Biomass and Bioenergy Resource Assessment State of Hawaii

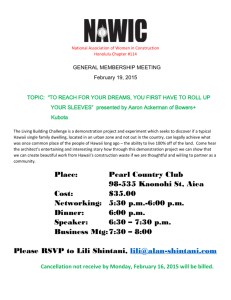

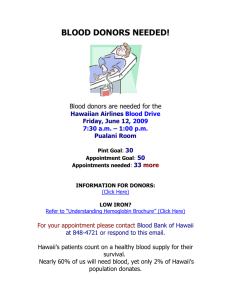

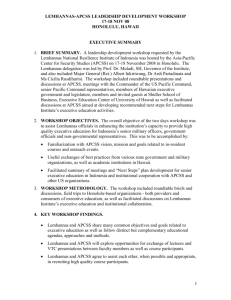

advertisement