20 Wind Power Seneca, PA Energy Storage Power Output 18 16 Power (MW) 14 Proposed Energy Storage System Dual Fluid Energy Storage: Does NOT require natural gas NOT site specific High efficiency 12 10 8 6 4 2 Stored energy (normalized) as a function of alpha (ratio of initial to final volume of air). Pressurize 0 0 1 2 3 4 5 6 7 Time (days) Daily scheduled power output, such as to meet peak demand Power is input to the compressor until the target pressure is reached Extract •Pressurized air exerts a spring-like force on the water; valve is opened allowing water to drive an impulse turbine connected to a generator •Power output from turbine controlled through variable diameter nozzle Vent/Re-Fill •After tank is empty of water, residual pressure (and thus energy) remains in the tank • If residual pressure is left in the tank, additional energy is required to pump water back into tank • Venting the residual pressure increases energy losses per cycle • Using a two-tank venting algorithm, water can be moved back into the tank while only venting a fraction of the residual energy Mechanical diagram of energy storage system. Further Research • Investigate ways in which this system could benefit grid operators • For desired power capacity, energy capacity, and time of storage, a correctly sized system could be determined • Applications and performance metrics can be adjusted to function in various regions according to different grid requirements • Investigate batch operation: multiple tanks within a correctly sized system providing a continuous power output under variable input • Determine how application, power capacity, and energy capacity influence capital costs and payback periods