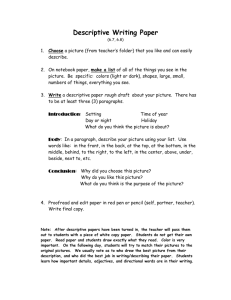

Product Development Processes and Their Importance to Organizational Capabilities

advertisement