Chemical Analysis

advertisement

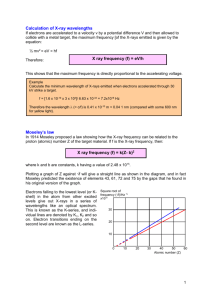

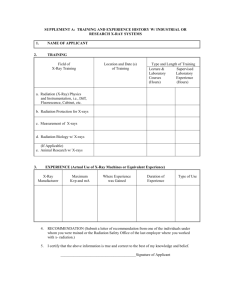

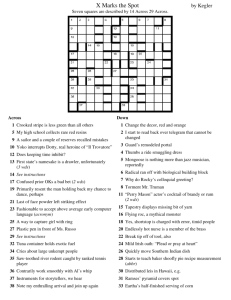

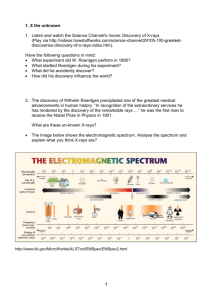

MSE 421/521 Structural Characterization Chemical Analysis We have so far discussed several of the signals detected on interaction of a high-energy electron beam with a solid sample (secondary, backscattered, transmitted, and diffracted electrons); however, none of these give us any direct information about the chemical composition (elements present) of the sample. To obtain this information, we must detect the x-rays emitted using the techniques of energy dispersive spectroscopy (EDS) or wavelength dispersive spectroscopy (WDS) or transmitted electrons using electron energy loss spectroscopy (EELS). Energy Dispersive X-Ray Spectroscopy (EDS) When high-energy electrons hit the sample, their deceleration causes x-rays to be emitted. In other words, their kinetic energy is transformed into photons of x-ray radiation. These x-ray emissions are sometimes called heterochromatic, polychromatic, continuous, or white radiation, as it is made up, like white light, of a mixture of rays with many wavelengths. It is also called Brehmsstrahlung (German for “braking radiation”) because it is caused by electron deceleration. These electrons are also capable of ejecting an inner electron from the atom, thus leaving a hole in the lower shell and putting the atom in an excited state. An outer electron can fill this hole by dropping down into it, releasing a quantum of energy via an x-ray photon (§ II.E.3.d., & IV.A.2.d). The energy of this photon will correspond exactly to the quantum energy difference between the outer and inner shells of the atom, which is a specific value for each species of atom. Wavelengths for the x-ray photons released by transitions of electrons from the L to K shell (socalled Kα photons) and from the M to K shell (Kβ photons) in some elements are: Element Cr Fe Co Ni Cu Mo Wavelength (Å) Kα Kβ 2.29100 2.08487 1.937355 1.75661 1.790260 1.62079 1.659189 1.500135 1.541838 1.392218 0.710730 0.632288 In reality, two finely separated wavelengths are observed for Kα (Kα1 and Kα2) for each element due to the exchange of angular momentum between the electron and the x-ray photon. In EDS, a reverse-biased Li-drifted Si semiconductor detector with gold electrodes is used to classify the x-rays according to energy. This type of detector is made in various sizes. A typical crystal for an SEM has a detecting area of about 10mm2. The analytical TEM will use a 30mm2 detector placed very close to the specimen to make the most of the weak signals from very small areas. X-rays from the sample pass through a thin Be or polymer window into the Si where they create electron-hole pairs which cause a current pulse proportional to the x-ray energy. Absorption of each individual x-ray leads to ejection of a photoelectron which gives up most of its energy in the formation of electron-hole pairs. The number of electrons formed per photon is: R. Ubic VII-1 MSE 421/521 Structural Characterization N= x − ray energy (eV ) 3.81 eV where 3.81 eV is the average energy for electron-hole formation in Si. The electron-hole pairs are swept away by an applied bias which is set high enough to separate them before recombination occurs. The charge pulse formed is converted to a voltage pulse by a charge-sensitive pre-amplifier (a field effect transistor - FET). The signals are further amplified and shaped by a main amplifier and finally passed to a multi-channel analyser (MCA) where they are sorted by voltage. Note that the voltage pulse is proportional to the x-ray energy. The contents of the MCA memory are transmitted to a computer for further processing such as peak identification or quantification. The memory typically has 1000 channels each 20eV wide so that the energy range covered is 20keV, and this range is analysed simultaneously (it is a parallel technique). Ca½NdTi2O6 4000 O Kα 2500 Nd Lα 2000 1500 Ca Kα 1000 Ca Kβ 500 0 0 2 4 Ti Kβ 1500 1000 Ca Kα Nd Lβ1 Nd Lβ2 Nd Lγ Cu Kα 6 8 Energy (keV) 500 Cu Kβ 10 SEM Be window Ti Kα 2000 Intensity Intensity 3000 TEM thin window Ti Kα 3500 Ca½NdTi2O6 2500 0 0 Ca Kβ 2 4 Nd Lα Ti Kβ Nd Lβ 1 Nd Nd Lβ2 Lγ 6 Energy (keV) 8 10 The Si detector is mounted on a cold finger connected to a liquid N2 dewar which holds up to a week’s supply. The system is sealed under vacuum both to prevent contamination and to more easily maintain the low temperature. The Si crystal is held at liquid N2 temperature to limit the mobility of the Li+ ions and stop the thermal creation of electron-hole pairs in the Si. In order to prevent the crystal becoming contaminated with hydrocarbons from the vacuum system, it is typically screened with a thick (7.5µm) Be window or a thin (1µm) Mylar window. With a Be window, soft (low-energy) x-rays are blocked so only elements with Z>11 (Na) can be detected. With a thin Mylar window, elements as low as Z=5 (B) can be detected. On some instruments the window has been removed completely (windowless), but even then the detector has poor sensitivity for light elements. EDS systems are frequently used on SEMs and TEMs where they give rapid qualitative analysis of the elements present in small volumes of the sample. R. Ubic VII-2 MSE 421/521 Structural Characterization Wavelength Dispersive X-Ray Spectroscopy (WDS) In WDS a crystal monochromator, X, is used to analyse x-rays from a specimen, S. The diffracting crystal, X, is rotated through a range of angles θ while the detector, C, is rotated simultaneously through angle 2θ. This set-up is exactly analogous to the monochromators used in x-ray diffractometers. S C X 2θ θ Values of θ at which the output of the detector passes through a maximum are measured, enabling the corresponding values of λ to be calculated from Bragg’s Law. WDS is thus a serial technique in that peaks are measured one at a time as the crystal and detector are slowly rotated. A series of interchangeable crystals with different d spacings are used to cover a large range of wavelengths. The crystal spectrometer has a rotatable turret with up to four crystals (of area 10x30 or 20x25mm). Approximate range covereda Formula or abbreviation LiF PET ADP TAP RAP LTD STE LOD LTE a Chemical name Lithium fluoride Pentaerythritol Ammonium dihydrogen phosphate Thallium acid phthalate Rubidium acid phthalate Lead tetradeconate Stearate Lead octadeconate Lead lignocerate d (Å) 2.013 4.371 5.321 12.87 13.06 39 50 50.35 65 λ (Å) 0.97-3.65 2.12-7.92 2.57-9.64 6.23-23.3 6.32-23.7 18.90-70.7 24.20-90.6 24.40-91.3 31.50-118 Κ 20-36 14-24 13-22 9-14 8-14 5-8 5-7 5-7 4-7 L 50-89 36-63 34-57 24-39 24-39 17-25 17-23 17-22 17-20 Μ -71-92 66-92 53-76 53-76 ----- Calculated for a spectrometer with “average” range of 2θ coverage, 28° - 130°. With appropriate crystals WDS can be used to analyse for elements with Z as low as 4 (Be). The advantages of WDS are its high sensitivity, 7 - 1950 ppm, meaning easier trace element analysis, and its high energy resolution (2 - 48eV), enabling close peaks (overlapping in EDS) to be resolved. A perennial problem in barium polytitanate-based ceramics, for example, is the difficulty in quantifying Ba and Ti contents due to the overlap of the Ba Lα1 (4.46626 keV) and Ti Kα1 (4.508 keV) peaks in EDS. These peak maxima occur 41.74eV apart, but as the typical resolution of an EDS detector is ≈135eV, they are unresolvable by EDS. The increased resolution available via WDS enables both the separation of these two peaks and reliable quantification of results. R. Ubic VII-3 MSE 421/521 Structural Characterization Typically, a proportional counter is used to detect the x-rays in a WDS system. The diffracted x-rays are detected by a simple gas ionisation process. X-rays are incident on the device and pass through an x-ray-transparent window into a chamber filled with an inert gas, e.g., Ar. The x-rays ionise gas atoms, and the free electrons created accelerate towards the wire anode by a 1000 V potential difference. The positively charged gas ions move towards the casing. Because the field is so intense, the electrons acquire a great deal of energy on their race to the wire – so much so that they are able to knock additional electrons off atoms they hit along the way, thus causing a cascade of electrons or gas amplification. The current in the wire is proportional to the numbers of x-rays arriving, i.e., intensity. If the voltage is reduced to, say, 200 V, the result is what is usually called an ionisation chamber. Freed electrons will no longer have sufficient energy to further ionise atoms and cause amplification. Such a device was used in the original Bragg spectrometer but is now obsolete because of its low sensitivity. If, on the other hand, the voltage is increased to, say, 1500 V, the device will act as a Geiger counter. Because they are unable to count at high rates, the Geiger counter is now also obsolete in diffractometry. R. Ubic VII-4 MSE 421/521 Structural Characterization X-rays in Argon gas Pulse counter electronics Window High voltage ≈ 1000V wire proportional counter An electron probe microanalyser (EPMA) is a dedicated system for the quantitative analysis of chemical composition using WDS; however, SEMs can have WDS spectrometers attached to them to facilitate accurate quantification and light-element analysis. Elemental Distribution The distribution of elements within a given microstructure can be obtained using an SEM or TEM with scanning attachments and either an EDS or WDS detector. The information is obtained either as a line scan or as a distribution dot map. Whichever the case, the spectrometer is operated so that only x-rays of a single energy or wavelength are recorded. This process is straightforward with a WDS crystal spectrometer, which detects x-rays in a serial manner anyway; but in an EDS system it involves setting a single element “window” so that an output pulse is obtained whenever a photon is received with an energy within a selected narrow band of channels situated on the strongest resolvable peak of the element. The individual pulses are used in dot mapping; in line scans they are processed by a ratemeter set to give an output voltage proportional to the rate of receipt of pulses. Line scans are carried out by scanning the electron probe in a straight line across a chosen region of the specimen. The ratemeter output from the spectrometer is applied to the y deflection of the CRT (or its digital equivalent) to indicate the variation in concentration of this element along the path of the probe. Dot maps are made by scanning the whole field with the spectrometer tuned to a chosen spectral line or energy. In this case the individual pulses from the detector are used to modify the intensity of the CRT spot (or its digital equivalent) for a given pixel producing a bright spot along the scan as each x-ray photon is received. As the scan proceeds an increase in the concentration of the element results in a more concentrated rash of speckles on the image. R. Ubic VII-5 MSE 421/521 Structural Characterization Ca map of oxalis seed coat Cathodoluminescence Cathodoluminescence (CL), already discussed in Ch.2, is a kind of fluorescence; but instead of being excited by photons (as in the case of XPS), it is excited by the incoming electrons. Electrons in the primary beam knock out outer electrons from atoms in the specimen, and the consequent relaxation mechanism causes the release of a photon of light. This mechanism is identical to that of EDS except that an outer electron is involved in CL and an inner one in EDS, resulting in high-energy photons (x-rays) in EDS and low-energy ones (visible light) in CL. Certain semiconductors and insulators will emit ultraviolet or visible light when bombarded with high-energy electrons. The intensity of these emissions is modified by the presence of impurities or defects like dislocations. This imaging technique is used extensively to examine defects in semiconductors like GaAs and AlN. Because these photons can be ejected from anywhere within the sample interaction volume, spatial resolution is normally fairly poor in CL images, but it can be improved by using low voltages or narrower beams such as produced by a FEG. The peak in photon energy detected corresponds to the band gap of the specimen, and the width of the peak decreases with temperature such that, at liquid helium temperatures, very small local alterations in band gap due to composition can be detected and related to levels of impurity < 0.01 ppm , making CL several orders of magnitude more sensitive than EDS or other x-ray techniques. Quantitative Analysis Detection limit The minimum detectable concentration (MDC) of an element in EDS or WDS is especially important when low concentrations are present in a specimen. An x-ray peak can only be detected if it can be distinguished from the background. If the mean count level of the background is N then the noise varies up to R. Ubic N . It is commonly accepted that a peak can be VII-6 MSE 421/521 Structural Characterization recognised if it rises above the average background level by at least 2 N . If the average background count rate is b , then the MDC can, to a first approximation, be calculated as: MDC = ( ) 100 2 b t 200 b = pt − b t (p − b ) t where t is the counting time and p is the count rate at the peak in a standard pure-element reference material. According to this equation, the MDC can be decreased by decreasing b , increasing p, or increasing t. For a given system, the only one of these variables over which the operator has control is t; however, it becomes impractical to count for longer than about 15 minutes, not only because of the lengthy time involved but also because the beam intensity will not remain stable over such long time intervals, invalidating any comparisons with the standard. The variables of p and b really depend on the design and condition of the analysis and detector system. EDS systems have poorer signal-to-noise ratios than WDS systems, and both have worse signal-to-noise ratios for lighter elements. The MDC for many elements is about 0.1wt% by EDS and 0.01wt% by WDS. Elemental concentrations To estimate the amount of an element present, we determine the number of characteristic x-rays from the specimen in a fixed time interval, Nspec, and compare this figure with the number arriving from a standard of known composition, Cstd, in a similar time, Nstd. The concentration of this element in the specimen, Cspec, should be given by: C spec ≈ N spec C std = kC std N std Unfortunately, even if great care is taken to ensure that the conditions are identical when taking the standard and unknown counts, this equation needs some alteration. Most of the complicating factors arise because the specimen is not the same as the standard, which gives rise to the need for ZAF corrections to account for the differing effects of atomic number (Z), absorption (A), and fluorescence (F). X-ray counts from an element are measured from the standard and the sample, and their ratio, k, is calculated. Then, Cspec is given by: Cspec = kZAF assuming that Cstd = 1 (the standard is a pure element). The various corrections require a prior knowledge of the unknown sample composition, which is clearly impossible; instead, a rough estimate of Cspec is made, usually by taking it as k (Z = A = F = 1). This value is then used to calculate approximate values of Z, A, and F, which are then inserted back into the above equation for a more accurate value of Cspec. This iterative calculation is repeated until a constant Cspec results. R. Ubic VII-7 MSE 421/521 Structural Characterization With thin TEM specimens, the path length of the x-rays in the sample are so short that A and F corrections may not be necessary, so that: Ca N = k ab a Cb Nb where Na and Nb are measured characteristic x-ray intensities, and Ca and Cb are the weight fractions of any two elements a and b in the specimen. Semiquantitative k factor corrections (Cliff-Lorimer constants) have been determined from first principles and computer packages are available with the EDS systems so that preparation of standards is not necessary for rough quantification. Electron Energy Loss Spectroscopy (EELS) An EELS spectrometer does not detect x-rays but rather the electrons which have generated them on their way through the sample. Such electrons, by inelastically interacting with the sample, carry information about the atoms in it. They can also be used to detect light elements, such as He, Li, and Be, whose characteristic x-rays have too little energy to be detected by EDS. EELS is also much more sensitive than even windowless EDS to elements from B to Ne (including C, N, and O). Energy-filtered elemental maps can be produced with very high spatial resolution, and the fine structure of the EELS spectrum also contains information about the valence state of atoms/ions and their coordination. The energy lost by an electron varies with the thickness and density of the sample through which it has travelled, so thickness measurements can be performed on samples, and the very low energy loss signal provides information about the dielectric properties of materials. If, on passing through a thin TEM specimen, an electron undergoes an inelastic scattering event which causes it to lose more than 1eV of energy, this energy loss can be measured using a magnetic spectrometer. R. Ubic VII-8 MSE 421/521 Structural Characterization B D (a) S B P (b) The spectrometer is located below the projector lenses of the microscope and is the final component at the bottom of the TEM vacuum column. It uses a magnetic field (B) to deflect all the electrons through about 90°. The more energetic electrons are deflected slightly less, and the beam is dispersed into a spectrum of energies. The radius of their path, R, depends on their velocity, v, mass, m, and strength of the magnetic field, B: R= mv eB If a single detector is used, then the spectrum is scanned across a slit by varying the strength of B, so that each energy is detected in turn. A serial spectrometer works this way. If a multiple position-sensitive detector is used, then the whole spectrum is collected at once, as in parallel electron energy loss spectroscopy (PEELS). R. Ubic VII-9 MSE 421/521 Structural Characterization An EELS spectrum consists of three regions. Most electrons suffer negligible inelastic scattering and contribute to the zero loss peak. The low loss or plasmon region contains electrons which have lost up to about 50eV largely due to plasmon scattering. The useful part of the spectrum contains the characteristic edges corresponding to inner shell excitation and is just as useful as the characteristic x-ray spectrum used in EDS analysis. Since the number of electrons undergoing characteristic losses is small, a gain change is needed at >50eV to see the edges. Because they arise from the same electronic transitions, EELS edge energies will be close to, but not exactly the same as, the energies of characteristic x-rays (EELS peak energies should be slightly higher). As a guideline, if the intensity in the first plasmon peak is greater than one tenth of the zero-loss intensity, then the specimen is too thick for EELS analysis. Since plasmon scattering is well described by the Poisson equation, we can take the ratio: p (1) (t / λ ) exp(−t / λ ) t = = p ( 0) exp(−t / λ ) λ The thickness (t) of the specimen can thus be calculated in terms of the plasmon mean free path (λ) from the ratio of the first plasmon peak to the zero-loss peak. For example, if the plasmon mean free path is 100 nm, the sample must be no thicker than: p (1) t = = 0.1 ∴ t = 0.1λ = 0.1(100nm) = 10nm p ( 0) λ The mean free path can be looked up or calibrated with a specimen of known thickness. R. Ubic VII-10